Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Water resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

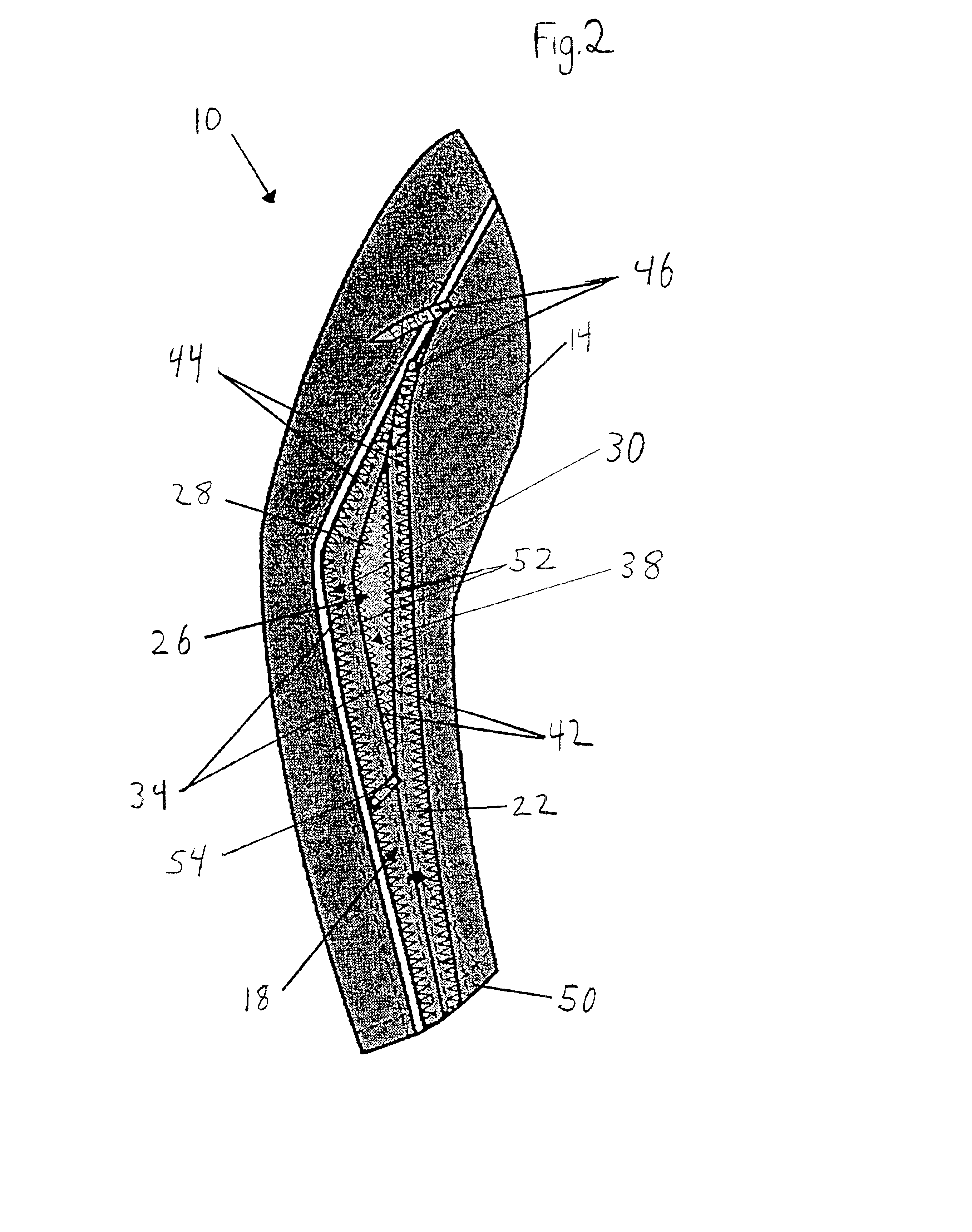

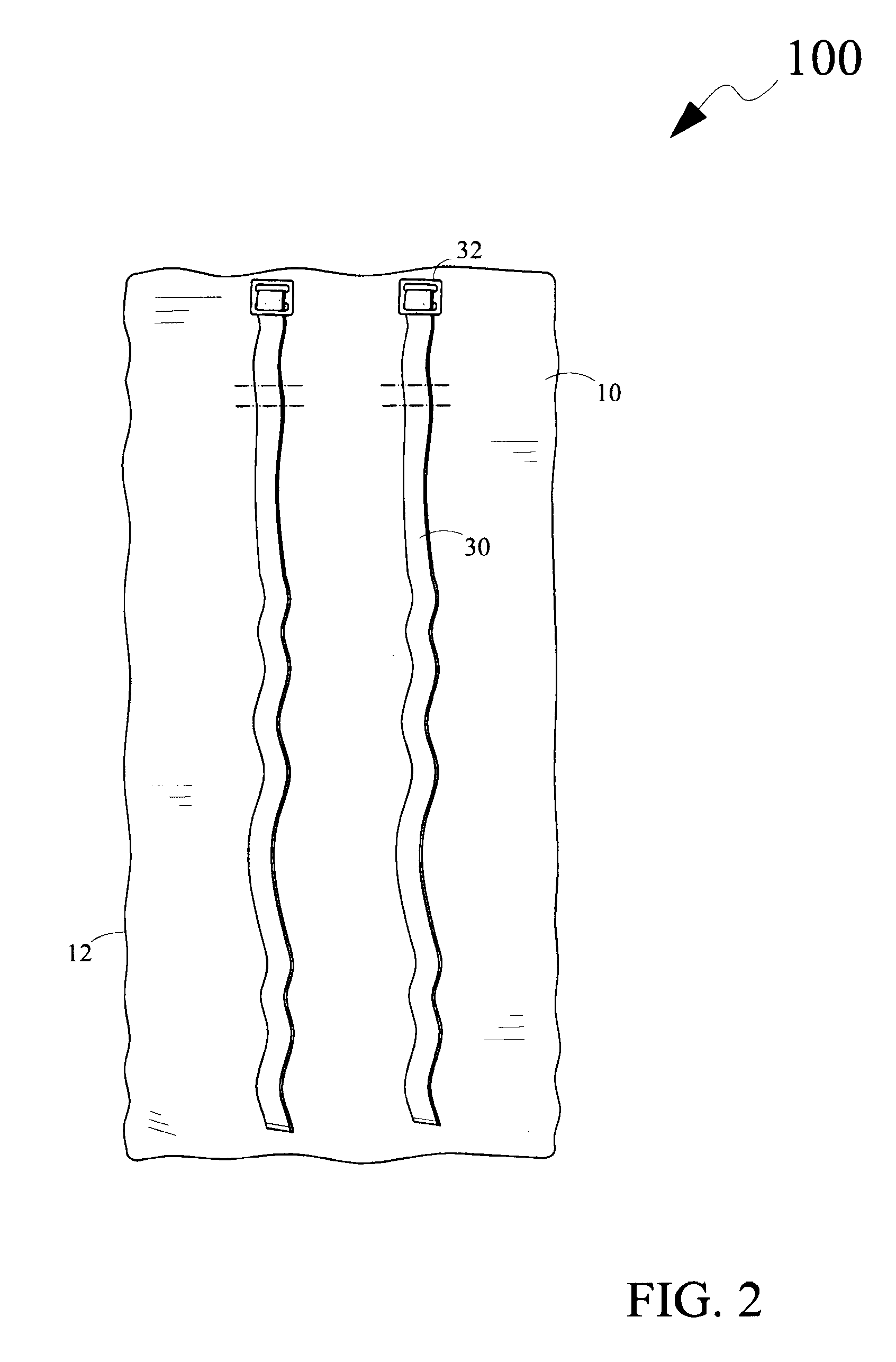

Garment ventilation system

InactiveUS6792621B2Synthetic resin layered productsCellulosic plastic layered productsEngineeringWater resistant

Owner:HARLEY DAVIDSON MOTOR COMPANY GROUP INC

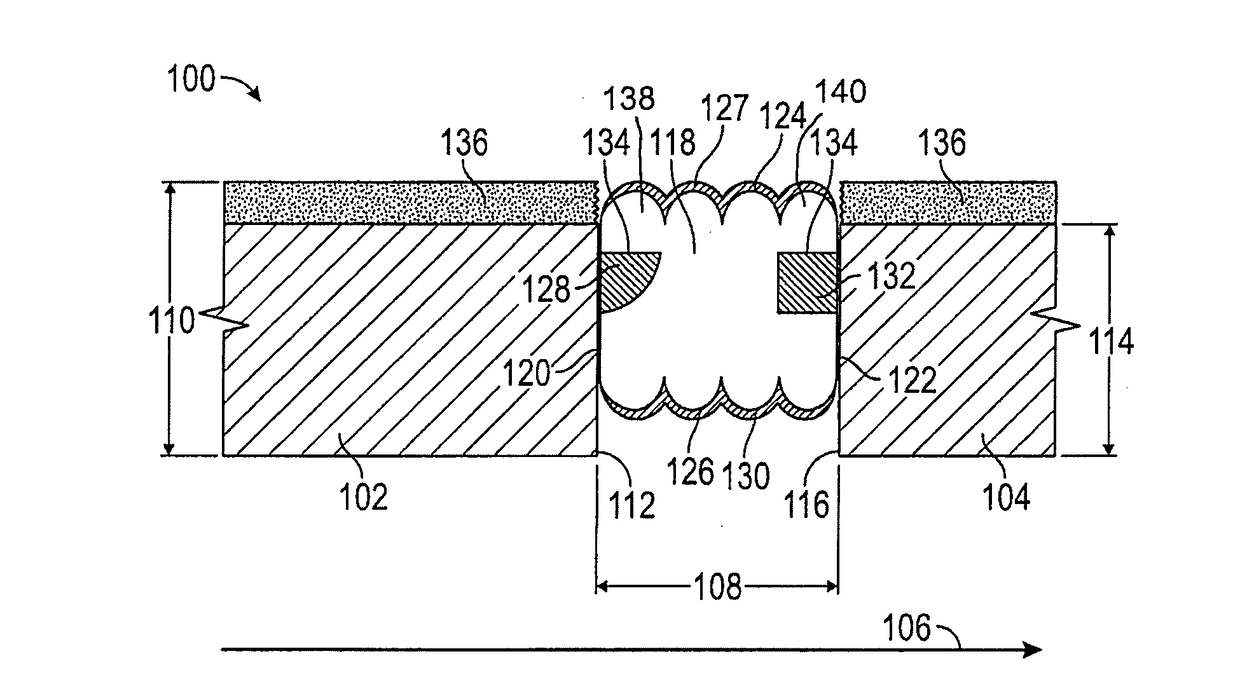

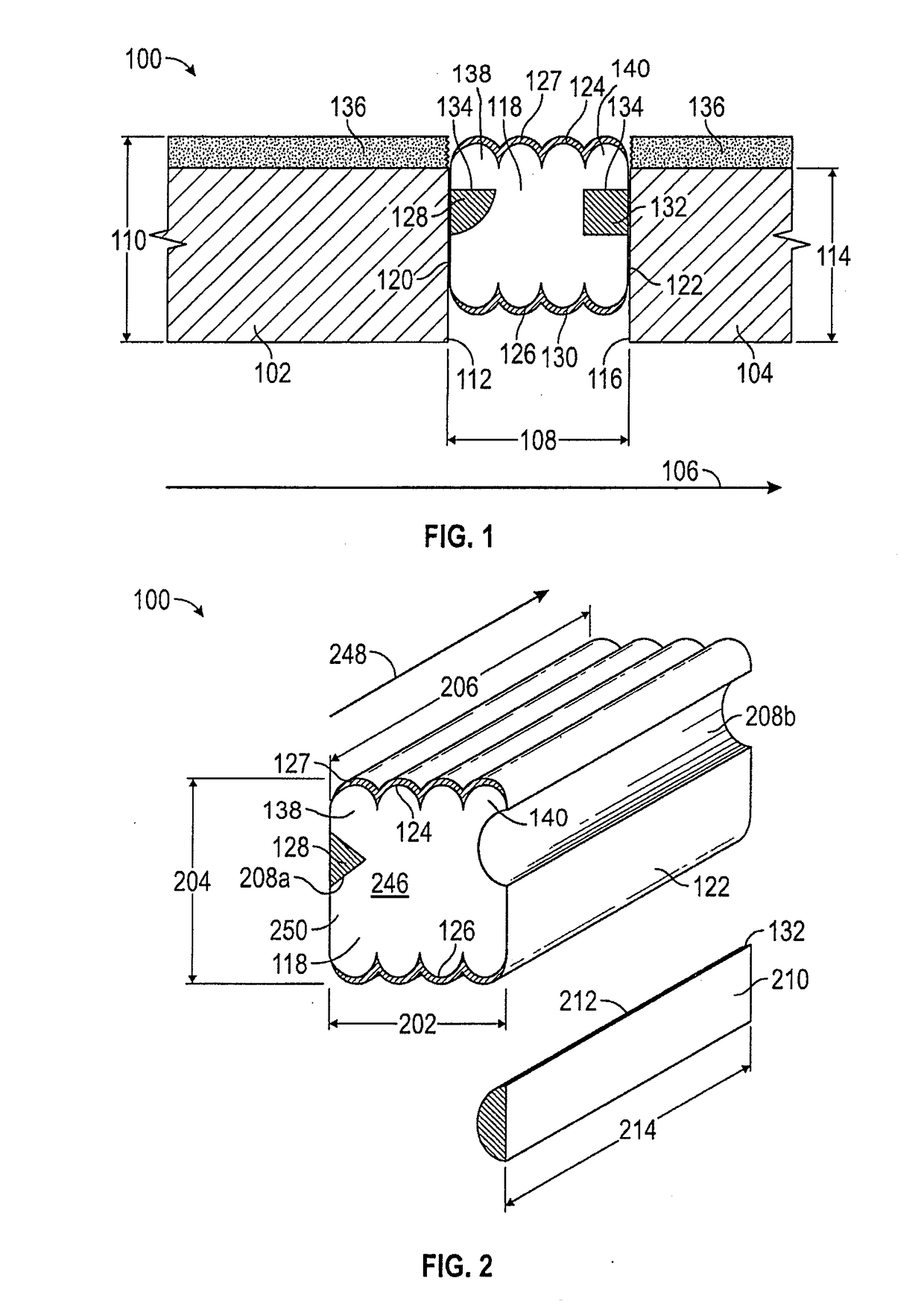

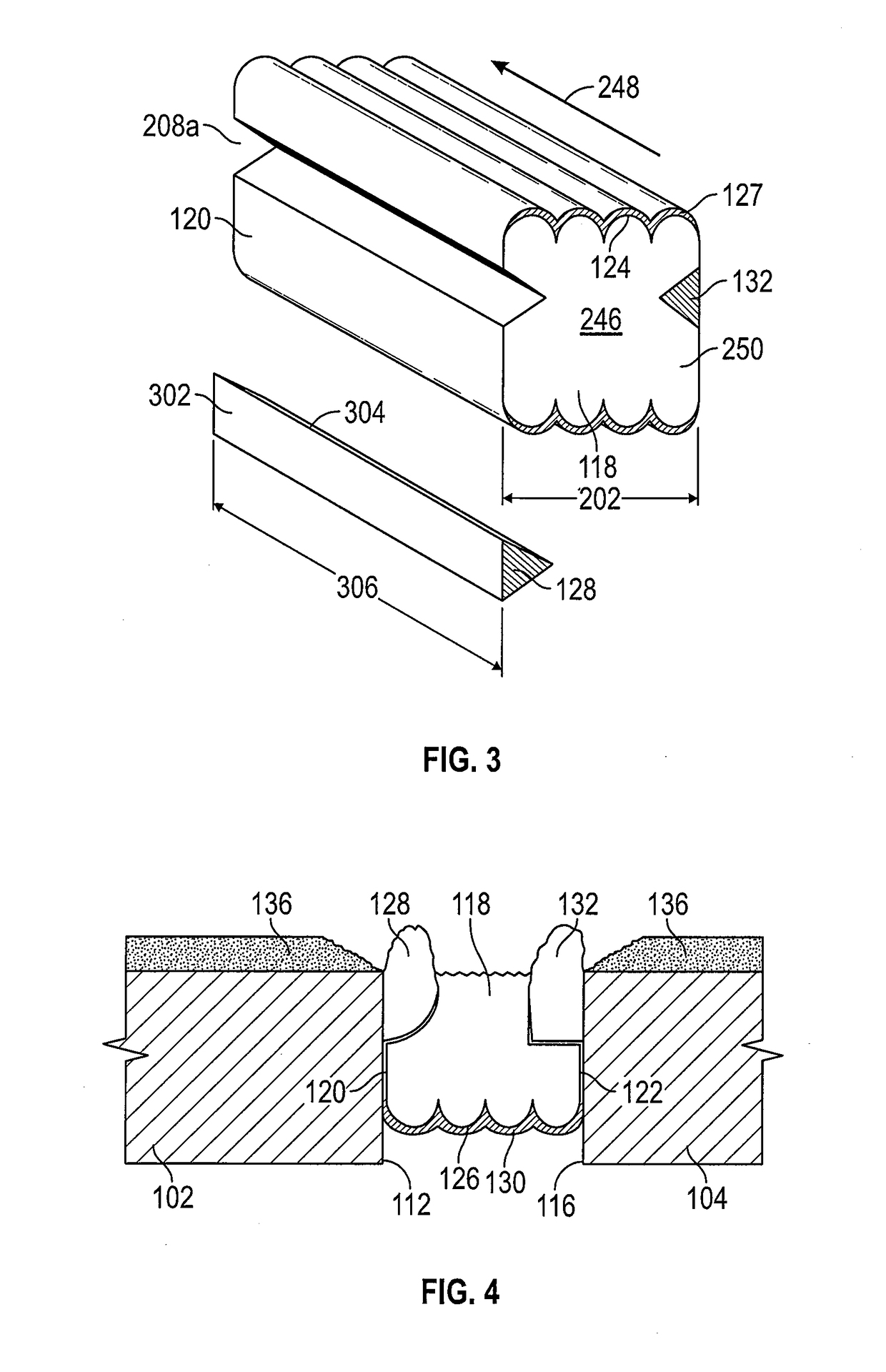

Expansion Joint Seal System

Owner:SCHUL INT COMPANY

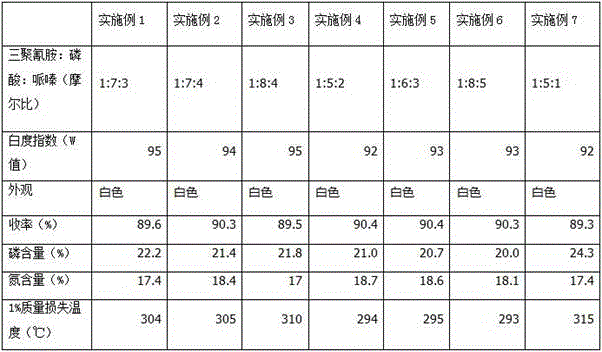

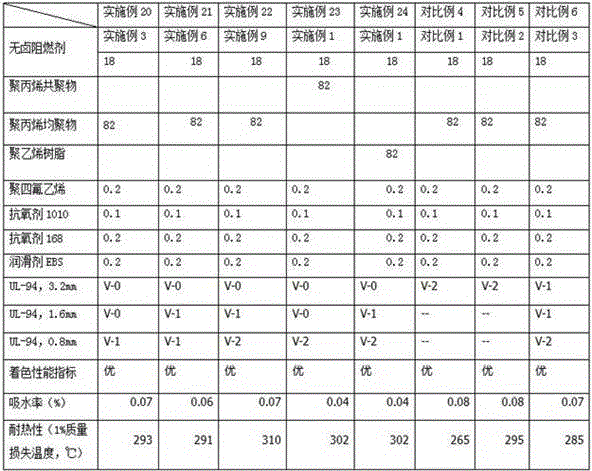

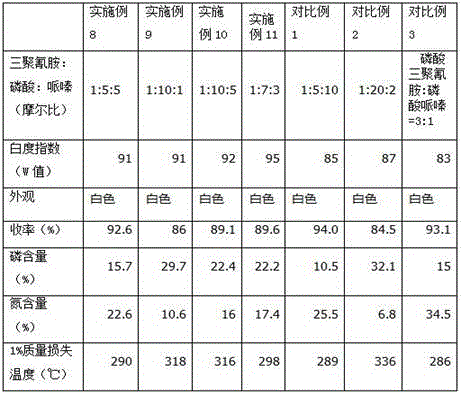

Halogen-free flame retardant and preparation method thereof and flame-retardant polyolefin composition composed of same

ActiveCN105837855AImprove thermal stabilityThe content of functional components is flexible and adjustableOrganic chemistryPolymer sciencePolyolefin

Owner:KINGFA SCI & TECH CO LTD

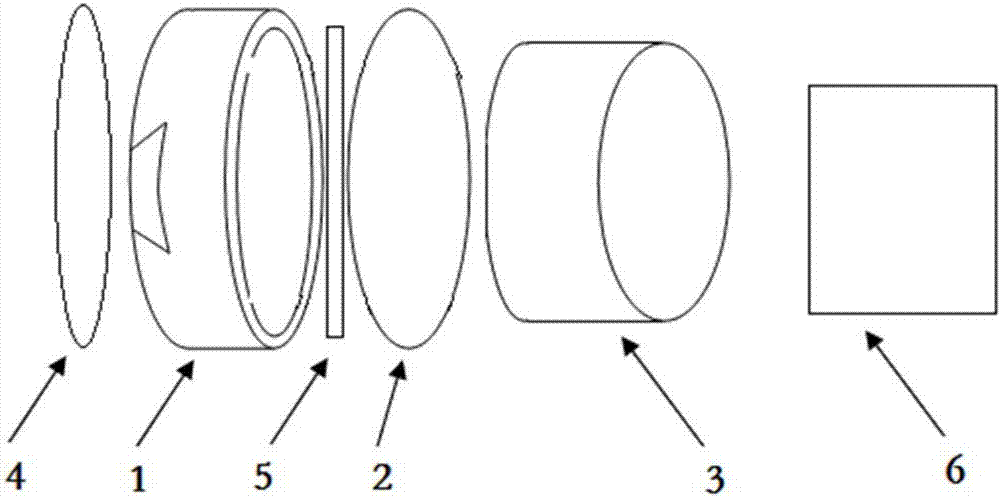

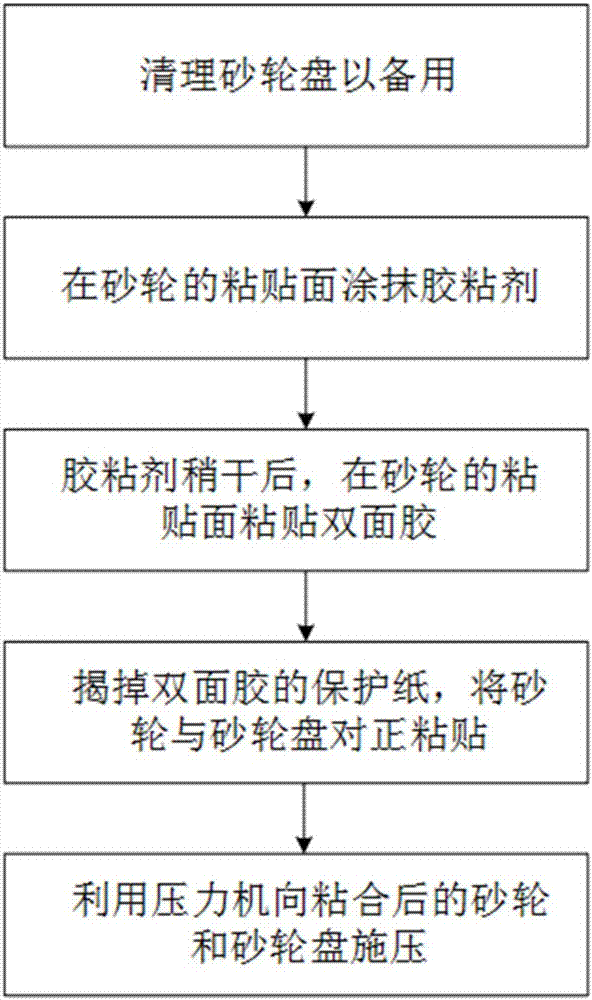

Production process of polyester water-resistant emery cloth with high adhesive power

InactiveCN107139087AImprove waterproof performanceLower surface energyNon-macromolecular adhesive additivesLiquid surface applicatorsEpoxyRubber material

The invention discloses a production process of high-adhesion polyester water-resistant abrasive cloth, which adopts water-resistant sandpaper as a cloth base for production; after scraping the sand-planted surface of the cloth base, corona treatment is performed on the sand-planted surface of the cloth base; Squeegee coating material, base rubber material and re-adhesive compound are all added with heat-dissipating materials and heat-conducting materials; the abrasive used for sand planting is diamond abrasive grain; the diamond abrasive grain layer (3) is coated with a re-adhesive layer (4) , the substrate (1) is a non-woven material; by mass percentage, the components of the primer layer (2) and the contents of each component are: 50% to 75% of epoxy modified phenolic resin, 15% to 15% of softening agent 35%, thickening lubricant 2%~5%, tackifier 8%~15%, the sum of the mass percentages of the above-mentioned components is 100%; by mass percentage, the components and The content of each component is: 60%-75% of water-based epoxy resin, 2%-10% of internal mixed antistatic agent, 15%-35% of auxiliary materials, and the sum of the mass percentages of the above-mentioned components is 100%.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

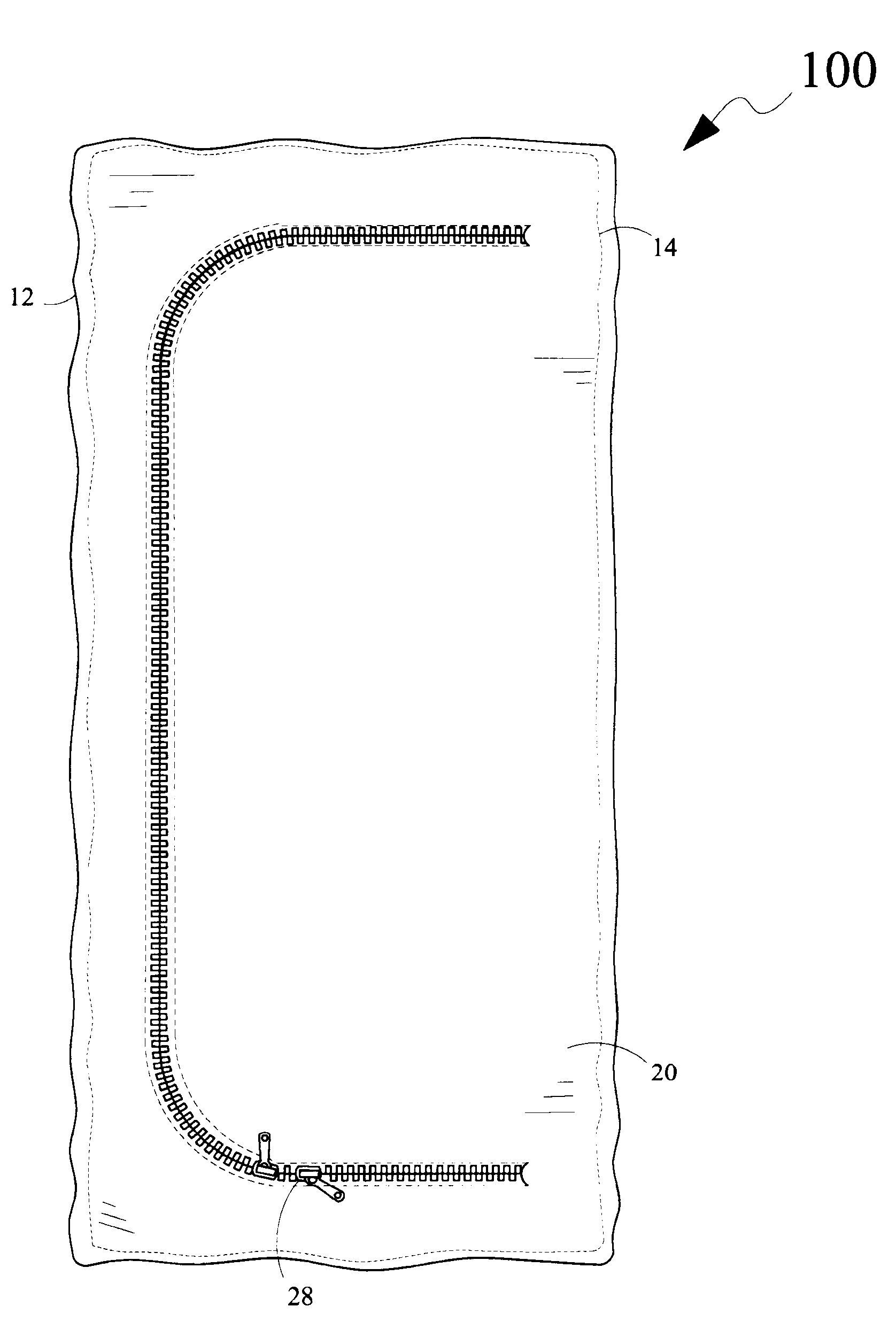

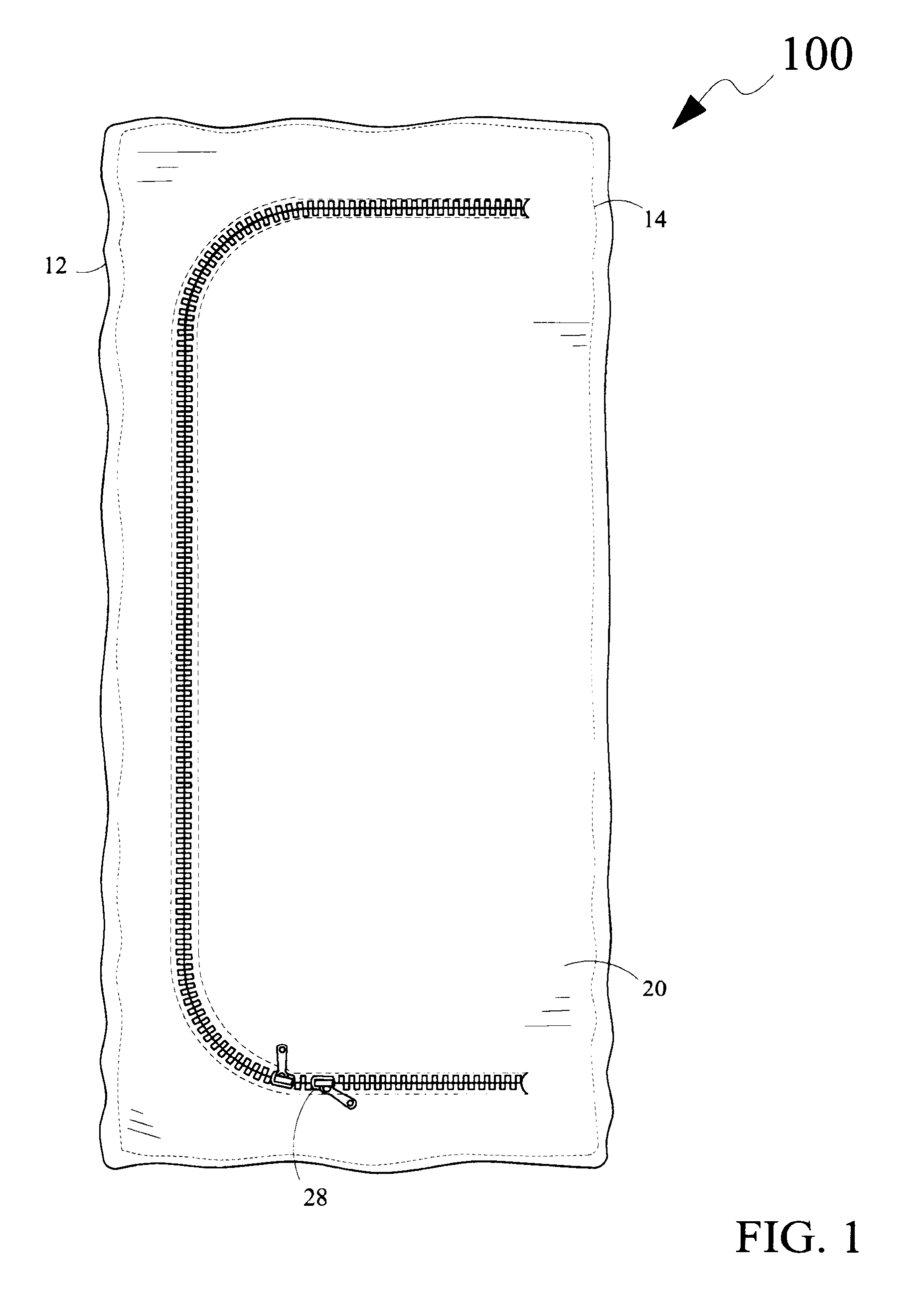

Bedroll Protector

InactiveUS20090035499A1Increase temperature ratingSynthetic resin layered productsLuggageEngineeringWater resistant

Owner:WANDEL TOM

Anti-cracking epoxy ceramic paint and preparation method thereof

InactiveCN108864898AHigh hardnessImprove mechanical propertiesFireproof paintsAnti-corrosive paintsWater resistantDodecylbenzene

The invention provides anti-cracking epoxy ceramic paint, which is prepared from the following raw materials in parts by weight: diatomite, silicon carbide powder, corn starch, coconut oil acid diethanolamide, aluminum oxide, C12 alcohol ester, triphenyl phosphate, diethylene glycol monobutyl ether, expanded vermiculite, nanometer silicon dioxide, barium sulfate, styrene-acrylate emulsion, tri(dodecyl benzene sulfonyl) titanium isopropoxide, carbon fiber, epoxy resin E-44, diluents 660A, triglycidyl p-aminophenol, bisoxaldihydrazone, water glass, hydroxypropyl methyl cellulose and a proper amount of deionized water. The prepared epoxy ceramic paint has excellent characteristics that the coating is compact and smooth, and is firm as ceramics; the bonding is firm; the thickness is uniform; the water-resistant, anti-corrosion and electric insulation performance is excellent, and the like.

Owner:黄春梅

Production process of environment-friendly water-based anti-corrosion coating

InactiveCN104449091AImprove anti-corrosion performanceGood resistance to nitro paintAnti-corrosive paintsWater basedWater resistant

Owner:QINGDAO SHOUSHENG IND

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap