Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Calcium silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium silicate is the chemical compound Ca₂SiO₄, also known as calcium orthosilicate and is sometimes formulated as 2CaO·SiO₂. It is also referred to by the shortened trade name Cal-Sil or Calsil.

Paper making method with pulp and product of high-surface-intensity offset printing paper

ActiveCN103526630AImprove retentionHigh strengthWater-repelling agents additionInorganic compound additionCalcium silicateFiber

The invention discloses a paper making method with pulp and a product of high-surface-intensity offset printing paper. The paper making method with the pulp comprises the steps that (1) multi-hole calcium silicate and mixed wood pulp fibers are subjected to mixing pulping, mixed pulp is obtained; (2) retention and drainage agents A, sizing agents and retention and drainage agents B are added into the mixed pulp in sequence, even stirring is carried out, papermaking pulp is obtained; (3) the papermaking pulp is subjected to papermaking, squeezing and drying, body paper is obtained; (4) surface sizing agents are used for carrying out surface sizing on the body paper, and the offset printing paper is obtained. The multi-hole calcium silicate is used as the papermaking padding, during a papermaking process, paper pulp / padding medium-high-concentration mixing pulping, CS / CPAM double-element retention and surface sizing agent formula improving and other measures are used, the padding retention rate is improved, paper intensity is effectively improved, and the waterproof performance, the oil resistance, the paper surface intensity, the tensile strength and other performance indexes of paper are obviously improved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

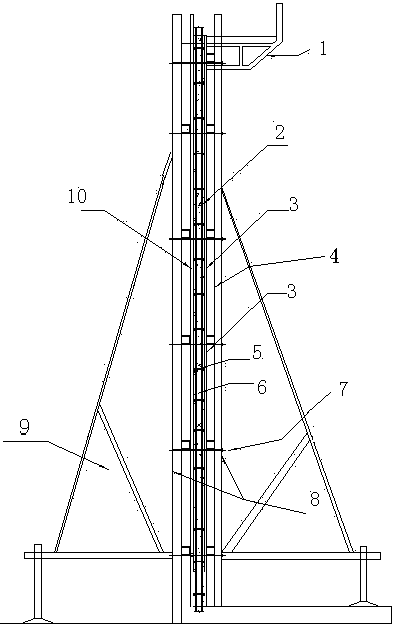

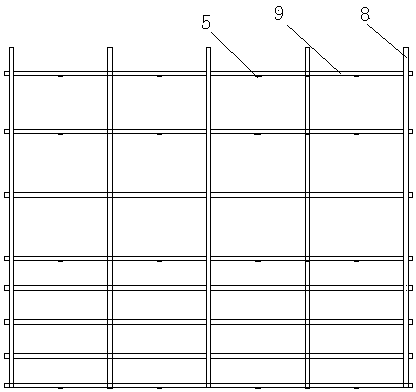

Construction method for concrete shear wall

InactiveCN103741846AReduce construction costsShort construction periodWallsHeat proofingFiberCalcium silicate

Owner:山西省第二建筑工程公司

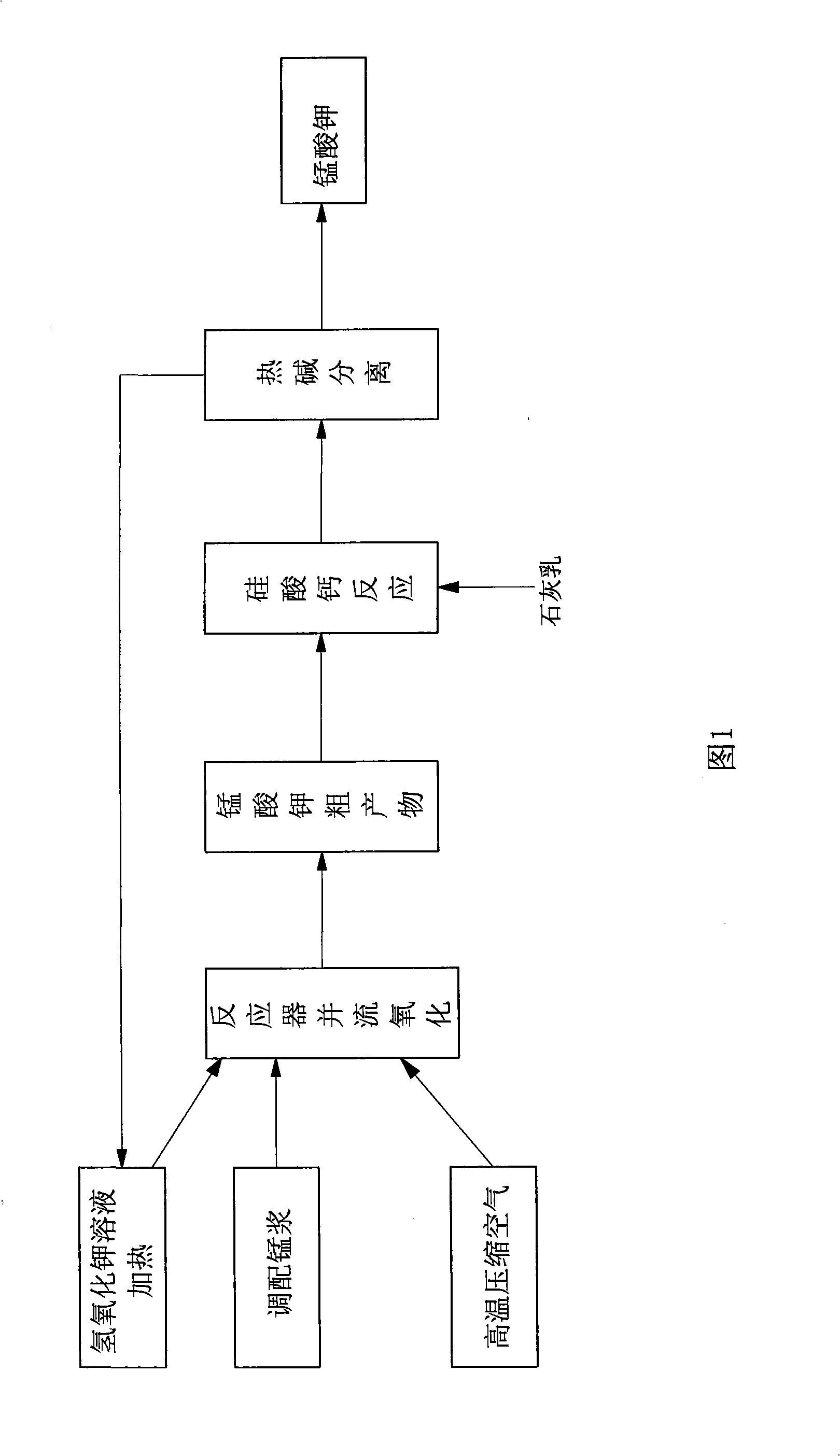

Method and equipment for manufacturing potassium manganate

InactiveCN101492182AWidely sourced and inexpensiveEfficient use ofEnergy inputManganates/permanganatesNatural resourceCalcium silicate

Owner:ZUNYI SHUANGYUAN CHEM IND GROUP

Seam binding agent with modified fatty amine as epoxy curing agent resin

ActiveCN102816501AFast shapingEasy constructionNon-macromolecular adhesive additivesEpoxy resin adhesivesCalcium silicateFiber

The invention relates to a seam binding agent with modified fatty amine as epoxy curing agent resin. The agent is suitable for easy-cracking positions in indoor and outdoor decorations. The agent is filled into seams of same or different materials such as wood, brick and stone, gypsum board, calcium silicate, and the like, for providing an excellent anti-cracking effect. The agent can also be used as a binding agent for roof leakage repairing, wood, and plastic. The agent can be used in crack sealing and water proofing of various grouting projects, bridges, and tunnels. According to the invention, a novel nano fiber binding technology is adopted. When the product is cured, nano fibers in the product form a high-molecular high-density net-shaped film at a seam position, wherein the physical density of the film is close to that of wood board or gypsum board. The film can expand or contract synchronically with the board when weather is changed, and has good cracking resistance, adhesive force, and flexibility. The seam binding agent is advantaged in fast shaping, easy construction, and low sagging.

Owner:SKSHU PAINT

Method for extracting valuable metal elements from coal gangue

ActiveCN113061728ALow chemical stabilityAchieve primary separationSilicaCarbon compoundsFerric hydroxideCalcium silicate

The invention provides a method for extracting valuable metal elements from coal gangue. The method comprises the following steps of: crushing and grinding coal gangue ore, performing supercritical / subcritical water activation, classifying the coal gangue ore into an organic liquid phase and a slag phase by a hydrocyclone, and synthesizing carbon dioxide and water from the organic liquid phase through a supercritical reaction, wherein the carbon dioxide is used for a subsequent sodium aluminate reaction to obtain aluminum hydroxide, the water is used for supplementing water to a shaking table, and the slag phase passes through the shaking table to obtain enriched ore of carbon and silicon dioxide, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements. Carbon and silicon dioxide are separated and collected through electric separation, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements are added into sodium carbonate and calcium carbonate to be roasted and dissolved after roasting, slag of calcium silicate and calcium titanate is obtained and can be used as a coating, a dissolving solution contains sodium aluminate, sodium ferrite and other substances, sodium hydroxide is added into the dissolving solution to generate ferric hydroxide and sodium aluminate, the ferric hydroxide can be used as a coating, and carbon dioxide is introduced into the sodium aluminate to generate aluminum hydroxide which is used as an inorganic flame-retardant additive.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Multifunctional fertilizer for preventing and treating open rice glumes

InactiveCN105418219APromote tilleringIncrease resistanceFertilizer mixturesCalcium silicateChelated zinc

Owner:武汉盛大神农生物工程有限公司

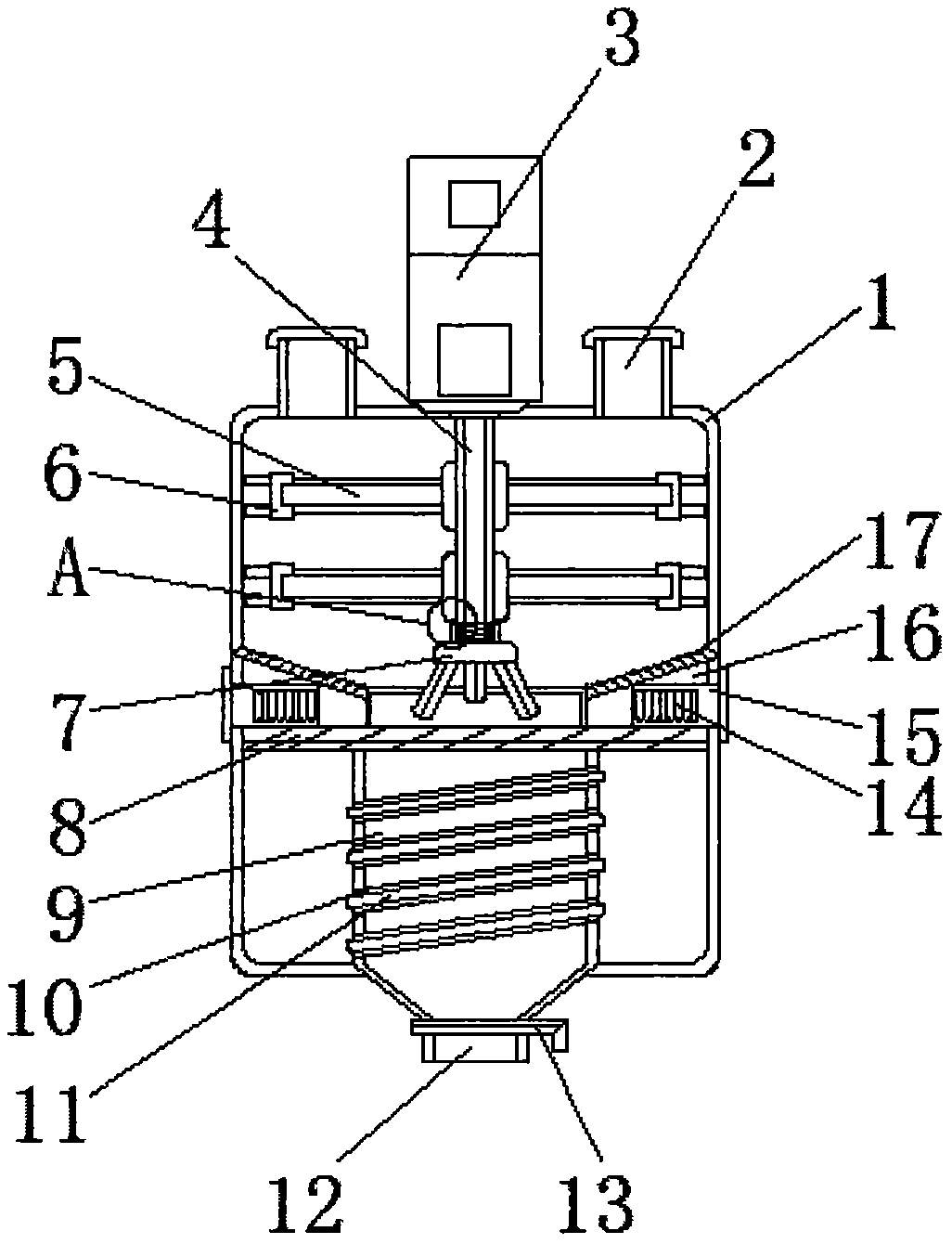

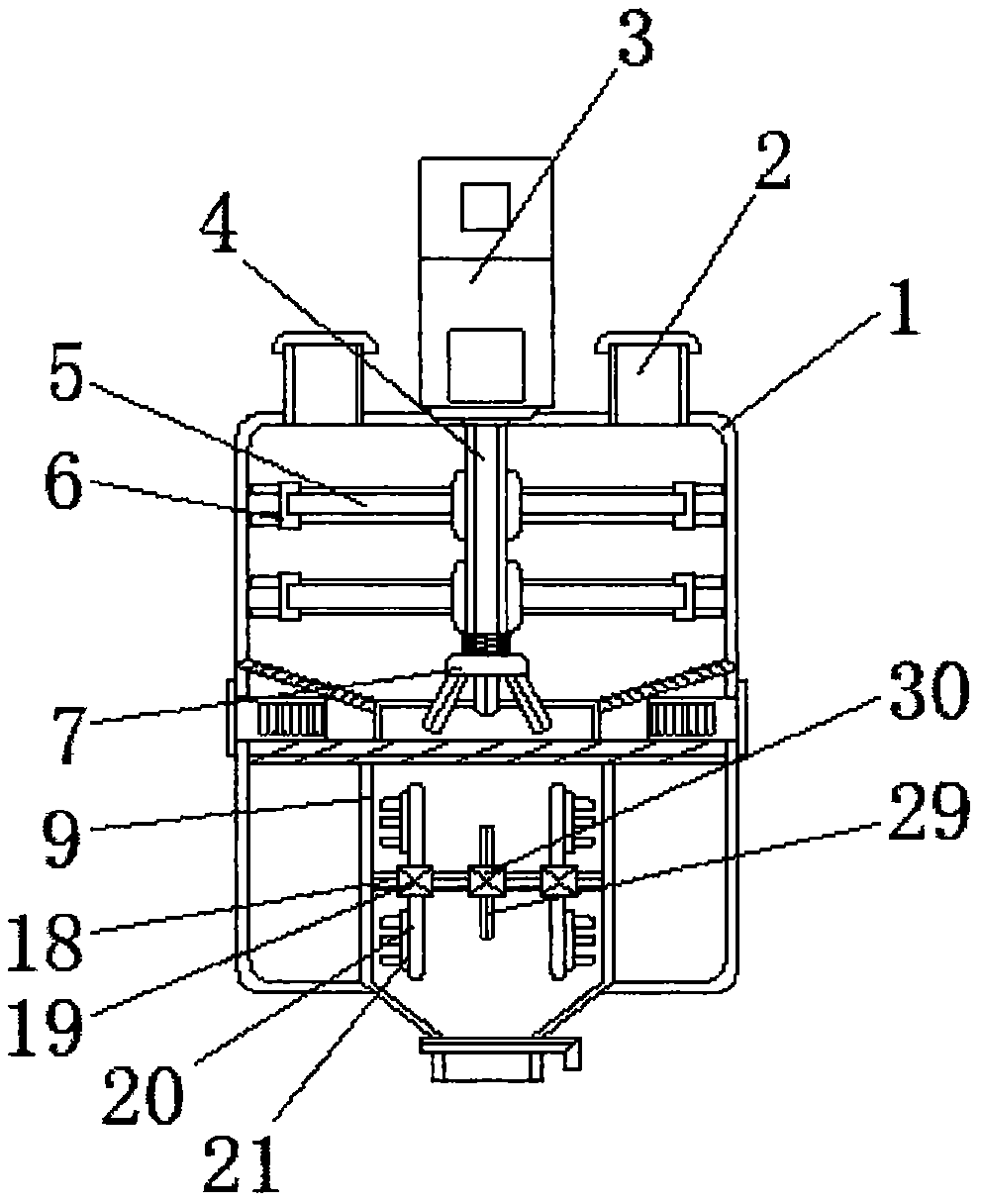

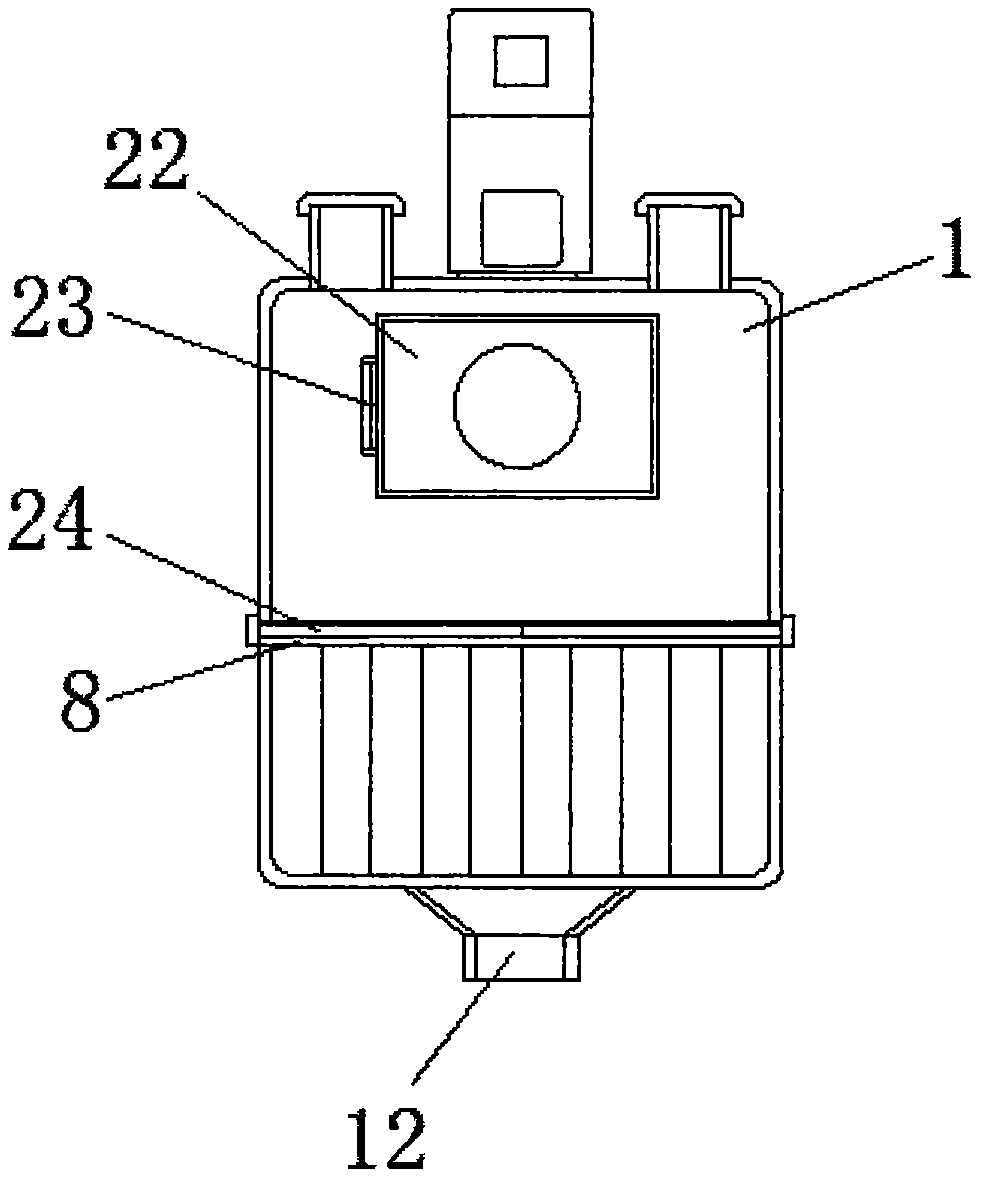

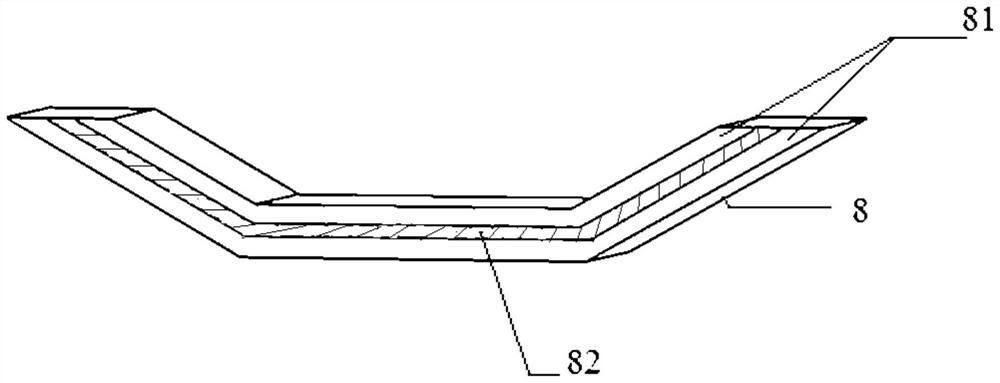

Mixing and stirring device capable of uniformly heating for producing calcium silicate board

InactiveCN109012481AMixing Works ExcellentSpeed up the mixingRotary stirring mixersTransportation and packagingCalcium silicateEngineering

Owner:湖南长乐建材有限公司

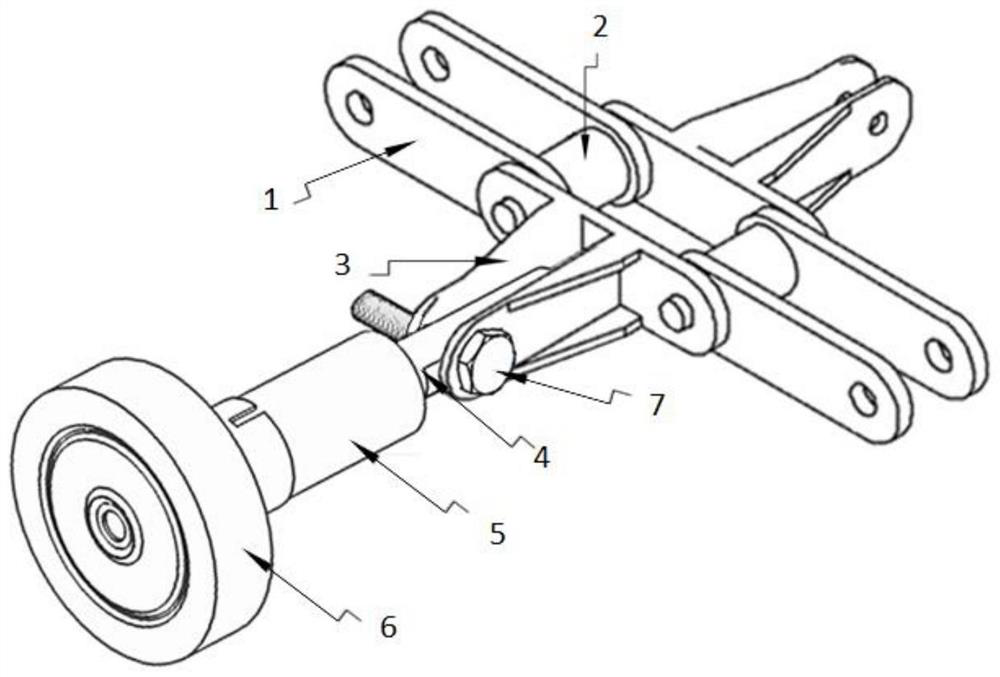

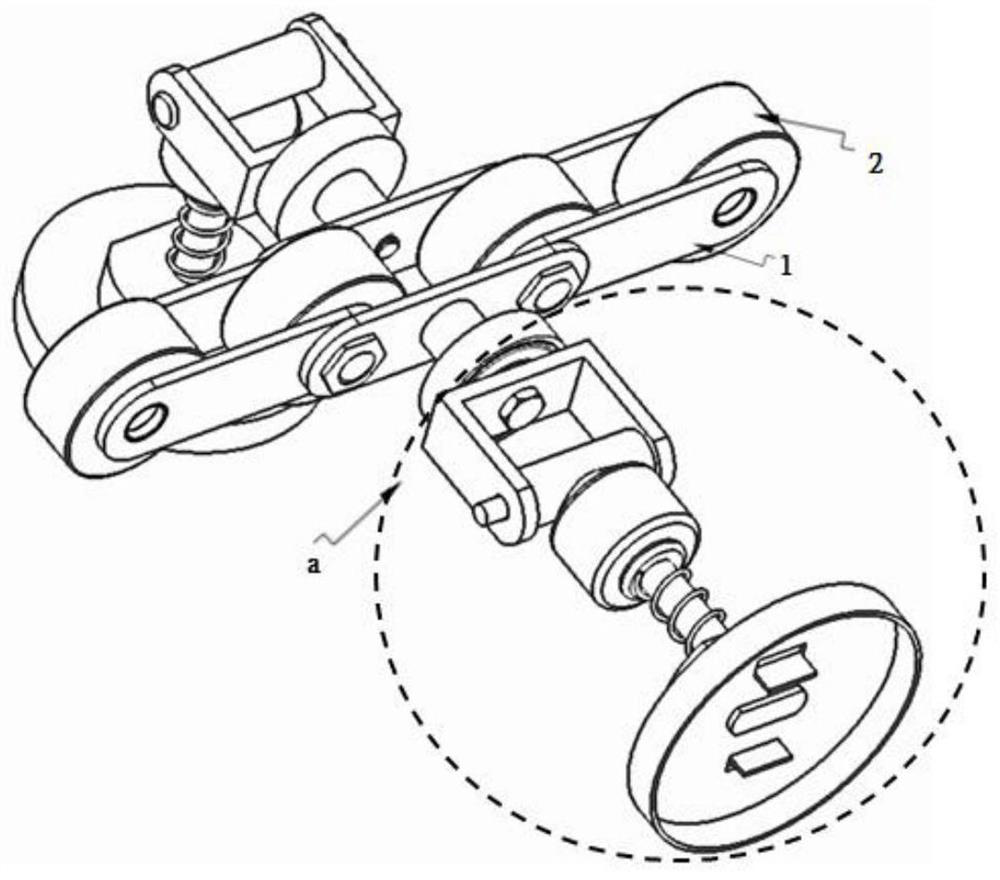

Application of energy-saving heat preservation tank in production line of glove machine

ActiveCN108866799BExtended service lifeReduce replacement costsKnittingCalcium silicateThermal insulation

Owner:上海华新医材有限公司 +2

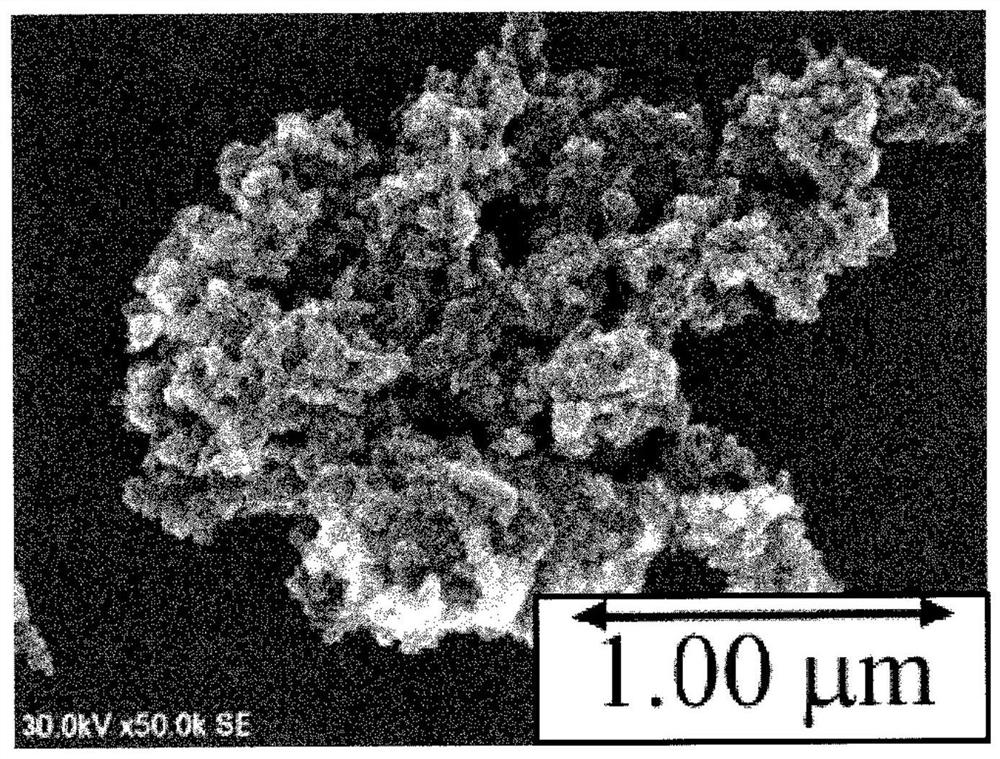

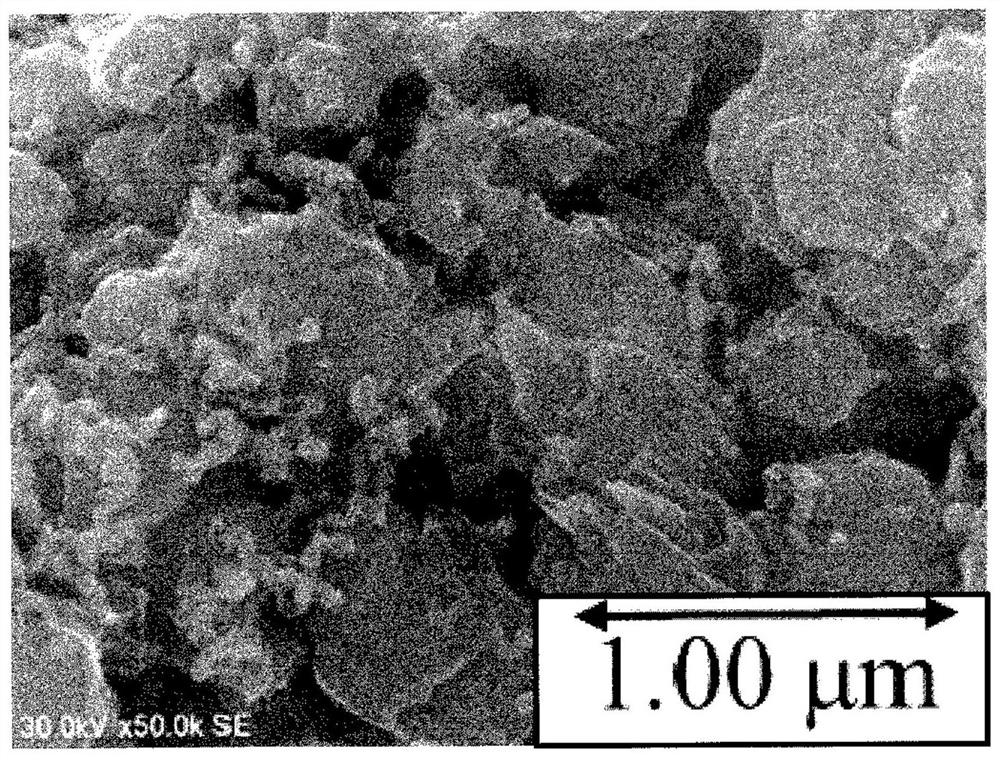

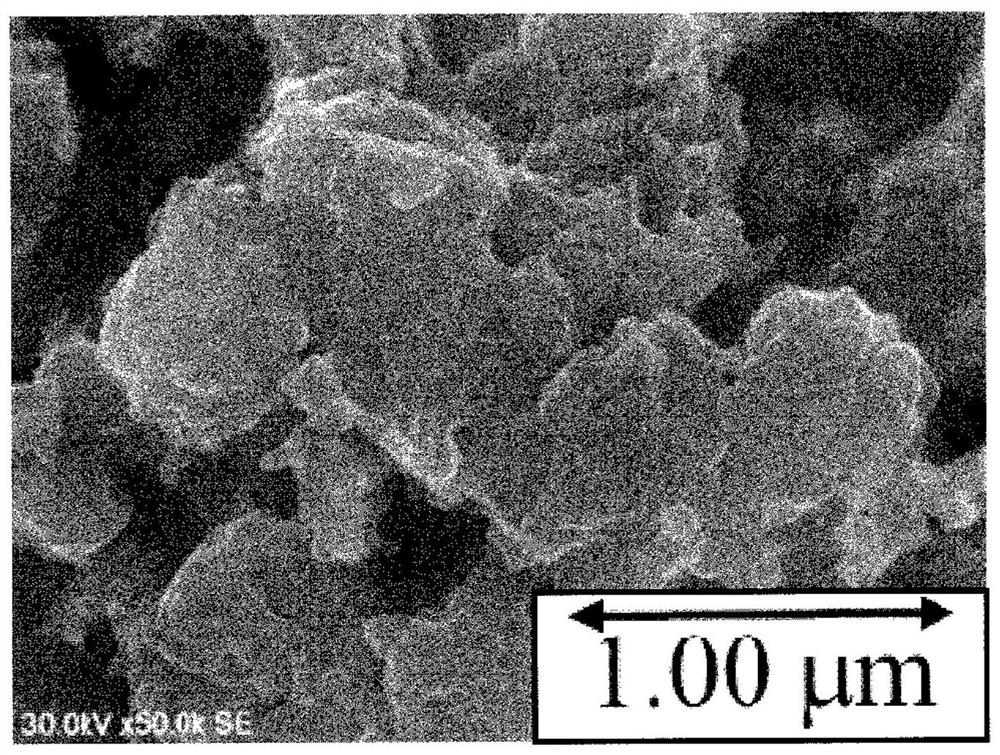

Nanocomposite formulation for use in hemostasis

The present invention relates to a nanocomposite formulation for use in hemostasis comprising at least one calcium-silicate and at least one polysaccharide. The invention also relates to solvent-free process for preparation of the nanocomposite formulation.

Owner:INDIAN INSTITUTE OF TECHNOLOGY BOMBAY

Flame-retardant ethylene propylene diene monomer

Owner:佛山市高明区生产力促进中心

Preparation method of welding glue for vehicle manufacturing

InactiveCN111334229AEasy to useMeet the needs of useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyCalcium silicate

Owner:浙江普利斐特汽车科技有限公司

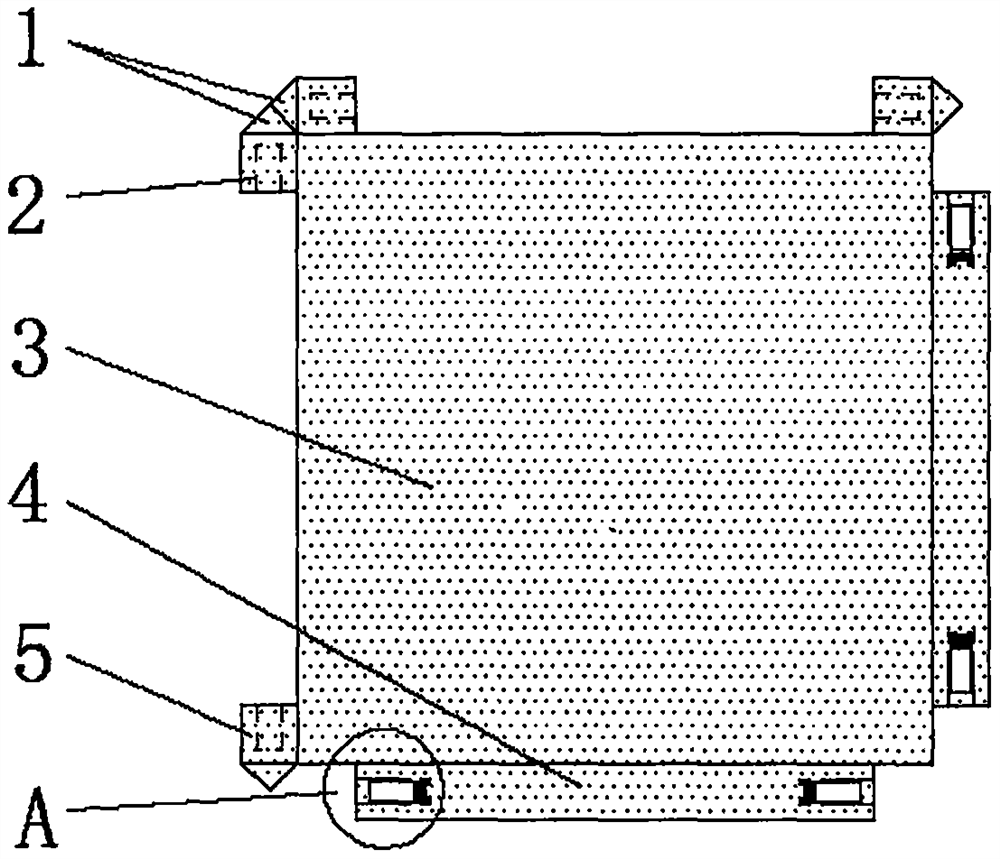

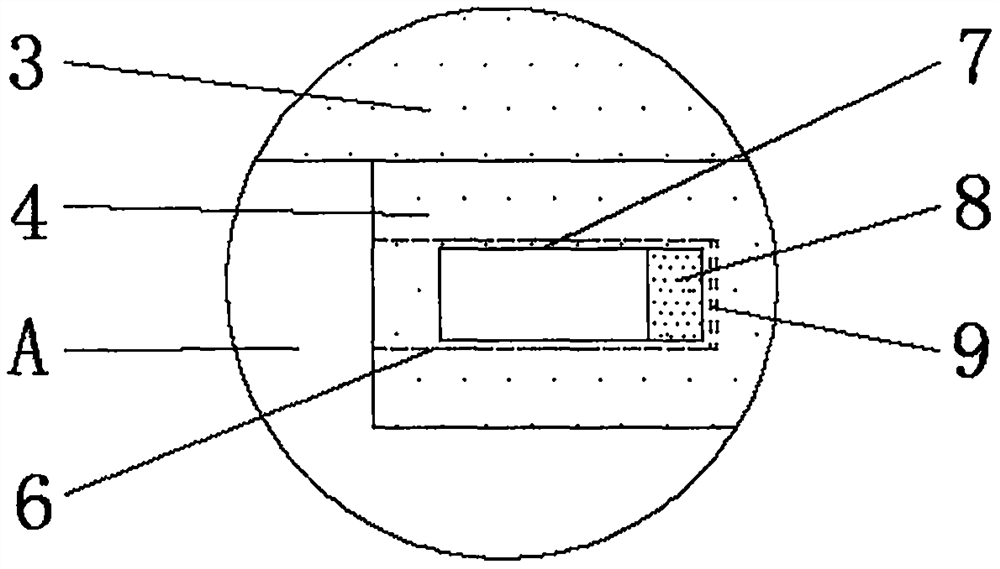

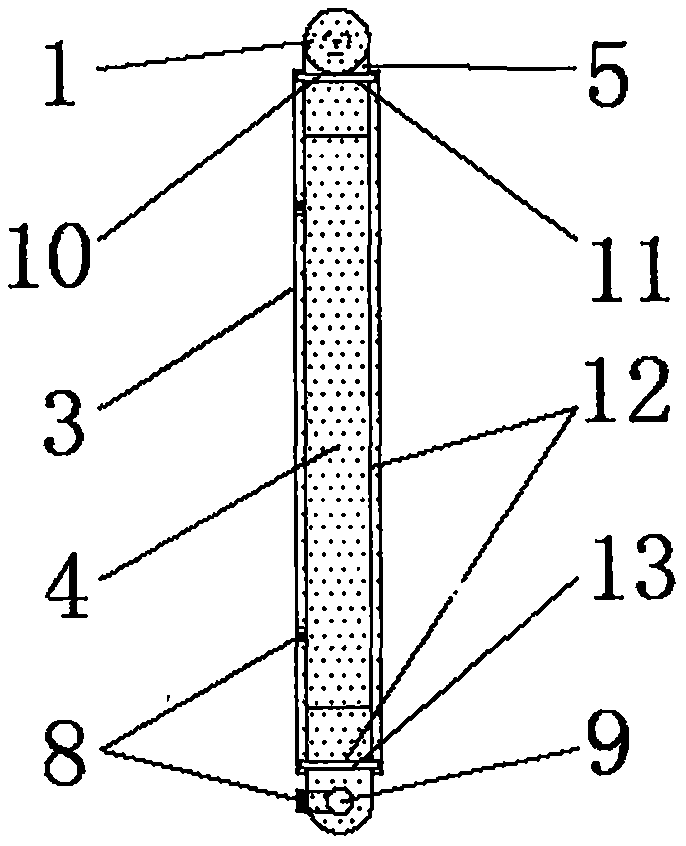

Magnesium calcium silicate heat preservation integrated plate and processing method thereof

InactiveCN112064936AAvoid accidental movementEasy to operateCovering/liningsCalcium silicateThermodynamics

Owner:SHANDONG HORIZON BUILDING ENERGY EFFICIENCY TECH CO LTD

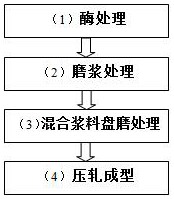

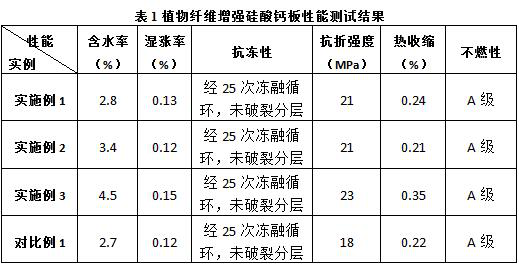

Plant fiber reinforced calcium silicate board and preparation method thereof

ActiveCN111646763AEasy fibrillationReduce cut-off rateCalcium silicatePlant fibre

Owner:肇庆三乐集成房屋制造有限公司

Chemical heat storage material and method for producing same

ActiveCN111918949AImprove repeat durabilityHeat-exchange elementsCalcium/strontium/barium oxides/hydroxidesCalcium silicatePhysical chemistry

Owner:SHIRAISHI CENT LAB +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap