Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Materials preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Materials preparation. Materials Preparation is one of the four tier 2 crafting skills in the Artisan branch. It allows to build simple constructions like a kiln or a furnace and to build wooden and plaster shacks as well as Sign on level 100. Level 30 of Artisan is required to learn this skill.

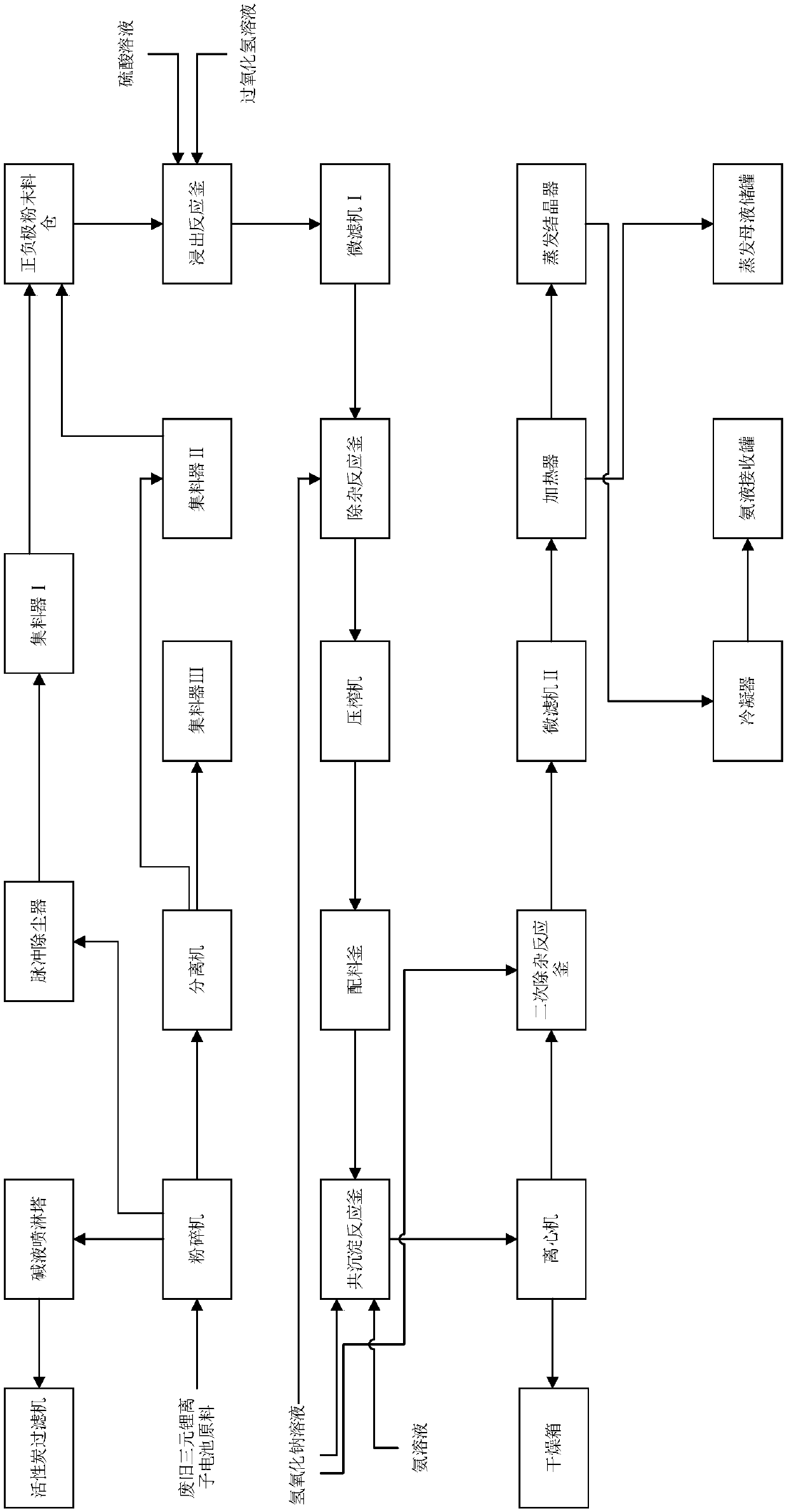

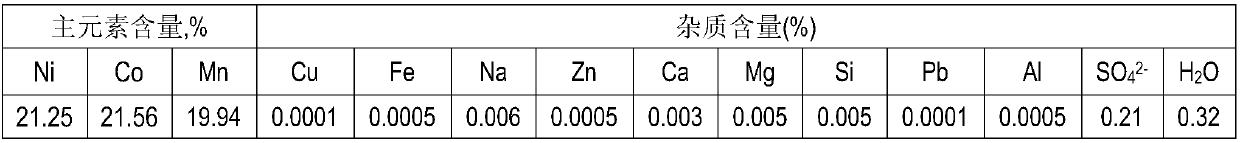

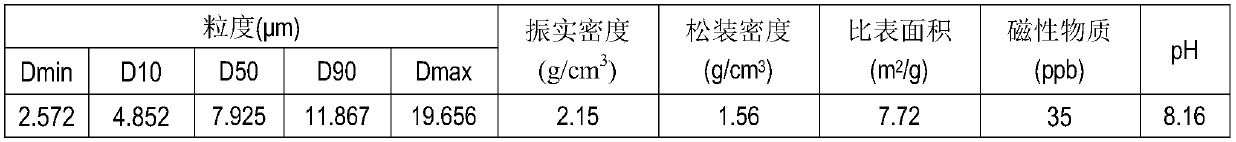

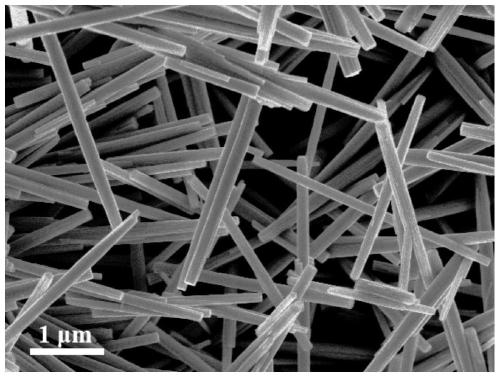

System and technology for continuously recycling waste ternary lithium-ion battery

PendingCN107946687AReduce manufacturing costAchieving continuous operationWaste accumulators reclaimingBattery recyclingManganeseEvaporation

Owner:TIANQI LITHIUM CORP

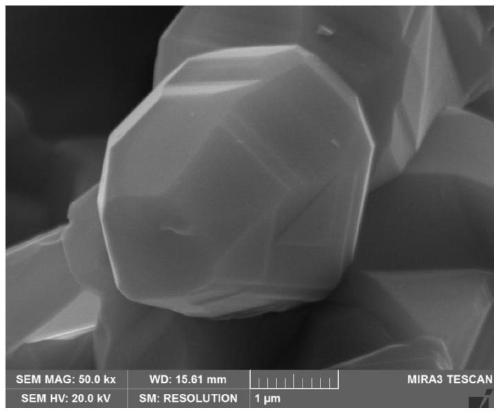

Silver sulfide/tungsten trioxide-based z-type photocatalytic material as well as preparation method and application thereof

ActiveCN109926068AShorten the migration pathReduce chance of recombinationPhysical/chemical process catalystsHydrogen productionMaterials preparationPhoto catalytic

Owner:WUHAN UNIV

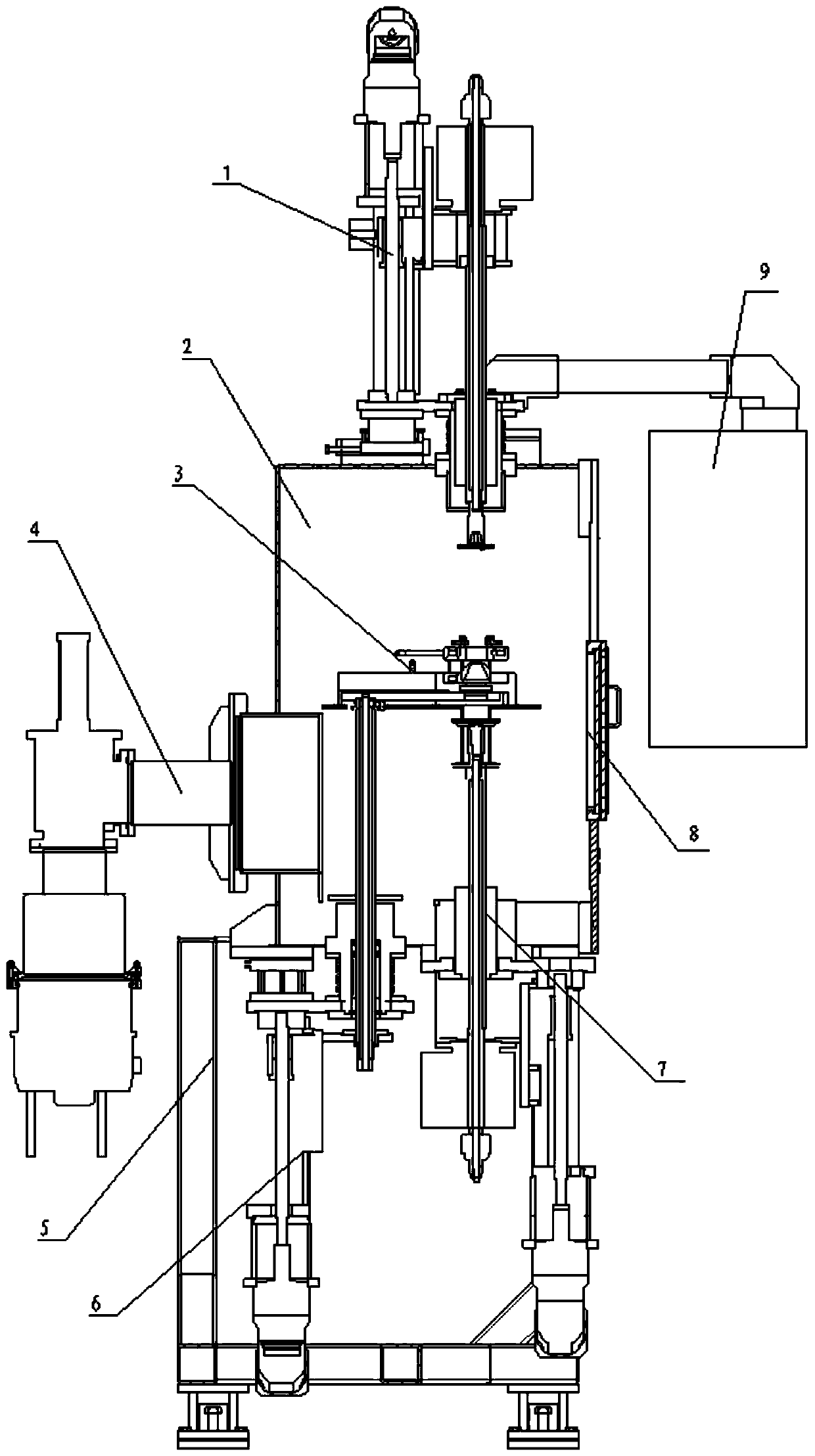

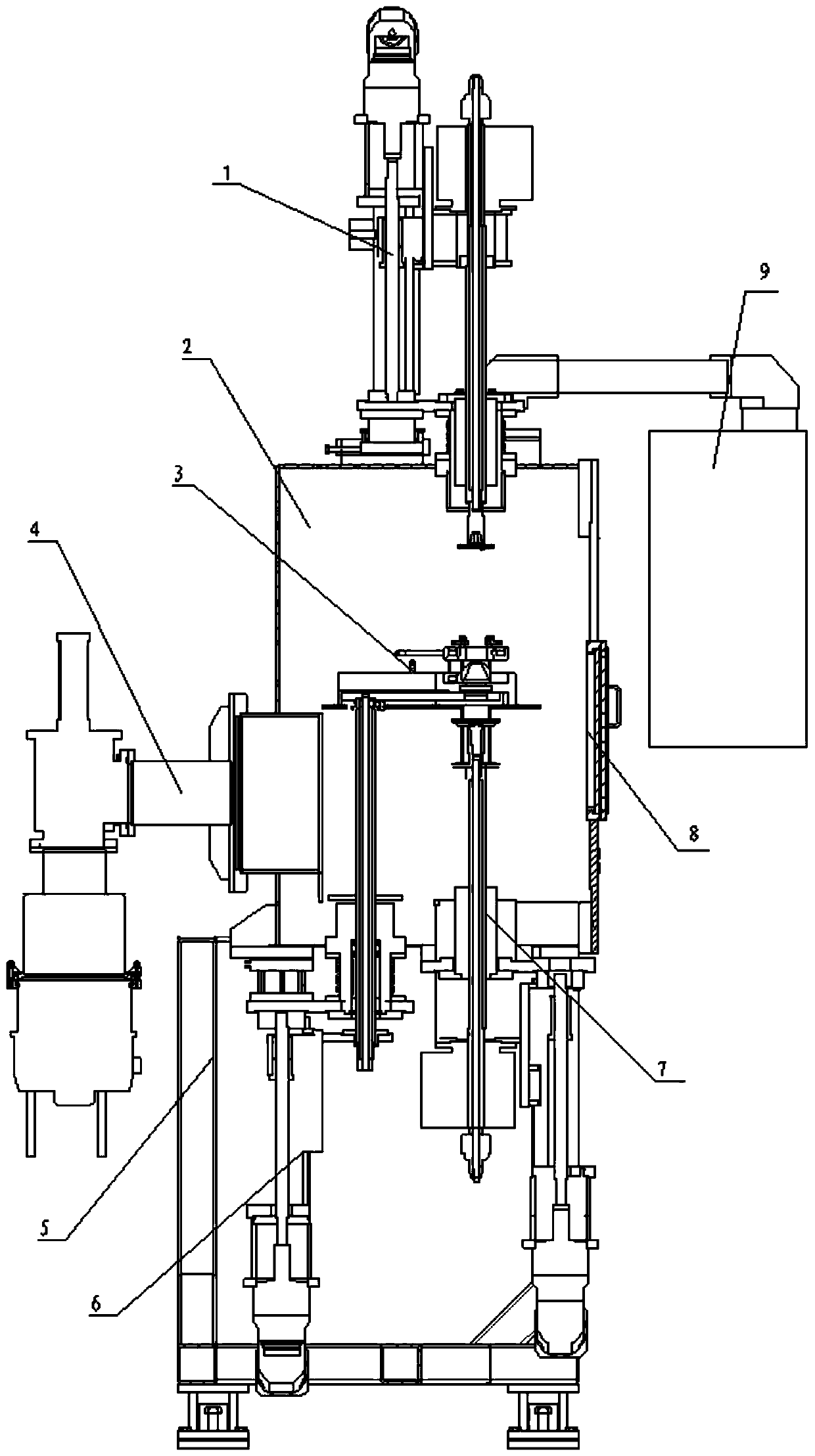

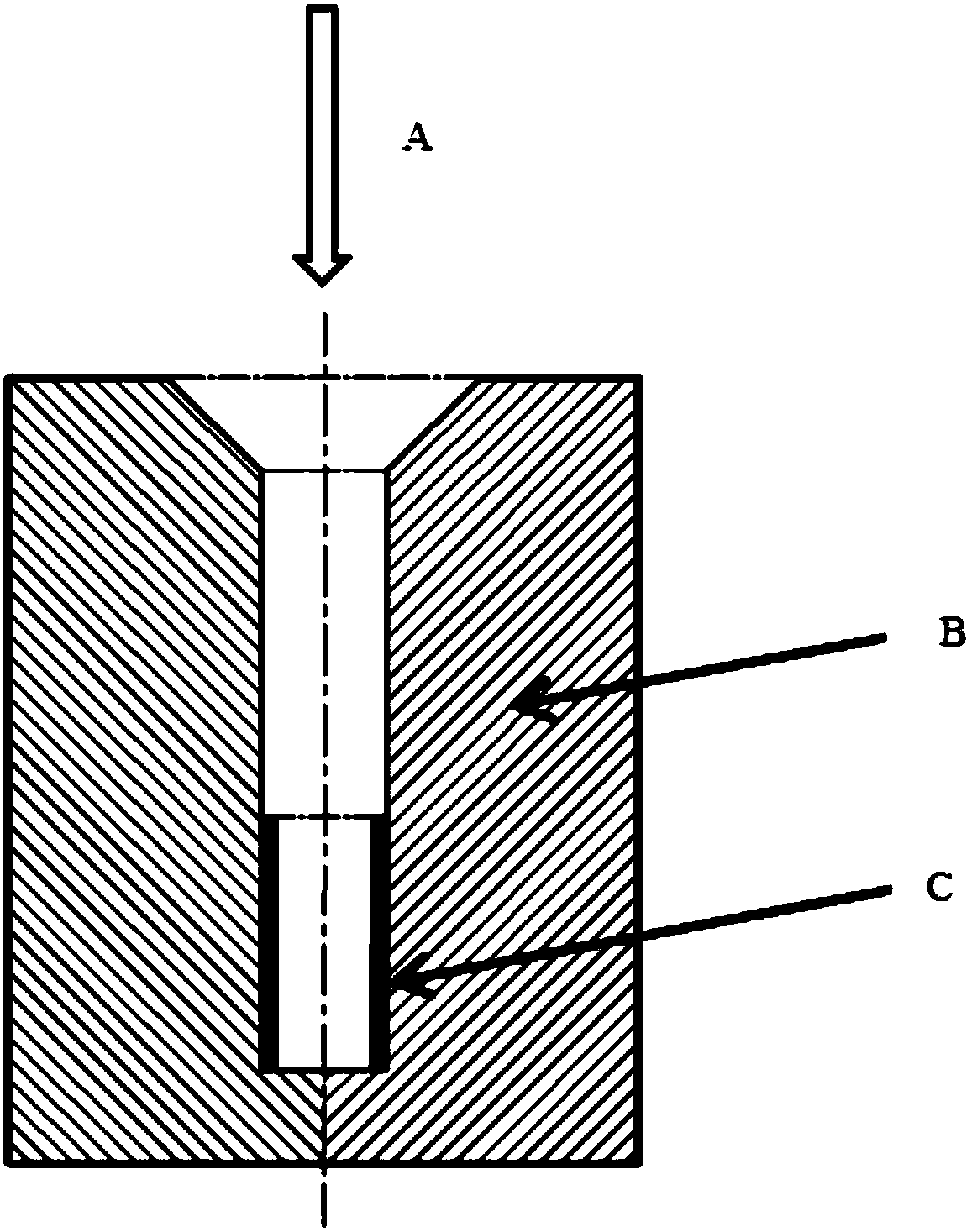

Rare-earth alloy permanent magnet material preparation device and technique

InactiveCN104308160ASolve segregationImprove coercive forceMagnetic materialsMaterials preparationRare earth

A rare-earth alloy permanent magnet material preparation device comprises a raw material treatment portion, a precipitation tank, an electrolytic furnace, a grinding mechanism, a stamping mechanism and a vacuum sintering furnace. The raw material treatment portion comprises a rare-earth metal treatment tank and a blending tank, a delivery pipe connected with the blending tank is arranged on the rear-earth metal treatment tank, the blending tank is connected with the precipitation tank through a complexing solution delivery pipe, the precipitation tank is connected with the electrolytic furnace, a feed inlet is arranged on one side of the electrolytic furnace, a casting chamber is arranged at the tail end of the electrolytic furnace and connected with a cooling chamber, the cooling chamber is connected with the grinding mechanism through a discharge pipe, and the grinding mechanism is connected with the stamping mechanism which is connected with the vacuum sintering furnace. The problem of segregation of alloy ingots is solved effectively, high temperature strength, structural stability, welding performance and corrosion resistance of the alloy ingots are improved beneficially due to addition of Sc, and the common electrolytic furnace can be used for smelting the alloy ingots by adopting mixture after Nd, Pr, Dy and Sc complexing.

Owner:NANJING SABER IND DESIGN & RES INST CO LTD

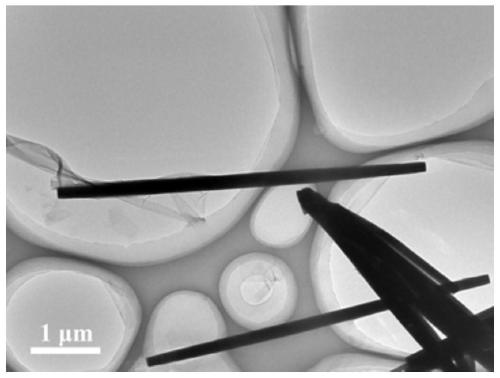

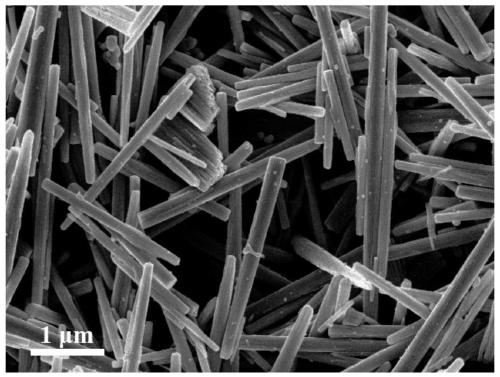

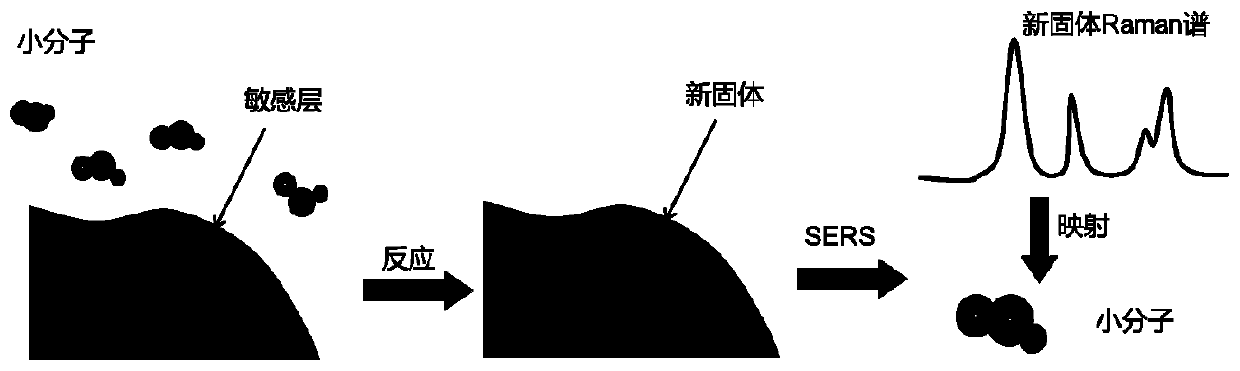

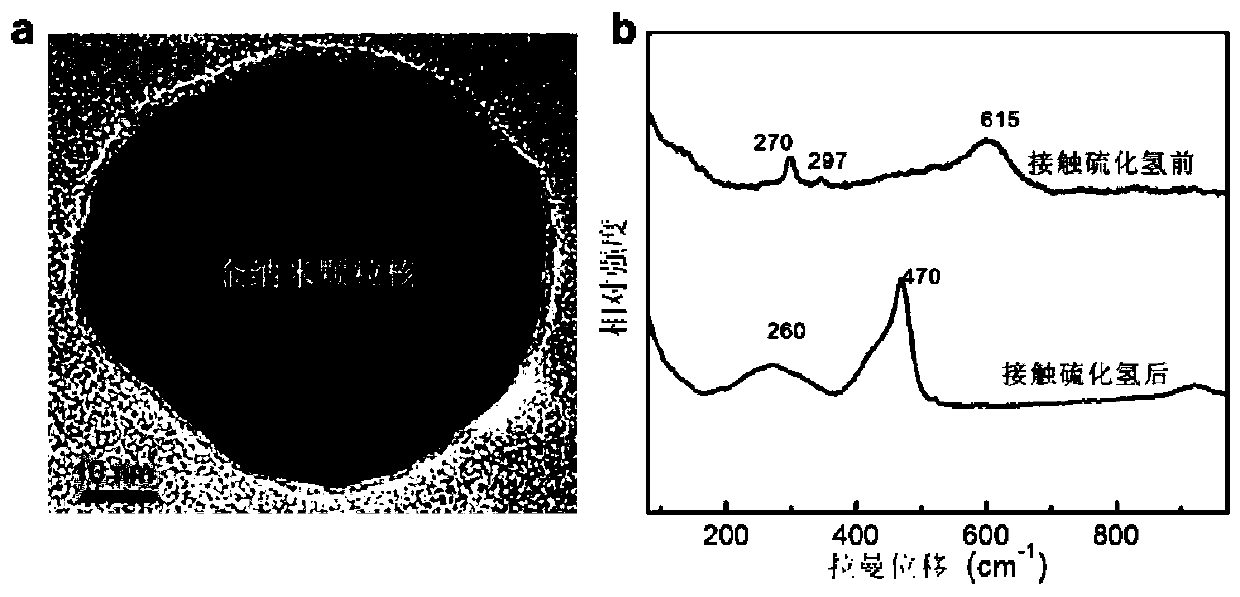

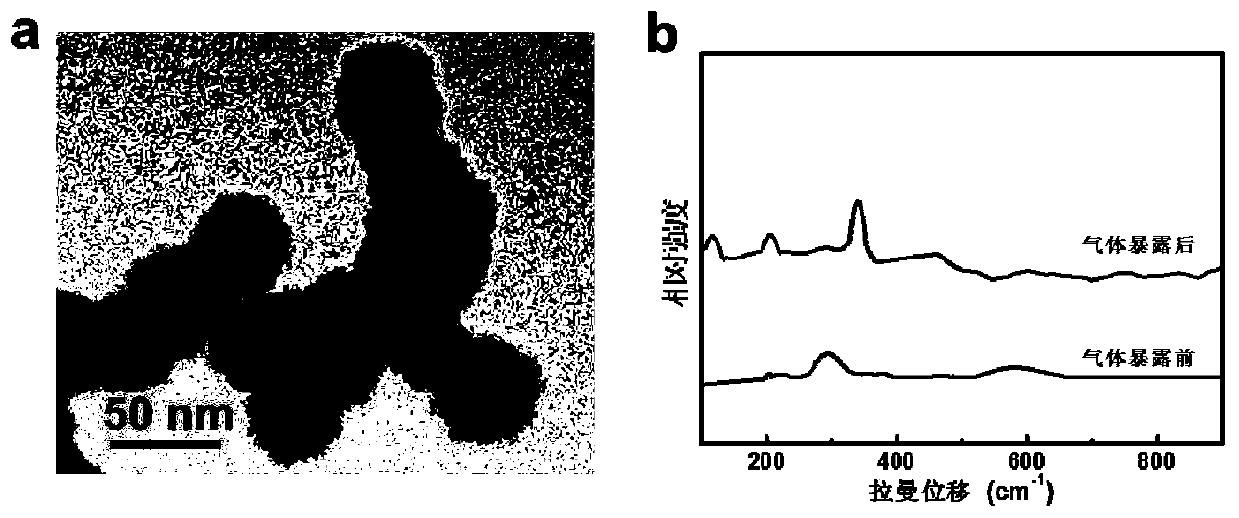

Inorganic sensitive layer based surface enhanced Raman spectrum detection technology and material preparation thereof

ActiveCN110514640AEfficient detectionEasy to makeTransportation and packagingMetal-working apparatusSurface-enhanced Raman spectroscopyThiourea

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

UV wax oil and preparation method thereof

InactiveCN110079198AIncrease productivityHigh coating hardnessWax coatingsAntifouling/underwater paintsVegetable oilUltraviolet

The invention discloses UV (ultraviolet) wax oil which comprises the following raw materials in percentage by mass: 40-60% of vegetable oil modified epoxy acrylate, 10-20% of Chinese wood oil, 5-10% of rosin, 5-10% of paraffin, 2-6% of beewax, 3-7% of palm wax, 3-6% of photoinitiator, 0.5-2% of assistant and 10-20% of wear-proof powder. The raw materials are combined together organically, so thatthe UV wax oil can be used for roller coating or rubbing coating and produced on a production line; and the production efficiency is greatly improved. The UV wax oil is free from VOC (volatile organiccompound) emission, belongs to an environment-friendly product, is high in film hardness, good in wear resistance, water resistance and fouling resistance, high in adaptability and low in productioncost, and can completely substitute the traditional common wax oil; the high-quality UV wax oil can be prepared through a series of operation of material preparation, ester addition, addition of the oil, the wax, the rosin and the like, re-charging, inspection and packaging; intensive mixing of the raw materials is facilitated; the raw materials are made full use of; and the production quality ofthe UV wax oil is improved.

Owner:YOUCAI (SHANDONG) ENVIRONMENTAL PROTECTION TECH CO LTD

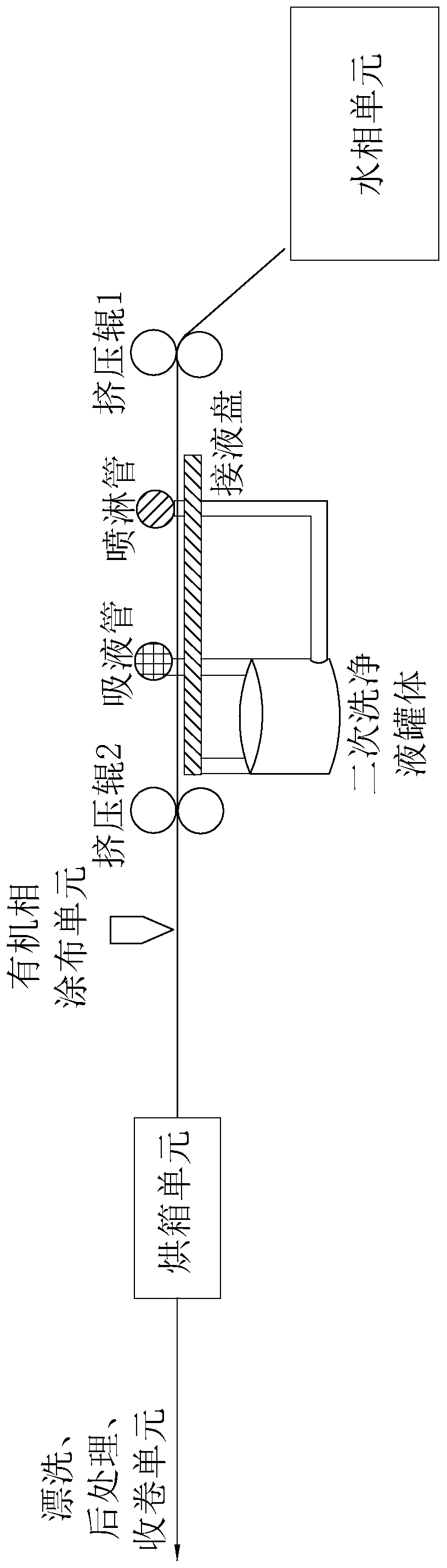

Preparation method of nanofiltration film

ActiveCN110327794AHigh molecular weightImprove hydrophilicitySemi-permeable membranesMembranesMaterials preparationSolvent

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

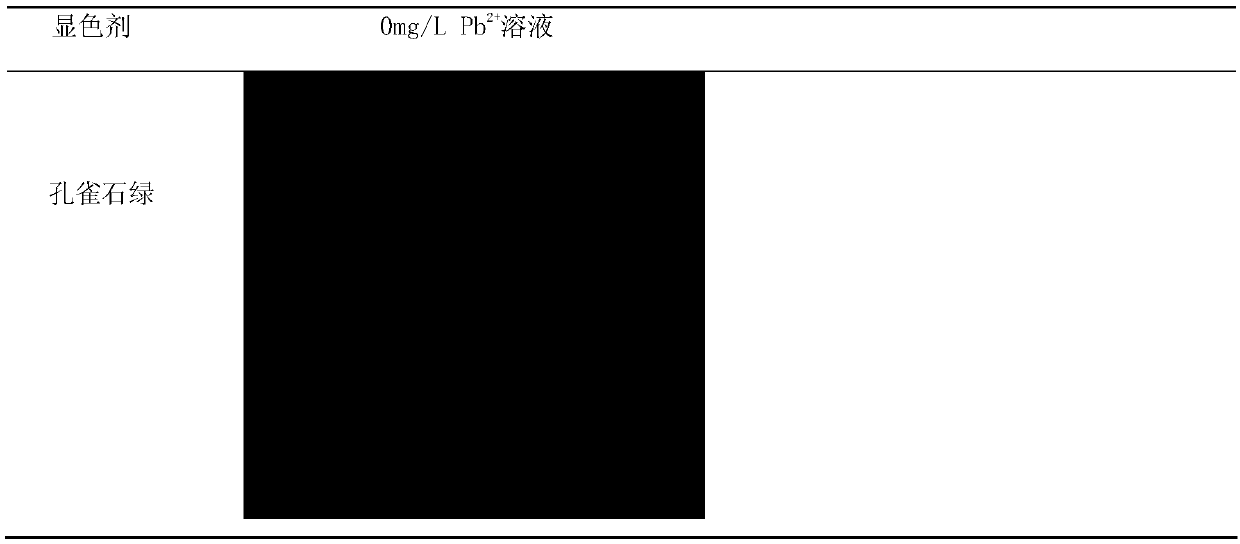

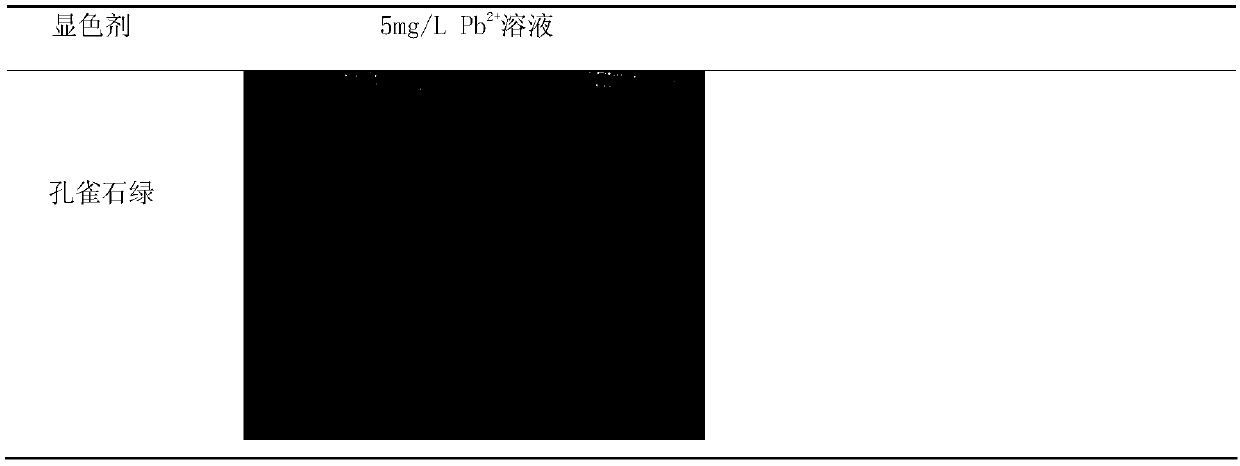

Preparation method of color-changeable cloth capable of detecting heavy metal ions in water, and method for detecting heavy metal ions in water by using color-changeable cloth

InactiveCN109612984AIn line with the trend of environmental protectionEasy to carryMaterial analysis by observing effect on chemical indicatorMalachite greenMalachite green stain

Owner:浙江省轻工业品质量检验研究院

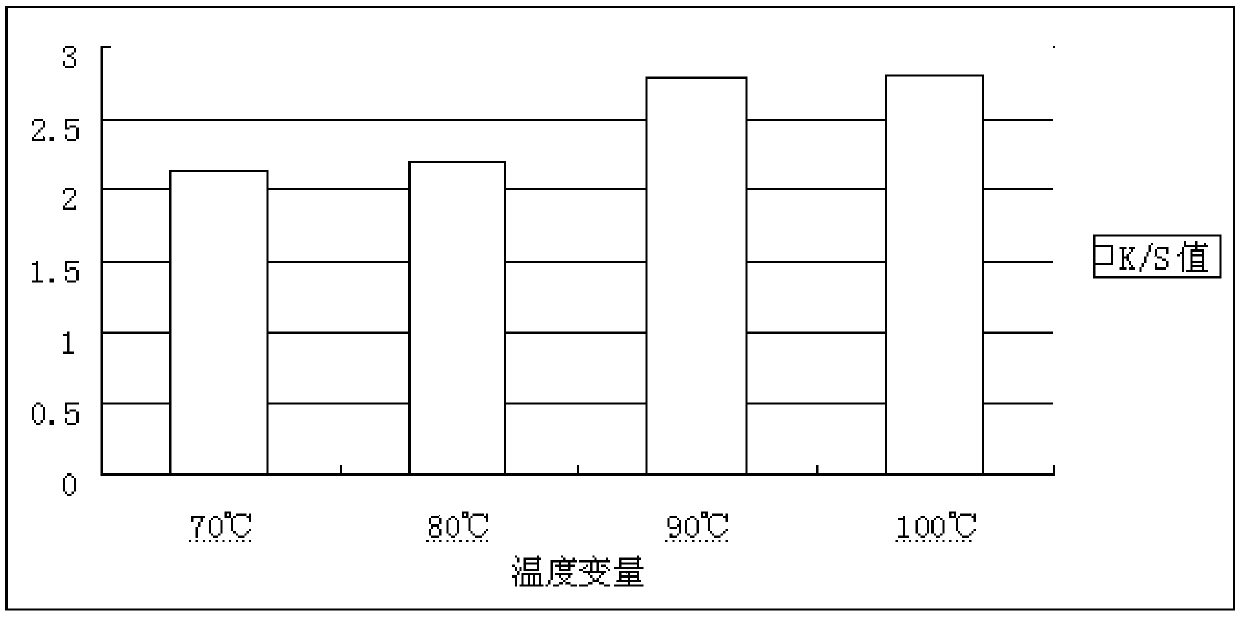

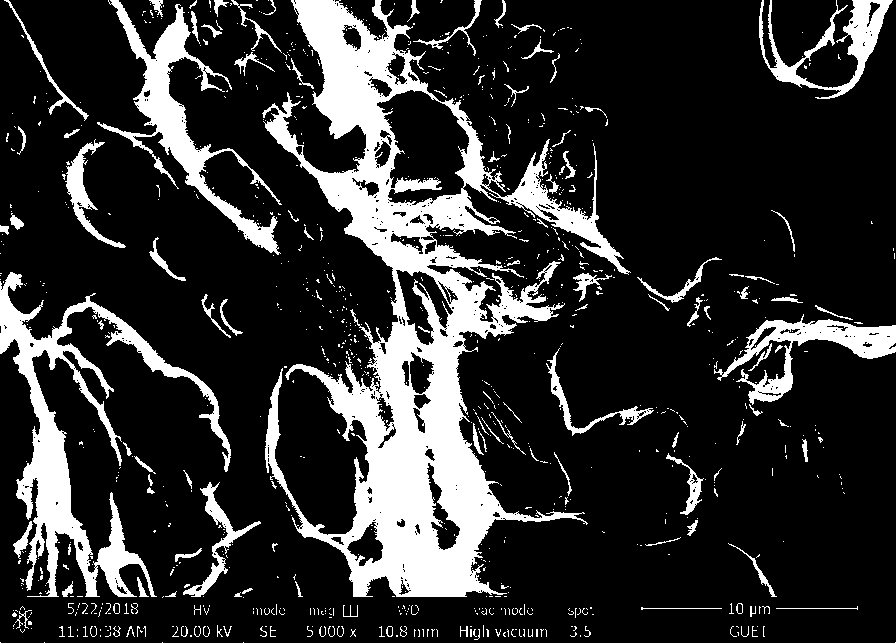

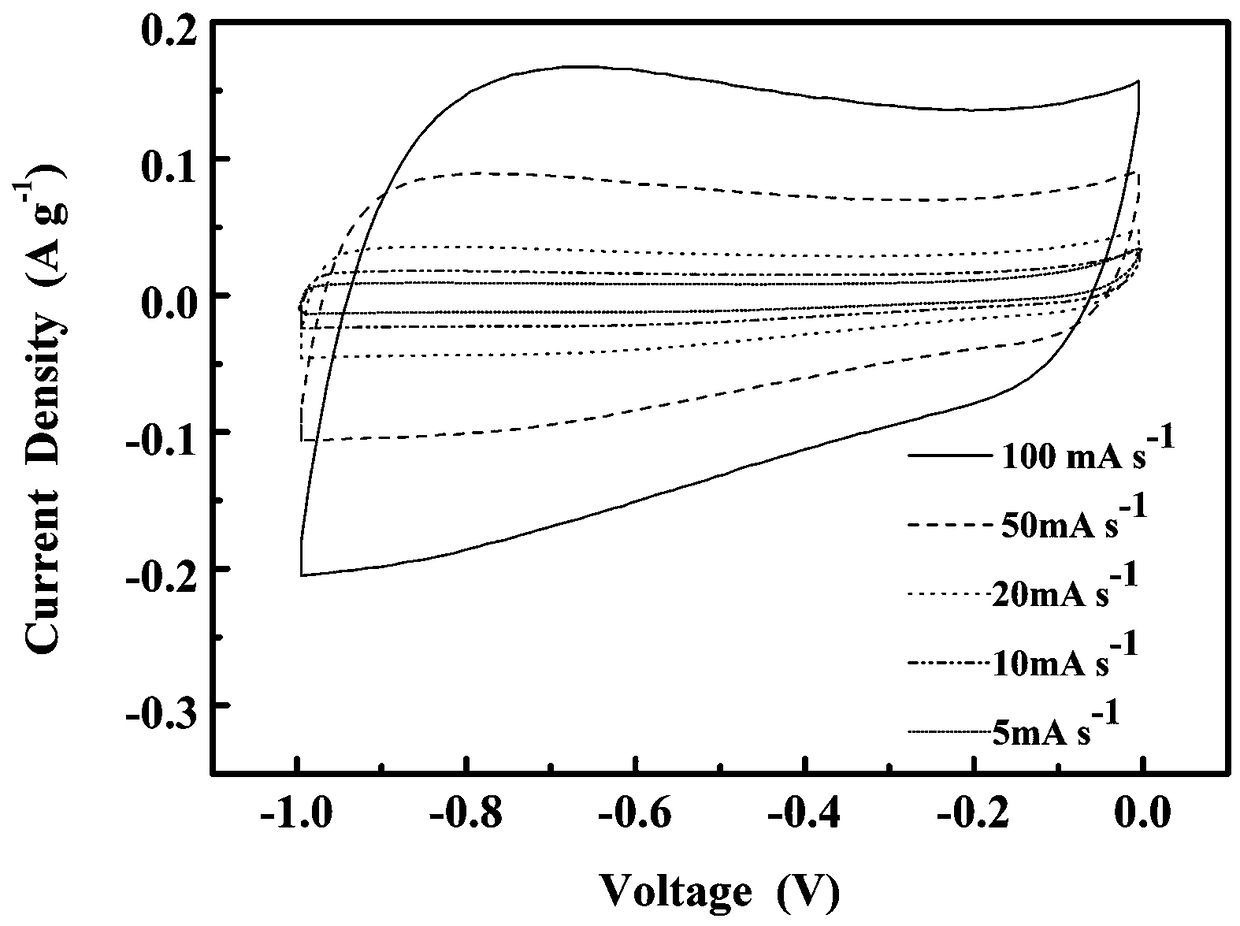

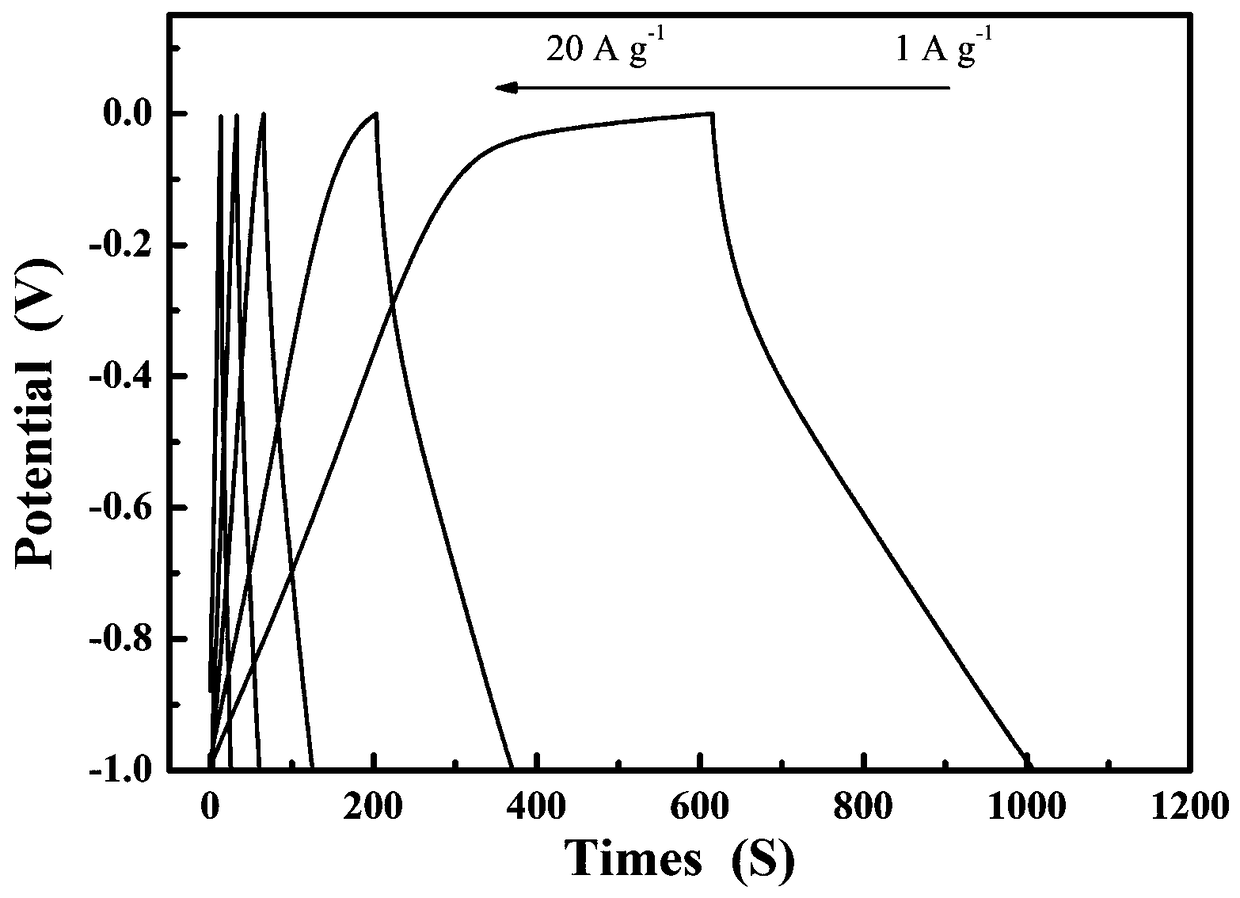

Fish roe based porous carbon material preparation and application

InactiveCN108793158ASimple design processLow activation temperatureCarbon compoundsMaterials preparationCapacitance

Owner:GUILIN UNIV OF ELECTRONIC TECH

Multifunctional electron beam zone melting furnace

PendingCN111118596AMeet the smelting methodSynchronized Coordinated MovementsPolycrystalline material growthBy zone-melting liquidsAutomatic controlZone melting

Owner:GRIMAT ENG INST CO LTD

Low-energy-consumption medical refrigerator heat preserving material and preparing method thereof

InactiveCN107057328ALow densityLow temperature resistance and good dimensional stabilityMaterials preparationManufacturing technology

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

Method for improving indoor temperature compressing plasticity of amorphous alloy

ActiveCN108543930AImprove room temperature compression plasticityInhibit rapid expansionMaterials preparationAlloy composite

Owner:HARBIN INST OF TECH

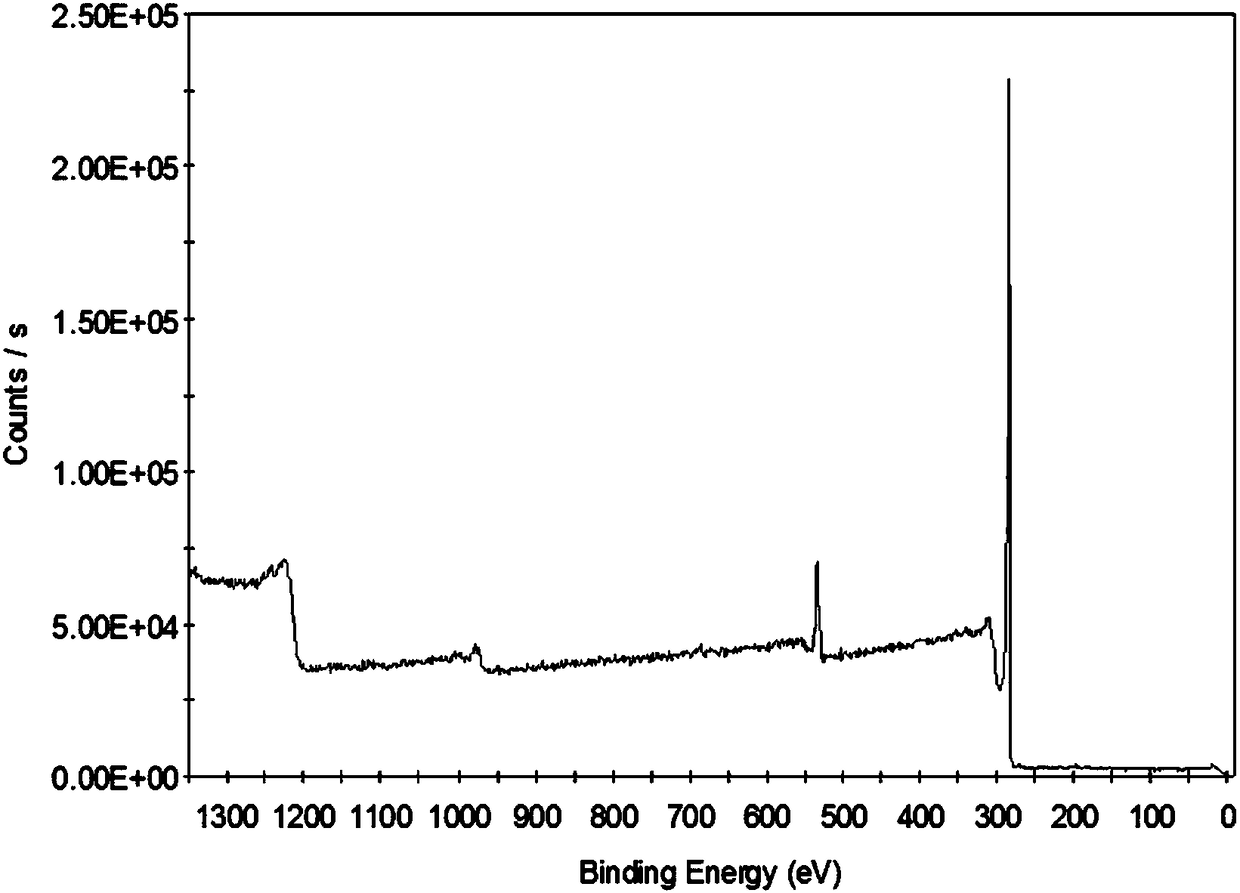

Highly-conductive carbon material and low-temperature preparation method thereof

ActiveCN108298516AImprove conductivityImprove stabilityCell electrodesHybrid capacitor electrodesChemical synthesisMaterials preparation

Owner:INST OF CHEM CHINESE ACAD OF SCI

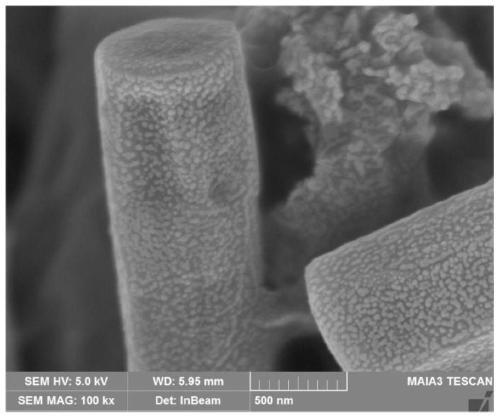

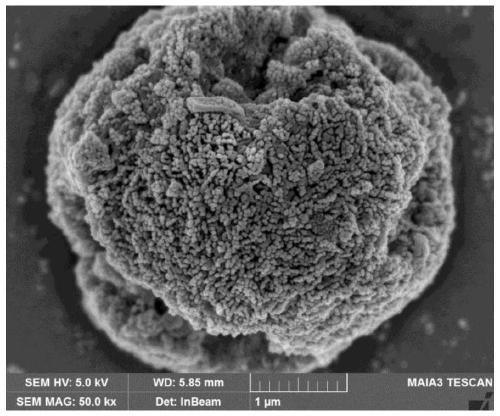

Preparation method of special-morphology micro nano structural lithium-rich manganese-based cathode material

ActiveCN110143619AAchieving controllable equipmentRealize controllable preparation of special morphologyMaterial nanotechnologyPositive electrodesNickel saltHigh energy

Owner:JISHOU UNIVERSITY

Manufacturing method for colored flowerpot

InactiveCN105906327AReceptacle cultivationTO-18Materials preparation

Owner:焦汉林

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap