Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "Bisphenol A" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bisphenol A (BPA) is an organic synthetic compound with the chemical formula (CH₃)₂C(C₆H₄OH)₂ belonging to the group of diphenylmethane derivatives and bisphenols, with two hydroxyphenyl groups. It is a colorless solid that is soluble in organic solvents, but poorly soluble in water (0.344 wt % at 83 °C).

Fiber-enhanced epoxy resin composition for quickly forming automobile part and preparation method thereof

ActiveCN106674900AMeet heat resistance requirementsPromote infiltrationDiethylenetriamineFiber-reinforced composite

Owner:芜湖天道绿色新材料有限公司

Anti-bacterial and mouldproof plastic

The invention discloses anti-bacterial and mouldproof plastic. The anti-bacterial and mouldproof plastic comprises the following substances by weight: 14-18 parts of cinnamyl aldehyde, 18-28 parts of POE, 2-5 parts of copper, 2-3 parts of glycerol triglycerate, 4-7 parts of polyvinyl ester, 3-7 parts of magnesium sulfate, 3-12 parts of polypropylene, 6-10 parts of a bisphenol A type polycarbonate, 5-8 parts of an active resin binder, 6-12 parts of triethanolamine, 2-6 parts of vinyl triethoxysilane and 8-16 parts of a drier. With the above technical solution, raw materials are easily available, and cost is low. By adding the drier, the surface of the plastic can be maintained relatively dry; an environment for microbial growth is broken; propagation of microbes is effectively suppressed; and mouldiness can be prevented.

Owner:JIANGSU XINRUN PLASTIC CO LTD

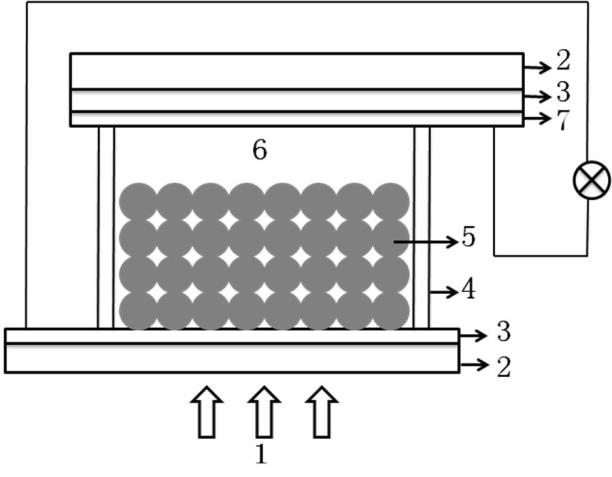

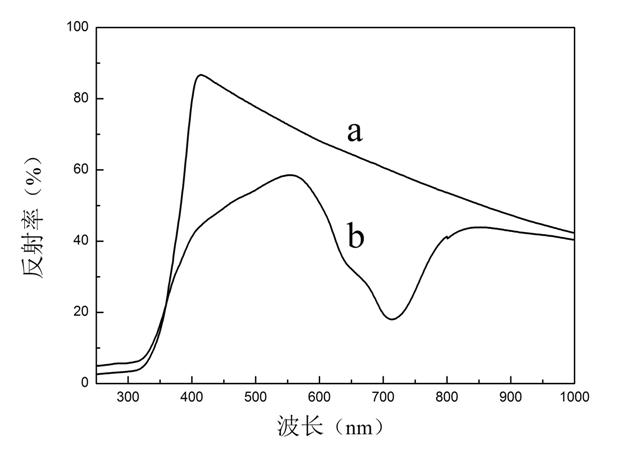

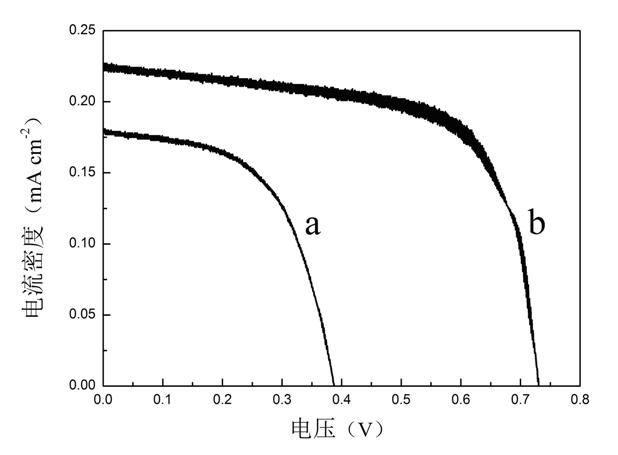

Preparation of solar battery sensitized by utilizing zinc phthalocyanine bisphenol A epoxide derivative

InactiveCN102637536ALight-sensitive devicesPhotovoltaic energy generationPerylene derivativesBisphenol A

The invention relates to a method for preparing a solar battery sensitized by utilizing a zinc phthalocyanine bisphenol A epoxide derivative, belonging to the field of a preparation process of the solar battery. The method comprises the following steps: firstly preparing tetranitro zinc phthalocyanine by adopting a phthalic anhydride-urea solvent method; reducing the tetranitro zinc phthalocyanine to tetraamino phthalocyanine through Na2S.9H2O; synthesizing bisphenol A diglycidyl epoxy ether; and reacting diglycidyl epoxy ether with tetraamino phthalocyanine to obtain a zinc phthalocyanine bisphenol A epoxide derivative; and taking the derivative as a dye photosensitizer to sensitize a TiO2 nanocrystal membrane to prepare into the dye sensitized solar battery. The dye photosensitizer is high in fluorescence quantum efficiency and good in light absorption at an ultraviolet band of 300-400nm and an infrared band of 600-800nm. Compared with tetraamino phthalocyanine, the dye sensitized solar battery prepared by the dye is higher in light current, light voltage and photoelectric conversion efficiency.

Owner:SHANGHAI UNIV

Tungsten trioxide/activated carbon/silver phosphate composite semiconductor photocatalytic material as well as preparation method and application thereof

ActiveCN112675886AInhibitory complexInhibition of recombinationWater/sewage treatment by irradiationTungsten oxides/hydroxidesActivated carbonTungsten trioxide

The invention discloses a tungsten trioxide / activated carbon / silver phosphate composite semiconductor photocatalytic material as well as a preparation method and an application thereof, and belongs to the technical field of photocatalysis. The composite semiconductor photocatalytic material comprises tungsten trioxide, activated carbon serving as a carrier and silver phosphate deposited on the surfaces of the tungsten trioxide and the activated carbon. The composite semiconductor photocatalytic material disclosed by the invention has the advantages of high photo-induced electron and hole separation efficiency, high photocatalytic efficiency, good catalytic stability and the like; the preparation method is simple, conditions are mild and easy to control, the technological process is environmentally friendly, and industrial production and utilization are easy to achieve. The composite semiconductor photocatalytic material provided by the invention can be applied to efficient removal of bisphenol A pollutants, has the advantages of simple application method, high degradation efficiency, good photocatalytic performance stability and the like, and has a very good practical application prospect.

Owner:GUANGXI UNIV

Preparation method of energy-saving and environment-friendly flame retardant tetrabromobisphenol A

PendingCN112830867AReduce generationSodium Consumption SavingsOrganic chemistryOrganic compound preparationChlorobenzeneTetrabromobisphenol A

Owner:山东迈特新材料科技有限公司

UV light-cured wood coating and preparation method thereof

InactiveCN114292572AAchieve complete deodorizationIncrease viscosityEpoxy resin coatingsPolymer scienceMeth-

The invention relates to the field of coatings, in particular to a UV light-cured wood coating and a preparation method thereof. The wood coating comprises the following components in parts by weight: 20-50 parts of resin, 20-40 parts of a monomer and 3-7 parts of an initiator, wherein the resin is epoxy acrylate or modified bisphenol A epoxy acrylate; the monomer is a mixture of trimethylolpropane triacrylate and diethylene glycol diacrylate; the initiator is a mixture of active amine and one or more of TPO, PBZ and OMBB. The wood coating provided by the invention can be cured under UV light, and the wood coating can realize complete odor removal; meanwhile, the wood coating has good viscosity, heat resistance, stability, leveling property and adhesive force, and relatively high curing speed.

Owner:PUYANG ZHANCHEN NEW MATERIALS CO LTD

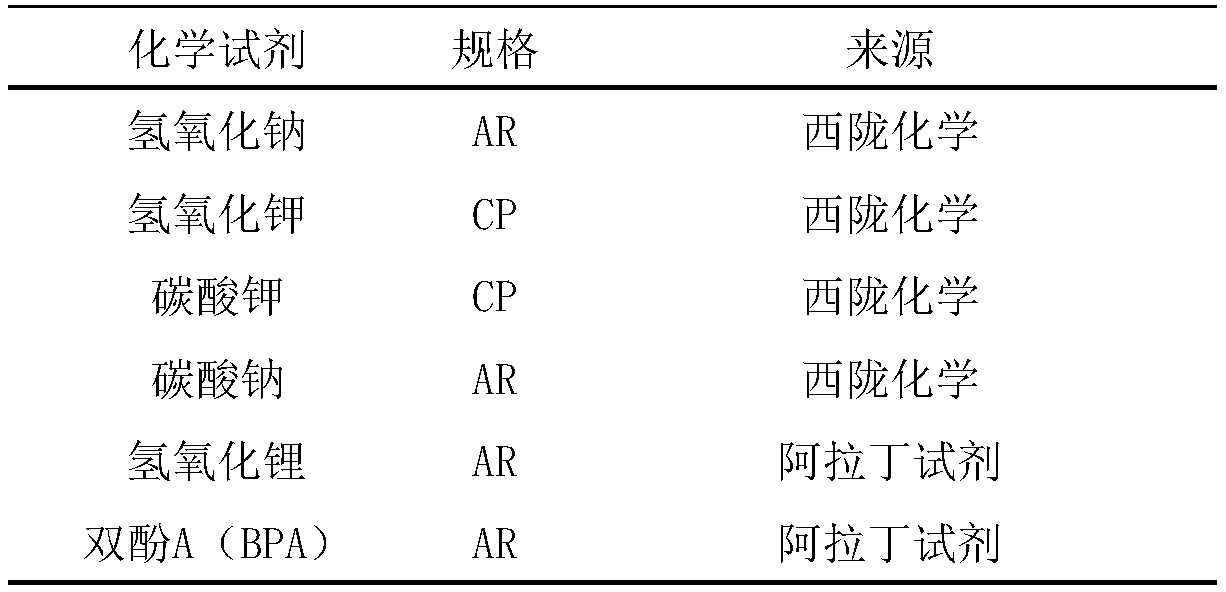

Bisphenol A salt preparation method

ActiveCN110878009AHigh solid contentQuick responseOrganic chemistryOrganic compound preparationDistillationSolvent free

Owner:WANHUA CHEM GRP CO LTD

Preparation method of multi-phase catalyst for synthesizing dimethoxy bisphenol bimethyl carbonate

ActiveCN108816213AImprove conversion rateHigh selectivityPreparation from organic carbonatesMetal/metal-oxides/metal-hydroxide catalystsMethyl carbonateHigh pressure

The invention discloses a preparation method of a multi-phase catalyst for synthesizing dimethoxy bisphenol bimethyl carbonate. The preparation method comprises the following steps: (1) dissolving polyvinyl pyrrolidone into deionized water, and stirring for fully dissolving the polyvinyl pyrrolidone, thus obtaining a solution A; (2) adding a lithium source and a titanium source in the solution A one by one or at the same time, ultrasonically stirring for 30 to 60 minutes, and then stirring for 6 to 12 hours, thus obtaining a solution B, wherein a molar ratio of the lithium source to the titanium source is 1:1 to 1:10; (3) transferring the solution B into a high-pressure reaction kettle, putting the high-pressure reaction kettle at 150 to 180 DEG C, and reacting for 3 to 6 minutes with pressure; opening the high-temperature reaction kettle after cooling, evaporating a solvent, and drying obtained solid at 80 to 120 DEG C for 6 to 12 hours, thus obtaining white solid; (4) roasting the white solid in a muffle furnace of which the temperature is 300 to 600 DEG C for 2 to 6 hours, thus obtaining the multi-phase catalyst. A Ti / Li bimetal catalyst is prepared for the first time, and the Ti / Li bimetal catalyst is used in transesterification reaction of bisphenol A and dimethyl carbonate for the first time, so that the conversion rate of the bisphenol A is increased, the selectivity oftransesterification is increased, and alkylated products are reduced.

Owner:TIANJIN POLYTECHNIC UNIV

Processing material for stirring paddle of chemical reaction kettle and preparation method of processing material

InactiveCN106633653AImprove corrosion resistanceImprove wear resistanceChemical/physical/physico-chemical processesFiberChemical reaction

Owner:DONGZHI TIANFU CHEM

High-temperature-resistant thermoplastic elastomer and preparation method thereof

InactiveCN106674843AImprove aging resistanceImprove high temperature resistanceDiphenylmethaneElastomer

Owner:ANHUI TIANYUAN CABLE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap