Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22 results about "Sodium bicarbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium bicarbonate reduces stomach acid. It is used as an antacid to treat heartburn, indigestion, and upset stomach. Sodium bicarbonate is a very quick-acting antacid.

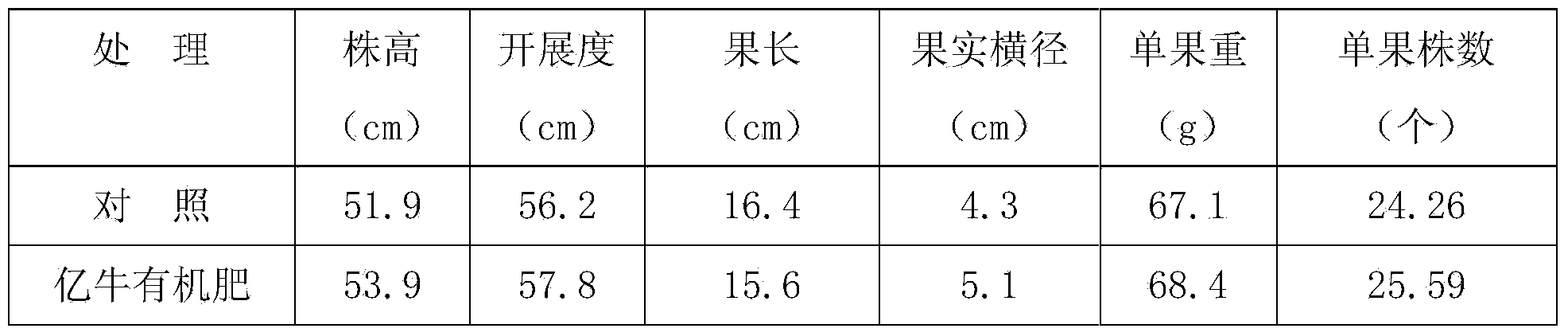

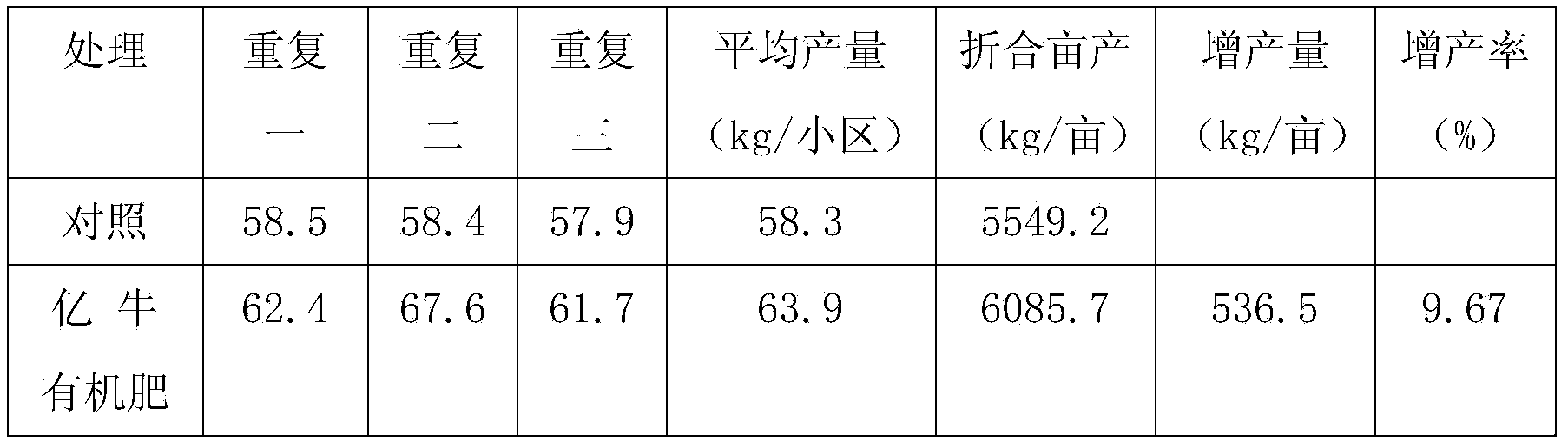

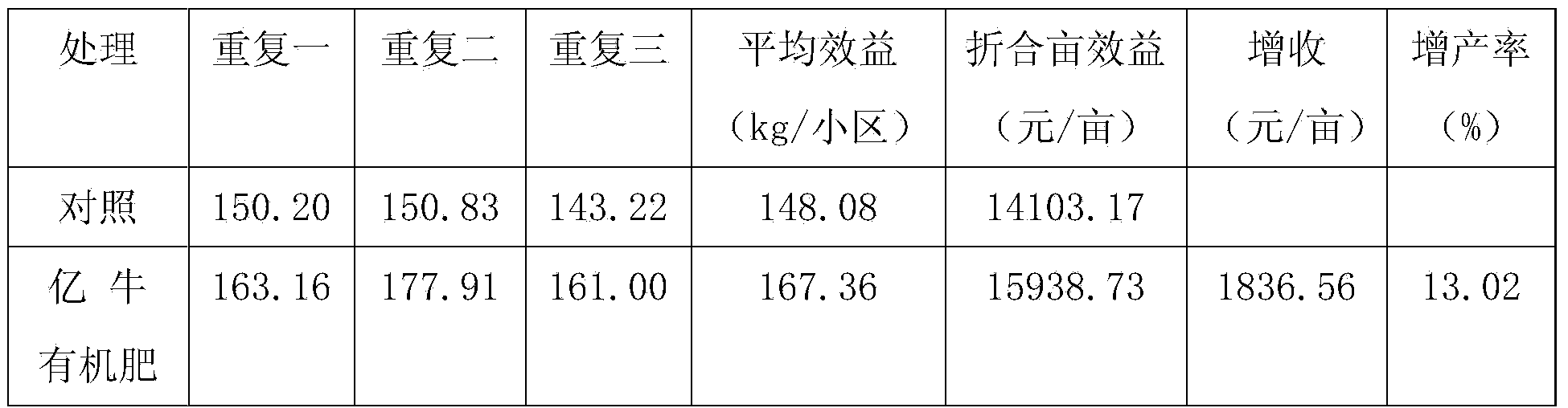

Method for preparing organic fertilizer by fermenting cow dung compost

InactiveCN103449864AGrow fastIncrease productionBio-organic fraction processingWaste based fuelSodium bicarbonateSodium Bentonite

Owner:六安亿牛生物科技有限公司

Environment-friendly concentrated liquid detergent for clothing materials

InactiveCN106047529AEasy to rinseConserve waterInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlkaneSodium bicarbonate

The invention provides an environment-friendly concentrated liquid detergent for clothing materials. The liquid detergent is environmentally friendly and easily degradable, does not stimulate the human body and has multiple functions of purifying, softening, fragrance depositing and the like. The environment-friendly concentrated liquid detergent comprises the following components in percentage by weight: 10%-15% of fatty alcohol-polyoxyethylene ether, 15%-20% of alkyl glycoside, 10%-12% of dodecyl dimethyl betaine, 6%-8% of seconary alkane sulphonate sodium, 3%-6% of fatty acid alkanol amide, 0-2% of citric acid, 0-2% of sodium carbonate, 0-2% of sodium bicarbonate, 0-1% of a flavoring agent and the balance of softened water.

Owner:ANHUI TAILONG CHENGYA GRP CO LTD

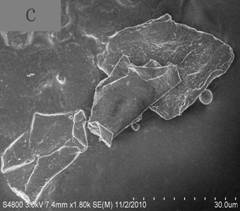

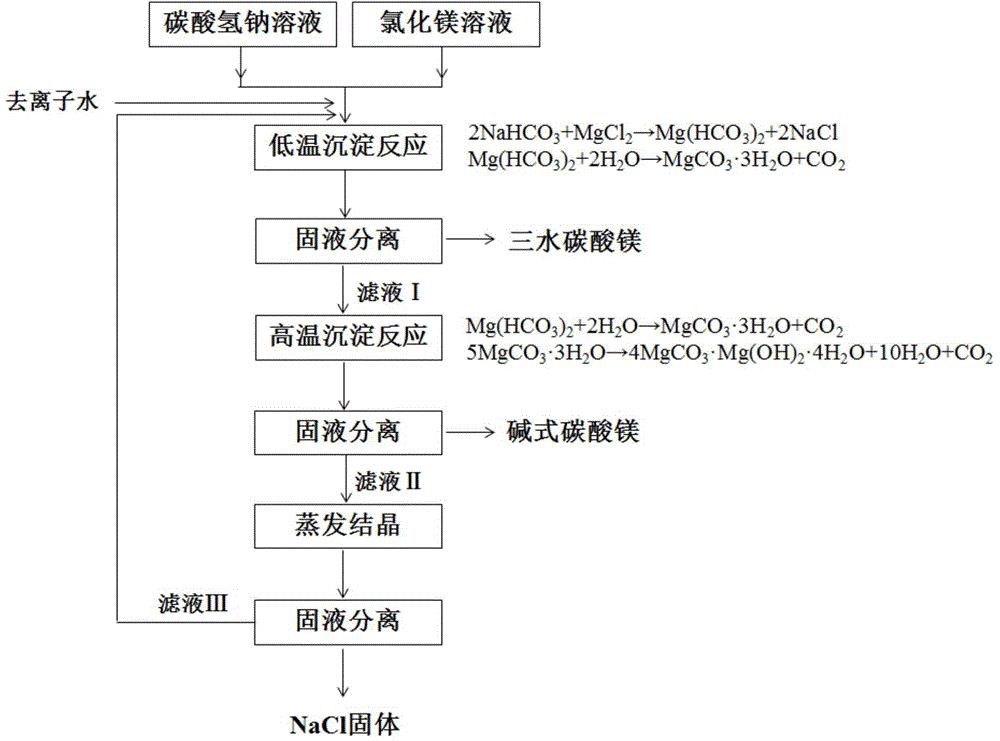

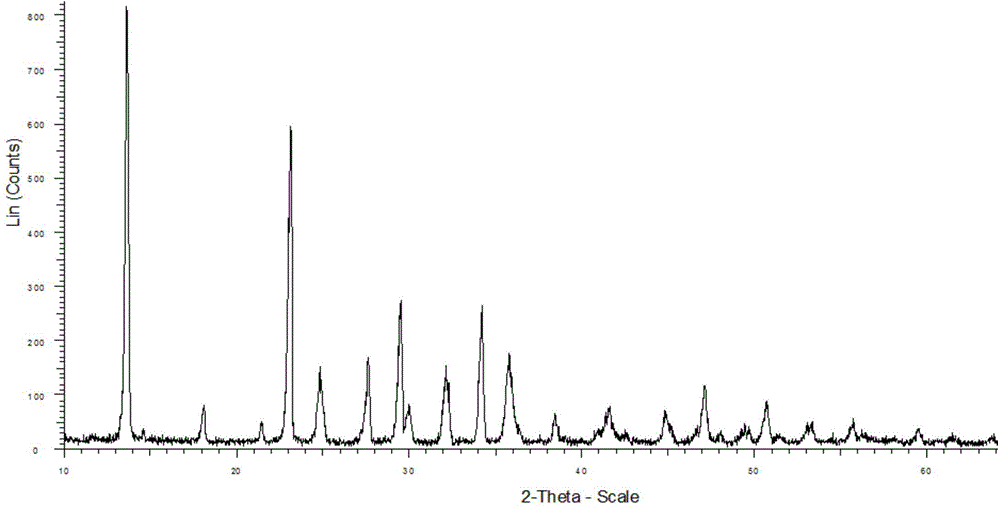

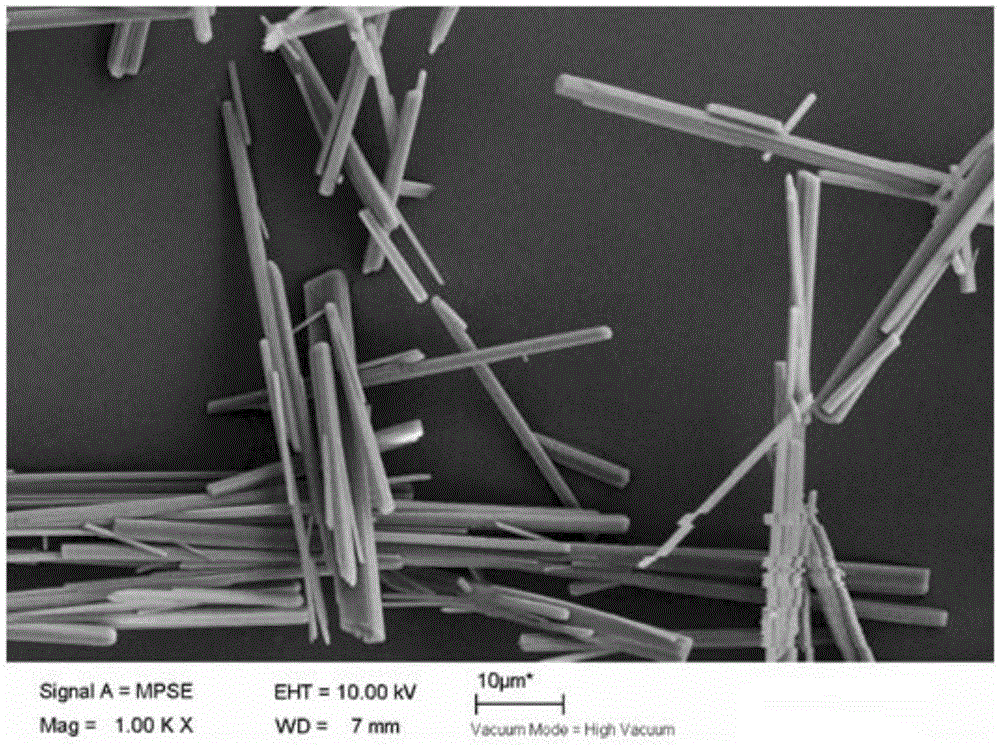

Method for preparing nesquehonite whiskers and nano flaky basic magnesium carbonate

InactiveCN104828847AGood dispersionHigh purityMagnesium carbonatesNanotechnologyDispersitySodium bicarbonate

Owner:COSL CHEM TIANJIN

Automobile trim material combined with non-woven fabric and woven fabric

InactiveCN105034535ASignificant advantage effectLow priceSynthetic resin layered productsLaminationSodium bicarbonateWarm water

Owner:湖北南泽汽车复合材料有限公司

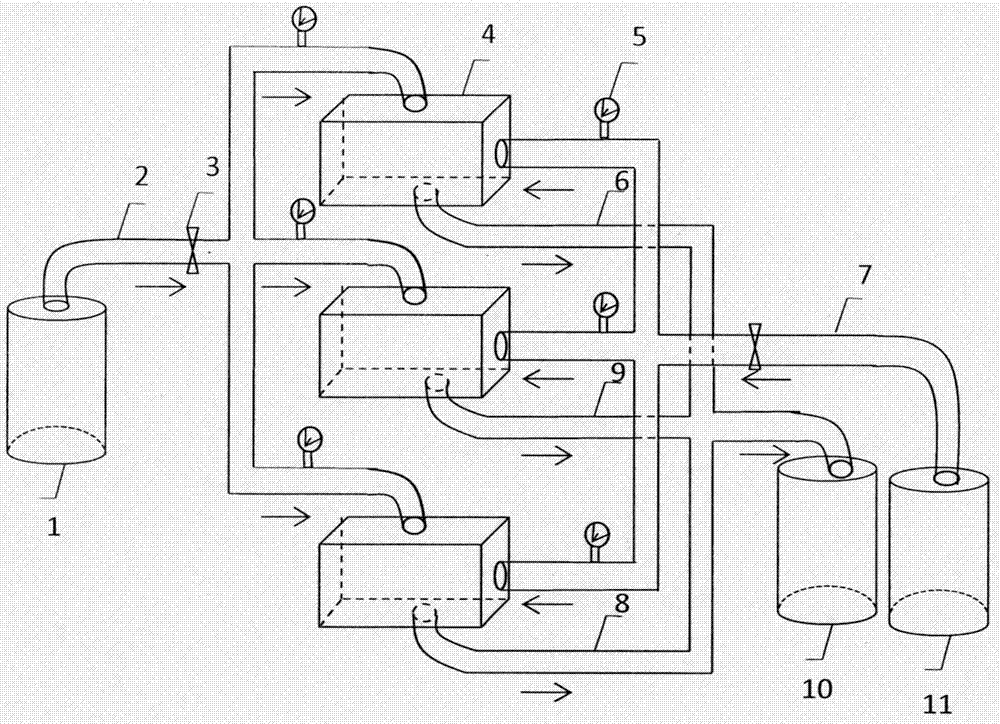

Preparation method for preparing nylon porous material on large scale

ActiveCN107353634ALarge specific surface areaWith insulationOther chemical processesWater/sewage treatment by sorptionPorositySodium bicarbonate

Owner:TIANJIN POLYTECHNIC UNIV

Making method of sugar-sweetened condensed milk

InactiveCN102669286AGuaranteed stabilityKeep healthyMilk substitutesFood scienceSodium bicarbonateNutritive values

The invention discloses a making method of sugar-sweetened condensed milk. The making method includes the steps of heating water, pouring soybean flour, sodium hexametaphosphate and sodium bicarbonate into hot water, adding a proper amount of vanillin and fragrance, mixing well, using a homogenizer to grind and homogenize mixture to obtain homogenized high-viscosity slurry; adding sugar into the slurry, heating to dissolve the slurry, mixing, using the homogenizer again to homogenize the slurry to obtain moderate-viscosity homogenized sugar-sweetened condensed milk; and dewatering the homogenized sugar-sweetened condensed milk in a vacuum container to obtain the low-viscosity easily flowing sugar-sweetened condensed milk. The sugar-sweetened condensed milk fully retains nutrients of soybean, has high economic benefit in comprehensive use of the soybean, is long in shelf life, is good in taste, high in nutritional value, easy to flow and moderate in sugar content, causes no diseases caused by eating condensed milk with high sugar content, and can be eaten to supplement body required energy and guarantee physical health.

Owner:赵宪兰

Black tea meal replacing cookie with intestine and stomach coordinating and slimming and shaping functions

InactiveCN107396954AExtended emptying timeBalanced nutritionDough treatmentModified nutritive productsIntestinal structureSodium bicarbonate

Owner:广东创美抗衰老研究有限公司

Preparation method of composite acrylate emulsion

ActiveCN109369842AImproved rheological propertiesSmall size effectWater bathsSodium bicarbonate

Owner:XUZHOU NORMAL UNIVERSITY

Extraction process of plant mildew-proof preservative

InactiveCN1672536AInfectiousEnhanced inhibitory effectFruit and vegetables preservationSodium bicarbonateWater vapor

Owner:CROPS BREEDING CULTIVATING INST SHANGHAI AGRI SCI ACAD

Copper material surface detergent

InactiveCN105018946AGood decontamination effectSystem stabilitySodium bicarbonateSulfamic acid

Owner:JIANGYIN SHENGYUAN COPPER MATERIAL

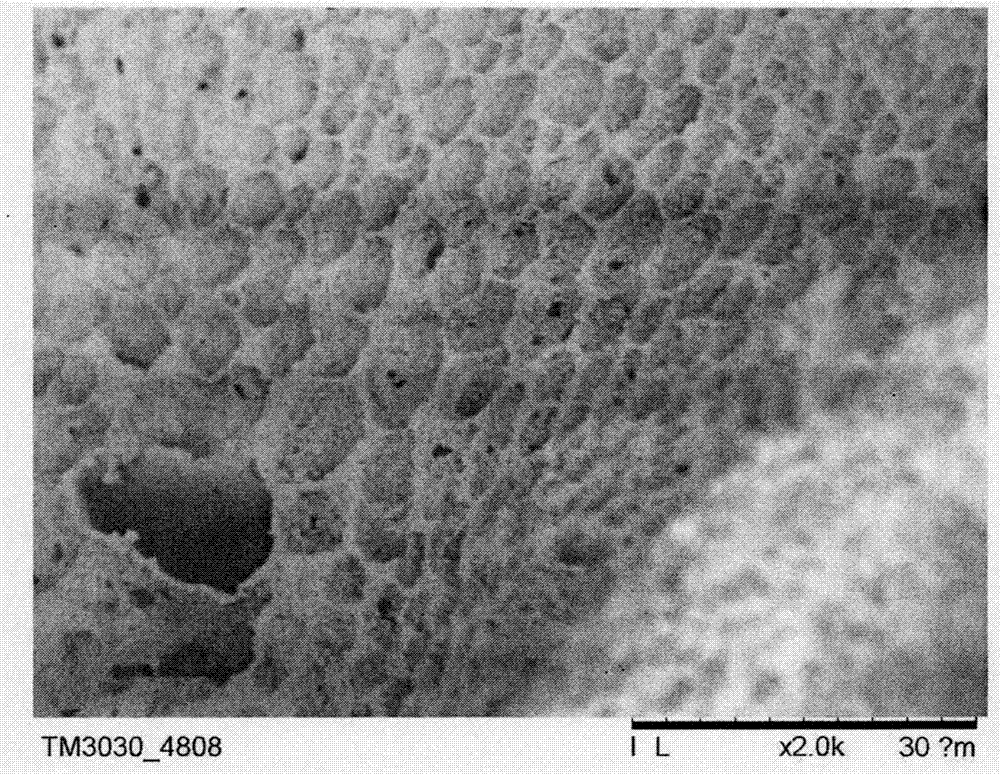

Preparation method of self-cleaning fibers

ActiveCN109382089ARetain high temperature resistanceRemain flexibleWater/sewage treatment by irradiationWater treatment compoundsFiberSodium bicarbonate

The invention provides a preparation method of self-cleaning fibers, and belongs to the field of water purification materials. The preparation method of the self-cleaning fibers comprises the following process steps: mixing deionized water, sodium metavanadate and ethylenediamine tetraacetic acid disodium, regulating pH of a solution with hydrochloric acid, and then adding a mixed solution of deionized water, bismuth nitrate pentahydrate, neodymium nitrate and sodium bicarbonate to prepare an active precursor solution; carrying out hydrothermal reaction on the active precursor solution and aluminium silicate fibers, and drying and calcining to obtain the self-cleaning fibers. The self-cleaning fibers consist of aluminium silicate fibers of which the surfaces are coated with bismuth neodymium vanadate, resist high temperature, are flexible, are high in strength, can float in water, and can degrade organic pollutants in water under the condition of illumination.

Owner:JIAXING RUYUN CONSTR TECH CO LTD

Dry powder extinguishing agent and preparation method thereof

InactiveCN107551444AReduce manufacturing costPrevent damp cakingFire extinguisherPotassium nitrateSodium bicarbonate

Owner:SUZHOU WUYUE SYNTHETIC FIRE SCI TECH

Oral composition for whitening teeth and flexible film patch

Owner:河南华尔登特生物技术有限公司

Novel benzimidazole isomer preparation and preparation method thereof

InactiveCN104288175AInhibition of secretionPlay a synergistic rolePowder deliveryOrganic active ingredientsSodium bicarbonateCyclodextrin

The invention discloses a novel benzimidazole isomer preparation. The novel benzimidazole isomer preparation is prepared from the following components in parts by weight: 1-1.5 parts of omeprazole, 1-1.5 parts of berberine hydrochloride, 50-60 parts of sodium bicarbonate, 45-50 parts of magnesium hydrate, 2-3 parts of oligoester beta-cyclodextrin, 20-30 parts of oleic acid and 80-95 parts of injection water. The invention also discloses a preparation method of the novel benzimidazole isomer preparation. Omeprazole and berberine hydrochloride disclosed by the invention have synergistic effects; and the berberine hydrochloride not only can prompt the omeprazole to restrain gastric acid secretion and increase effect, but also effectively reduces the adverse effects rate. The oligoester beta-cyclodextrin is also introduced into the novel benzimidazole isomer preparation, so that the effective ingredients omeprazole and berberine hydrochloride are coated by the oligoester beta-cyclodextrin; the water solubility is effectively improved; the oligoester beta-cyclodextrin is mixed into oleinic acid, so that emulsification of the oligoester beta-cyclodextrin is also further prompted; the conditions of uneven distribution such as suspension or sedimentation are prevented; and the curative effect is greatly improved.

Owner:DASHENGXIANG (WUHAN) TRADITIONAL CHINESE MEDICINE INVESTMENT MANAGEMENT CO LTD

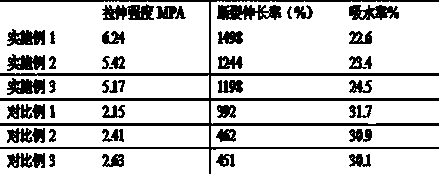

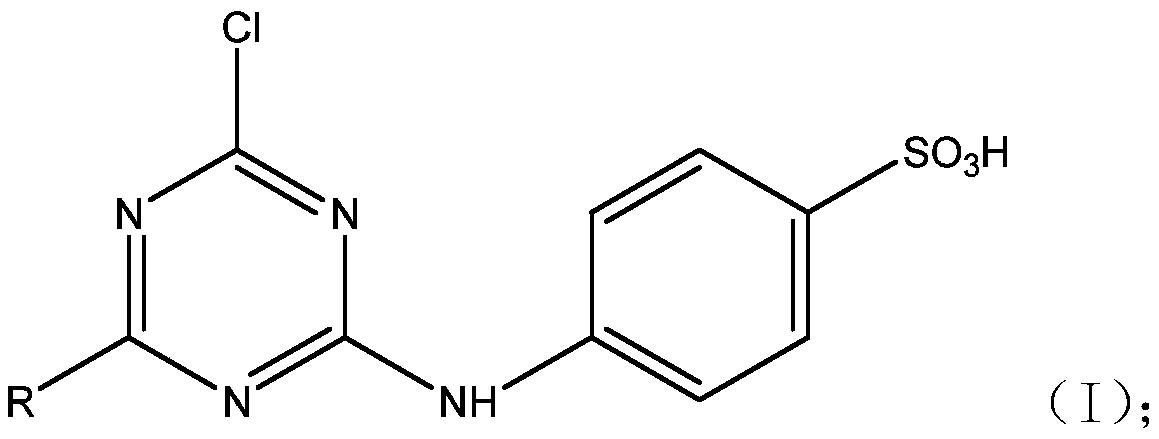

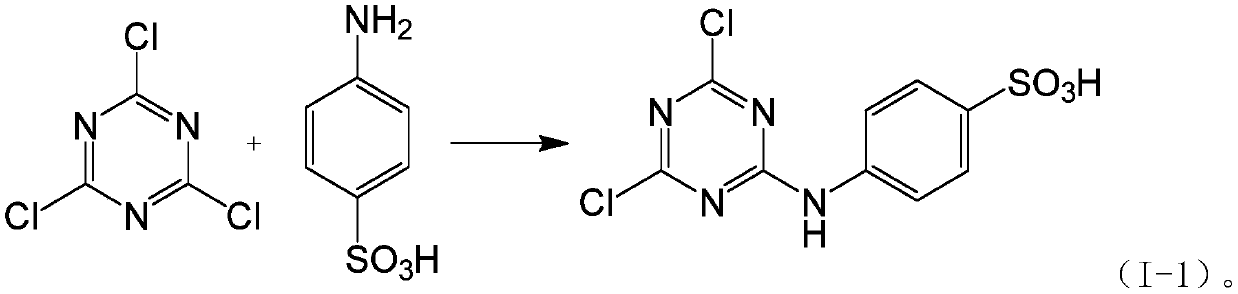

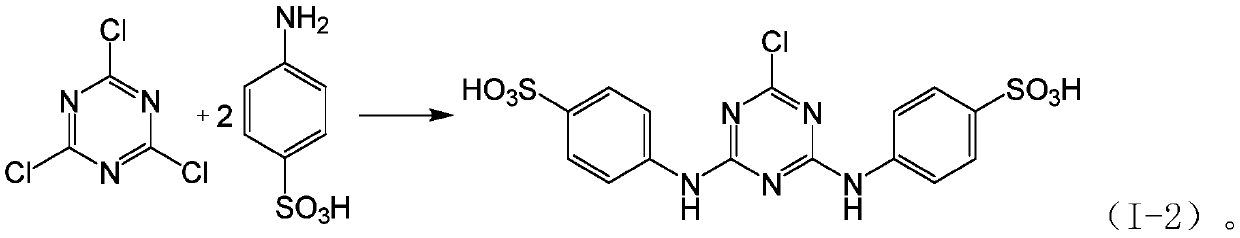

Cotton-fiber anionic modifier, preparation method thereof and dyeing process

InactiveCN110735331AColorfulVibrant color dyeing effectOrganic chemistryDyeing processSodium bicarbonateCotton cloth

Owner:ZHEJIANG YIDE CHEM

Food containing rich asparagus protein

InactiveCN104621626ARational use of antioxidant activityTake advantage of featuresFood ingredient functionsFood preparationBiotechnologySodium bicarbonate

Owner:FUZHOU UNIV

Diacetyl tartaric acid ester of mono(di)glyceride fried bread stick bulking agents

InactiveCN103891813ARaw materials are easy to getLow costDough treatmentBakery productsSodium bicarbonatePhosphate

Owner:韦谷林

Tenebrio molitor pet turtle feed and preparation method thereof

InactiveCN104814343APromote digestionMeet the needs of growthAnimal feeding stuffSodium bicarbonateAnimal science

Owner:HEFEI HAOWANG AQUACULTURE TECH CO LTD

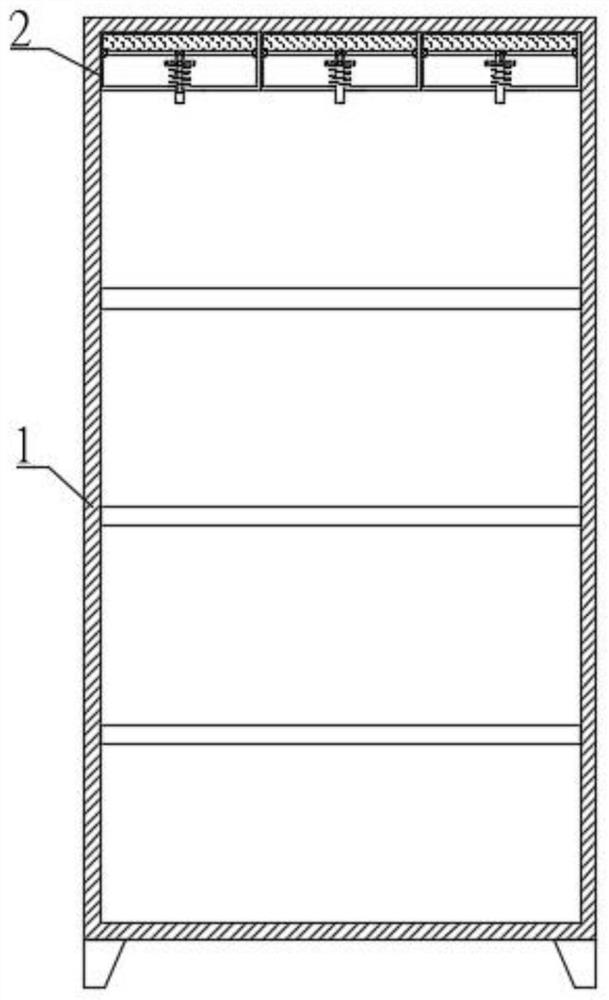

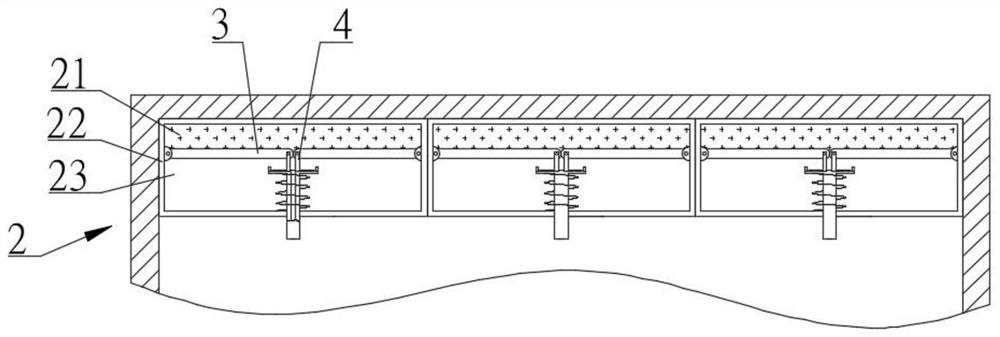

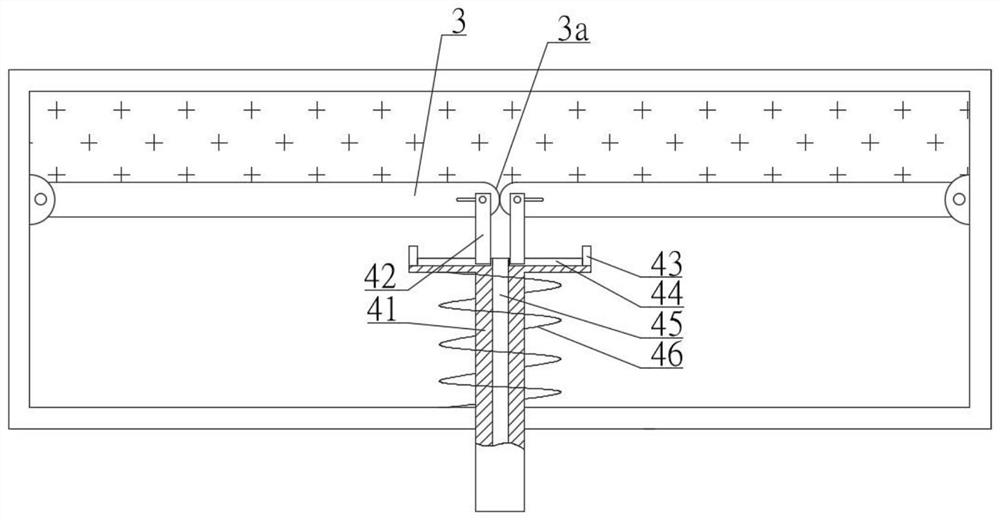

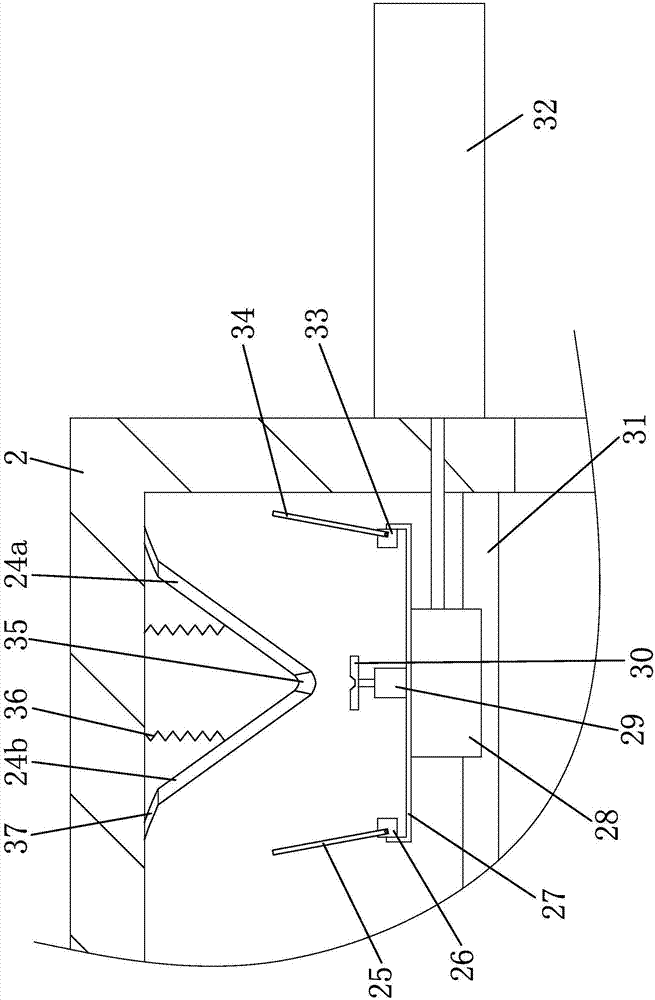

Fireproof distributed photovoltaic grid-connected cabinet

PendingCN113629512APlay the role of flame retardantSingle network parallel feeding arrangementsFire rescueSodium bicarbonateThermal dilatation

Owner:ANHUI FUHUANG ELECTRIC CONTROL EQUIP

Denim fabric printing and dyeing process

ActiveCN107254786AFast coloringNot easy to fadeLiquid/gas/vapor removalTextile treatment machine arrangementsSodium bicarbonateDenim

Owner:上海宛林服装有限公司

Photosynthetic bacterium medium formula

Owner:连云港巨森农业科技发展有限公司 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap