Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Copper oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper oxide is a compound from the two elements copper and oxygen.

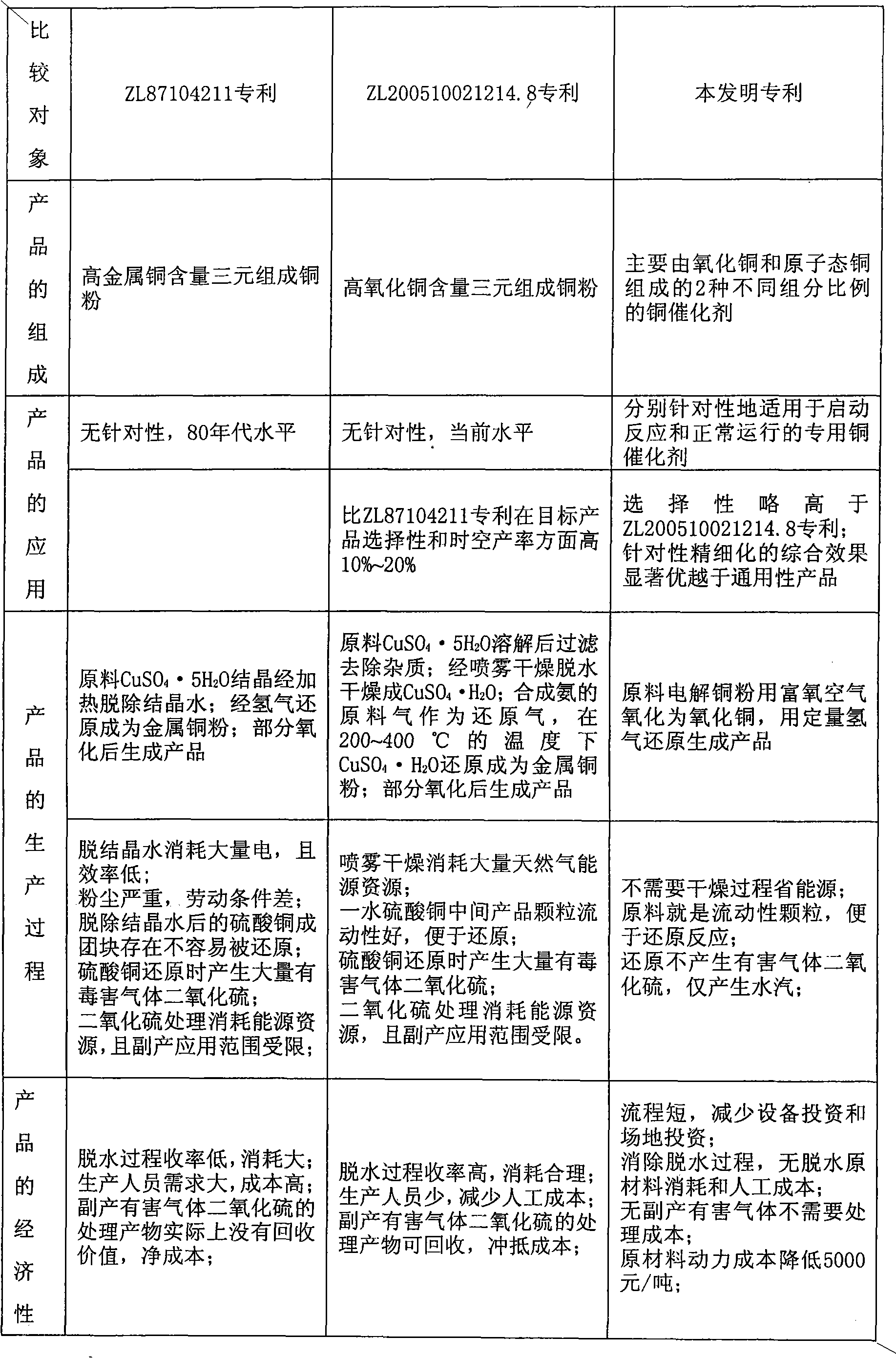

Two types of catalysts for synthesizing methyl chlorosilane and preparation method thereof

ActiveCN102059117AReduce solubilityReduce energy consumptionGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsCopper oxideImpurity

Owner:成都隆盛新材料股份有限公司

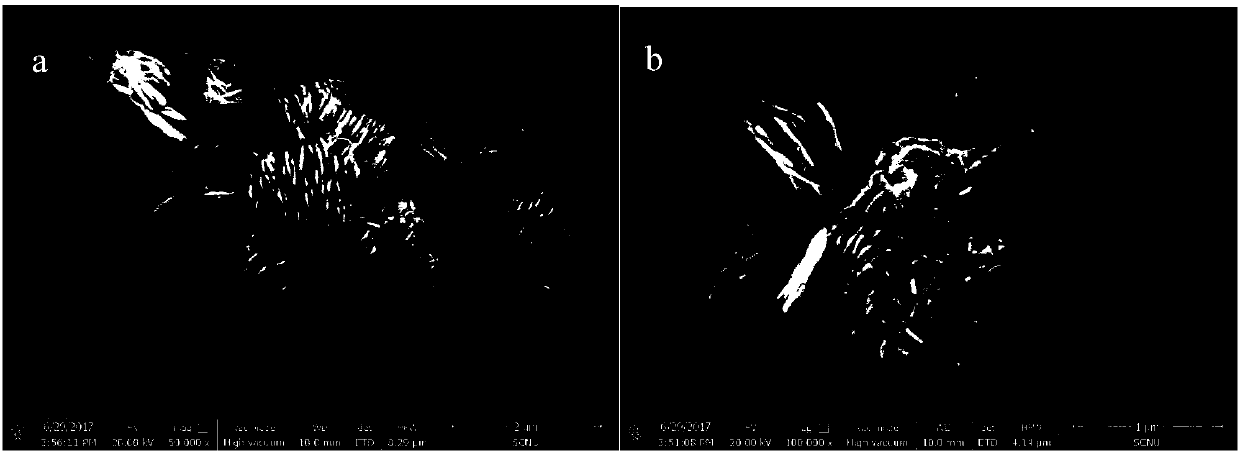

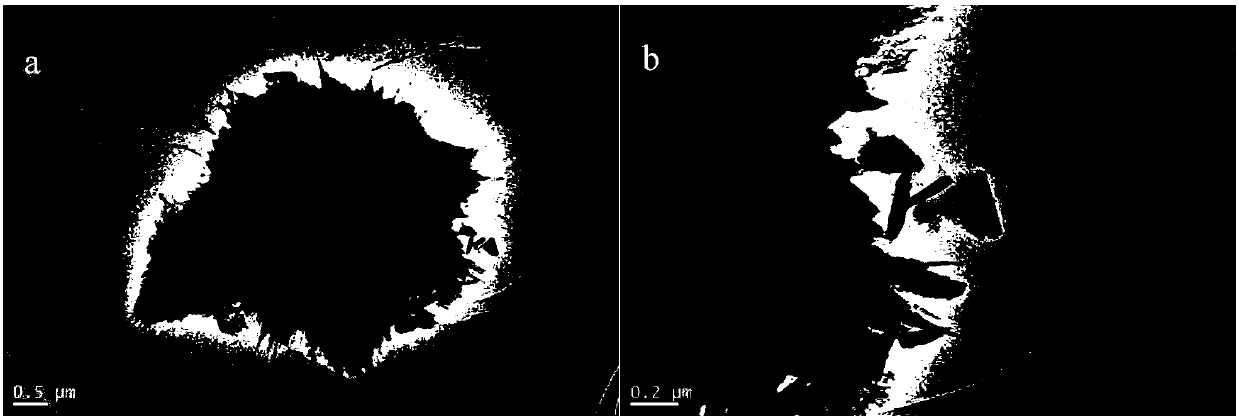

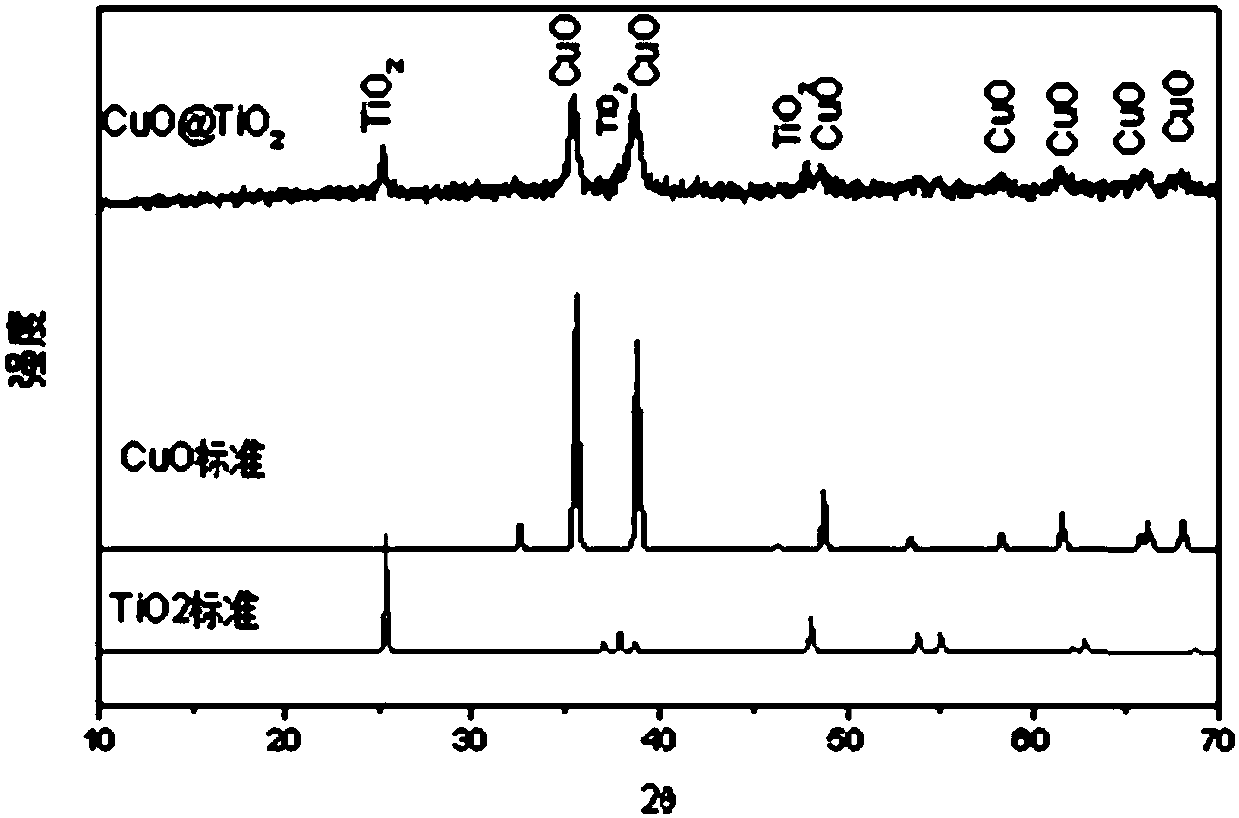

Titanium dioxide-copper oxide nano compound and preparation method and application thereof

ActiveCN107799744ARaw materials are easy to obtainSimple processMaterial nanotechnologyCell electrodesAir atmosphereFree cooling

Owner:SOUTH CHINA NORMAL UNIVERSITY

Flat ceramic membrane formulation carrying nano copper oxide and preparation method thereof

The invention a flat ceramic membrane formulation carrying nano copper oxide and a preparation method thereof. The flat ceramic membrane comprises a carrier and a separation membrane layer; the carrier incudes a main materials and auxiliary materials; the main materials of the carrier include one or more of alumina, mullite, dolomite, and bauxite; the auxiliary materials of the carrier include a sintering aid, a plasticizer, a pore-forming agent and a binder; the separation membrane layer is made with adhesive, nano copper oxide particles, a dispersing agent and a plasticizer. The flat ceramicmembrane carrying nano copper oxide has the advantages that the materials of the carrier are simple and easily accessible, the materials have antibacterial and catalytic functions, the pore size is flexibly controllable, and the materials have good features, such as excellent mechanical properties and low thermal expansion coefficient.

Owner:CHANGZHOU SUNAN WATER ENVIRONMENT RES INST CO LTD

Chemical pump inner cavity insulated oil paint and preparation method thereof

InactiveCN106046954AUniform textureGuaranteed to workRubber insulatorsRubber derivative coatingsRare earthPyrophosphate

Owner:安徽天富泵阀有限公司

Copper oxide/carboxymethyl cellulose gel modified composite film, and making method and use thereof

InactiveCN106943883AEfficient separationSimple construction methodSemi-permeable membranesNon-miscible liquid separationCarboxymethyl celluloseComposite film

Owner:JIANGSU UNIV

Method for preparing mesoporous zirconium phosphate supported nano copper oxide antibacterial polyester fibers

ActiveCN105350111AIncrease loadReduce releaseMonocomponent polyesters artificial filamentArtifical filament manufactureIn situ polymerizationCopper oxide

Owner:DONGHUA UNIV

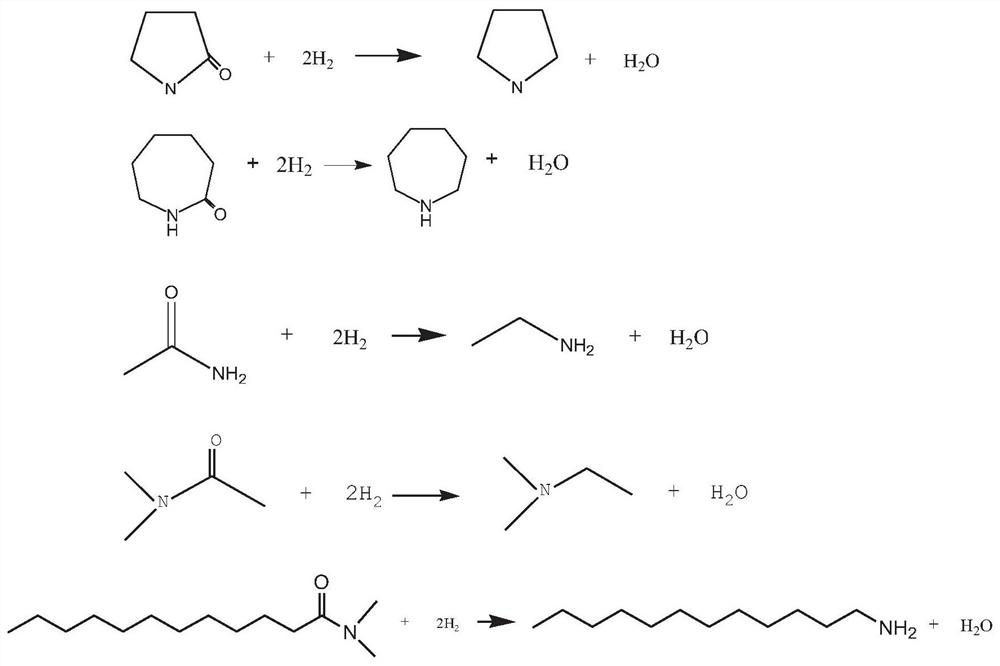

Amide hydrodeoxygenation method

PendingCN113429296ALow costImprove catalytic performanceOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

Owner:CHINA CATALYST HLDG CO LTD

Ceramic steel material

Owner:HUZHOU ZHIWEI TECHNICAL SERVICE CO LTD

Ceramic coating with corrosion resistance

InactiveCN109207016AImprove corrosion resistanceNot easy to corrodeAnti-corrosive paintsEpoxy resin coatingsFiberEpoxy

Owner:佛山市高明区生产力促进中心

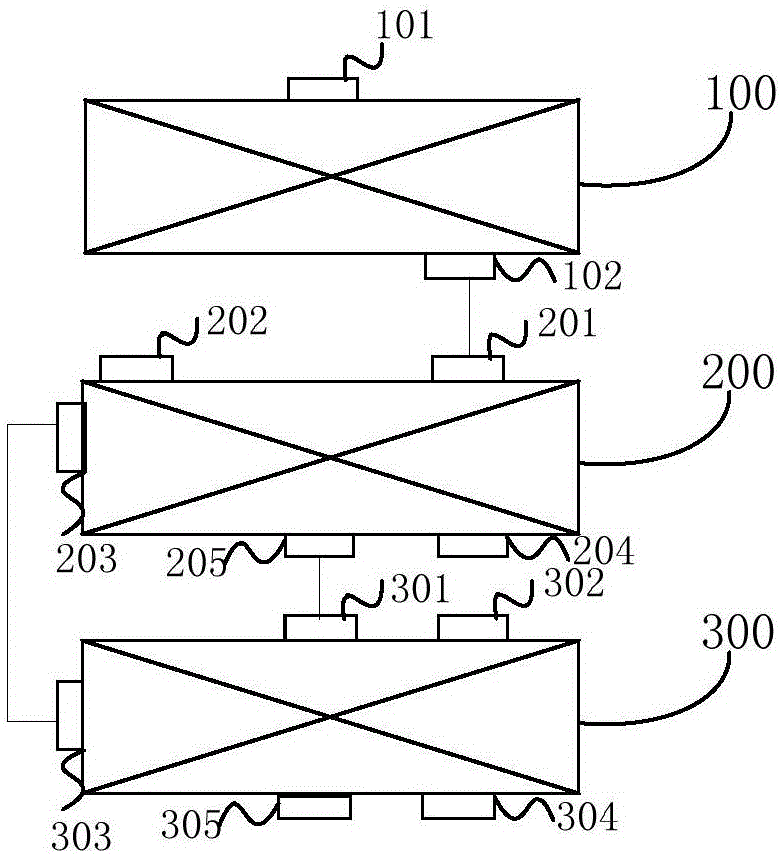

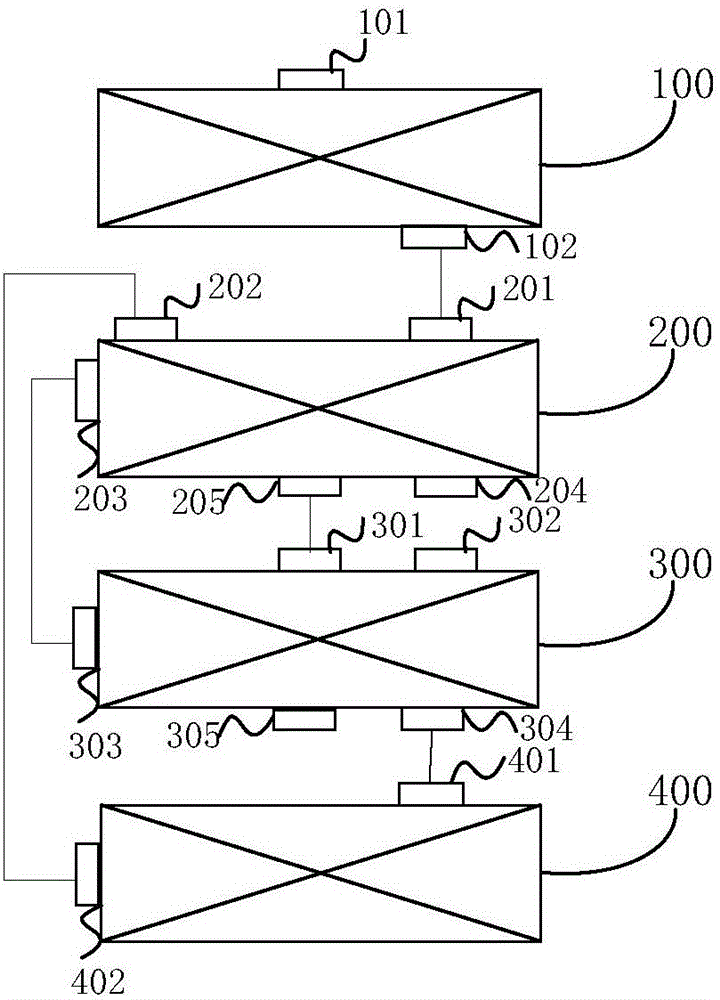

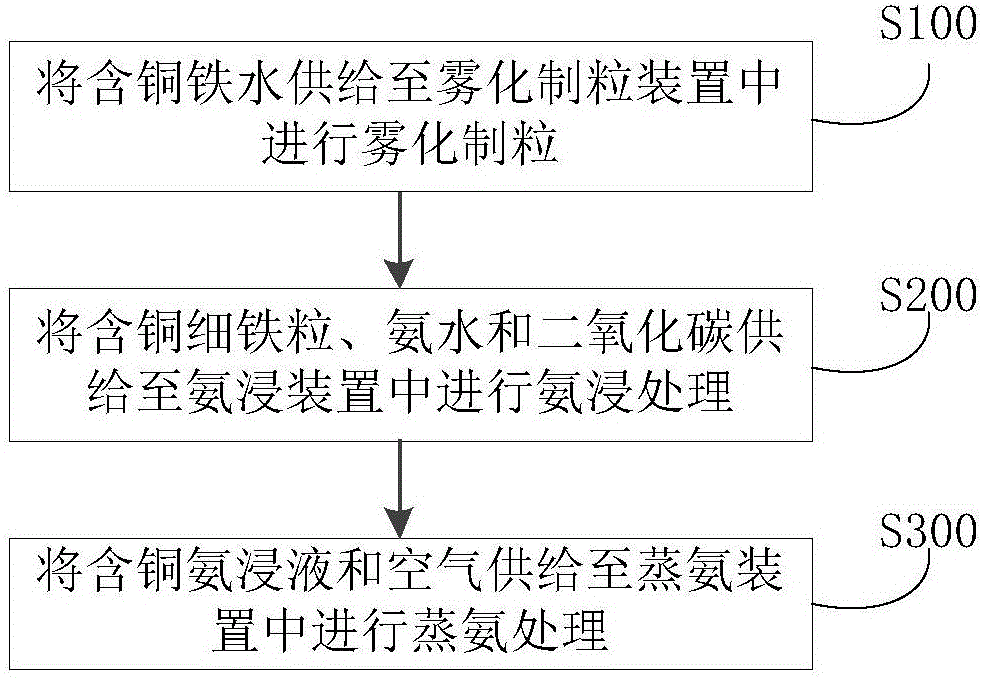

System and method for treating copper-containing molten iron

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Preparation method of methyl vinyl ketone

ActiveCN111320536AEase of industrial implementationEase of mass productionOrganic compound preparationPreparation by dehydrogenationYTTERBIUM OXIDEPtru catalyst

The invention discloses a preparation method of methyl vinyl ketone. The preparation method comprises the following steps: contacting a raw material containing 1,3-butanediol with a copper-based catalyst to carry out reactions under a dehydrogenation condition, and contacting the reaction effluent with a solid acid catalyst to carry out reactions under a dehydration condition to obtain methyl vinyl ketone. The copper-based catalyst comprises the following components in percentage by weight: 40-50% of copper oxide, 35-45% of at least one of ytterbium oxide, nickel oxide, and zinc oxide, 0.1-1%of potassium oxide and the balance being aluminum oxide. A new preparation method of methyl vinyl ketone is provided, is easy to implement industrially, and is suitable for large scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

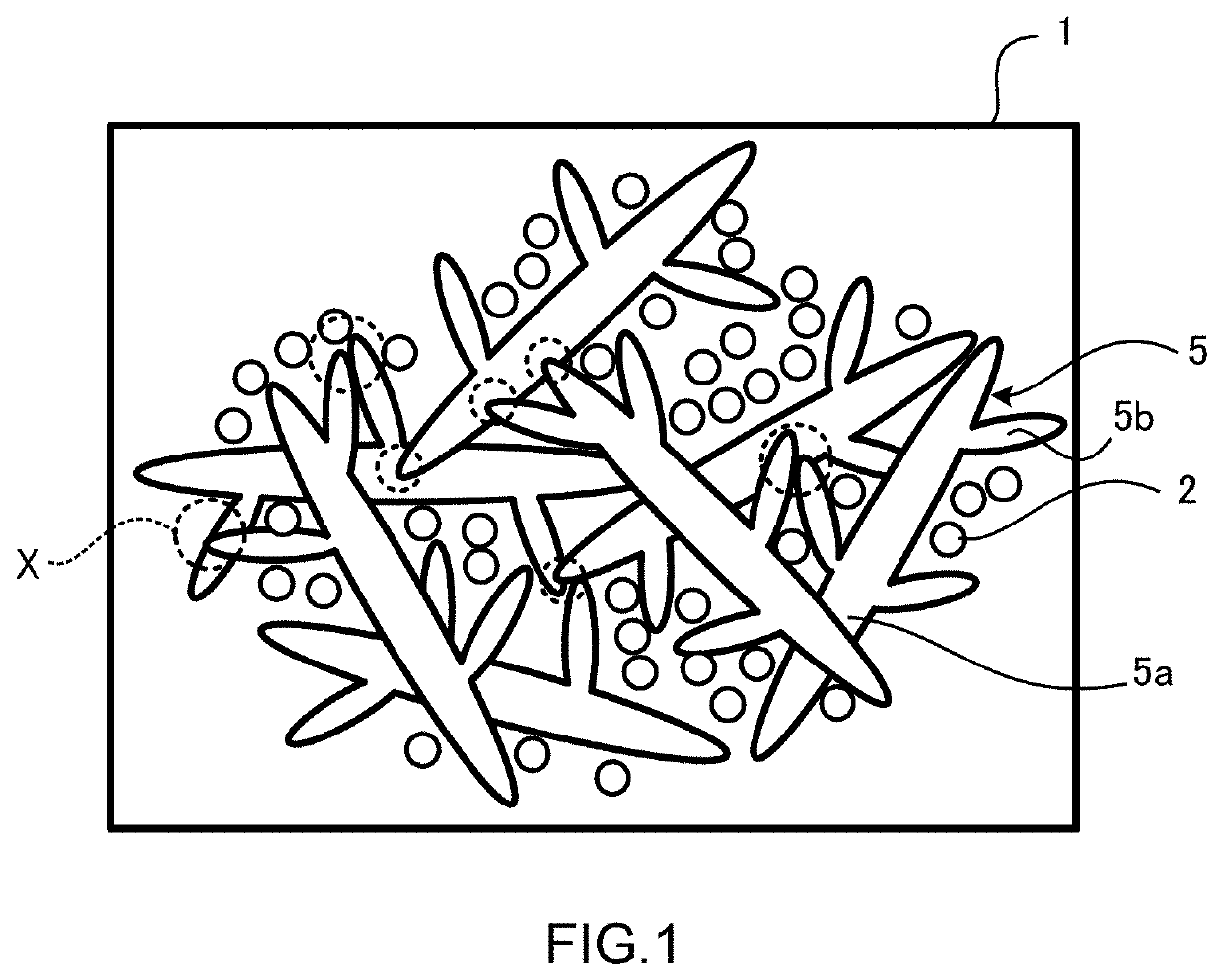

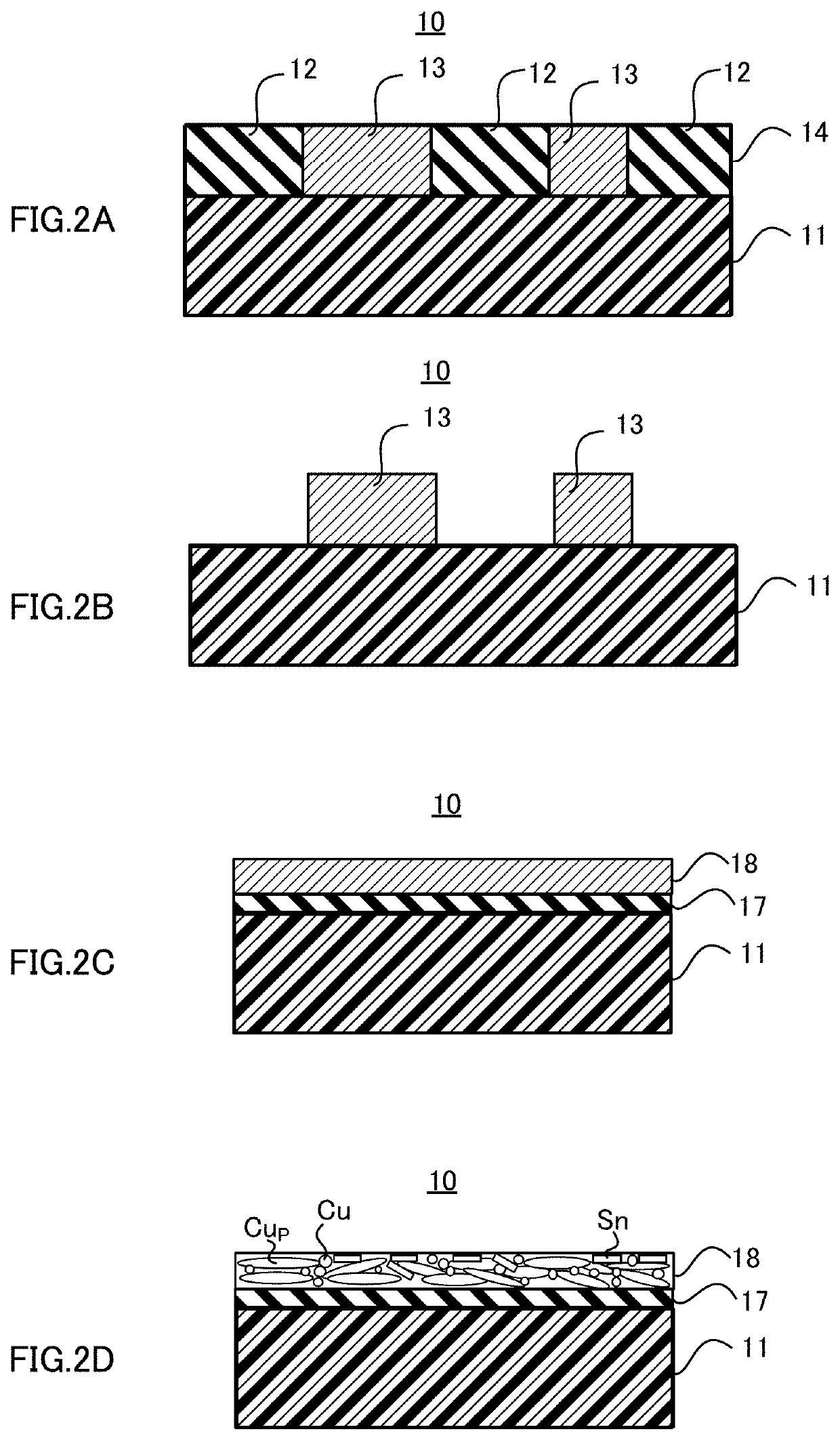

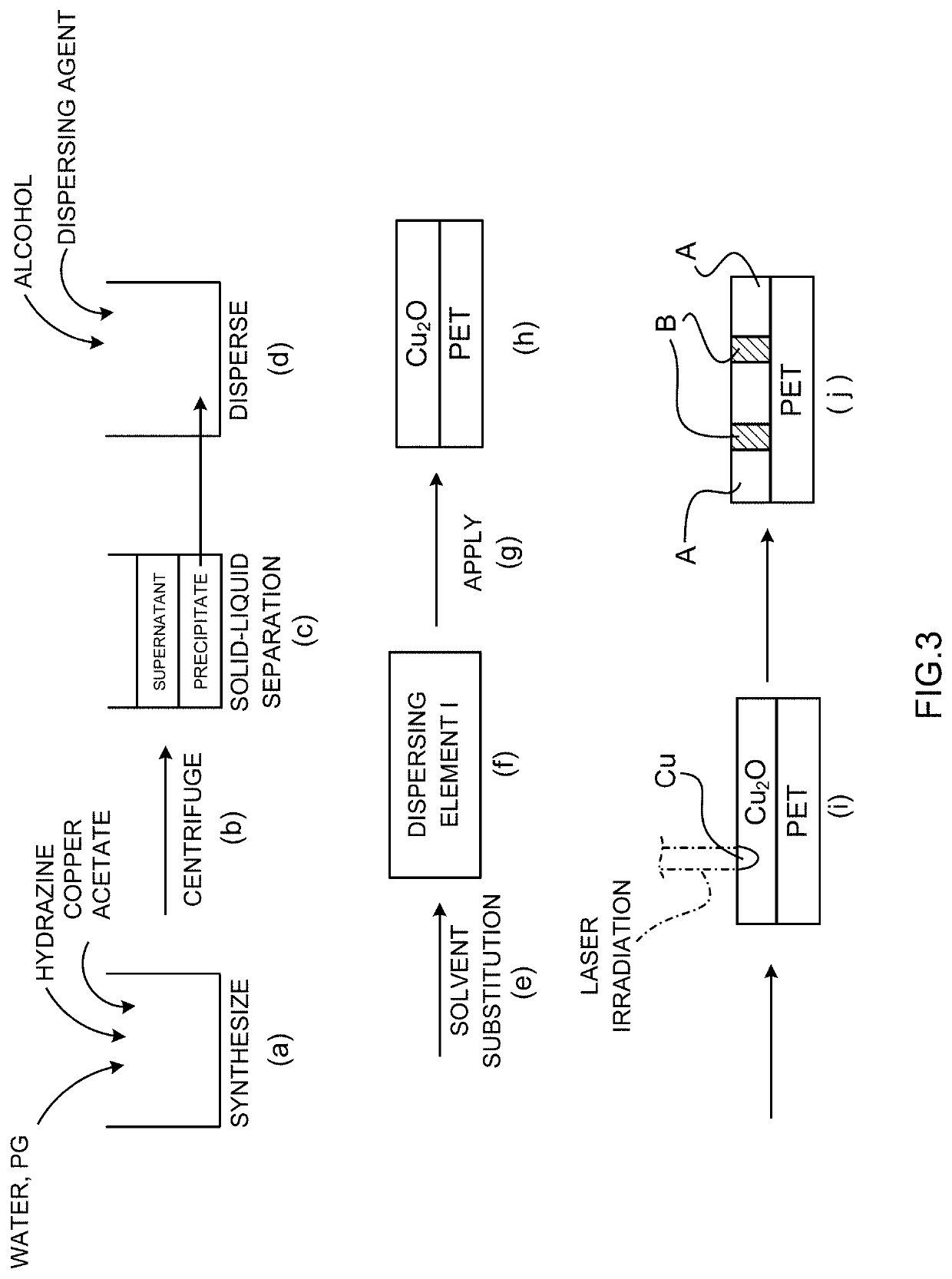

Dispersing Element, Method for Manufacturing Structure with Conductive Pattern Using the Same, and Structure with Conductive Pattern

ActiveUS20210225551A1Improve dispersion stabilityLower resistancePrinted circuit aspectsConductive materialElectrically conductiveCopper oxide

Owner:ASAHI KASEI KK

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap