Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Hot blast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. Hot blast also allowed higher furnace temperatures, which increased the capacity of furnaces.

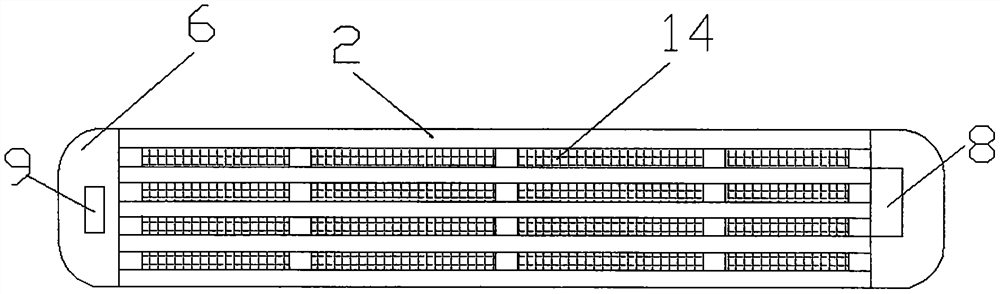

Powder packaging device of electronic element based on the heating structure with controllable wind direction and speed

InactiveCN101032715ABreak through the technical problem of uneven thermal claddingLiquid surface applicatorsCoatingsHeat flowFluidized bed

Owner:XI AN JIAOTONG UNIV

Hydrogen-rich oxygen blast furnace ironmaking method

InactiveCN108220514AAchieving no residueReduce inaccuracyBlast furnace detailsHydrogenHeating furnace

Owner:UNIV OF SCI & TECH BEIJING

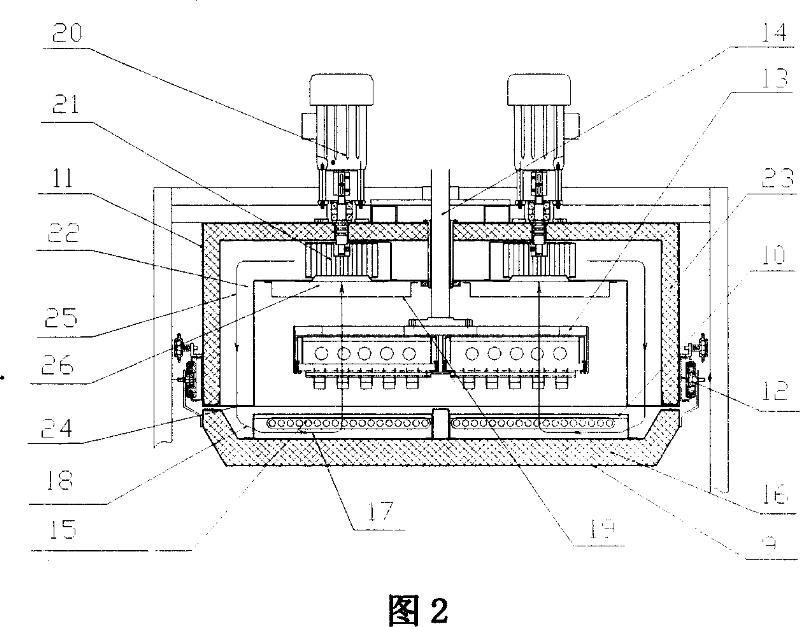

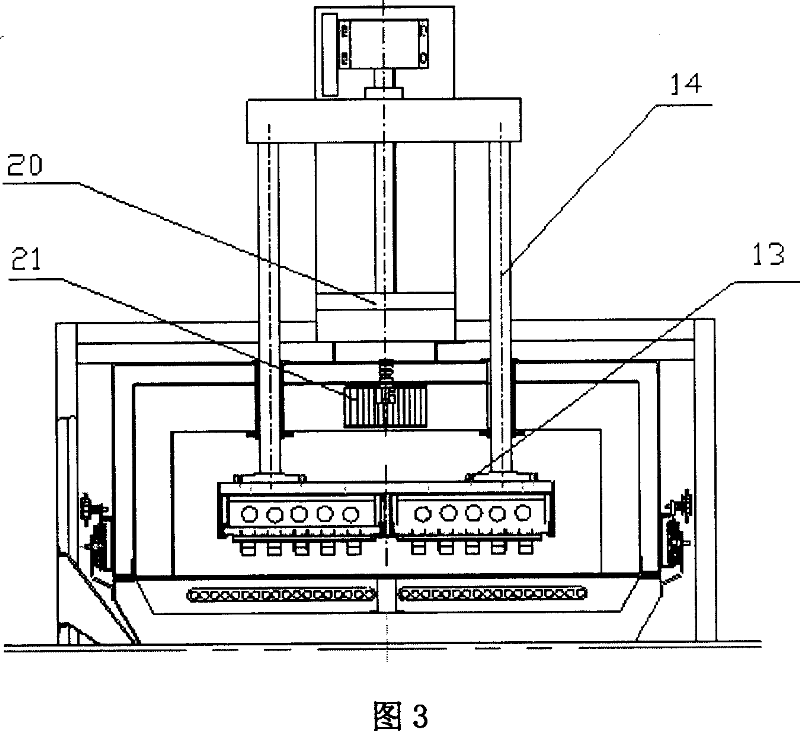

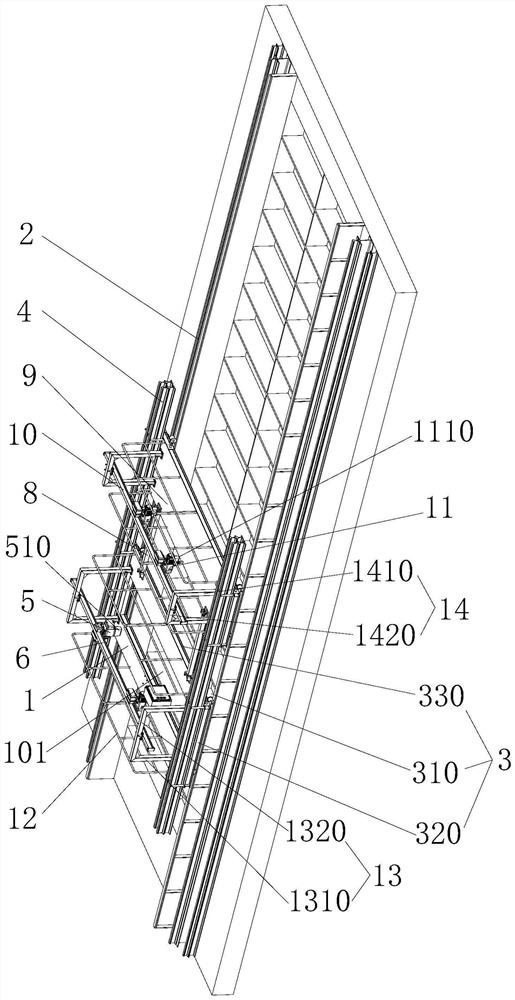

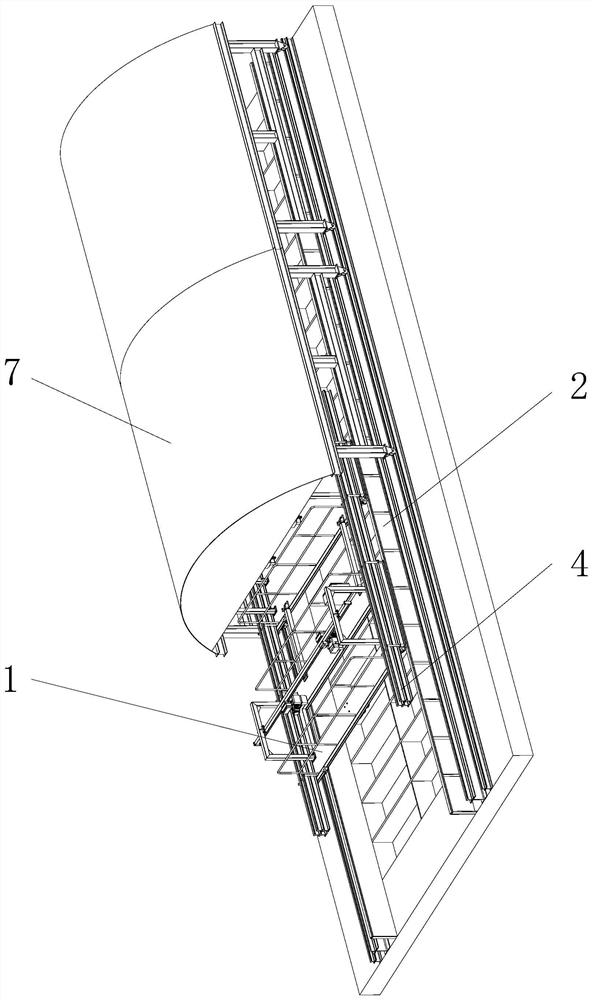

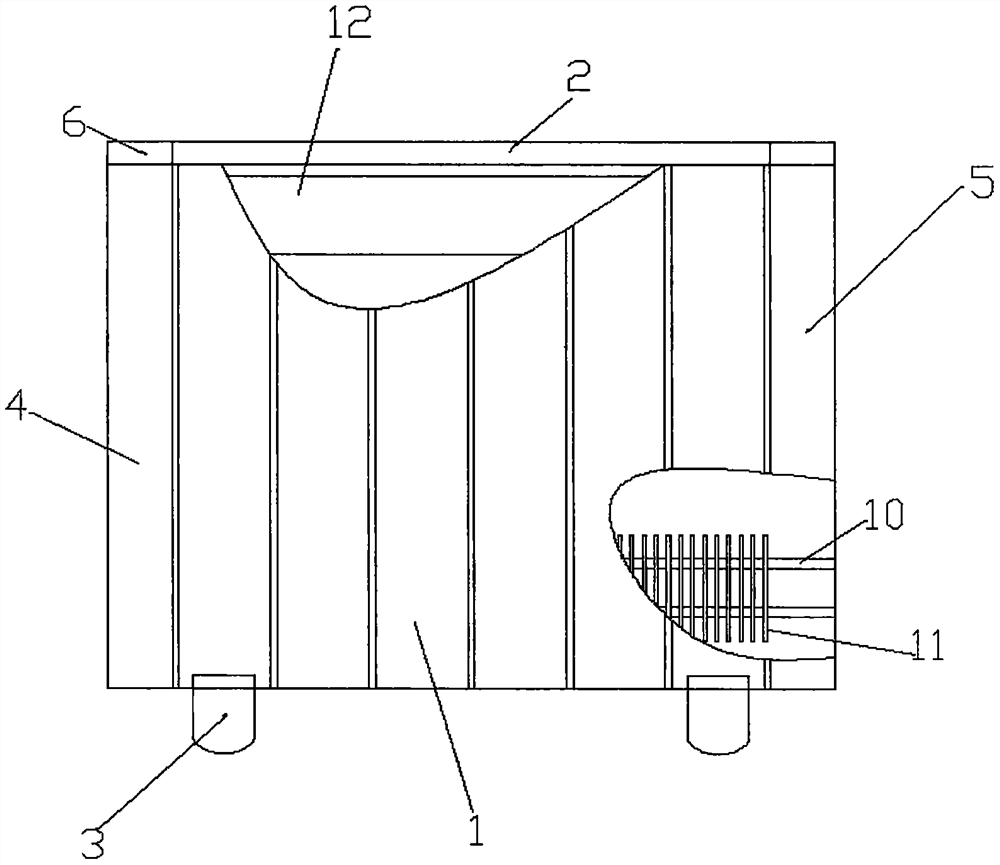

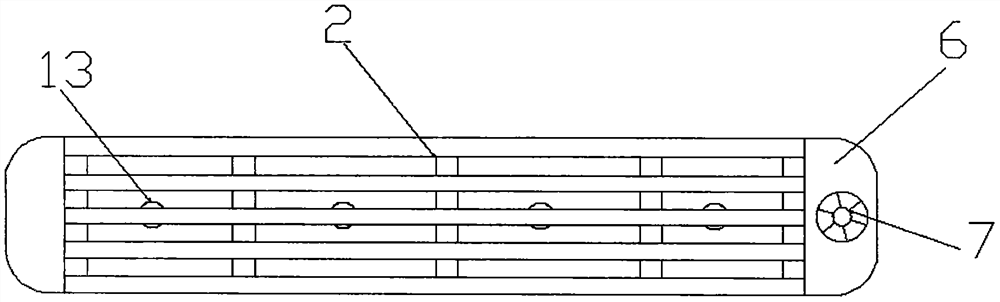

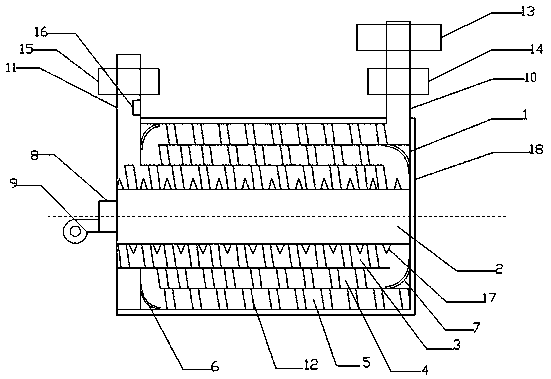

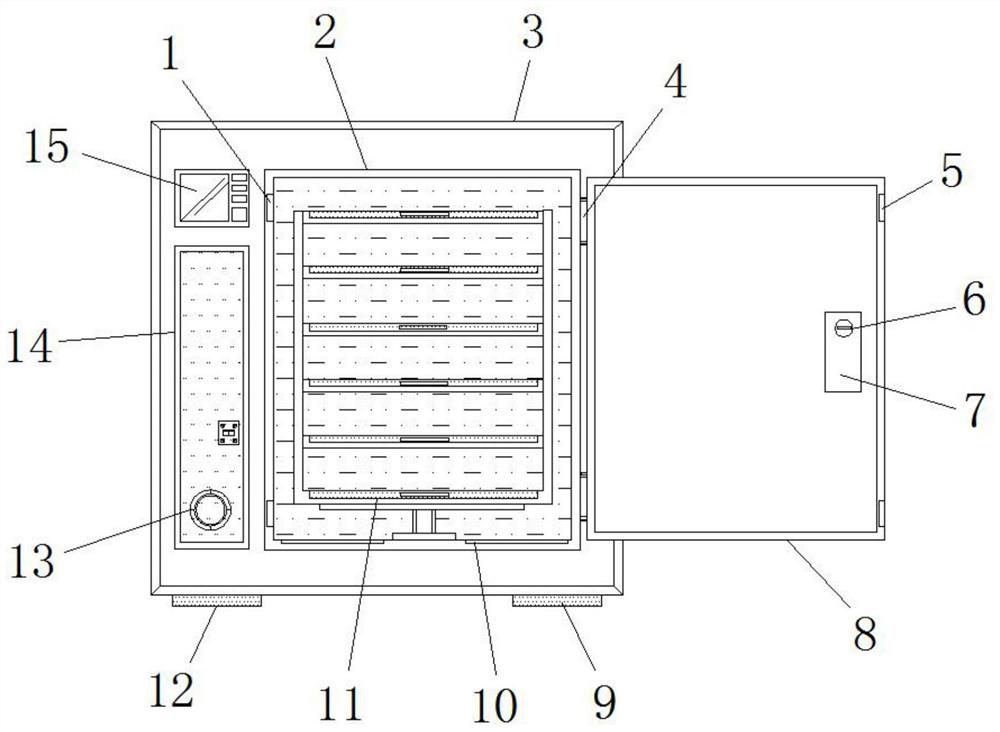

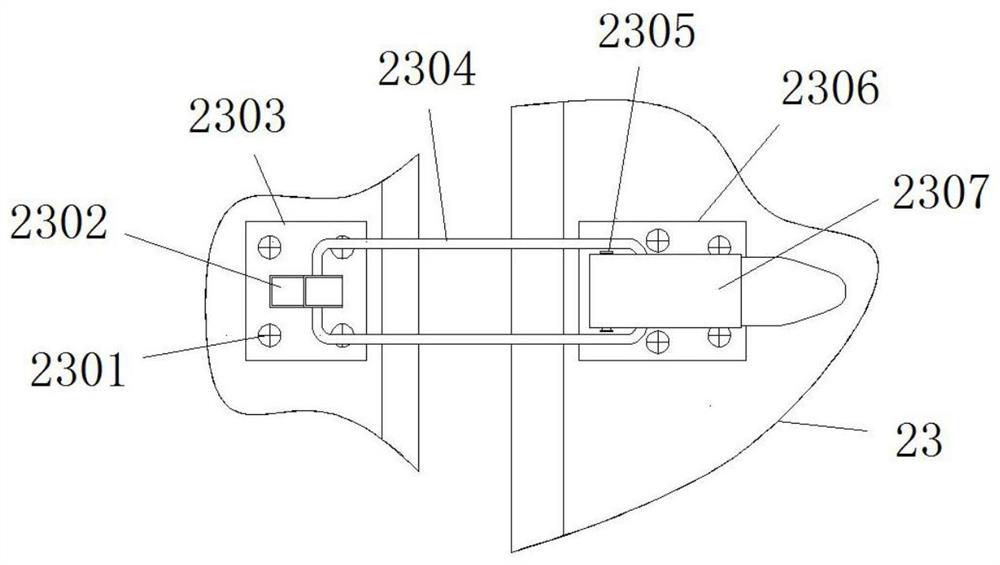

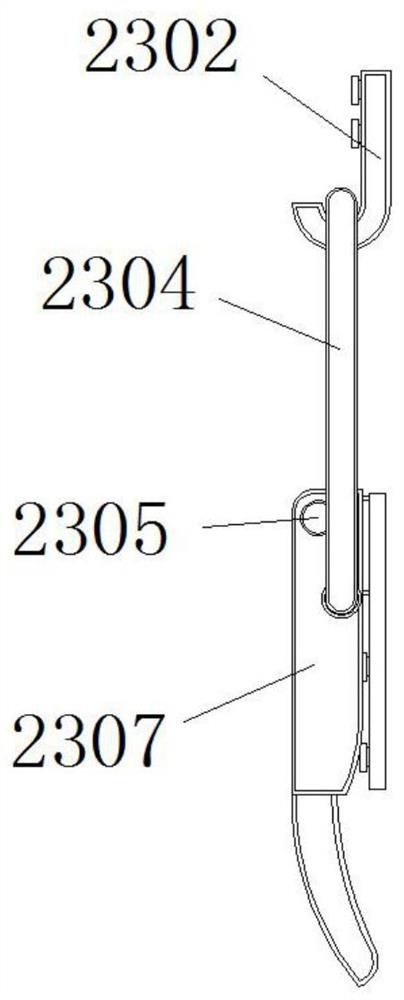

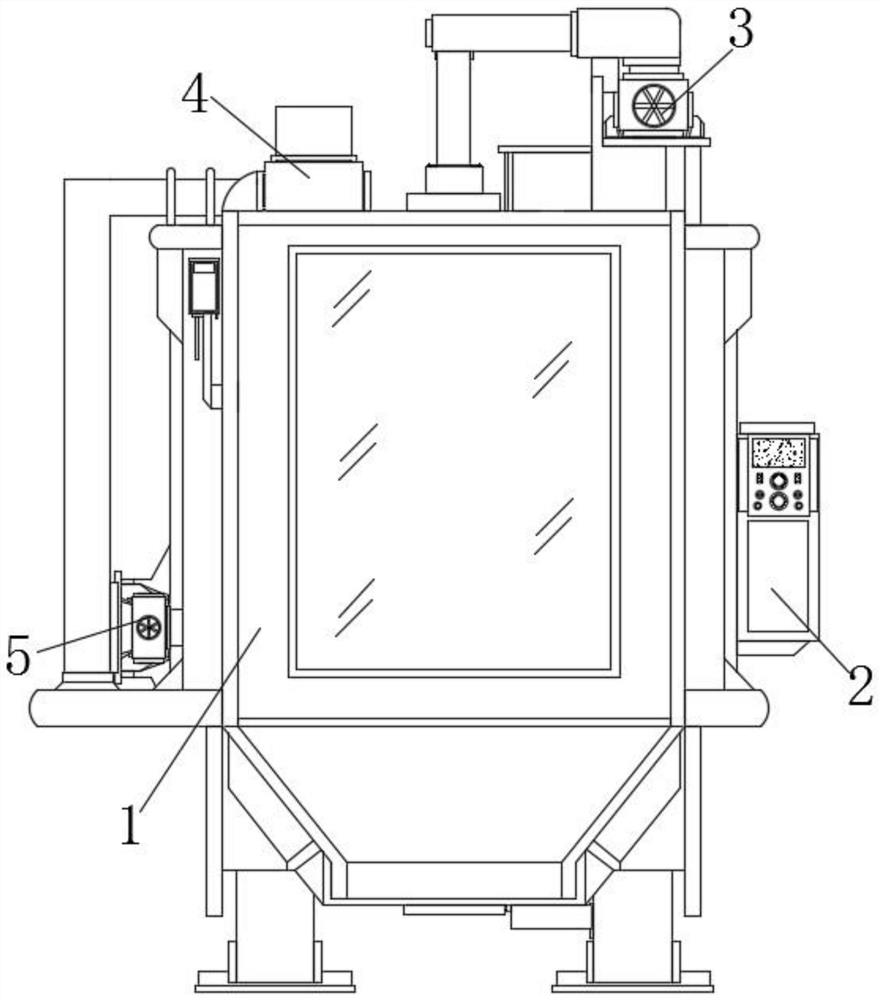

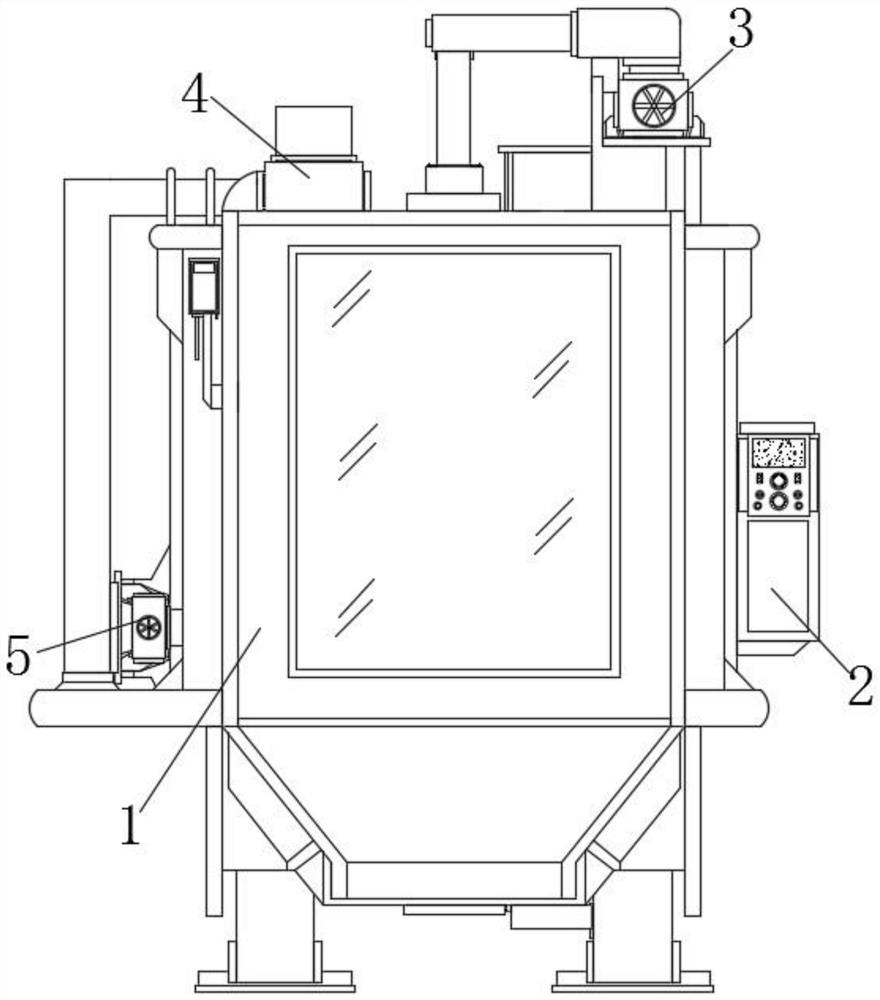

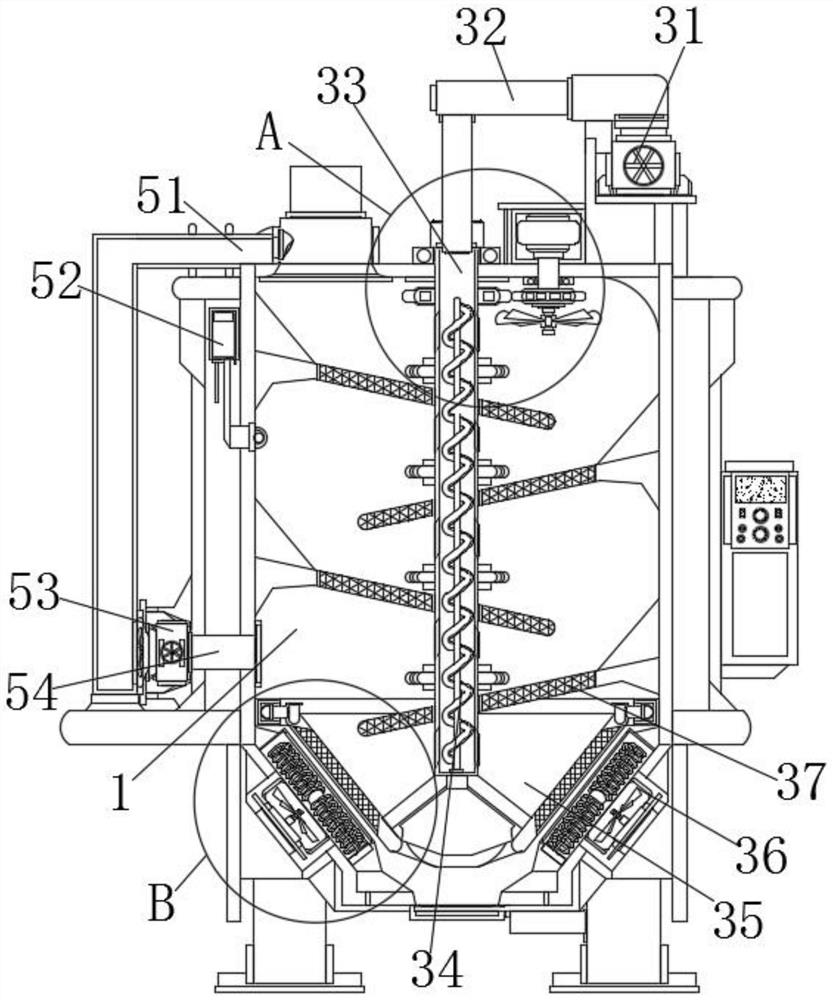

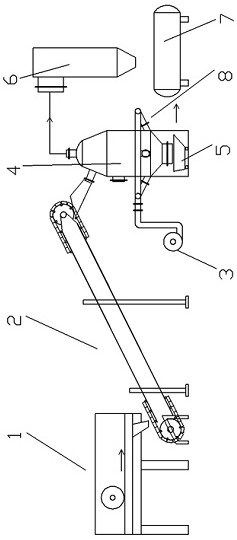

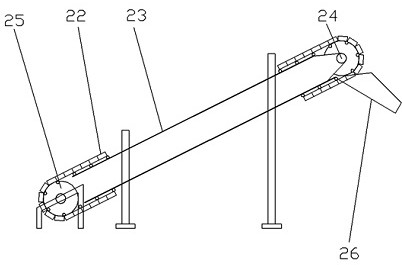

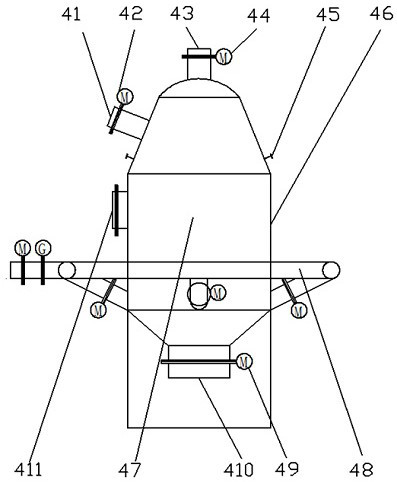

Efficient alloy baking device and baking method thereof

The invention discloses an efficient alloy baking device and a baking method thereof in the field of alloy baking. The efficient alloy baking device comprises a hot-blast stove, the hot-blast stove isconnected with an air inducing mechanism through a hot-blast pipeline, a temperature adjusting mechanism is further arranged between the air inducing mechanism and the hot-blast stove, the air inducing mechanism is connected with a baking bin, and the baking bin is arranged on a rack. The hot-blast stove is arranged on one side of the rack, a weighing and discharging mechanism is arranged below the baking bin, the baking bin is further provided with a feeding mechanism in a matched mode, and the hot-blast stove is controlled by an intelligent detection control system. The hot-blast stove andthe baking bin are of a separated structure, coal gas can be fully combusted, carbon monoxide poisoning accidents are avoided, safety measures are complete, the hot-blast stove is controlled by the intelligent detection control system, the hot-blast stove and the baking bin can be monitored in real time, and the heat energy utilization efficiency is greatly improved through the air inducing mechanism and the temperature adjusting mechanism. The efficient alloy baking device and the baking method thereof can be used for iron alloy baking.

Owner:JIANGSU EURASIA ENVIRONMENTAL PROTECTION TECH CO LTD

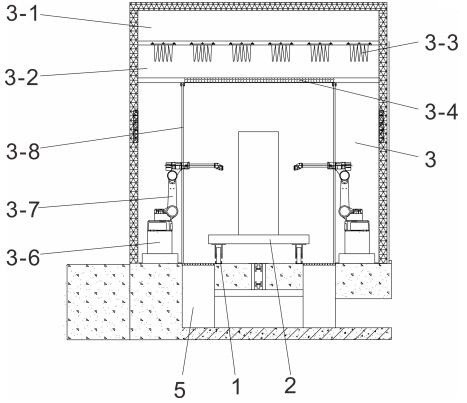

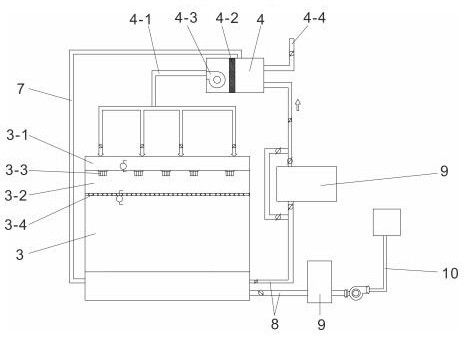

Paint spraying and drying integrated room for robot operation

Owner:苏州金迈驰航空智能科技有限公司

Lead-zinc oxide ore recycling and harmless treatment system and method

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

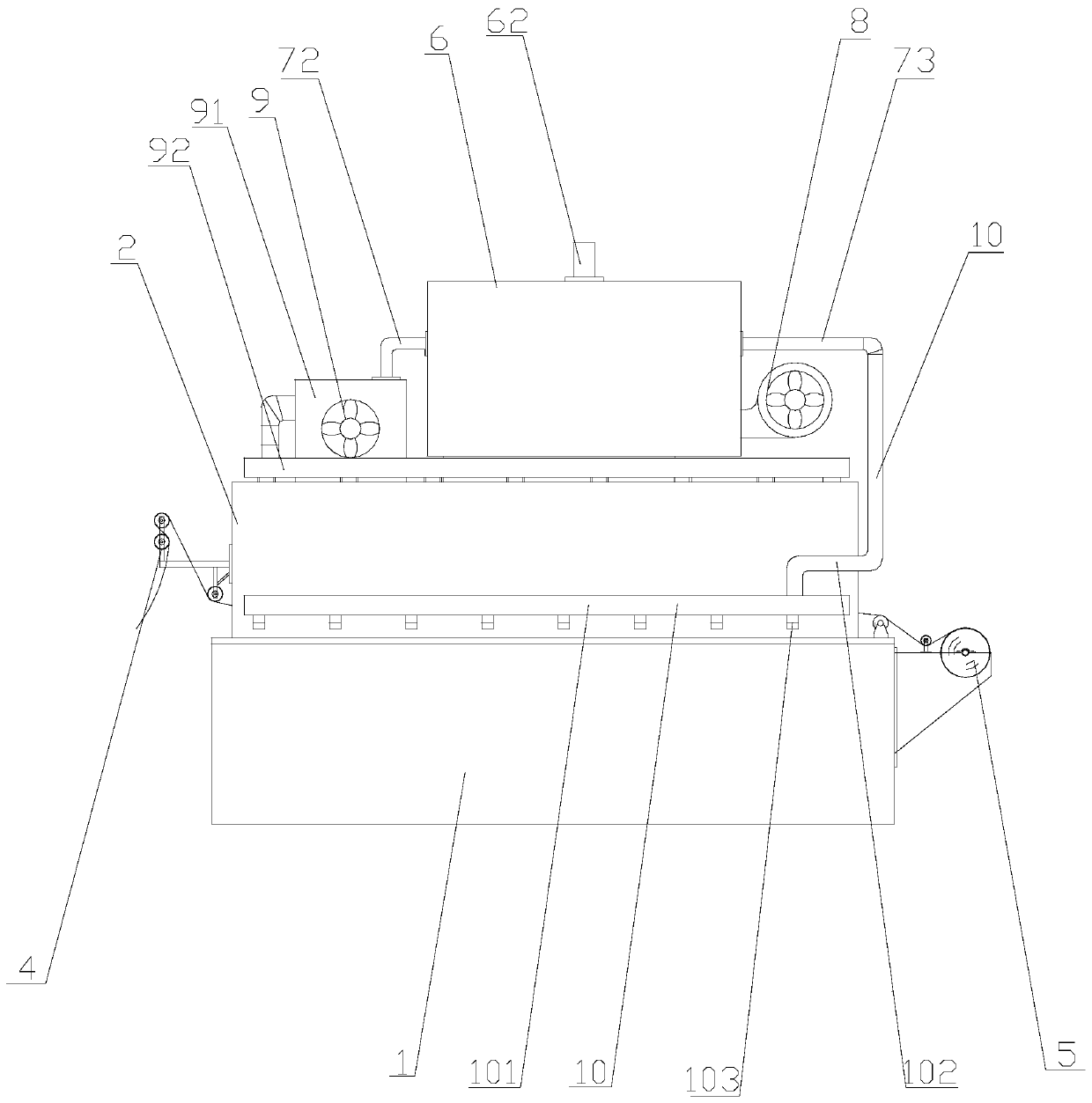

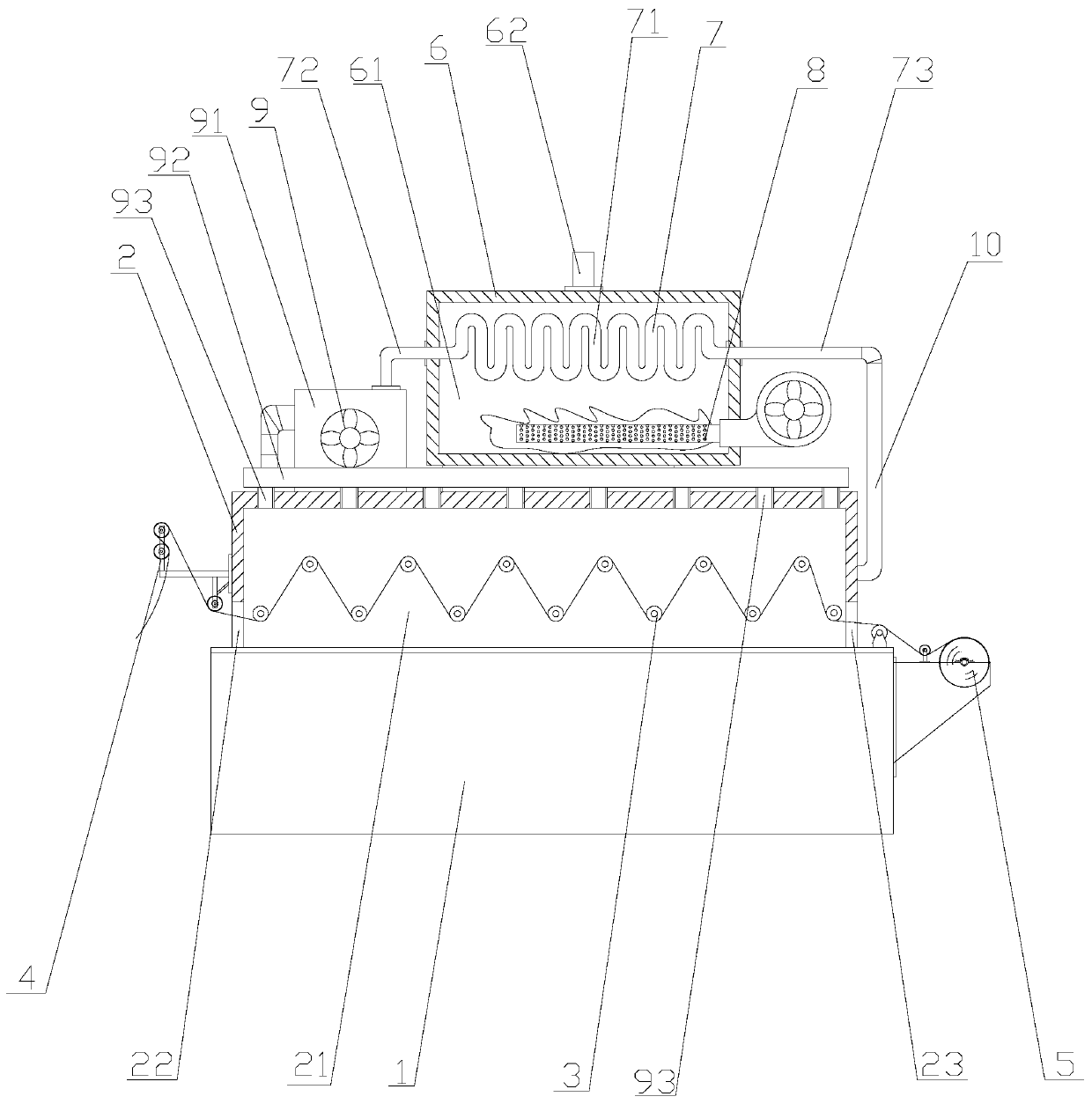

Steel drum film packaging thermal shrinkage treatment device and application method thereof

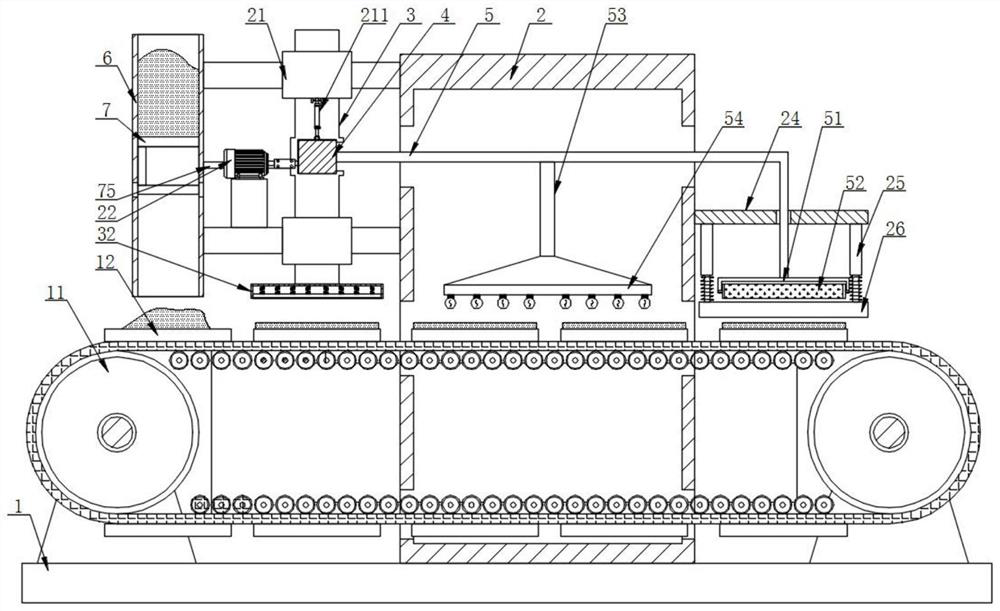

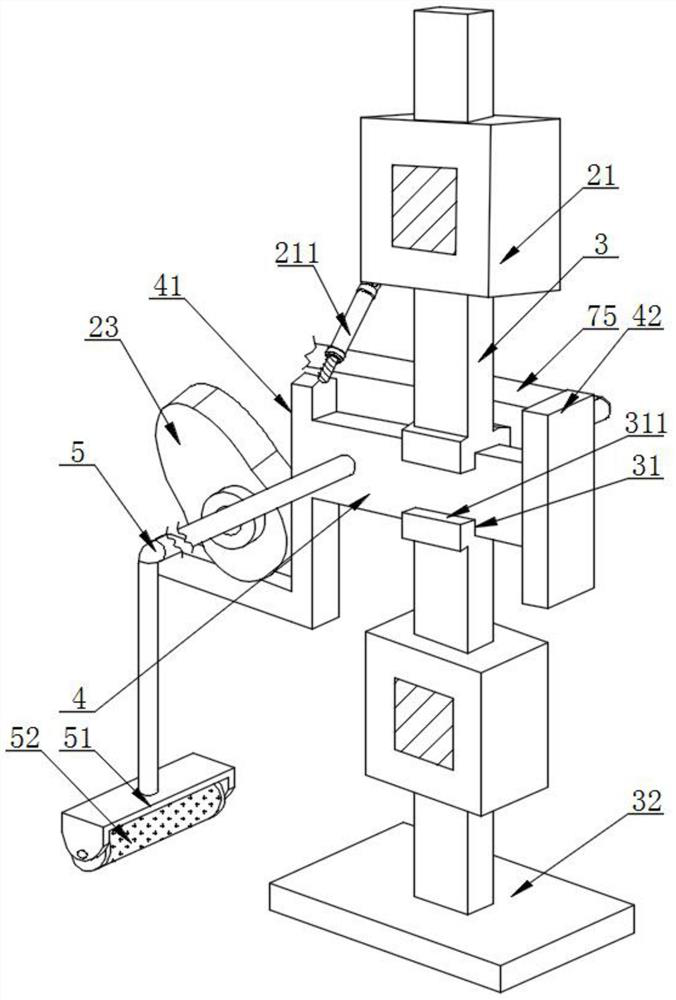

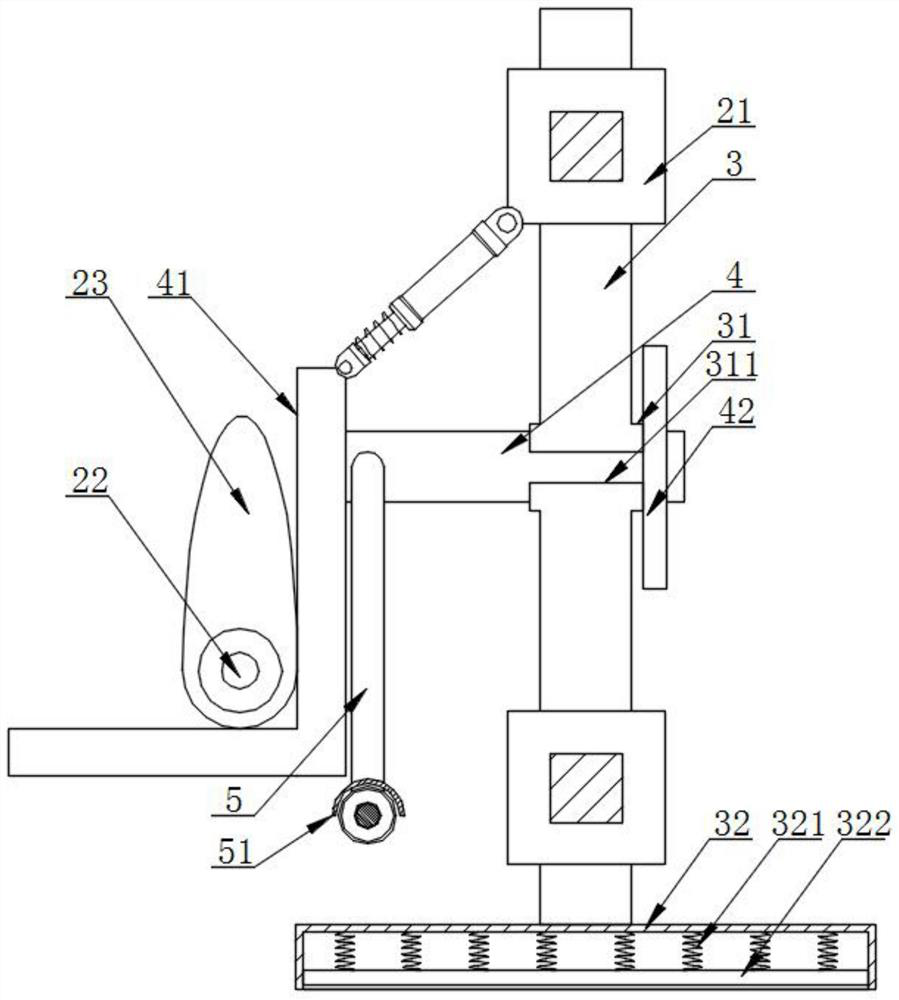

The invention relates to a steel drum film packaging thermal shrinkage treatment device and an application method thereof and belongs to the technical field of steel drum packaging. The thermal shrinkage treatment device comprises locating trays, a conveying device, a thermal shrinkage device, a hot air blowing device, a driving device, a baking device and a controller, wherein the locating traysare arranged on the conveying device; film packaged steel drums are arranged on the locating trays; the thermal shrinkage device is arranged above the conveying device; the hot air blowing device is arranged in the thermal shrinkage device; the thermal shrinkage device is connected with the driving device for driving the thermal shrinkage device to move up and down; the conveying device passes through the baking device; and the conveying device, the thermal shrinkage device, the hot air blowing device, the driving device and the baking device are connected with the controller. The steel drum film packaging thermal shrinkage treatment device achieves the technical effect that a film is attached to the steel drum closely, and no bubbles are generated in the plastic film packaging thermal shrinkage and fixing process of the plastic film packaged steel drum.

Owner:SHANGHAI JISHENG AUTOMATIC MACHINERY SYST

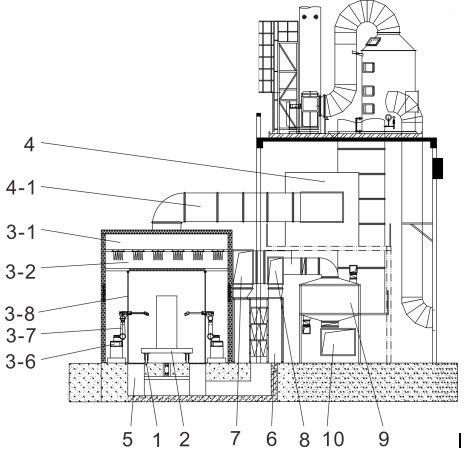

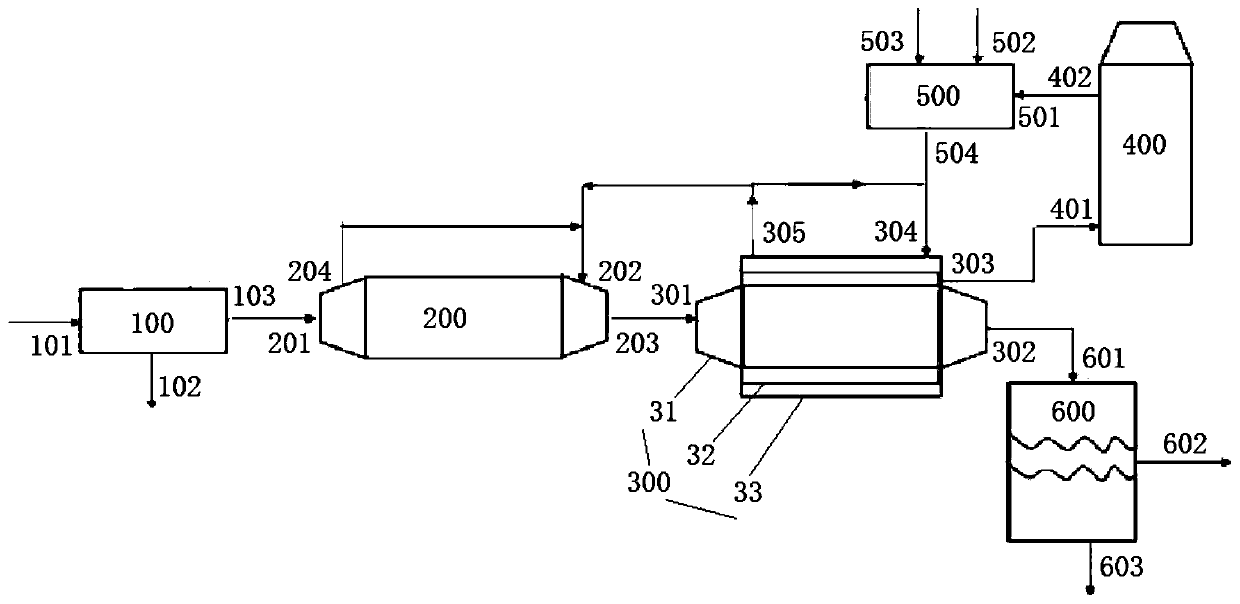

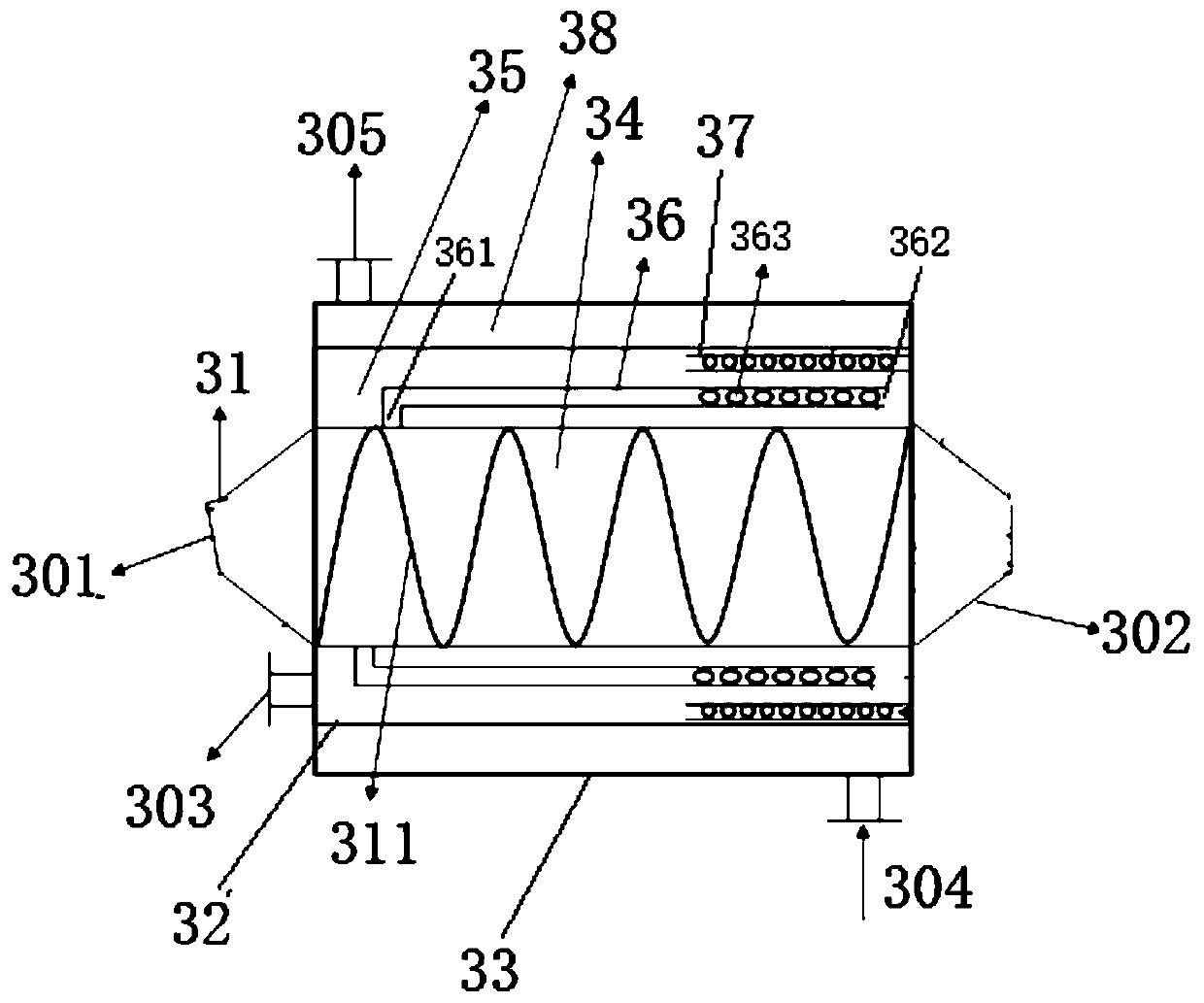

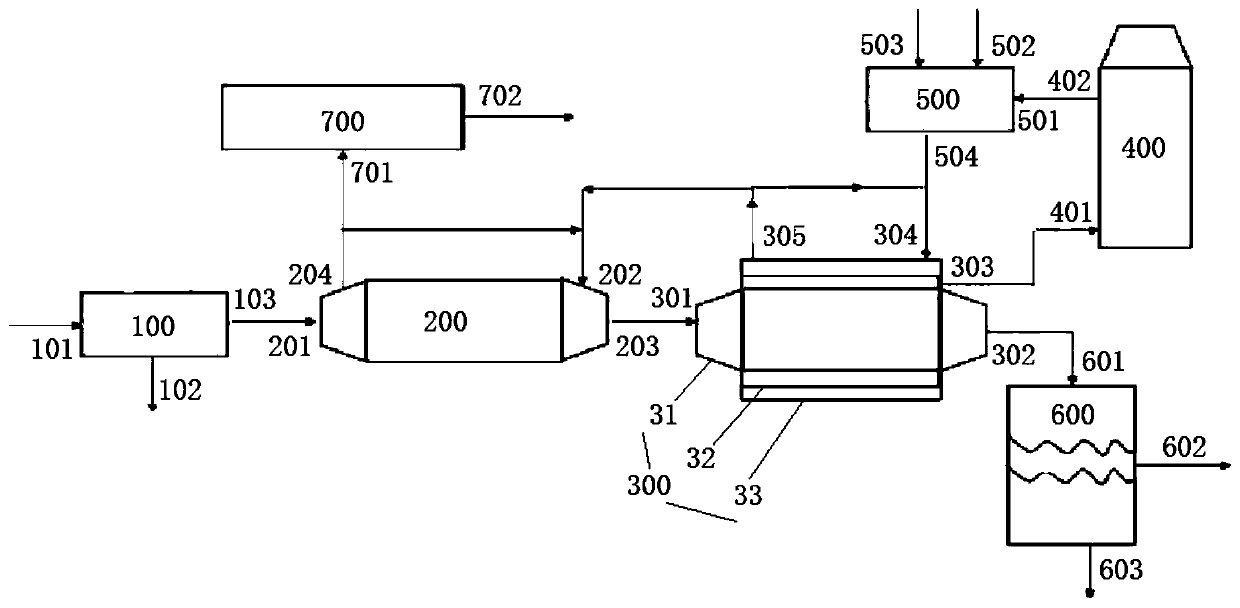

System and method for treating solid wastes

The invention discloses a system and method for treating solid wastes. The system comprises a pre-treatment unit, a drying unit, a pyrolyzation unit, a purifier, a burner and a screening unit, whereinthe pyrolyzation unit comprises an internal cylinder, a secondary external cylinder and an external cylinder. The internal cylinder is rotationally arranged, a pyrolyzation space is formed in the internal cylinder, a helical blade is arranged on the inner wall of the internal cylinder, a drying material inlet is formed in the front end of the internal cylinder, and a solid material outlet is formed in the rear end of the internal cylinder. The internal cylinder is sleeved with the secondary external cylinder to form a gasification space, a pyrolytic oil gas pipeline and an atomized water pipeline are arranged in the gasification space, one end of the pyrolytic oil gas pipeline is communicated with the pyrolyzation space, the other end of the pyrolytic oil gas pipeline extends into the gasification space, and a gasified gas outlet is formed in the portion, at the other end away from the pyrolytic oil gas pipeline, of the secondary external cylinder; the secondary external cylinder is sleeved with the external cylinder to form a heat exchange space, a high-temperature flue gas inlet and a heat-exchange flue gas outlet are formed in the heat exchange space, and the heat-exchange fluegas outlet and a drying cold air outlet are connected with a drying hot air inlet.

Owner:北京云水浩瑞环境科技有限公司

Ceramic tile processing equipment

Owner:新兴县致胜陶瓷有限公司

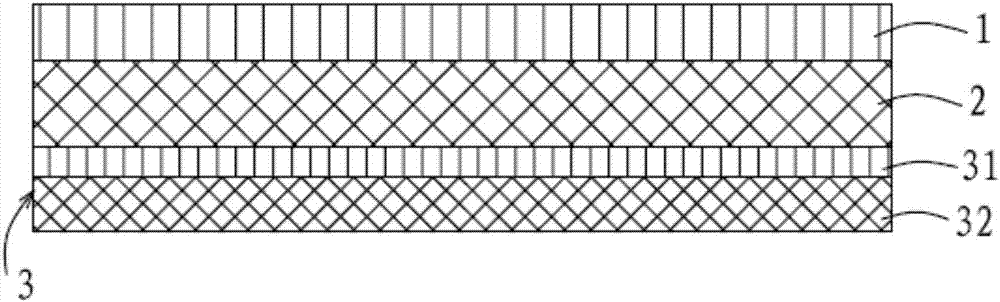

Super-dry hot-air nonwoven fabric

Owner:广东佳丝维新材料科技有限公司

Flat rail replacement equipment and method

PendingCN113734984ABase supporting structuresBraking devices for hoisting equipmentsHot blastElectrical and Electronics engineering

Owner:MCC BAOSTEEL TECH SERVICE

Healthy and non-dry electric warmer

Owner:山东普朗克电器有限公司

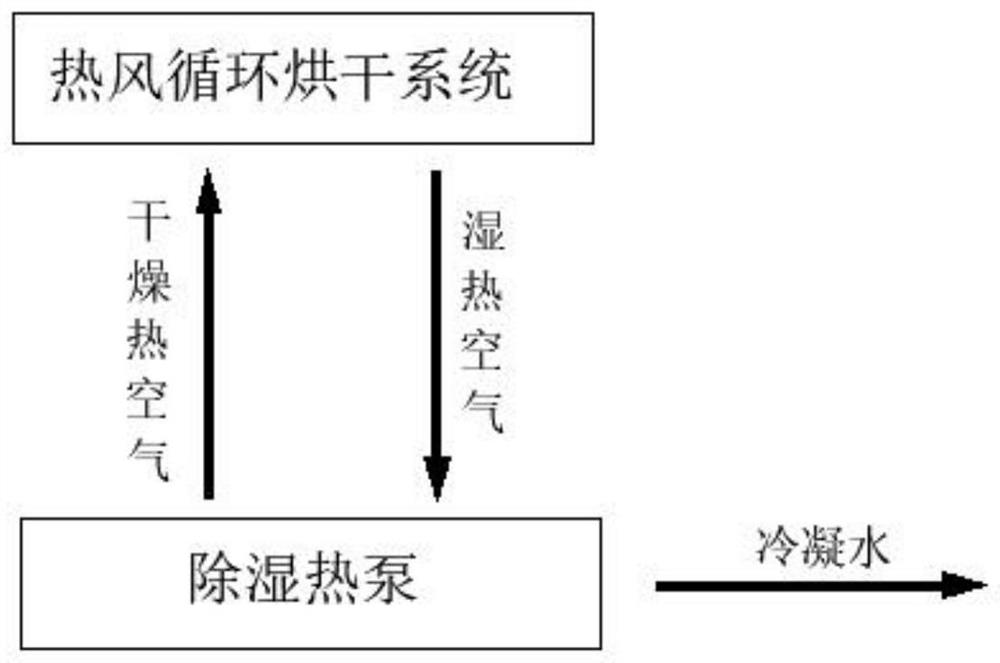

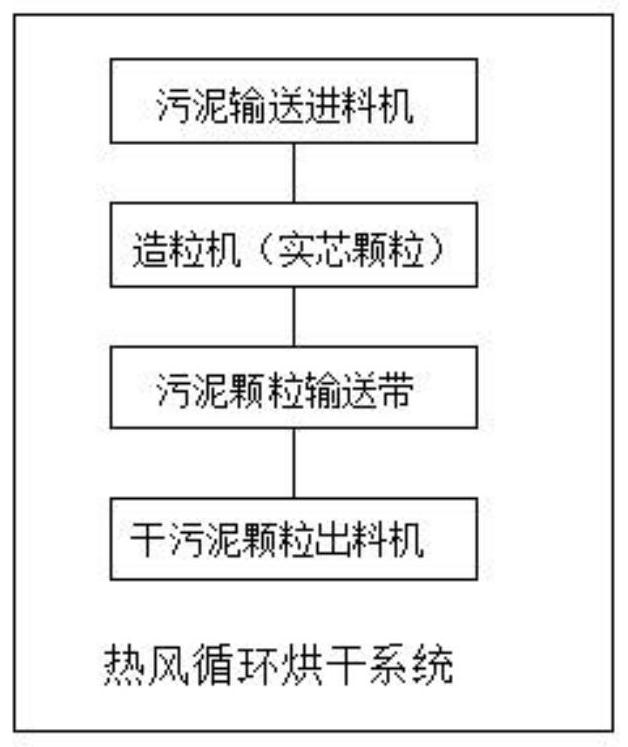

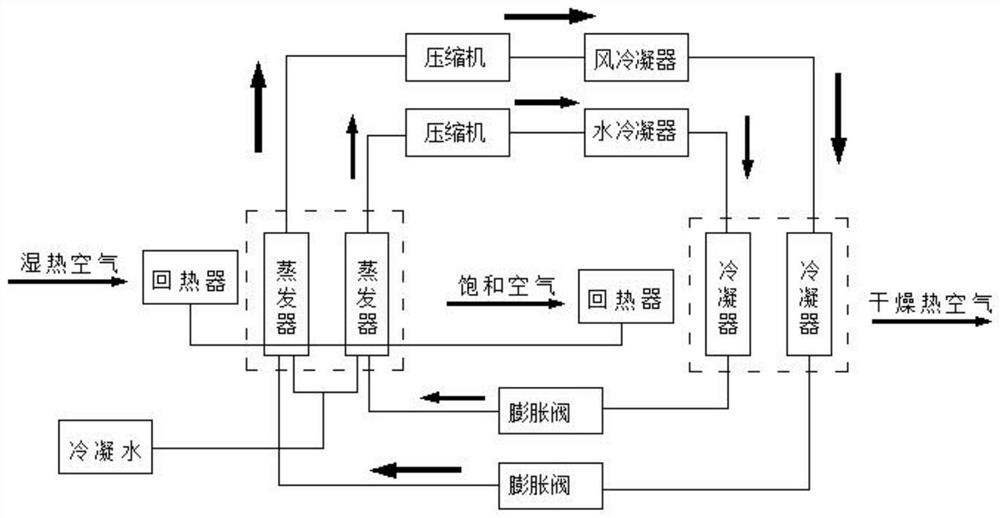

Anti-explosion low-energy-consumption type low-temperature sludge drying granulation process

Owner:南京韩测环境科技有限公司

Direct combustion type hot air penetration internal circulation drying device for non-woven fabric production

PendingCN110500865AAchieve cycleEasy drying processDrying gas arrangementsDrying machines with progressive movementsFiberCombustor

Owner:ZHEJIANG WANGJIN NONWOVENS CO LTD

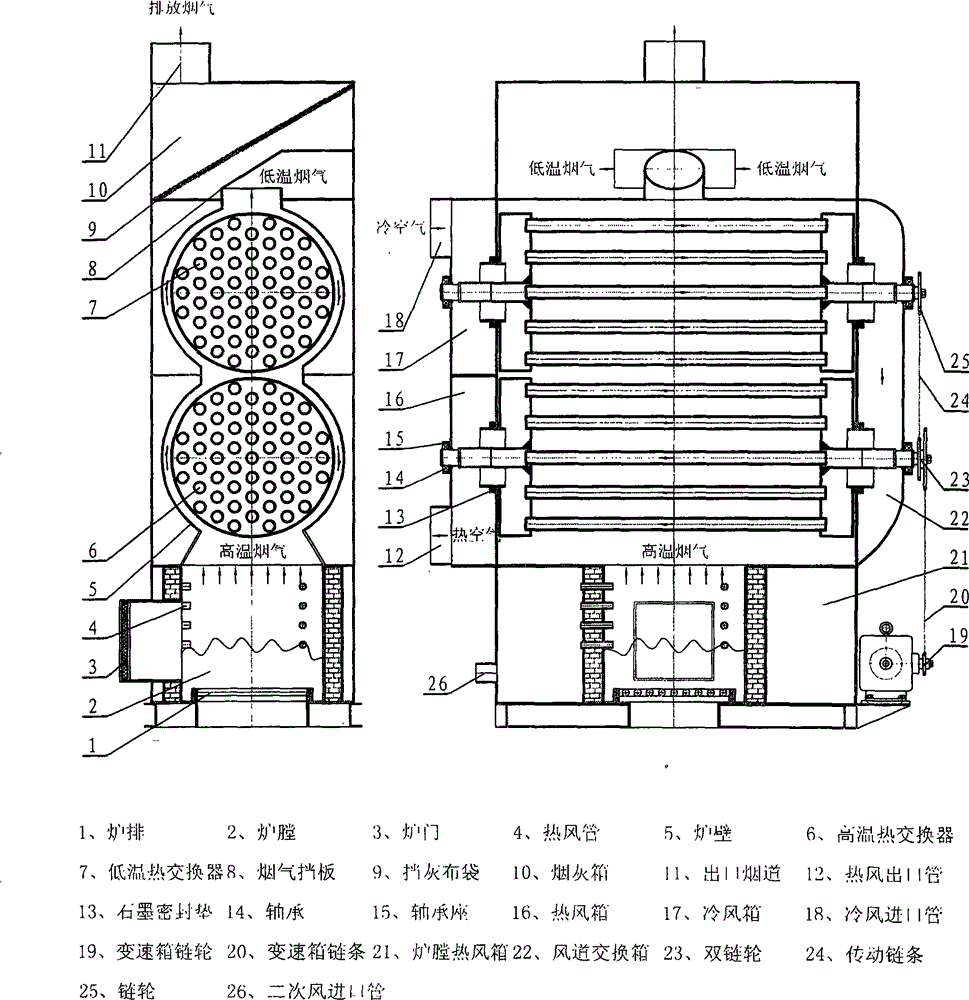

Gas-fired hot blast stove

Owner:WUHU MINGREN THERMAL ENERGY EQUIP

Gas heat value soft measurement method based on air and gas double-preheating

ActiveCN109655487ASolve the inconvenienceSolve problemsMaterial heat developmentComplex mathematical operationsCombustion systemReal-time data

The invention provides a gas heat value soft measurement method based on air and gas double-preheating. The soft measurement method comprises the steps of obtaining real-time data of a combustion system operation parameter; performing preprocessing on the acquired data, and obtaining effective data for solving the gas heat value; and according to the acquired effective data, calculating a gas drybase heat value. According to the method of the invention, the gas dry base heat value is indirectly calculated through a relation between a dry air amount and the gas heat value. The method is suitable for combustion equipment in which pure burning of blast furnace gas or converter gas and air and gas double-preheating technology are utilized. A calculating result can be used for guiding combustion optimization adjustment of the combustion equipment, thereby supplying a basis for safe and economic operation of the combustion equipment. The gas heat value soft measurement method can settle inconvenience and a difficulty in combustion equipment operation caused by no gas heat value online analyzer in a majority of steel plant gas combustion systems, and furthermore has high engineering value.

Owner:JIANGSU MARITIME INST

Drying equipment for metal product machining

Owner:常德市晟珺祺金属制品有限公司

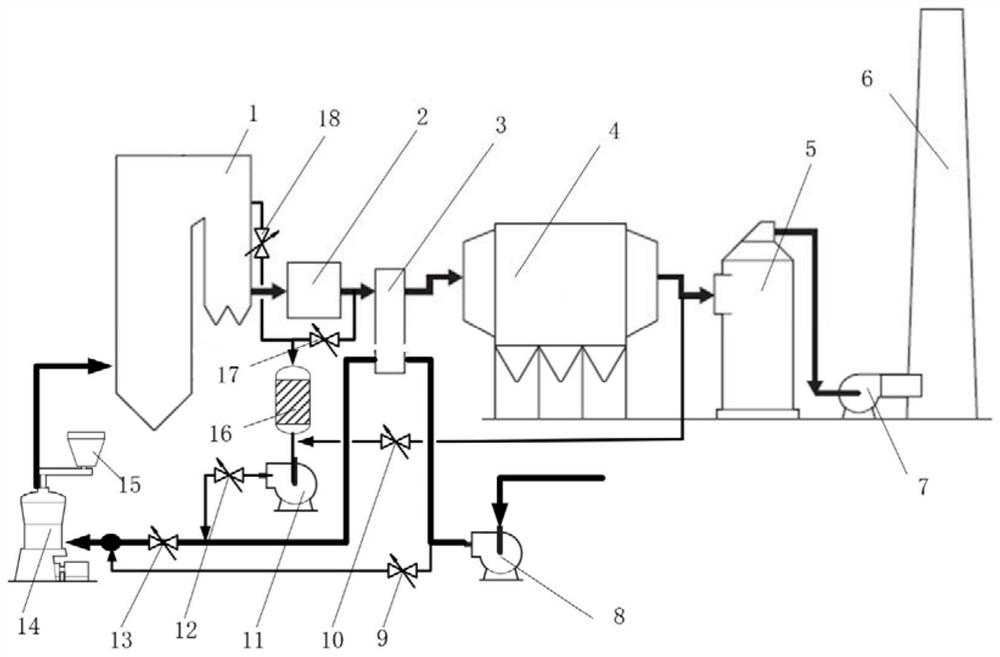

Steel slag waste heat utilization device and operation mode thereof

InactiveCN112251548AEfficient use ofReduce energy consumptionIncreasing energy efficiencyRecycling and recovery technologiesHot blastSlag

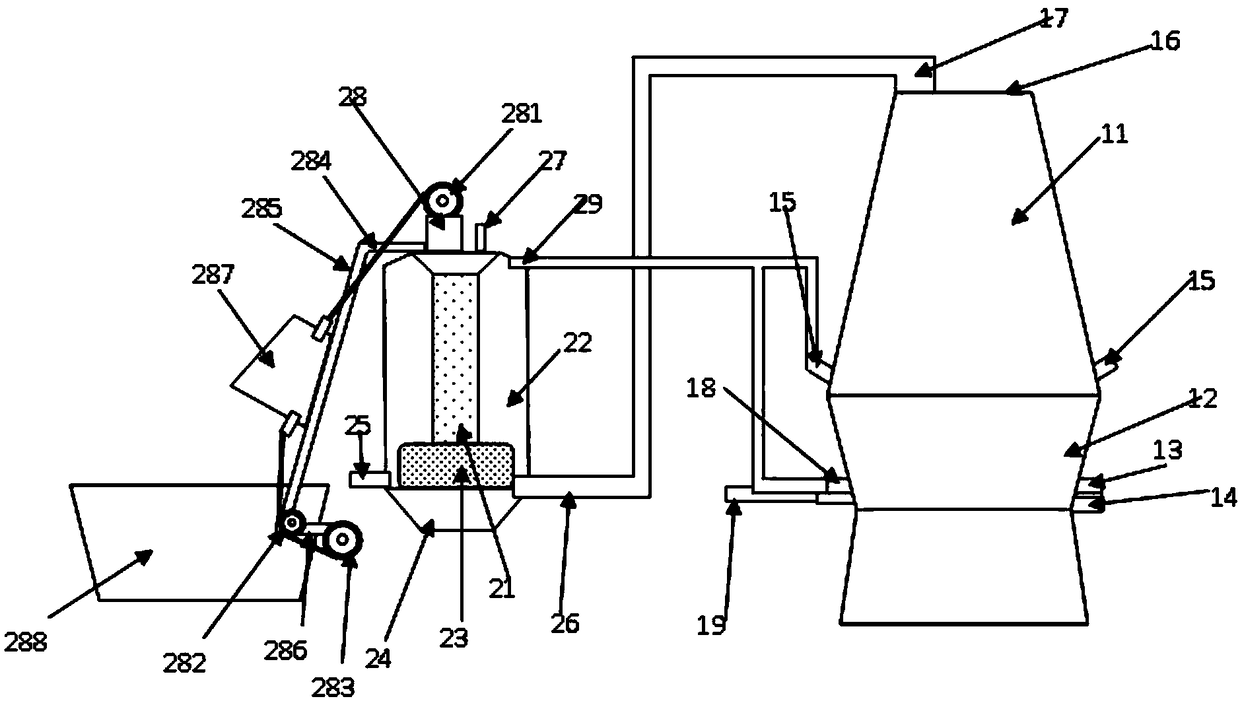

The invention discloses a steel slag waste heat utilization device and an operation mode thereof, and belongs to the field of recycling equipment. According to the technical scheme, the operation modeis characterized by comprising the steps that firstly, high-temperature blocky steel slag rolled and crushed by a roller press is discharged to a conveying tool; then, the high-temperature blocky steel slag is conveyed to a high position through the conveying tool and loaded into a high-temperature blocky steel slag heat taking device through a feeding port of the high-temperature blocky steel slag heat taking device; then, a fan supplies air, and cold air is fed into the high-temperature blocky steel slag heat taking device through an air distribution device of the high-temperature blocky steel slag heat taking device and exchanges heat with the high-temperature steel slag in the high-temperature blocky steel slag heat taking device; then, high-temperature air obtained after heat exchange and temperature rise is discharged from a hot air outlet in the top of the high-temperature blocky steel slag heat taking device and then introduced into a hot waste heat boiler for waste heat utilization; and then, the fan stops supplying air, and the cooled steel slag is discharged from a discharging port in the bottom of the high-temperature blocky steel slag heat taking device and loaded into a steel slag tank car. Therefore, effective utilization of steel slag waste heat is realized.

Owner:钟赛梅

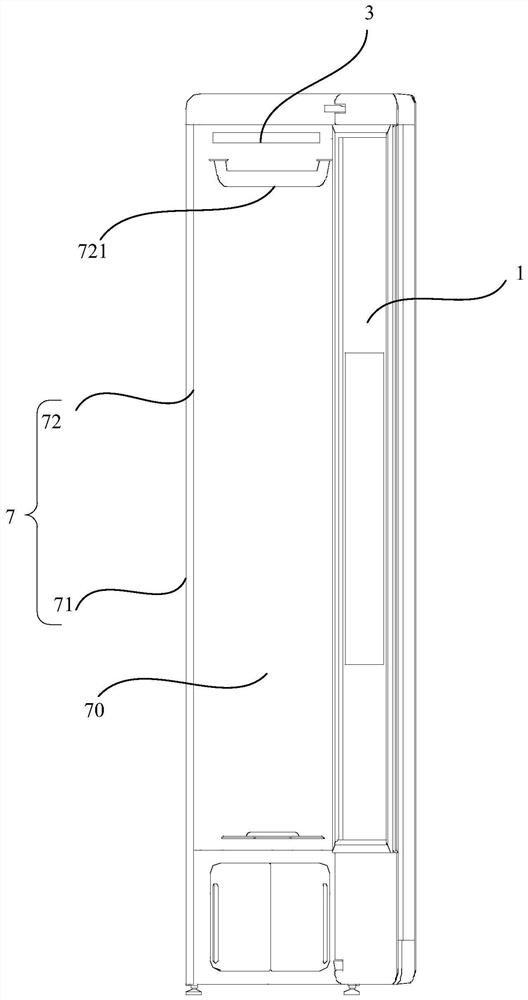

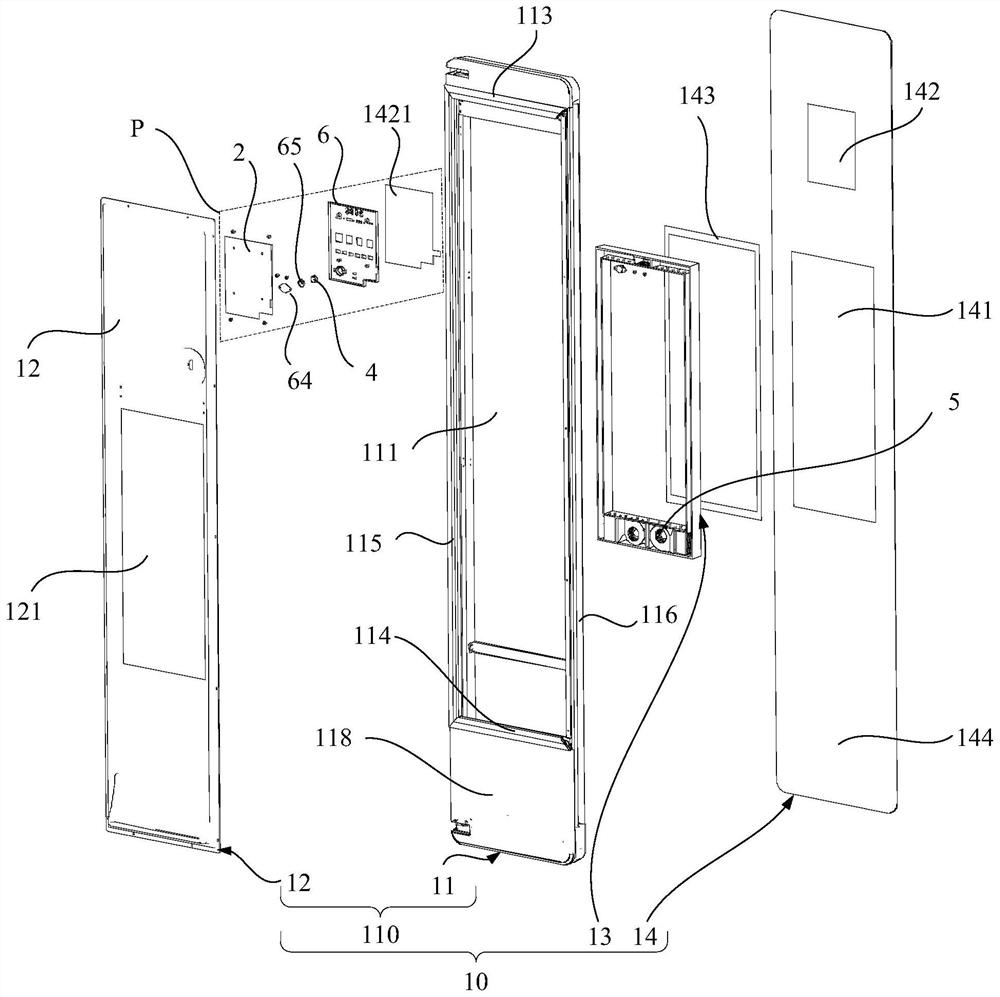

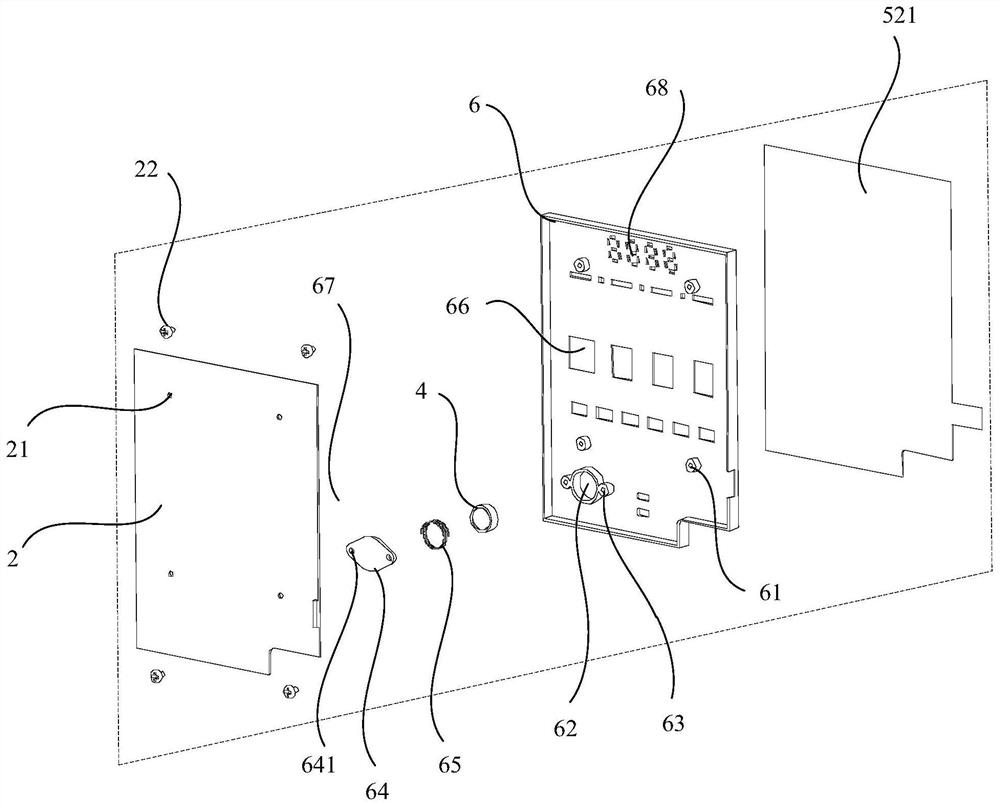

Clothes care machine

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

Safe and energy-saving comprehensive utilization system for boiler

Owner:DATANG DONGBEI ELECTRIC POWER TESTING & RES INST

Safe and environment-friendly aluminum powder and preparation method thereof

Owner:INNER MONGOLIA HEXI AEROSPACE TECH DEV

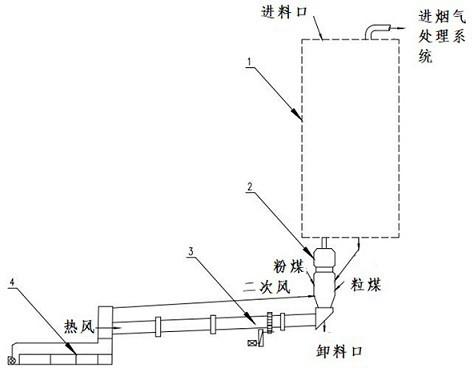

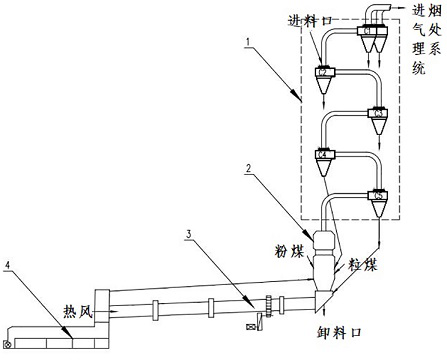

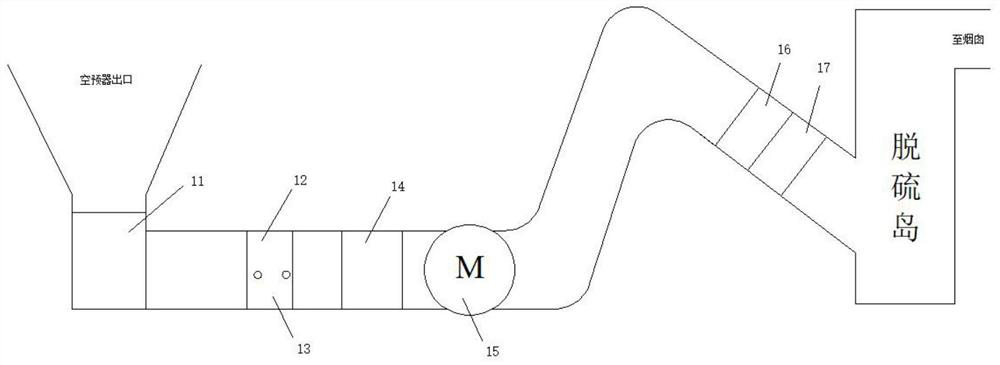

System for improving drying output of direct-fired pulverizing system

PendingCN114704847AAvoid explosionImprove efficiencyDrying gas arrangementsFire rescueAir preheaterBunker

Owner:XIAN THERMAL POWER RES INST CO LTD +1

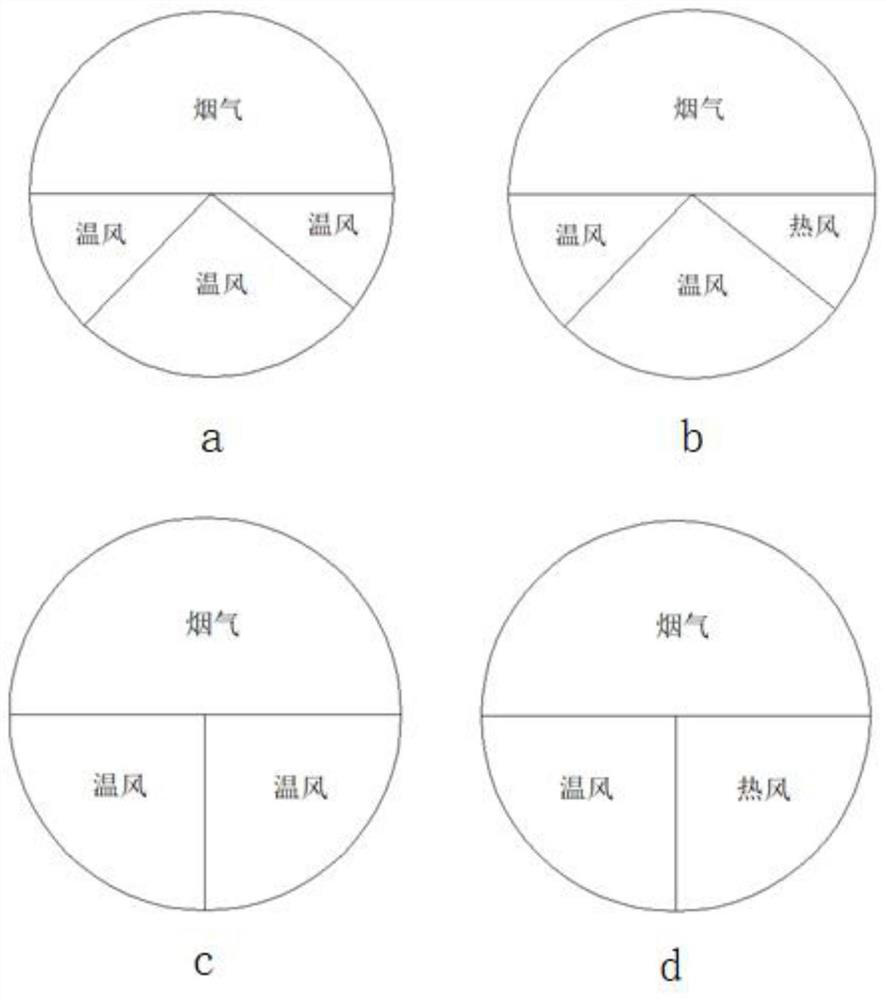

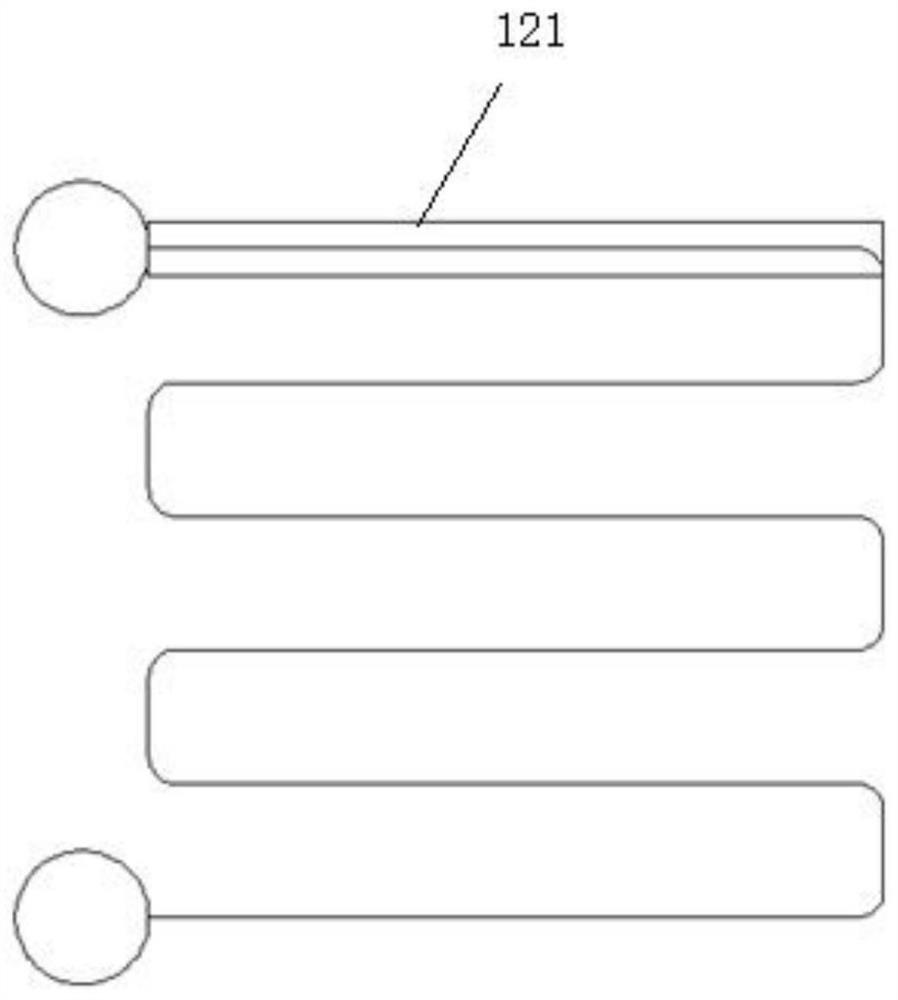

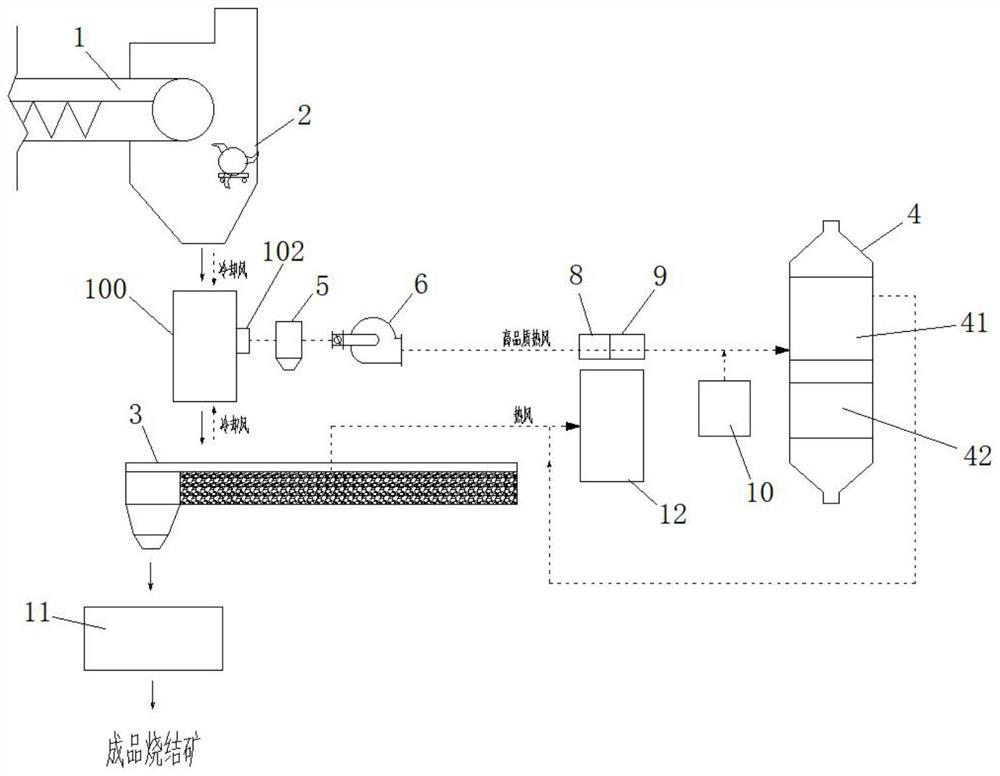

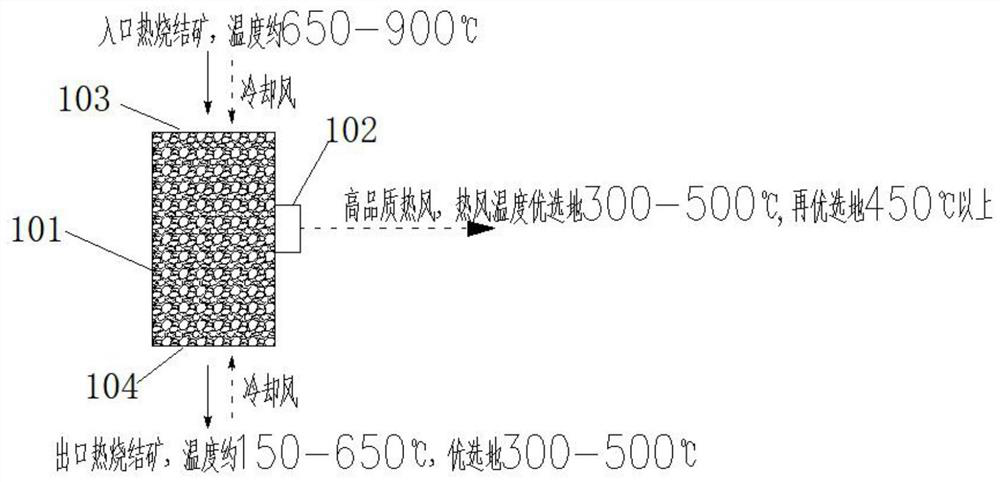

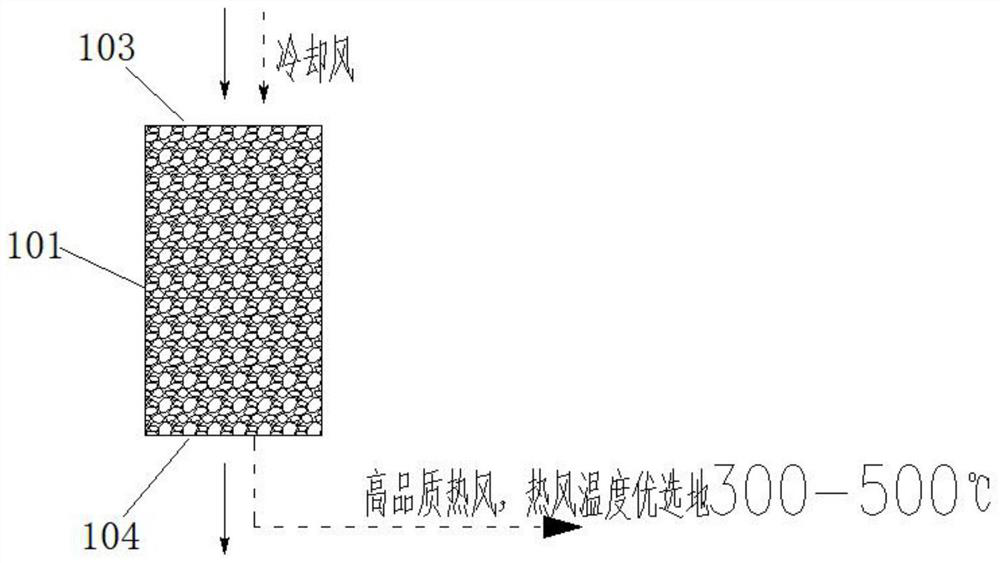

Sintering pre-cooling waste heat efficient utilization system and sintering cooling process

PendingCN113295009AReduce cooling air volumeEfficient use ofHandling discharged materialWaste heat treatmentThermodynamicsHot air oven

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap