Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

27 results about "Oil water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

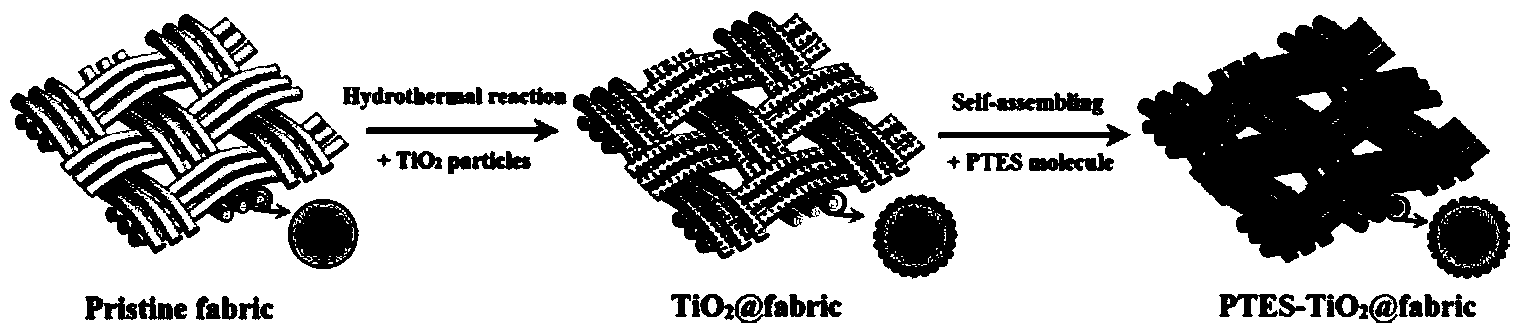

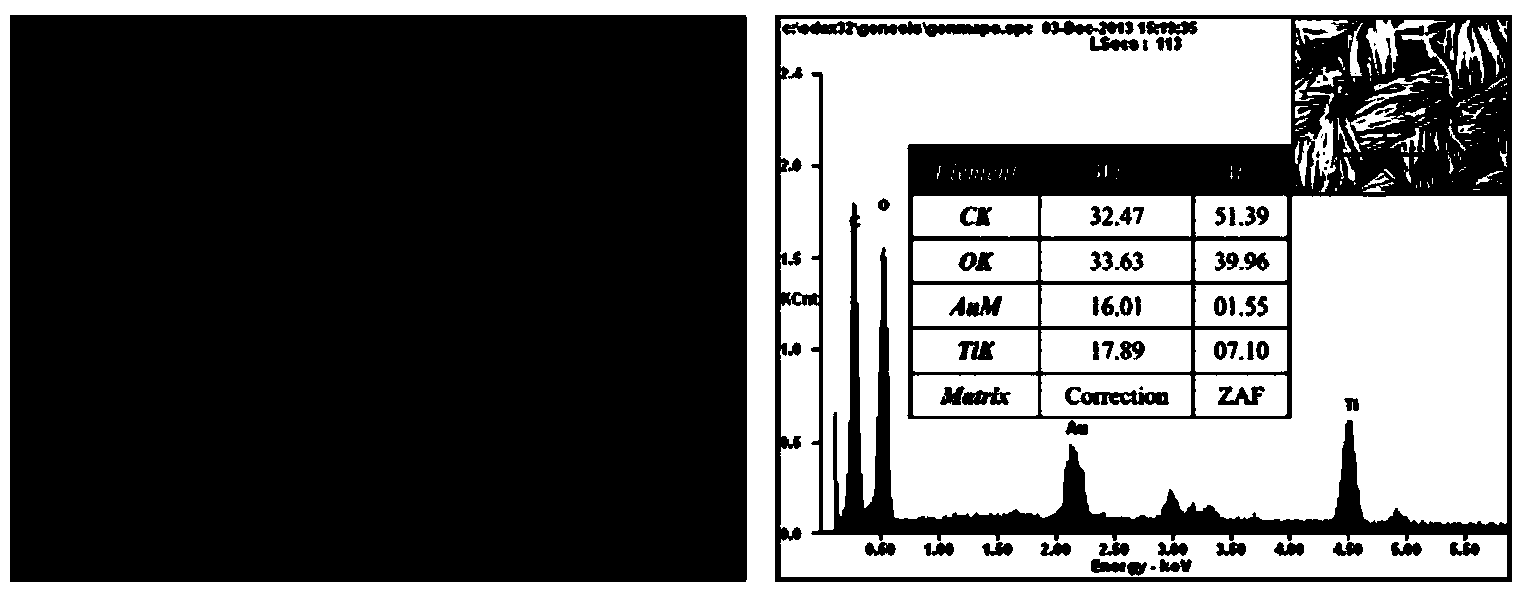

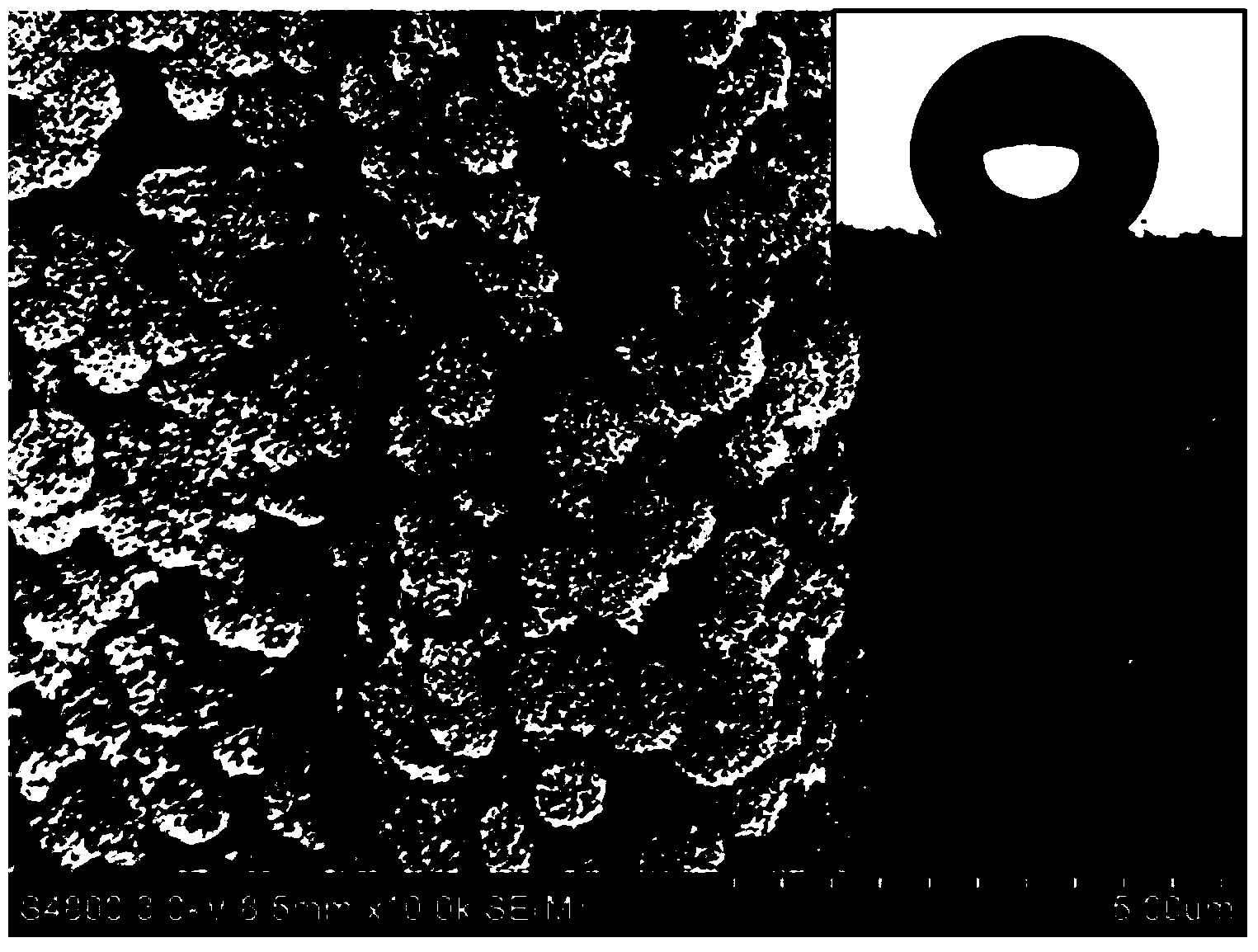

Preparation method of special-infiltration functional fabric surface with self-cleaning and oil-water separation functions

Owner:SUZHOU UNIV

Method for treating waste emulsion

ActiveCN104649482AGood removal effectExtended service lifeFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWater treatment systemEmulsion

The invention provides a method for treating waste emulsion. The method comprises the following steps: performing oil slick removal treatment on the waste emulsion to be treated to remove oil slick therein; performing oil-water separation treatment on the waste emulsion without oil slick to remove disperse oil therein; performing electrochemical treatment on the waste emulsion after the oil-water separation treatment to obtain roughly treated waste emulsion in which the oil slick and disperse oil are removed and the emulsified oil and dissolved oil are flocculated; and performing static settlement and ultrafiltration treatment on the roughly treated waste emulsion to obtain clear water without oil slick, disperse oil, emulsified oil or dissolved oil, wherein the electrochemical treatment is performed by use of energized aluminum plate and a nano ceramic membrane, and the ultrafiltration treatment is performed by use of the power-off nano ceramic membrane. Through the treatment of the method provided by the invention, the water quality of the yielding water is good, and the yielding water can completely meet the limitation requirements on the discharge into a public sewage treatment system in the Integrated Discharge Standard of Water Pollutants DB11 / 307-2013 of Beijing.

Owner:BEIJING SINORICHEN ENVIRONMENTAL PROTECTION

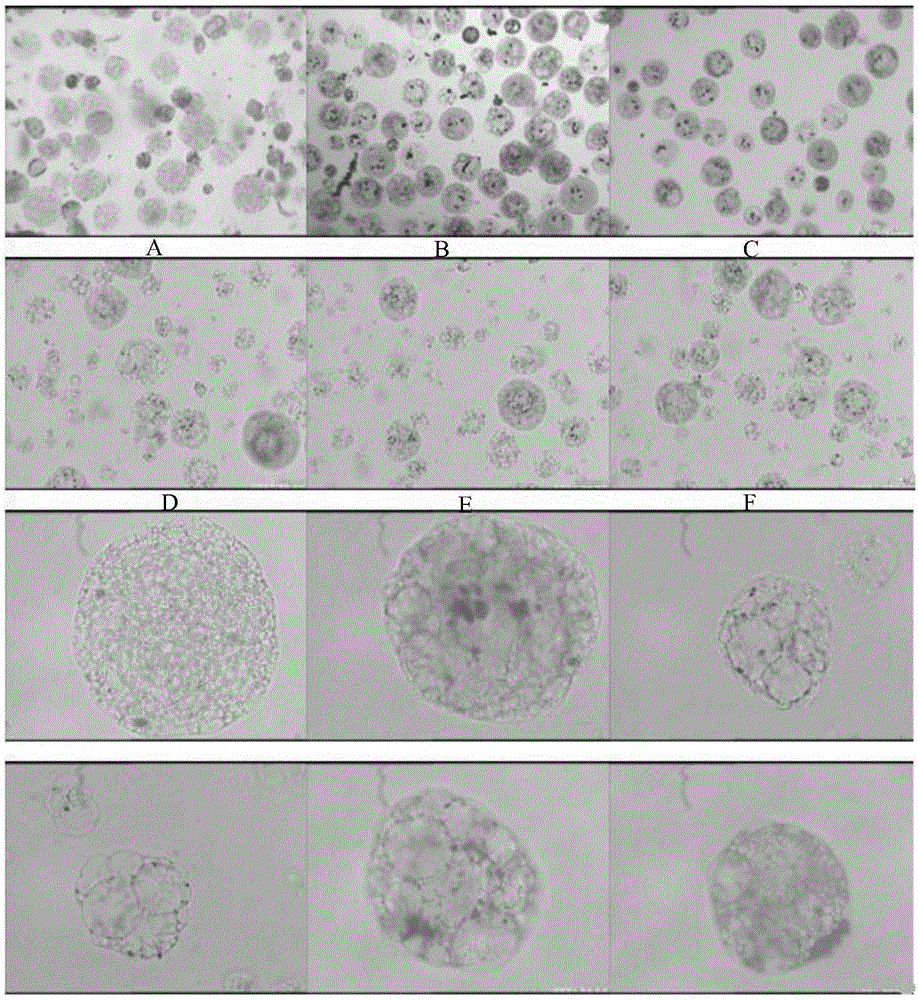

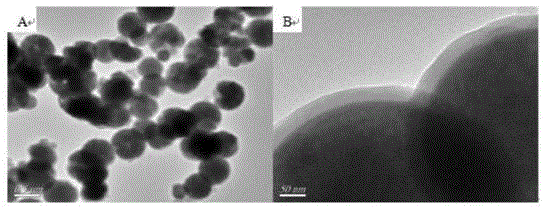

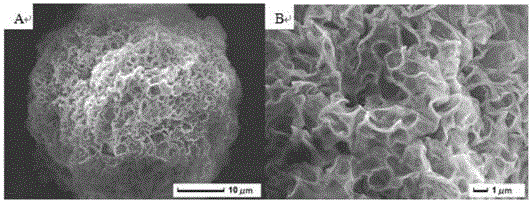

Three-dimensional wrinkle polylactic acid microballoons and preparation method and uses thereof

InactiveCN105273216AAchieve transformationLarge specific surface areaTissue cultureLiquid separationCell adhesionMicrosphere

Owner:JIANGSU UNIV

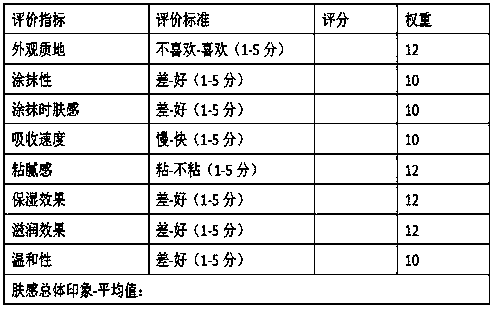

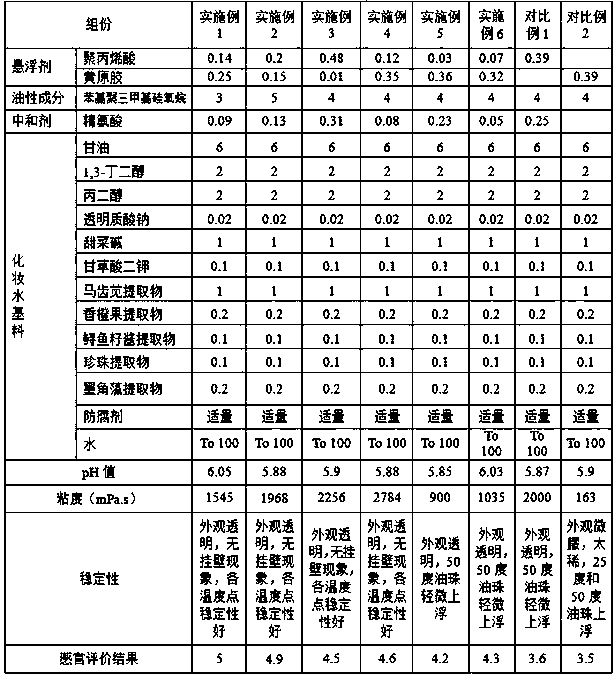

Suspension oil droplet toning lotion and preparation method thereof

ActiveCN107595761AUniform and stable suspensionReduce stimulationCosmetic preparationsToilet preparationsMedicineOil water

Owner:HUAANTANG BIOTECH GRP CO LTD

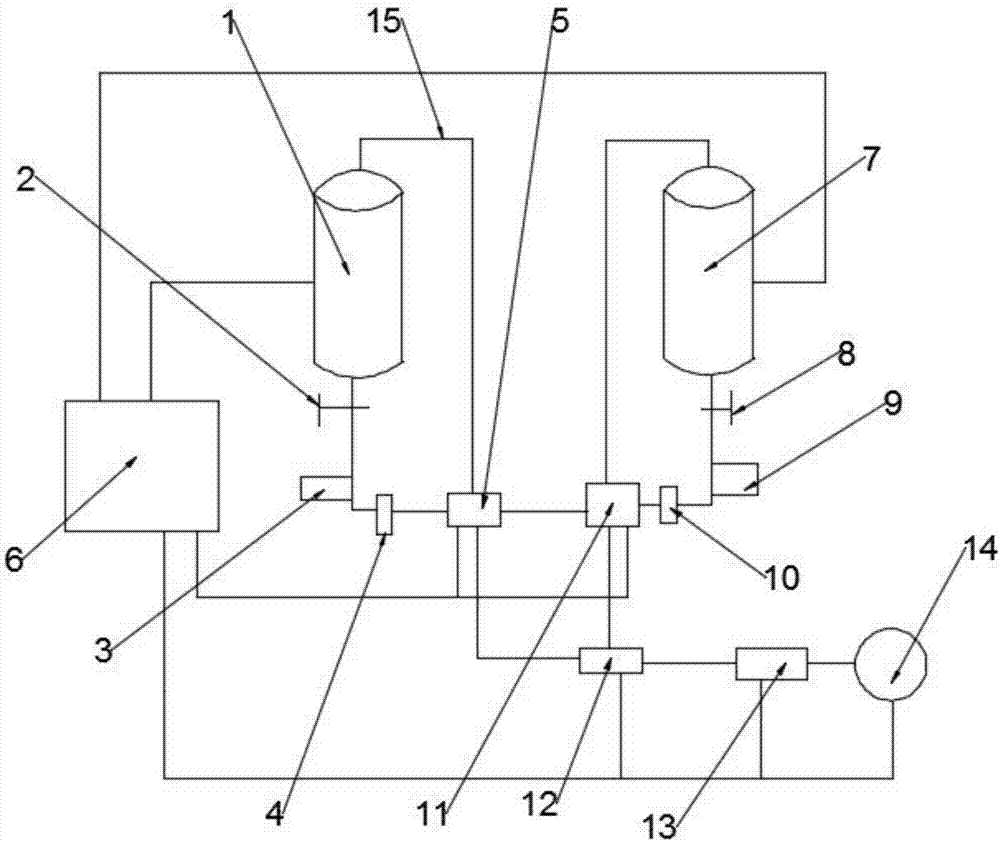

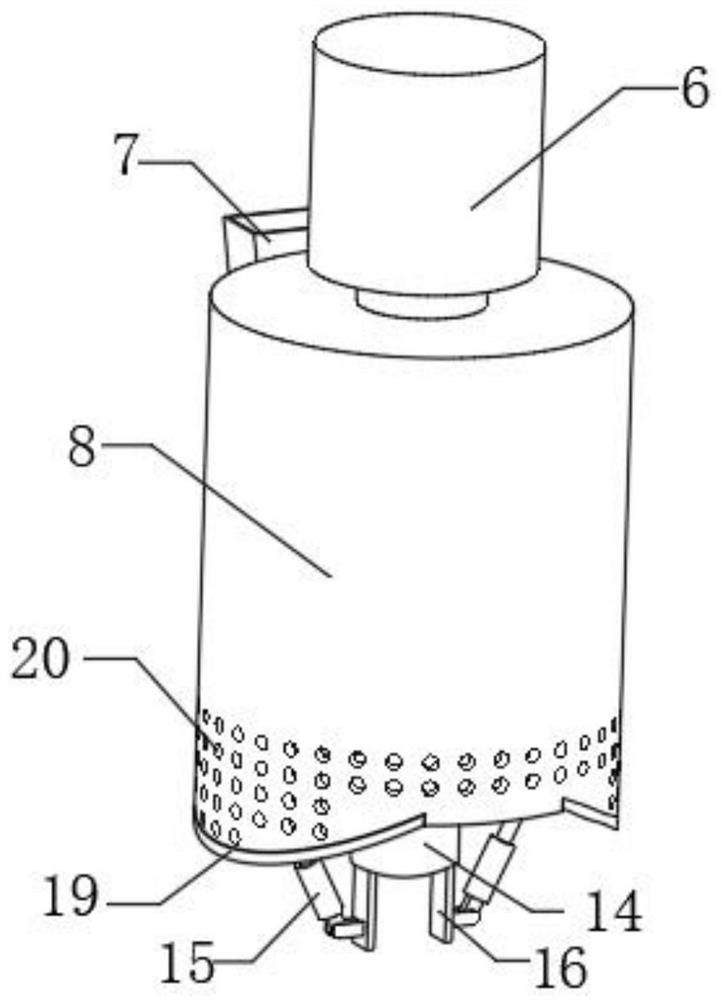

Water dividing oil purifier for lubricating oil used by ship

PendingCN107158750AChange physical and chemical propertiesExtended service lifeLiquid separation auxillary apparatusPropulsion power plantsControl systemFiltration

Owner:XINXIANG RIXIN PURIFY EQUIP

Oil and water impurity separating processing device for petrochemical industrial machine

InactiveCN109772008AImprove barrier propertiesEasy to rotate and dischargeMoving filtering element filtersOil waterPulp and paper industry

The invention discloses an oil and water impurity separating processing device for a petrochemical industrial machine. The device comprises an outer box, a forward and reverse motor, a heating wire and a top block. The forward and reverse motor is fixedly installed at the top of the outer box, a rotating rod is connected to the lower end of the forward and reverse motor, a first gear is fixedly arranged at the top of the rotating rod, an inner box is arranged at the inner side of the outer box, an inner cavity is formed inside the inner box, the right side of the rotating shaft is connected with a rotating disc, the lower portion of the rotating disc is connected with a connecting rod through a fastening bolt, the top block is fixedly arranged at the surface of the inner box, and a clamping groove is formed in the surface of the outer box. According to the oil and water impurity separating processing device for the petrochemical industrial machine, by arranging the threaded rotating rod and a spiral sliding groove, the rotating rod is driven by the forward and reverse motor to drive a supporting plate inside a filter net and a movable plate to move up and down inside the inner box,and dirt impurities are conveniently obstructed above the supporting plate through the supporting plate and the filter net.

Owner:朱德儒

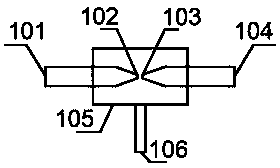

Oil-water separation device and application

The invention provides an oil-water separation device and application. Oil-water separation pipelines are arranged in a three-dimensional space according to a extended-range time delay principle; through layer-by-layer gravity sedimentation, water and oil in crude oil production liquid or oil-containing sewage are separated, thereby achieving a good oil-water separation effect; whether for a pre-separation, coarse separation or fine separation process, the effect of almost no oil in discharged liquid discharged from a water outlet pipe at the bottom of a pipe body can be achieved; the discharged liquid can directly enter a gravity settling tank or other processes through branch pipelines for further separation; and the water contained in the oil discharged from an oil outlet in the top ofthe pipe body can be reduced to less than 20%.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

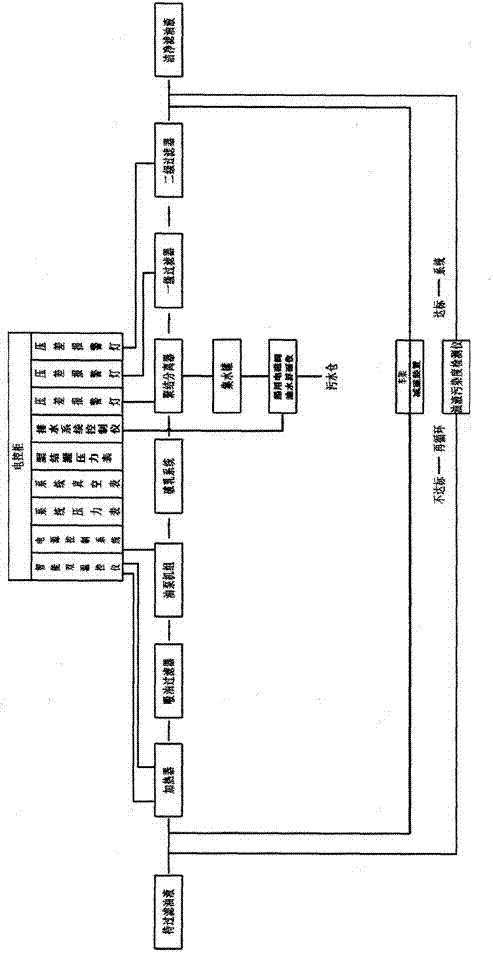

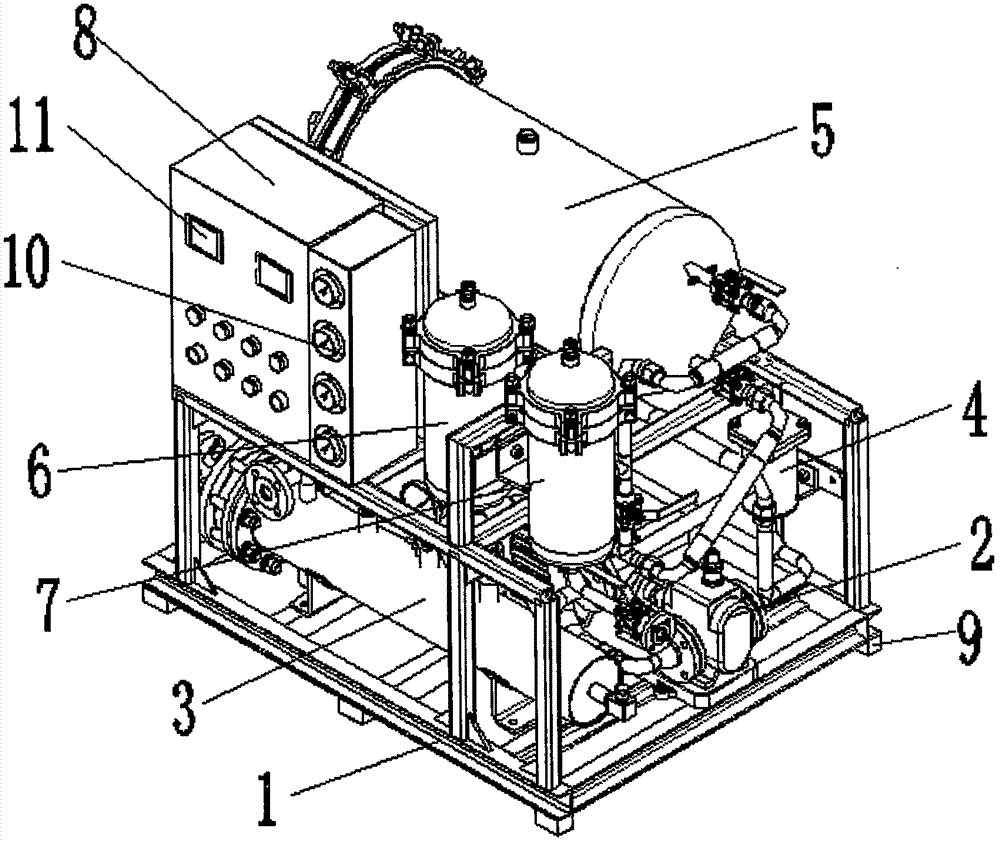

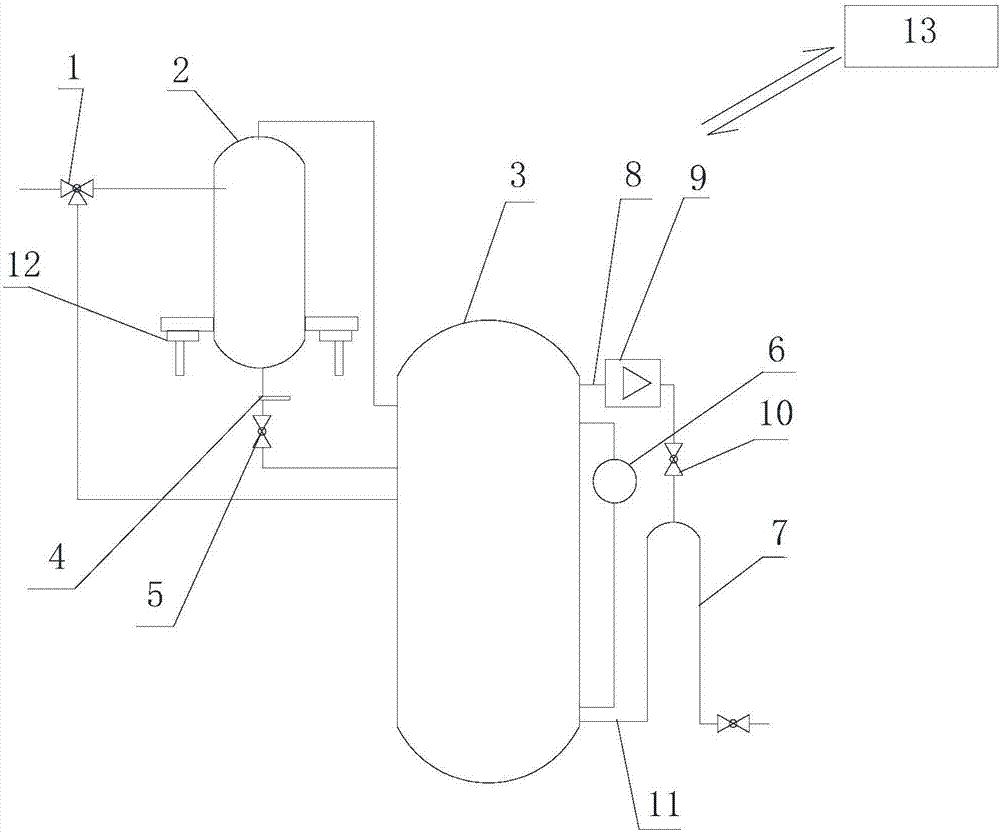

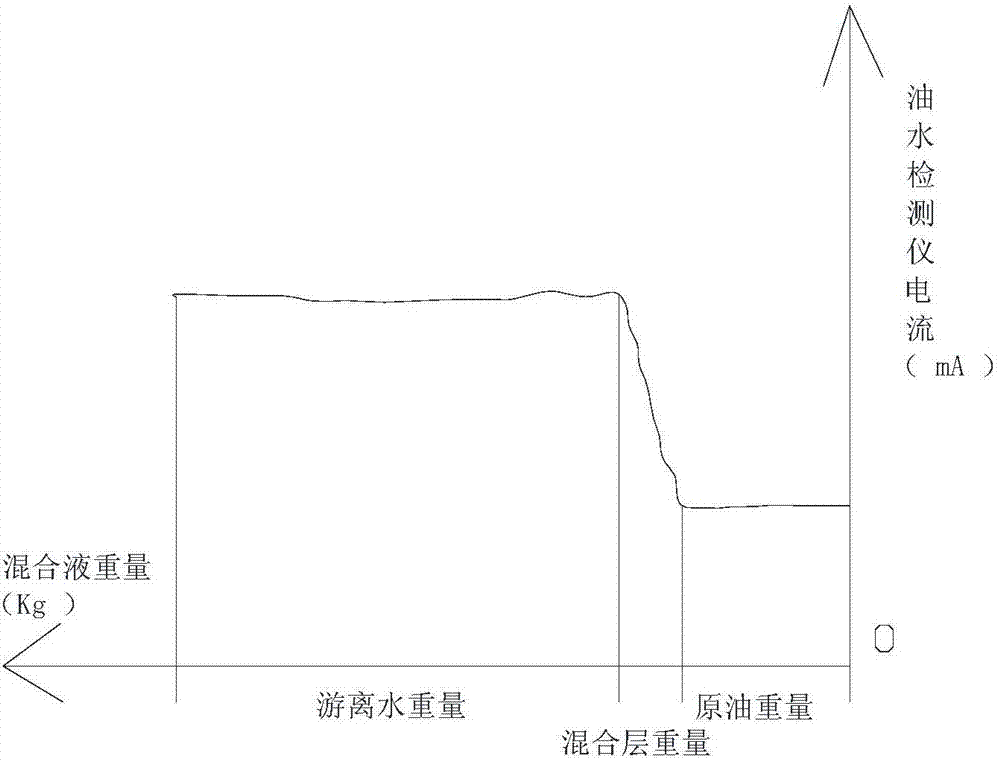

Weighting method three-phase metering device and metering method thereof

Owner:PETROCHINA CO LTD +2

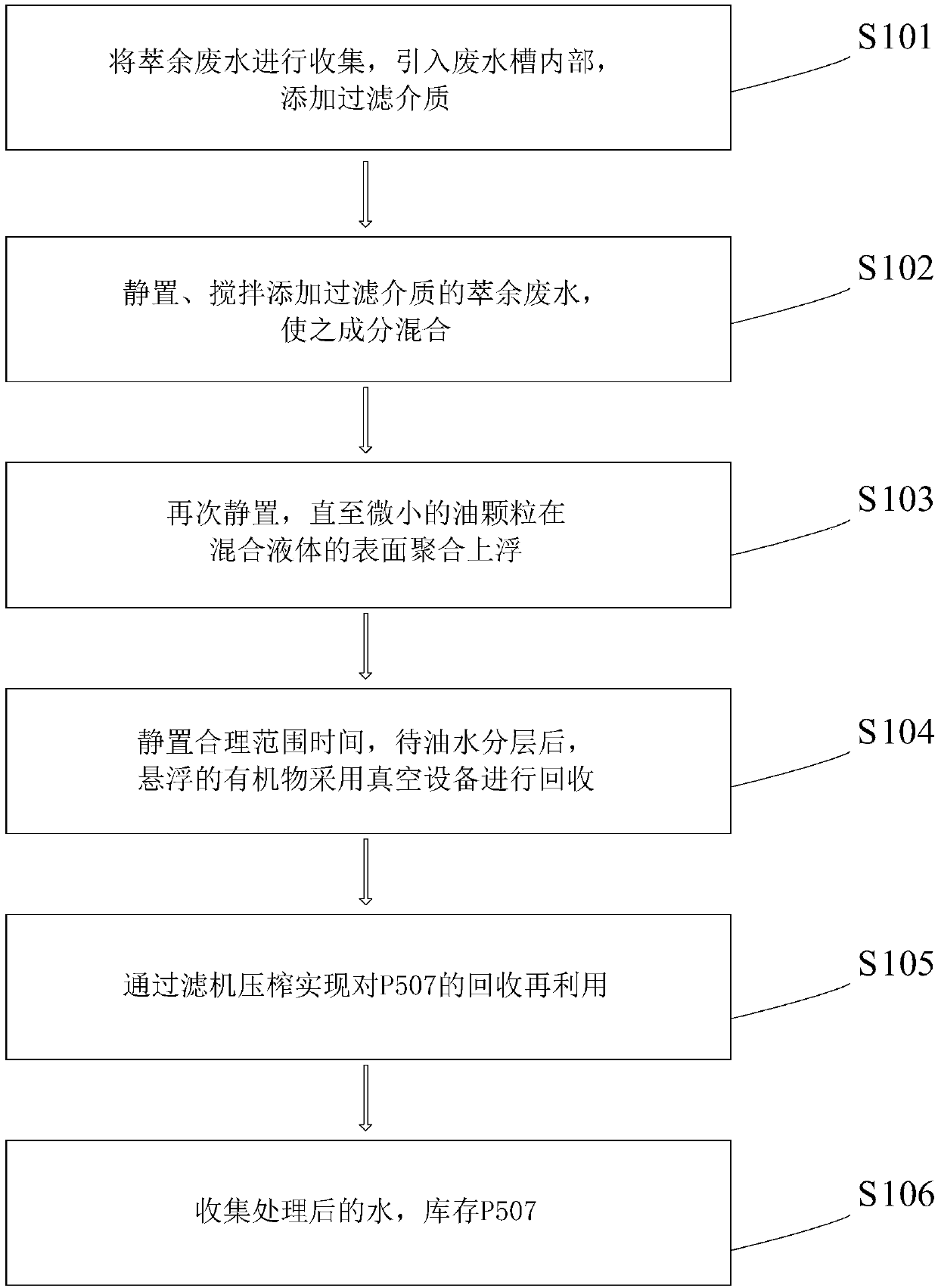

Method for recovering P507 from extraction raffinate wastewater

Owner:JIAN XINTAI TECH

Garbage sorting and screening mechanism of automatic sorting processor for kitchen wastes

InactiveCN112808749AEasy to cleanImprove screening efficiencySievingScreeningElectric machineProcess engineering

The invention discloses a garbage sorting and screening mechanism of an automatic sorting processor for kitchen wastes, in particular to the technical field of sorting and screening of the kitchen wastes. The garbage sorting and screening mechanism comprises a box body and an oily water collection box, wherein a water drain plate is horizontally and fixedly connected to the interior of the box body; reserved holes are formed in the water drain plate; and the oily water collection box is arranged at the bottom end of the water drain plate and is positioned in the box body. According to the garbage sorting and screening mechanism disclosed by the invention, through arrangement of a driving motor, rotary shafts, a frame body, a screening box, clamping slots, a cover plate, a handle and fixed blocks, the cover plate is opened, garbage is poured into the screening box, and then the fixed blocks are embedded in the clamping slots; the driving motor is started, the rotary shafts are driven through a driving shaft to be rotated; and because round holes are formed in the screening box, oily water and small solid garbage can be screened to the bottom of the screening box in a rotation process of the screening box, so that large solid garbage can be remained in the screening box, and therefore, the screening effect is better, the screening efficiency is higher, and the oily water can be conveniently separated from the solid garbage.

Owner:FUJIAN ZHONGHUI ENVIRONMENTAL PROTECTION EQUIP CO LTD

Extraction technology for swida wilsoniana oil

ActiveCN108865417AImprove extraction qualityImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionFiltrationOil water

Owner:于都中和光皮树开发有限公司

Method for removing metal from hydrocarbon oil by using by product generated in producing fatty acid through oxidizing paraffin

InactiveCN1431278ALow costImprove removal efficiencyRefining with acid-containing liquidsParaffin waxFatty acid

Owner:CHINA PETROLEUM & CHEM CORP +1

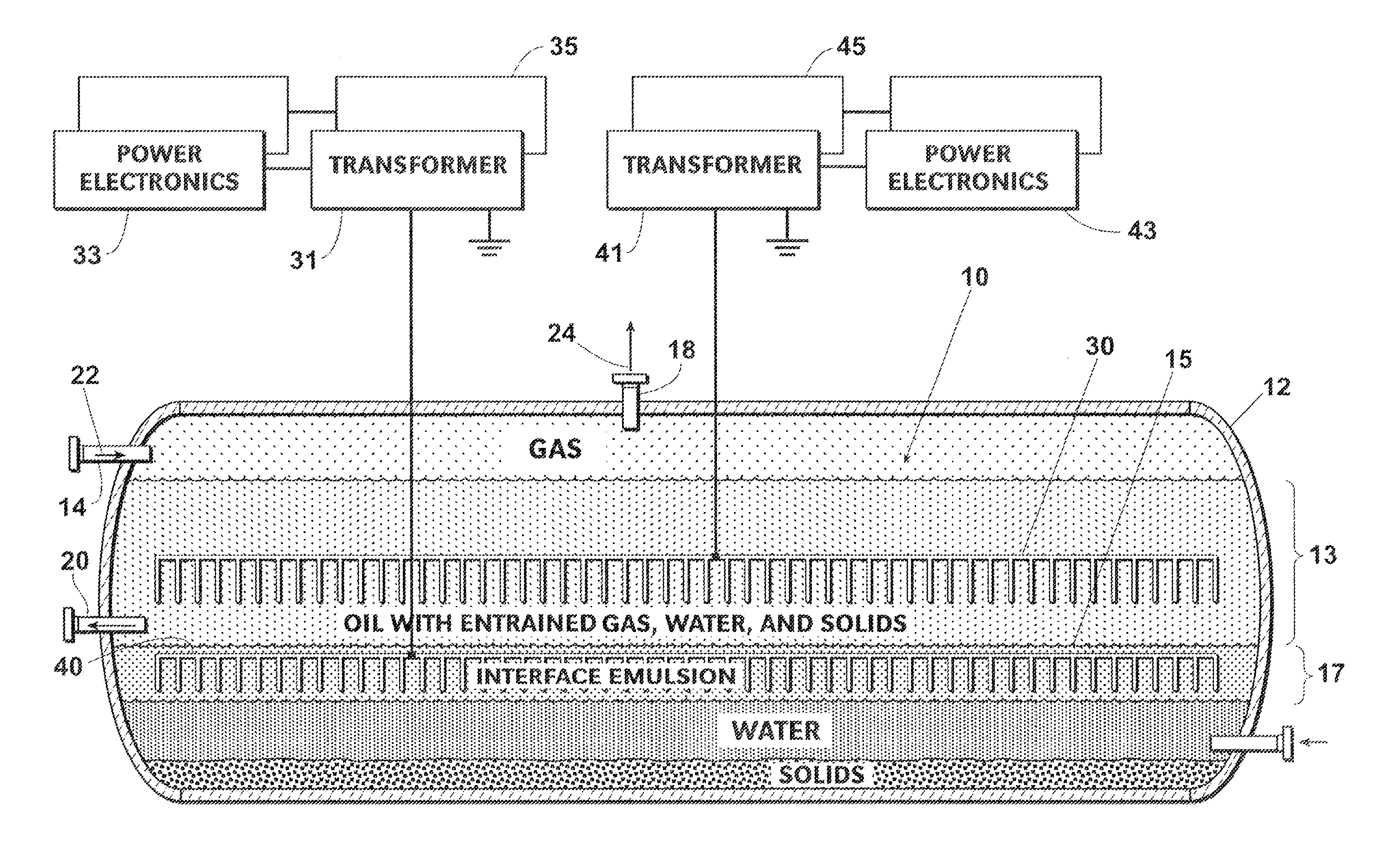

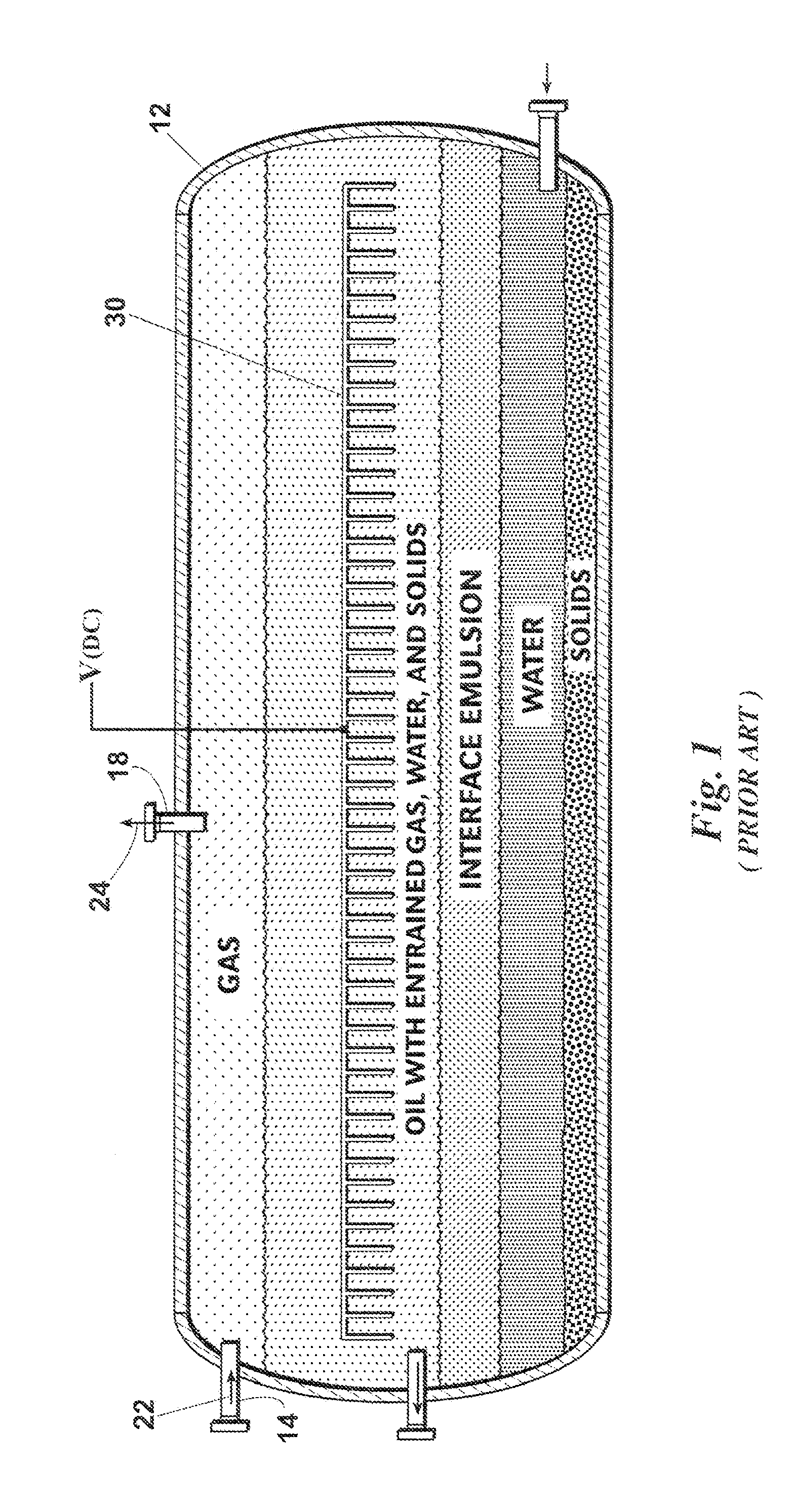

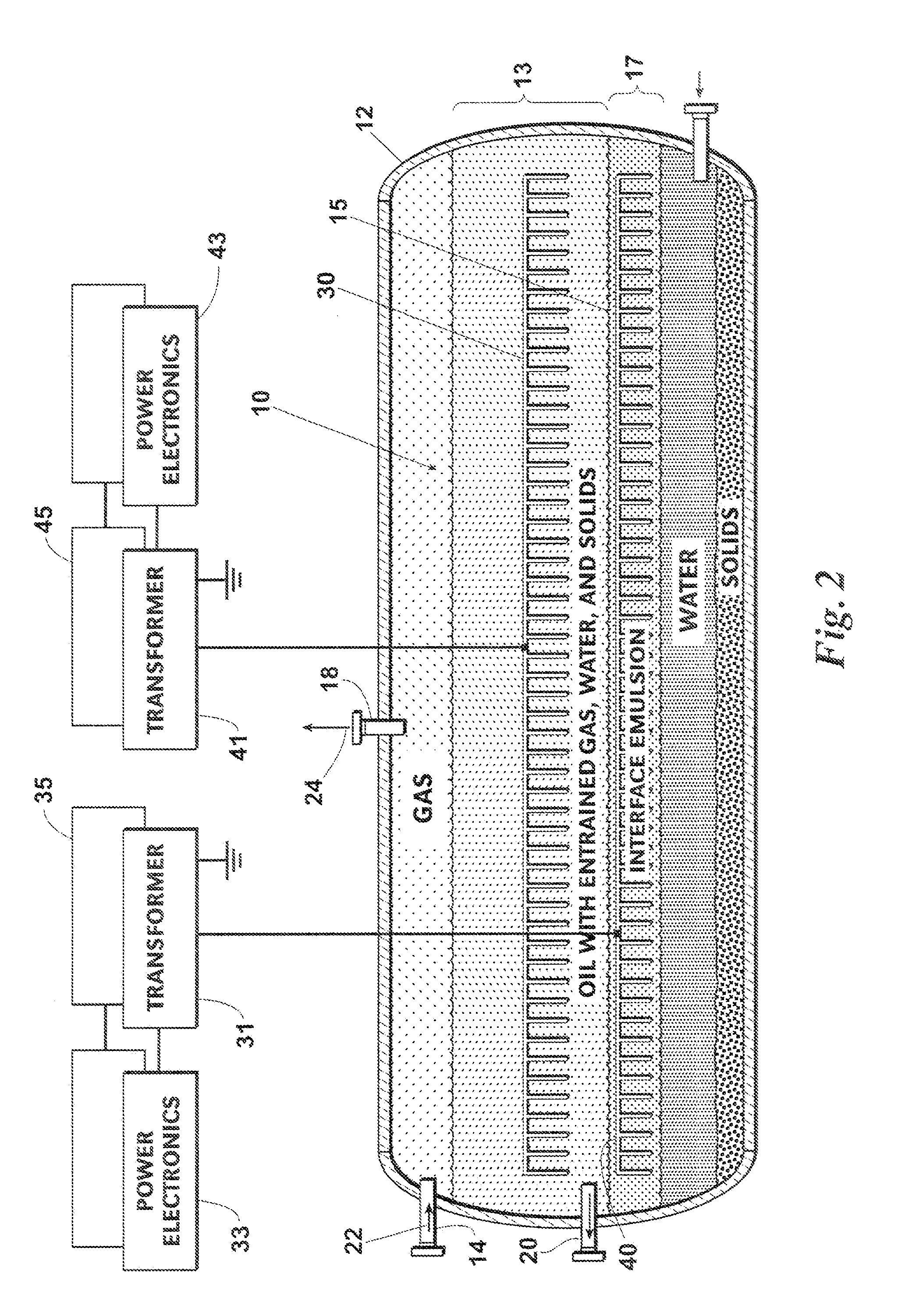

System To Reduce Interface Emulsion Layer Formation In An Electrostatic Dehydrator Or Desalter Vessel Through Use Of A Low Voltage Electrostatic Interface Emulsion Treatment System Inside The Vessel

ActiveUS20160289100A1Easy to controlReduce and eliminate needFatty/oily/floating substances removal devicesElectrostatic separatorsEmulsionLow voltage

Owner:CAMERON SOLUTIONS

Method for preparing feed ingredients from kitchen wastes

InactiveCN106071044ASolve processing problemsRealize resource utilizationAnimal feeding stuffAdditive ingredientOil water

The invention discloses a method for preparing feed ingredients from kitchen wastes. The method comprises the following steps: (1) solid-liquid separation: performing solid-liquid separation on the kitchen wastes through a filter device, performing oil-water separation treatment on liquid obtained by solid-liquid separation, and performing solid-solid separation on a solid mixture obtained by solid-liquid separation, wherein the solid mixture contains plastic products, metal products and food residues at the same time; (2) solid-solid separation: putting the plastic products and the metal products which are subjected to separation into the solid kitchen waste retreatment procedure, and putting the separated solid food residues into the dehydration treatment procedure; (3) dehydration treatment procedure: dehydrating and deoiling the solid food residues until the moisture content is below 60 percent, putting the treated solid food residues into the drying treatment procedure, and performing oil-water separation treatment on liquid collected by squeezing; (4) drying treatment procedure: drying the solid food residues at high temperature to obtain the feed ingredients. The process is simple and controllable; the industrial chain of production is complete, so that the problem of incomplete treatment is solved.

Owner:HOPE TECH (TIANJIN) CO LTD

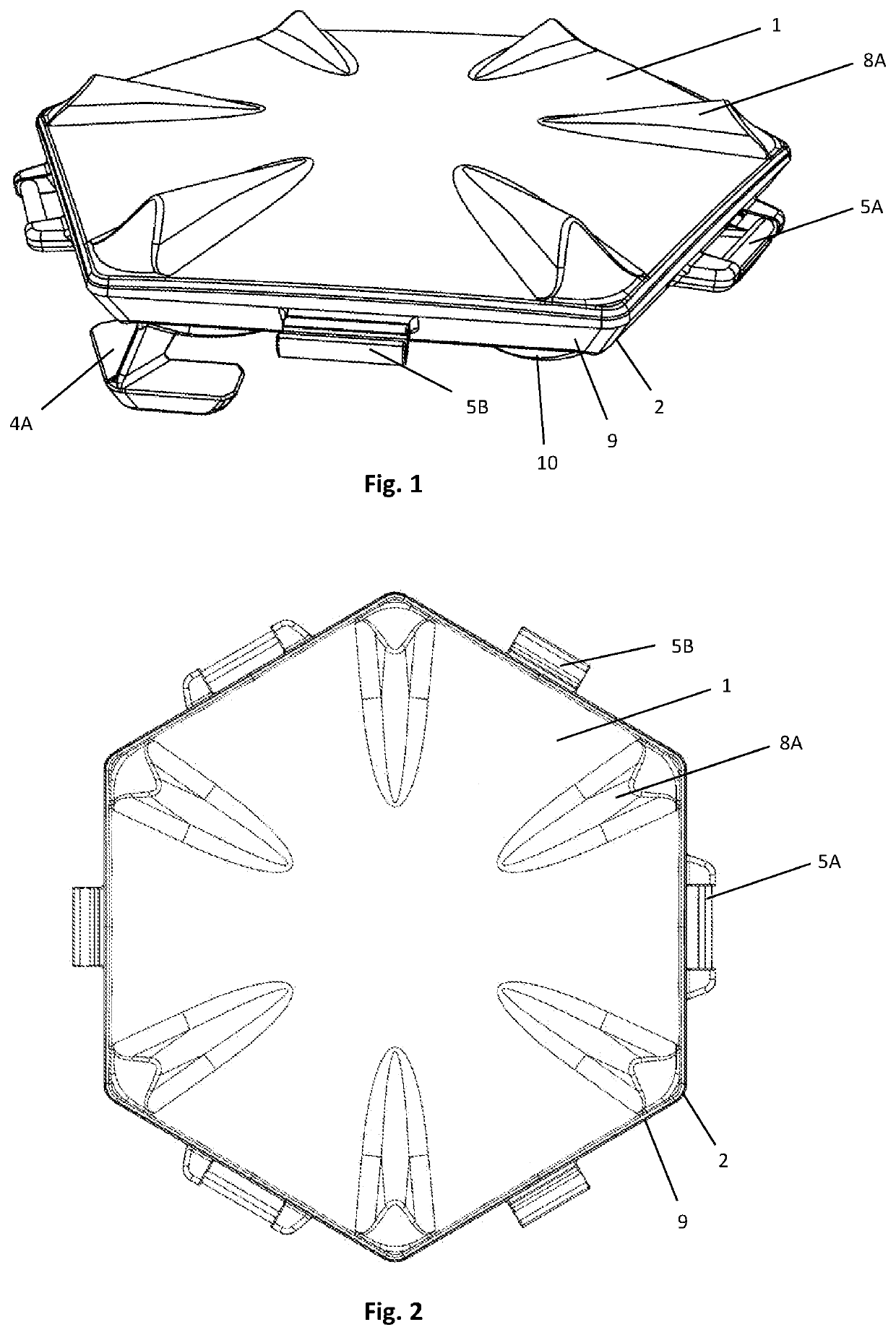

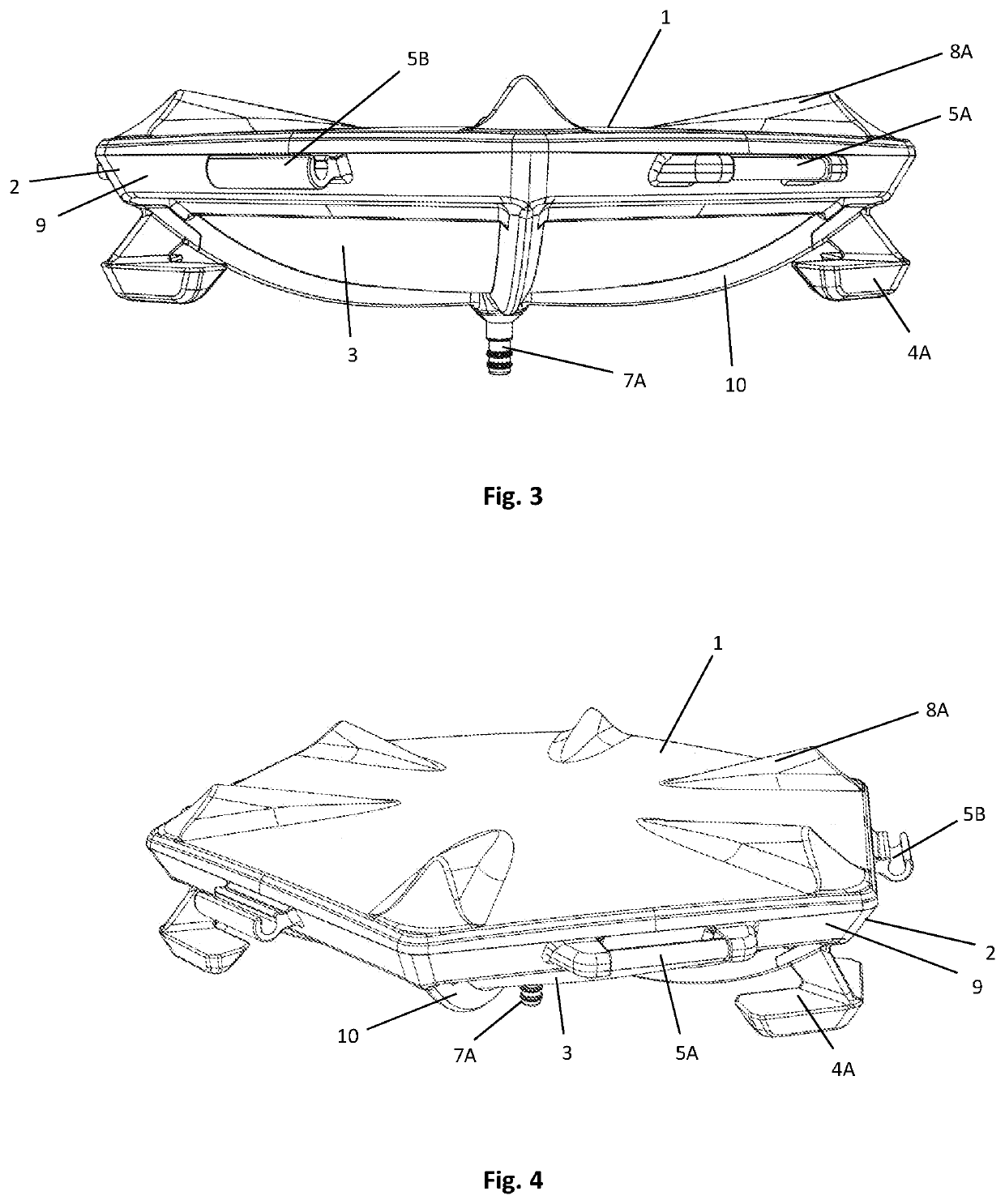

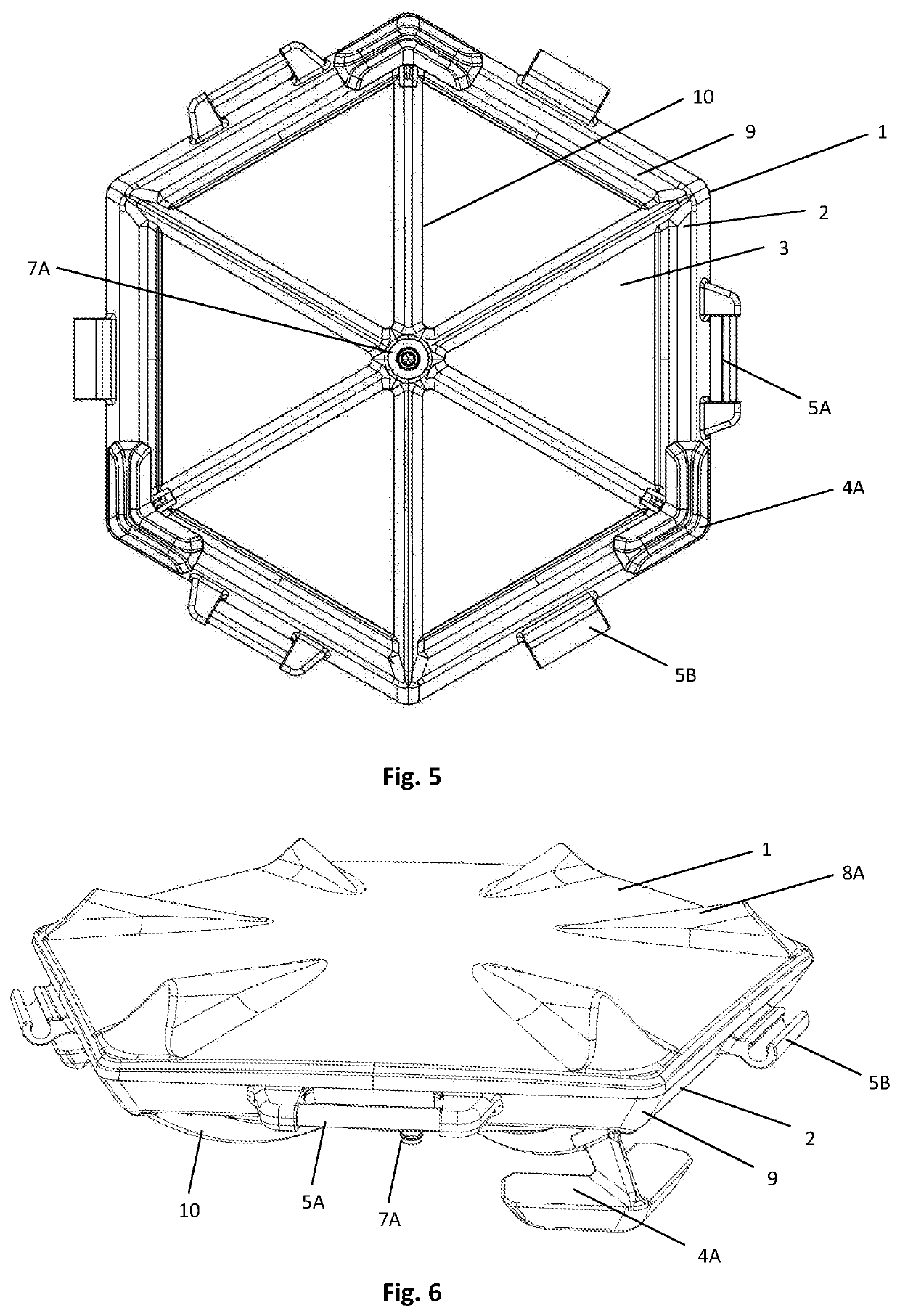

Oil and aqueous phase separator

ActiveUS20210039018A1Easy to separateImprove scalabilityLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesEngineeringOil water

Owner:YPF TECHA +1

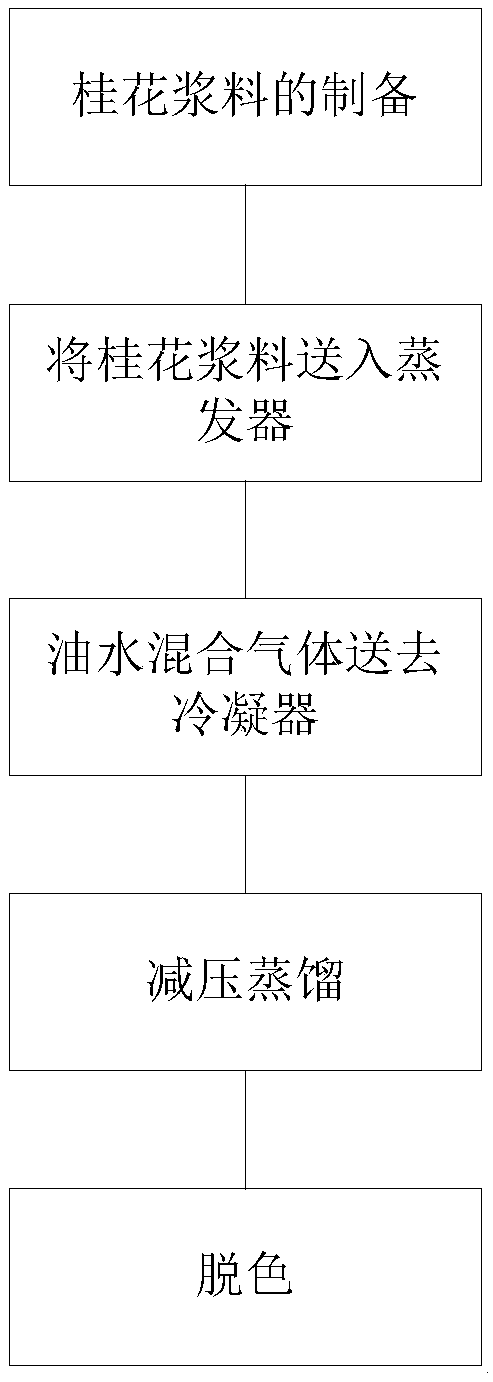

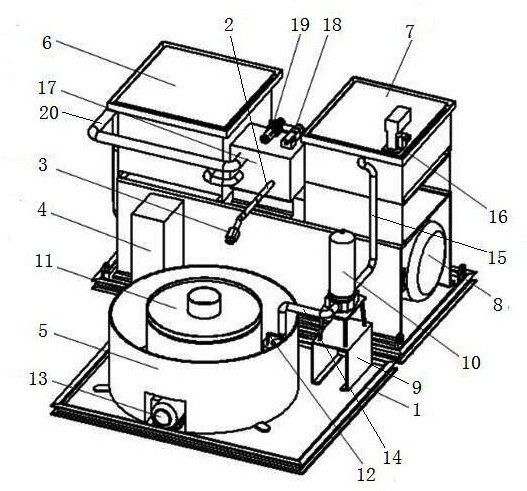

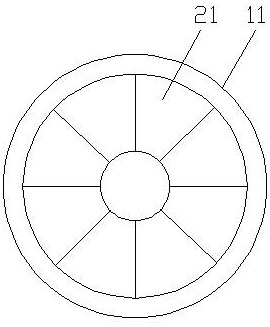

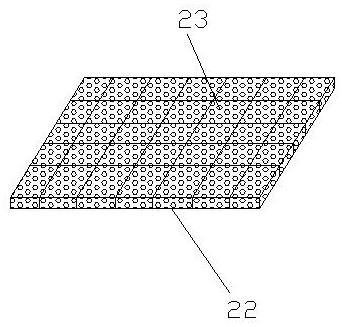

Method for extracting osmanthus flower essence

InactiveCN109777620AHigh extraction rateIncrease aromaEssential-oils/perfumesOil waterBULK ACTIVE INGREDIENT

Owner:苏洁萌

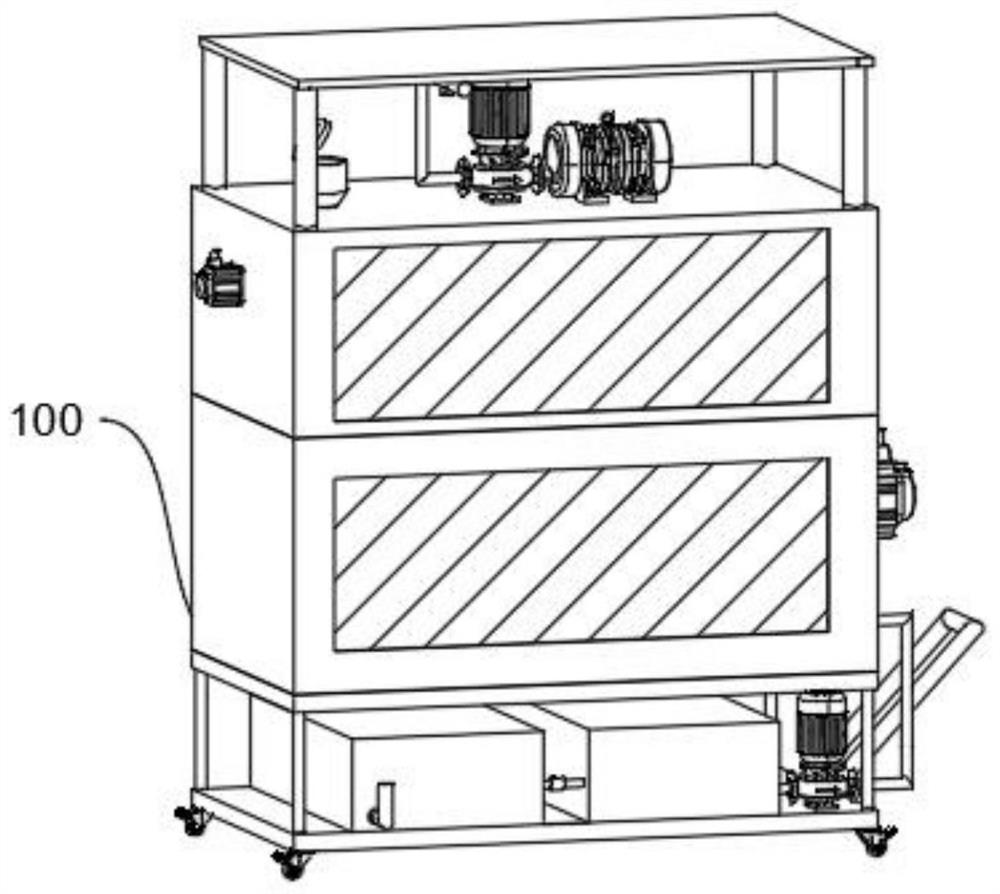

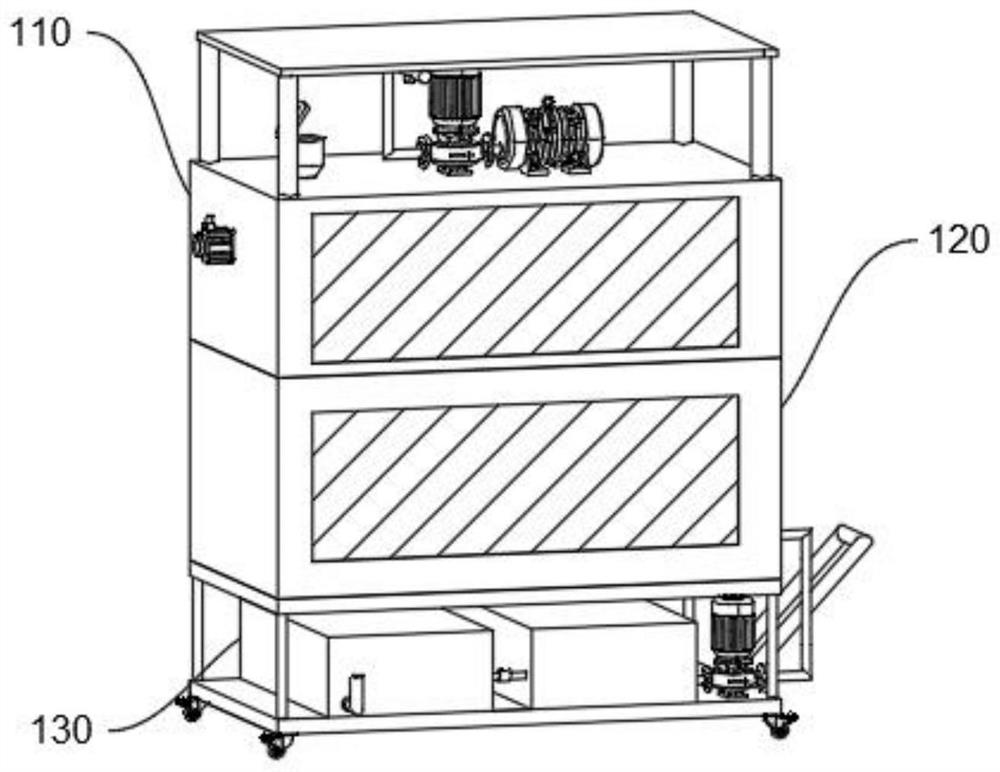

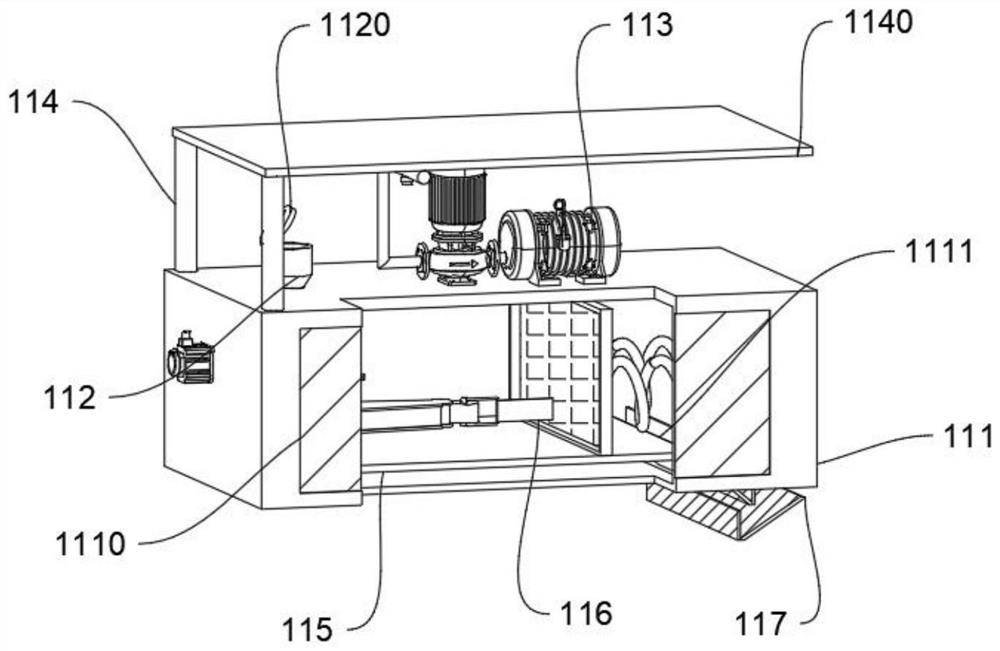

Small part cleaning equipment and cleaning method

PendingCN114472310AEfficient and environmentally friendly cleaningGuaranteed cleaning effectCleaning using liquidsMechanical componentsEnvironmental engineering

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

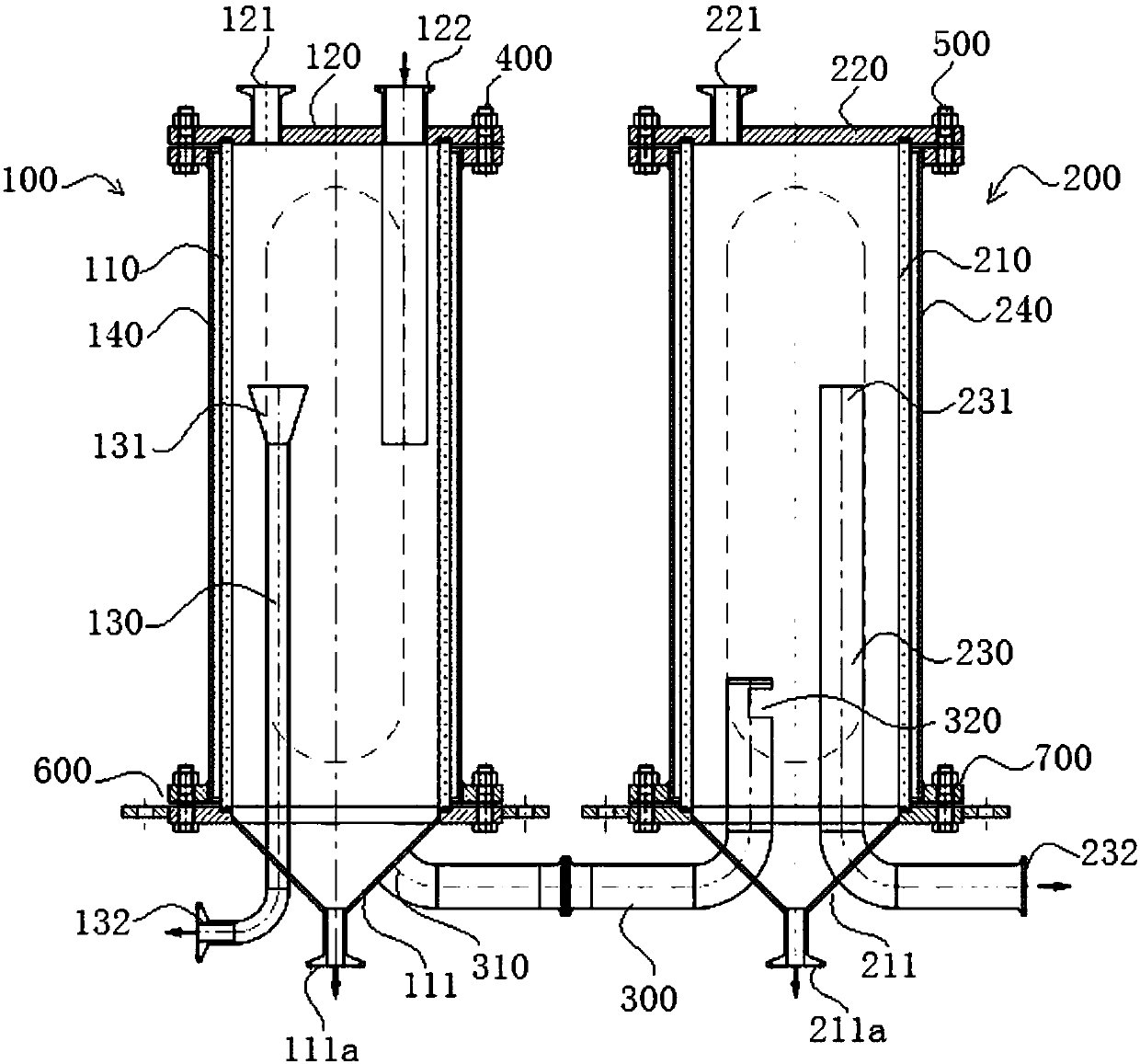

Duplex type oil-water separator

PendingCN108096879ALiquid separationFuel oilOil water

Owner:SHANGHAI UNIWIN PHARMA MACHINERY

Full-section overflowing mechanism of restaurant wastewater pre-treatment device and full-section overflowing method

ActiveCN108314101ASuitable for water flow characteristicsOverflow defect avoidanceWater distributersWaste water treatment from food industryWastewaterEngineering

The invention discloses a full-section overflowing mechanism of a restaurant wastewater pre-treatment device and a full-section overflowing method. The full-section overflowing mechanism comprises a machine case and a plurality of separation plates mounted in the machine case, wherein the plurality of separation plates comprise three full-section separation plates; two opposite side edges of the first full-section separation plate are fixed at two opposite sides of the machine case respectively and are vertically arranged above a bottom plate of the machine case; a transverse flow channel I isformed between the lower end of the first full-section separation plate and the bottom plate and the upper end of the first full-section separation plate is not in contact with a top plate of the machine case, so that the machine case is divided into an oil-water separation region and a liquid discharging region, which pass through the transverse flow channel I and are mutually communicated; thesecond full-section separation plate is located in the liquid discharging region; the upper end of the second full-section separation plate is fixed on the top plate and the lower end of the second full-section separation plate is not in contact with the bottom plate; meanwhile, a transverse flow channel II is formed between the upper end of the second full-section separation plate and the bottomplate; the lower end of the third full-section separation plate is vertically fixed on the bottom plate, and a vertical flow channel capable of enabling liquid to flow out from the upper end of the third full-section separation plate under the action of static pressure is formed by the lower end of the third full-section separation plate, the second full-section separation plate and the machine case.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

Waste mineral oil dehydration and impurity removal equipment based on pretreatment

InactiveCN112791464APrevent the formation of precipitatesNot easy to filter outCentrifugal force sediment separationDrive wheelDrive shaft

Owner:湖南两山环境科技有限公司

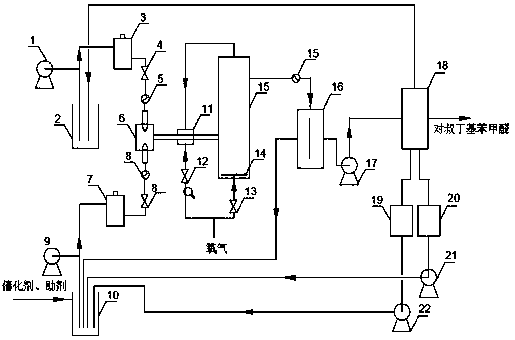

Method for preparing p-tert-butylbenzaldehyde by carrying out liquid phase oxidation on p-tert-butyltoluene

ActiveCN108440263ALow investment costImprove qualityOrganic compound preparationCarbonyl compound preparationP-tert-ButyltolueneOil phase

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

Method for preparing fuel oil by taking waste lubricating oil as raw material

InactiveCN103756725ASolve the disadvantages of landfill disposalReduce pollutionTreatment with hydrotreatment processesLubricant compositionPetrochemicalFuel oil

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

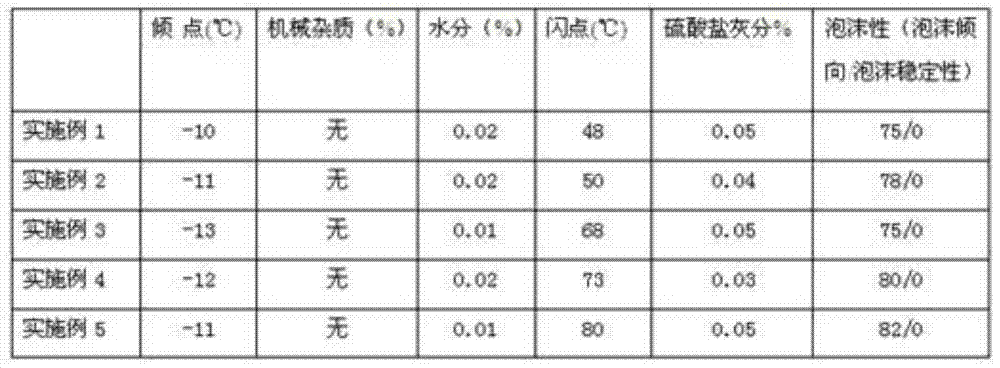

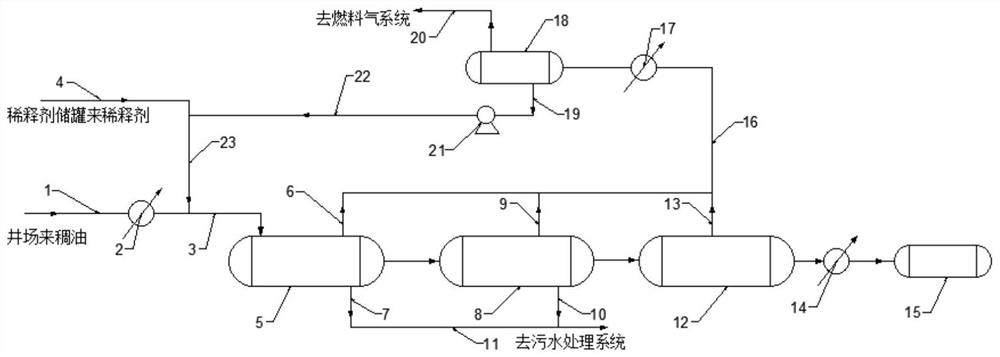

SAGD (steam assisted gravity drainage) thick oil dehydration method

InactiveCN113025373AReduce lossMeet the developmentDewatering/demulsification with chemical meansDiluentOil water

Owner:CHINA NAT OFFSHORE OIL CORP +1

Preparation method of oil-water separation membrane

The invention discloses a preparation method of an oil-water separation membrane, and belongs to the technical field of environmental protection. According to the method, wood stone fiber is mixedintopolyvinylidene chloride melt in a suitable temperature condition, and lignin reaches glassy state, is softened and flows under high pressure; nanofiber sponge is prepared from resin soaked activatedstone pulp; sea-foam stone powder in the activated stone pulp belongs to a magnesium-enriched silicate compound, can magnesium hydroxide crystal and ammonium phosphate under the action of ammonia gasand phosphoric acid, not only ensures that oil absorption sponge has high porosity, but also ensures that the oil absorption sponge has certain flame retardant property; firstly scale has a bionic hydrophobic structure, and a separation membrane structure with a hydrophobic exterior; finally during the process of copper film plating, the internal surface area of fiber fabric is greatly increased through activation of phosphoric acid, and a plurality of active centers are formed in the surface of the fiber fabric; granule suspension oil and dissolved oil liquid can be easily absorbed into interiors of pores, so that damage to the inner surface of the fiber sponge is weakened when the inner surface is scoured by liquid, and the oil-water separation membrane has a wide application prospect.

Owner:FOSHAN LINGXIE ENVIRONMENTAL PROTECTION TECH CO LTD

Efficient oil-water separation device

ActiveCN114212904AImprove stabilityRealize automatic impurity removalFatty/oily/floating substances removal devicesTreatment involving filtrationSeparation technologyOil water

The invention relates to an efficient oil-water separation device, and relates to the field of oil-water separation technologies. The oil-water separation device comprises a separation device body, an oil storage tank arranged below the separation device body, a supporting frame connected to the upper portion of the oil storage tank in a sliding mode, a storage bin fixedly arranged on the supporting frame, an oil outlet pipe arranged below the storage bin, a control valve arranged on the oil outlet pipe and a filter screen arranged at a feeding port of the separation device body. The impurity removing mechanism is arranged between the filter screen and the separation device body and used for removing impurities on the filter screen, and the moving mechanism is arranged between the supporting frame and the oil storage tank and used for driving the supporting frame to slide towards the side away from or close to the separation device body. The oil-water separator has the beneficial effects that a worker can conveniently remove impurities in the oil-water separator, the operation stability of the oil-water separator is improved, the labor intensity of the worker is relieved, and the treatment efficiency of the oil-water separator is improved.

Owner:SHENZHEN HENGXINGSHENG KITCHENWARE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap