Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Solid particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid particles. Solid particles multiply continuously in hydraulic systems. These particles flow through the hydraulic system under high pressure and at high speed and sandblast its components (pumps, valves, seals and cylinders). Particularly the tiniest particles which are either equal in size or smaller than the critical dynamic clearances...

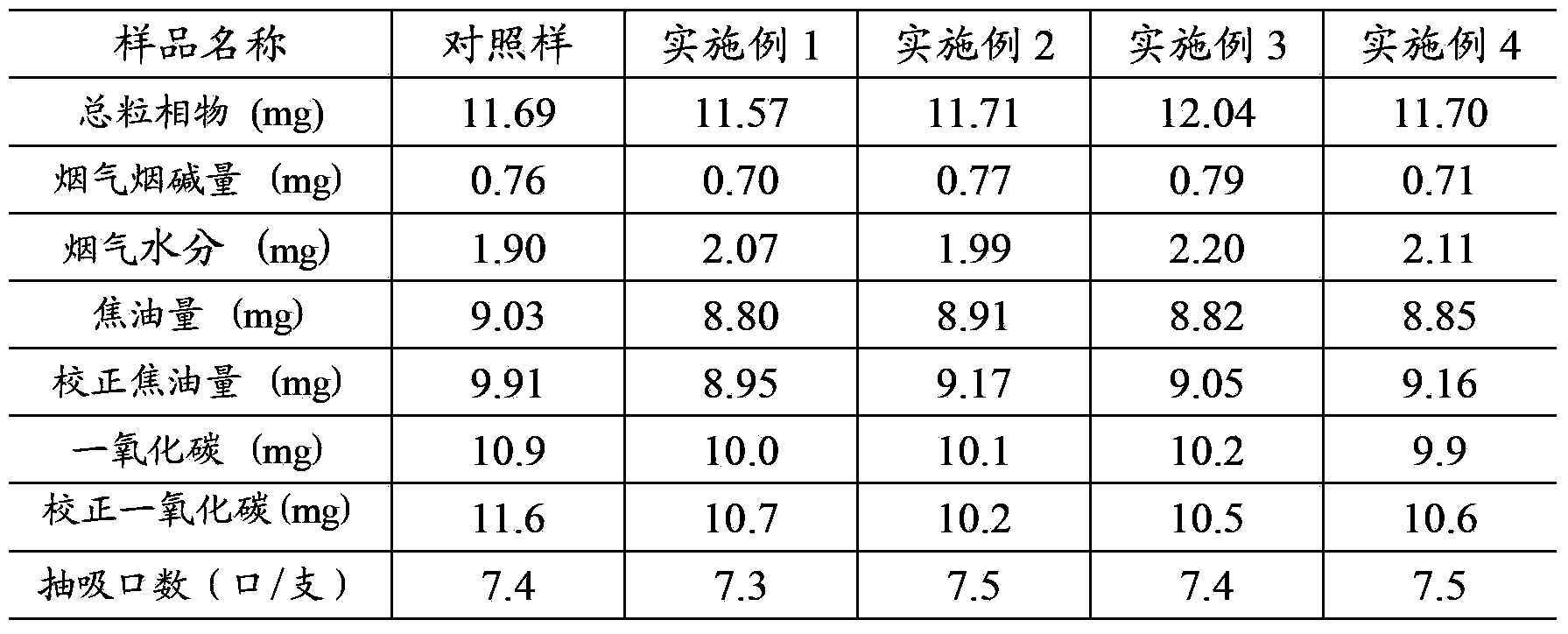

Solid-type filter stick formed by granular assembling and preparation method thereof

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

Washing machine and washing method

InactiveCN103061084ARealize deliveryAchieve separationOther washing machinesTextiles and paperSolid particleProcess engineering

Owner:XEROS LTD

Use of an acid soluble or degradable solid particulate and an acid liberating or acid generating composite in the stimulation of a subterranean formation

ActiveUS20150330197A1Increase volumeImprove permeabilityFluid removalDrilling compositionParticulatesWater insoluble

Owner:BAKER HUGHES INC

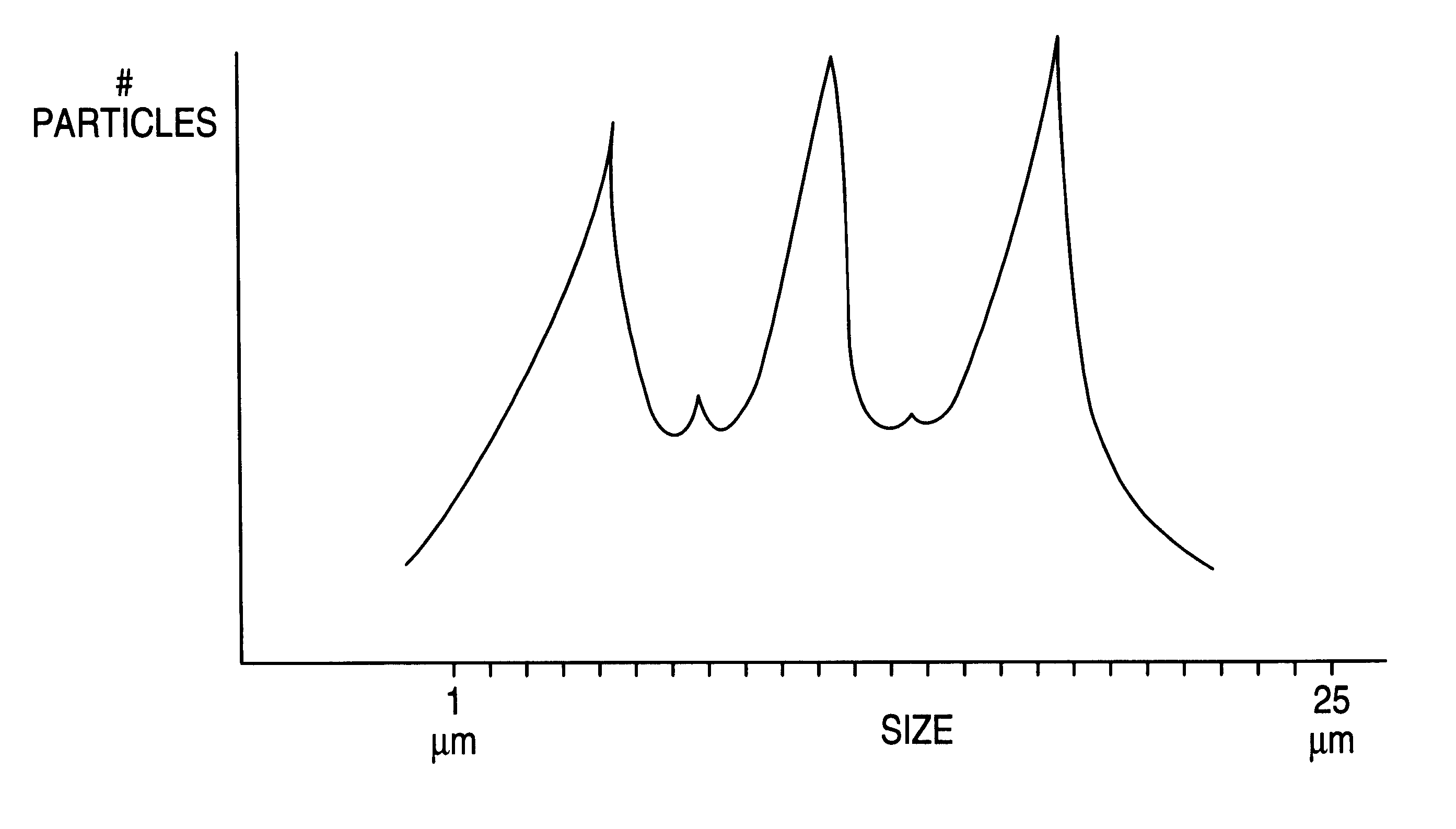

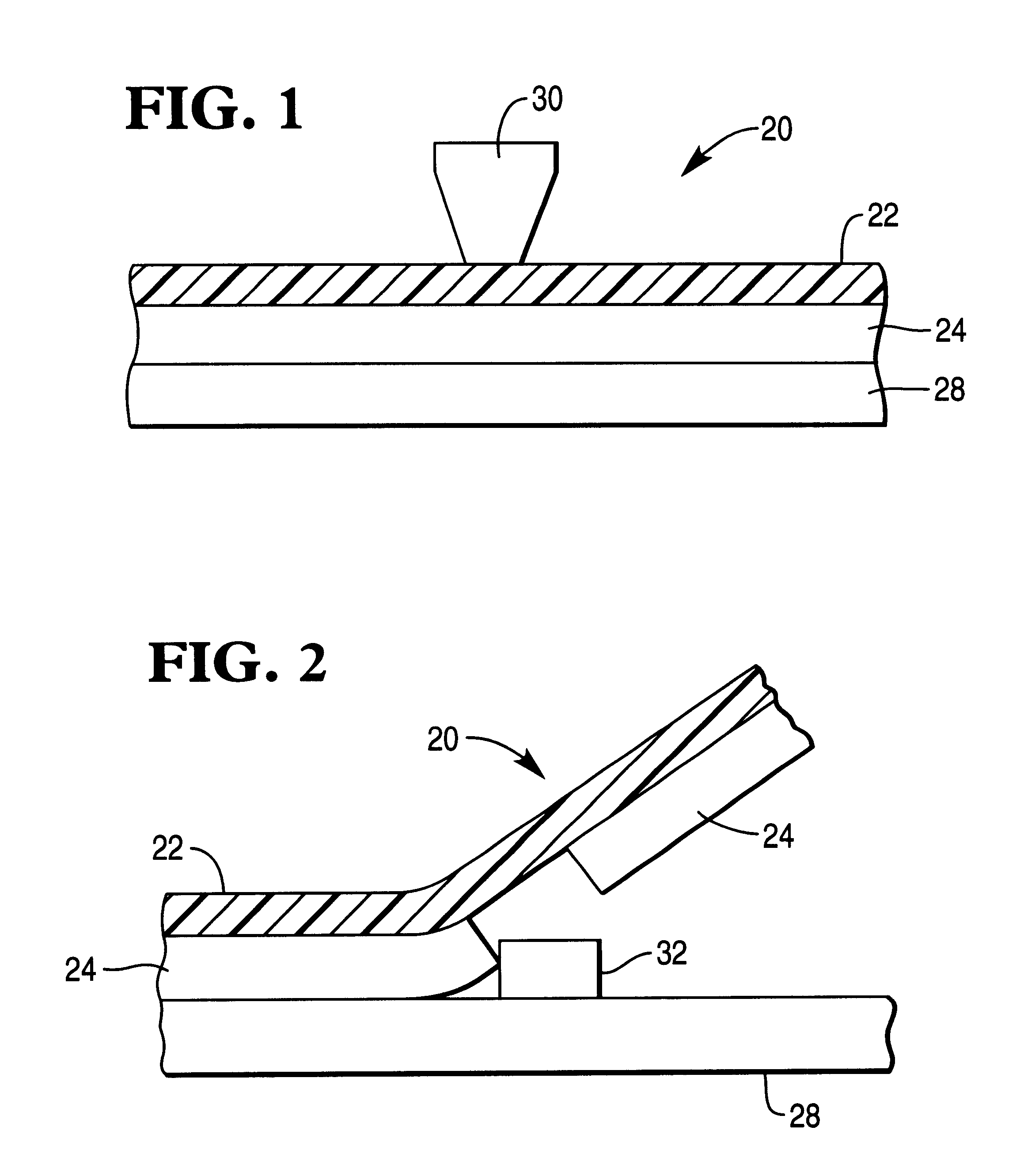

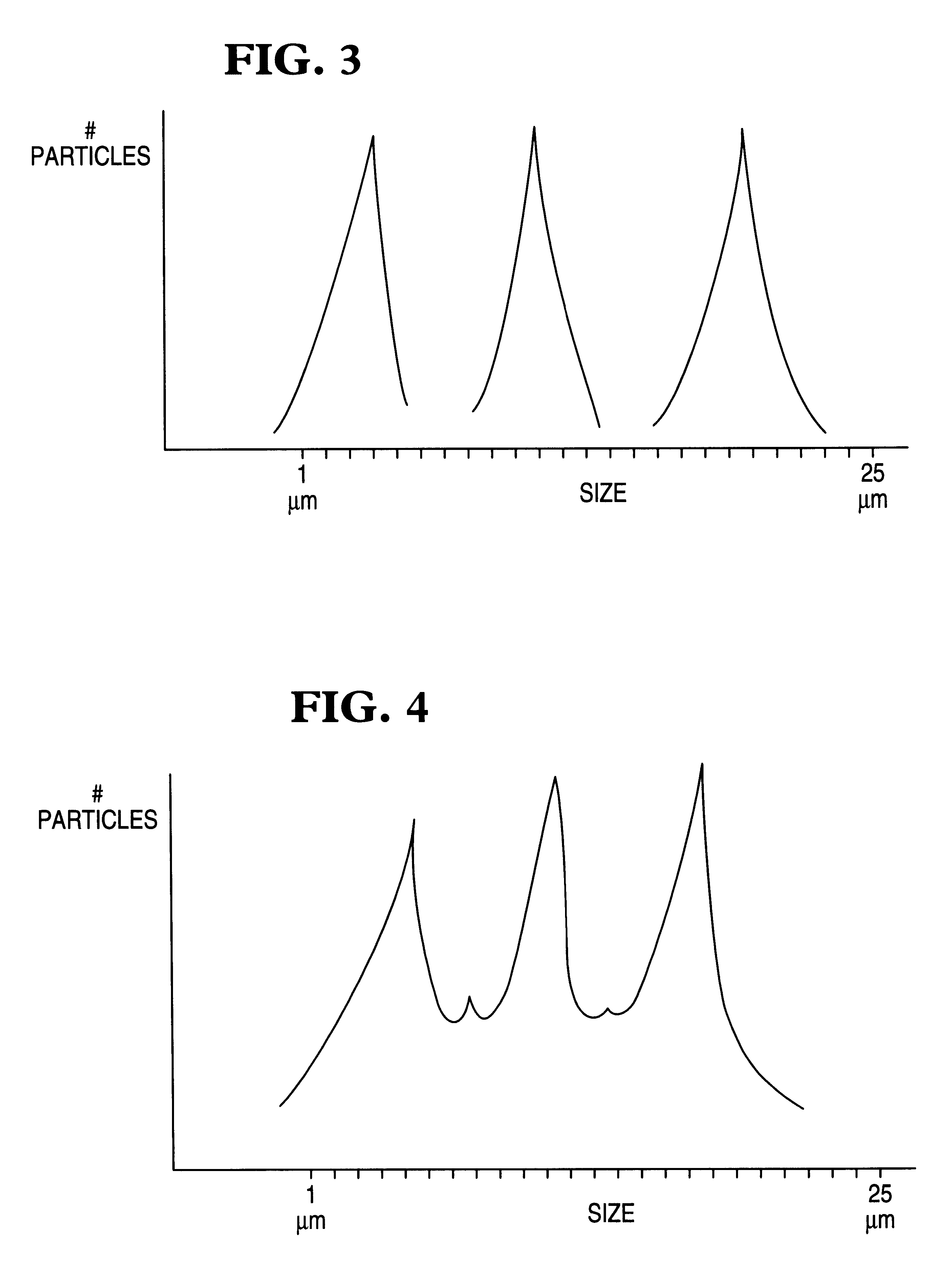

Thermal transfer media with a mixture of non-melting solid particles of distinct sizes

InactiveUS6171690B1Maintaining and reducing melt viscosityHigh densityLayered productsDomestic articlesHigh densitySolid particle

Owner:ICONEX LLC

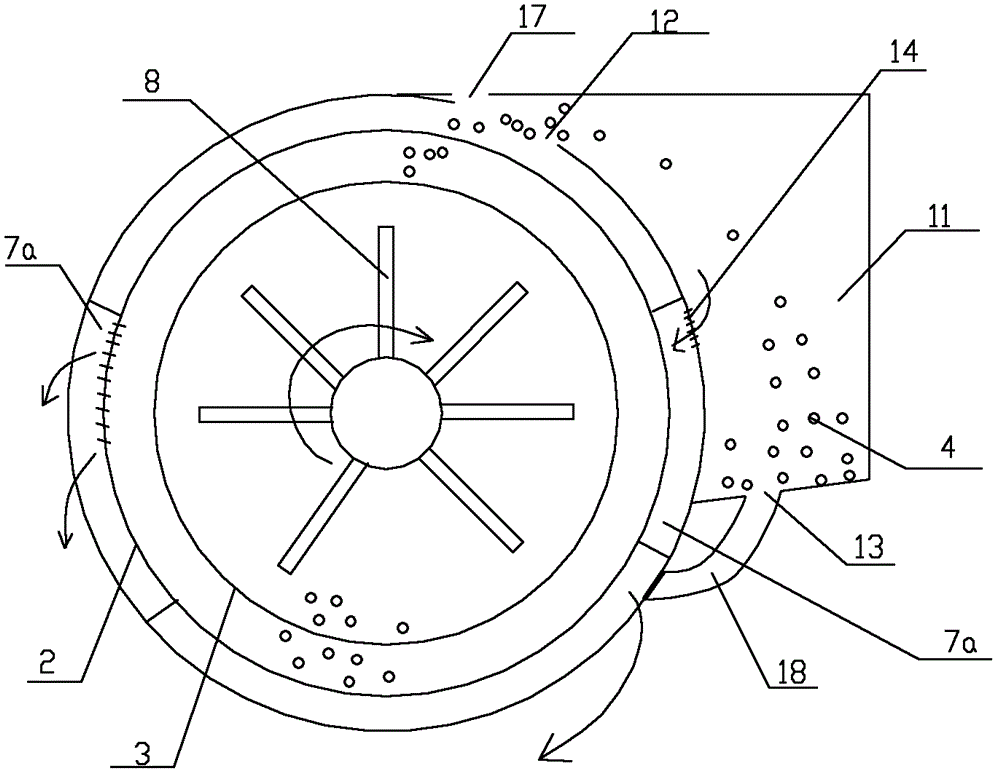

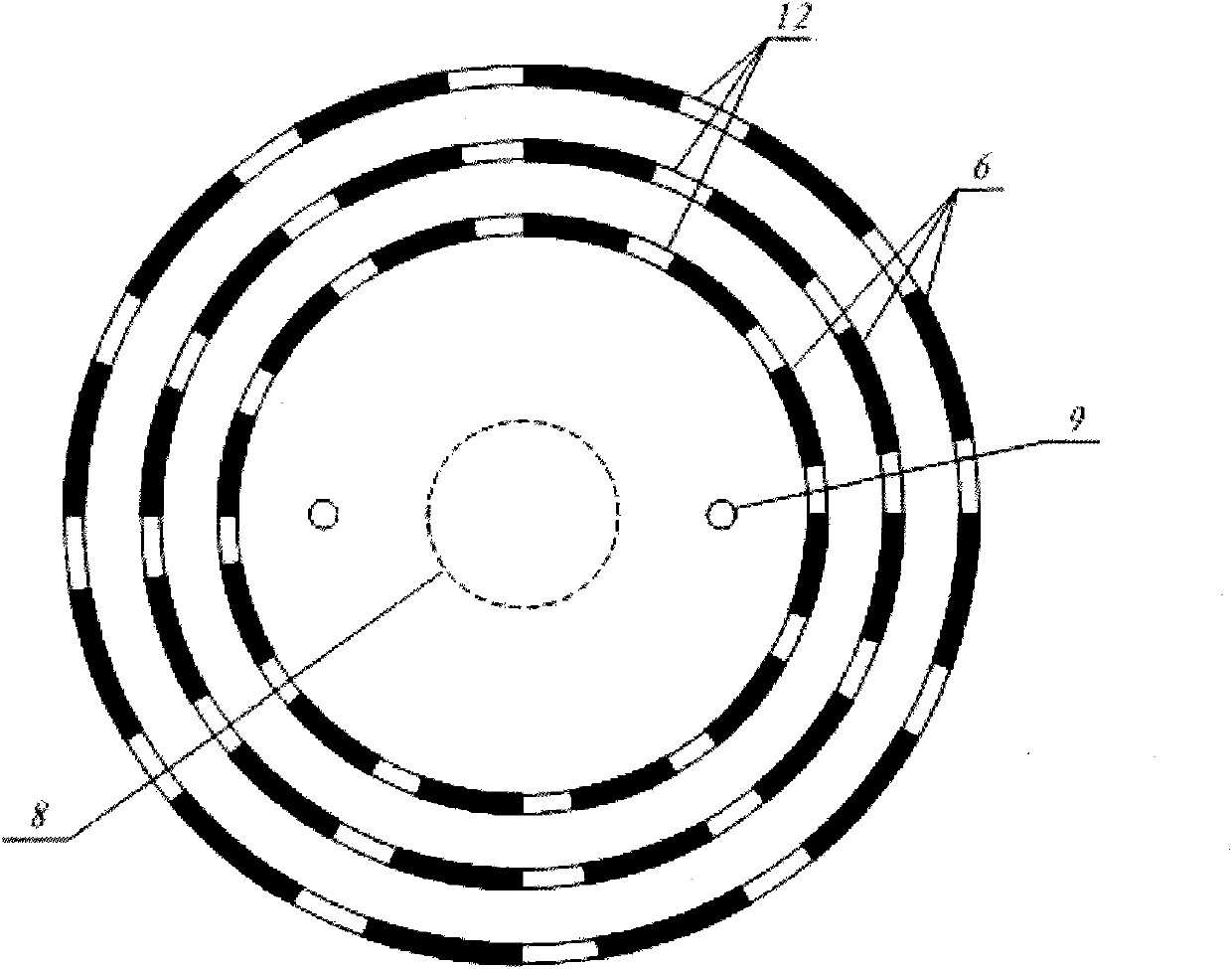

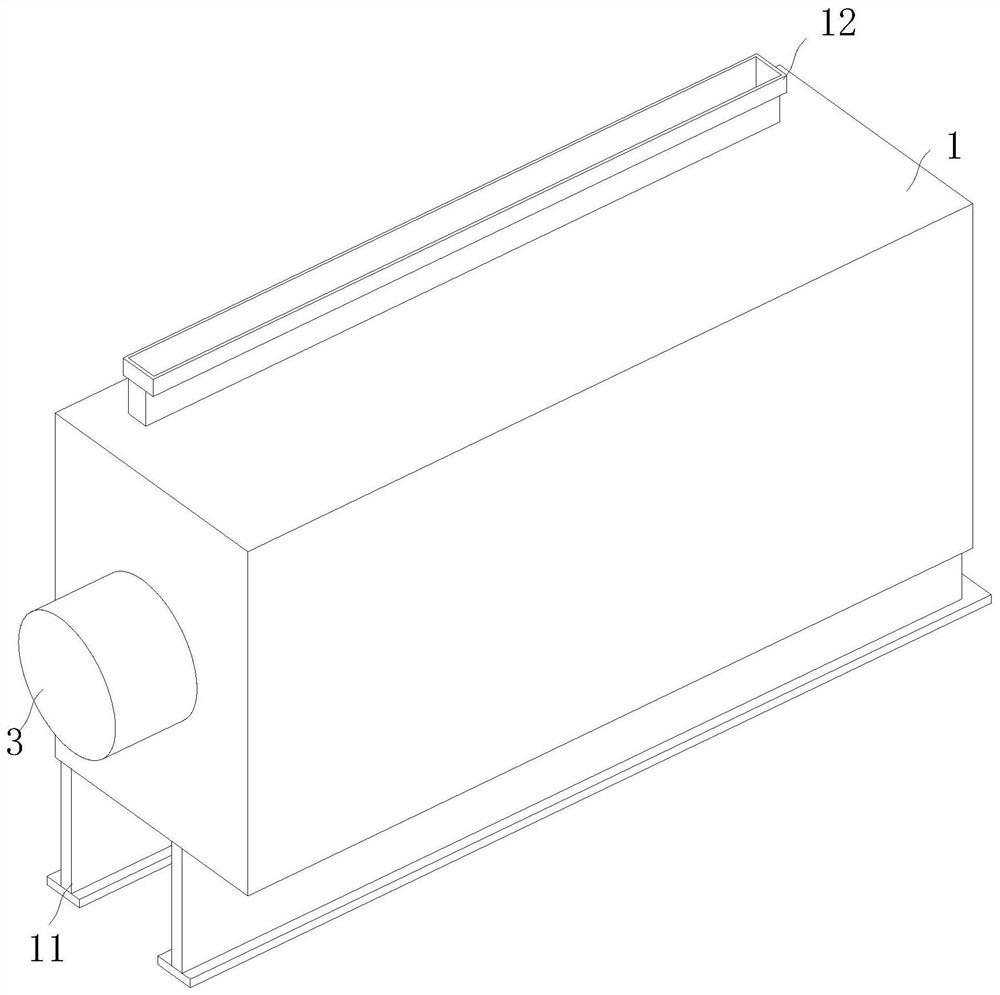

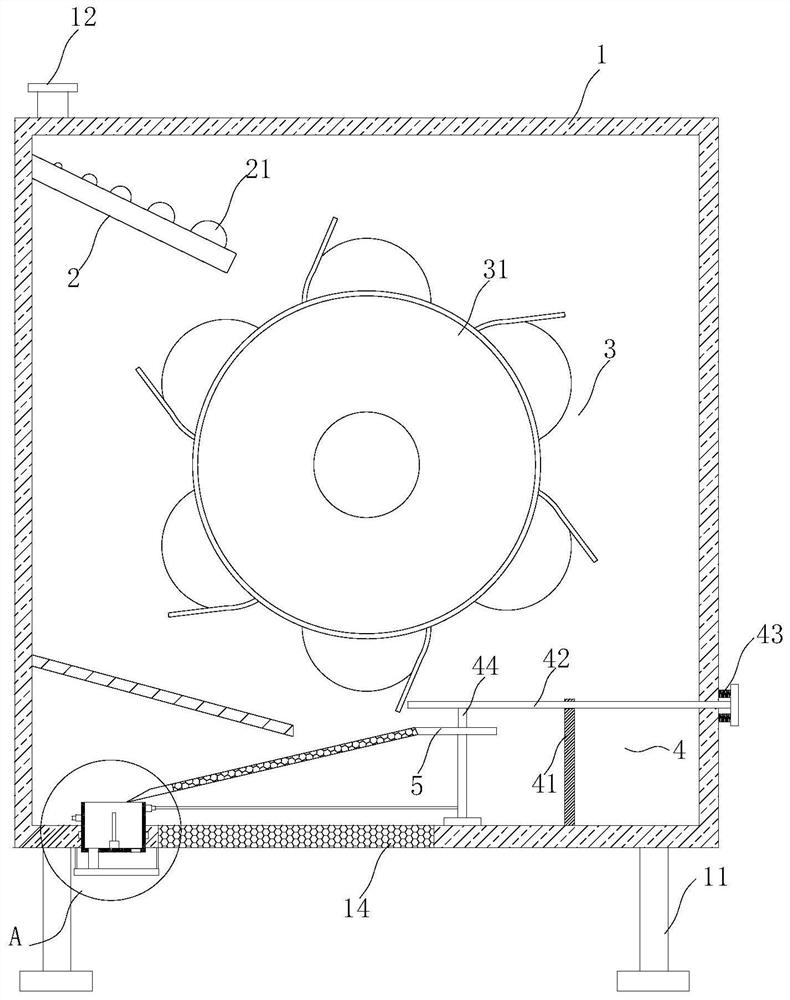

High-shear reactor with feed distribution device

InactiveCN101947427AAvoid cloggingUniform particle size distributionIsocyanic acid derivatives preparationOrganic compound preparationDrive shaftSolid particle

Owner:TIANJIN UNIV +1

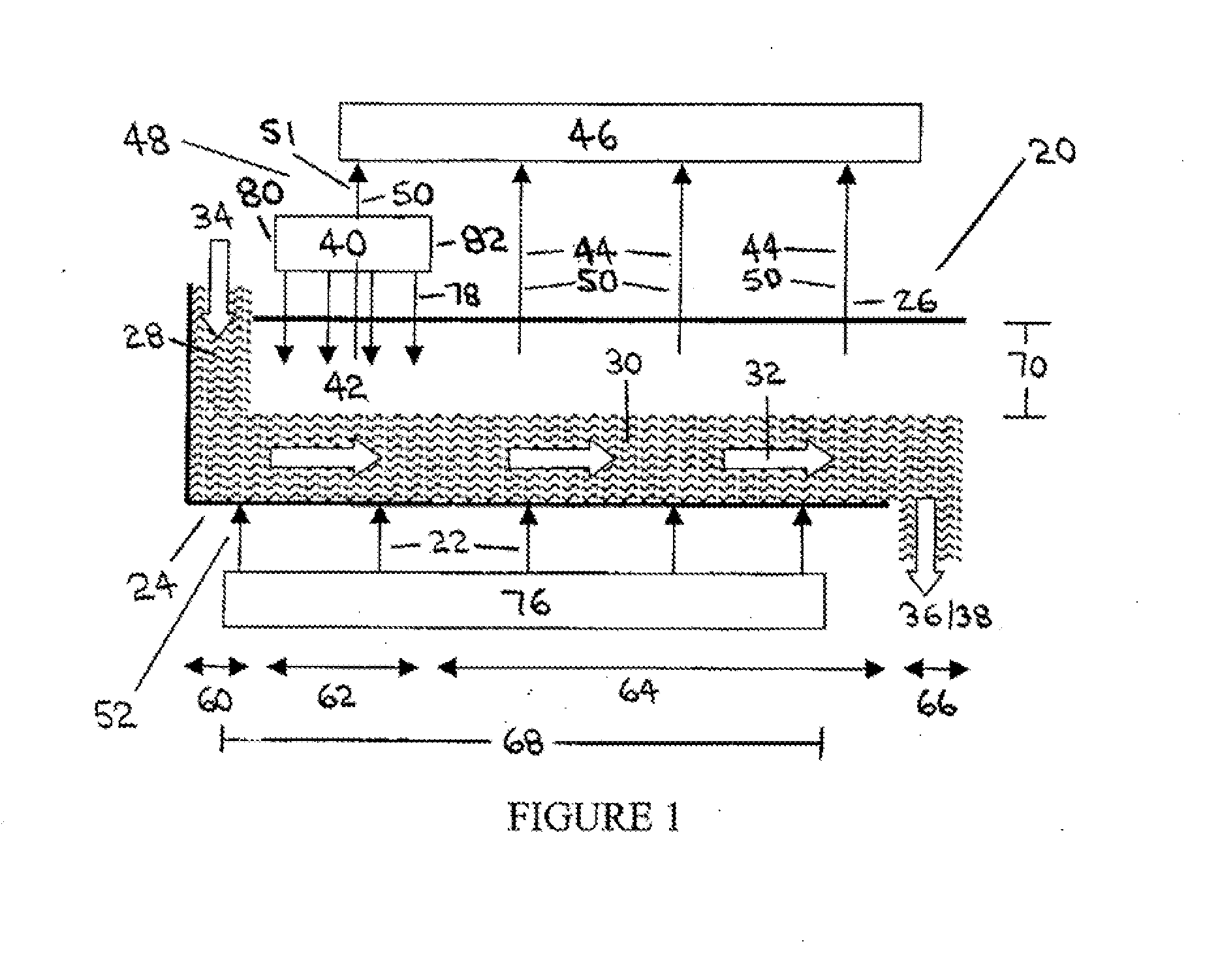

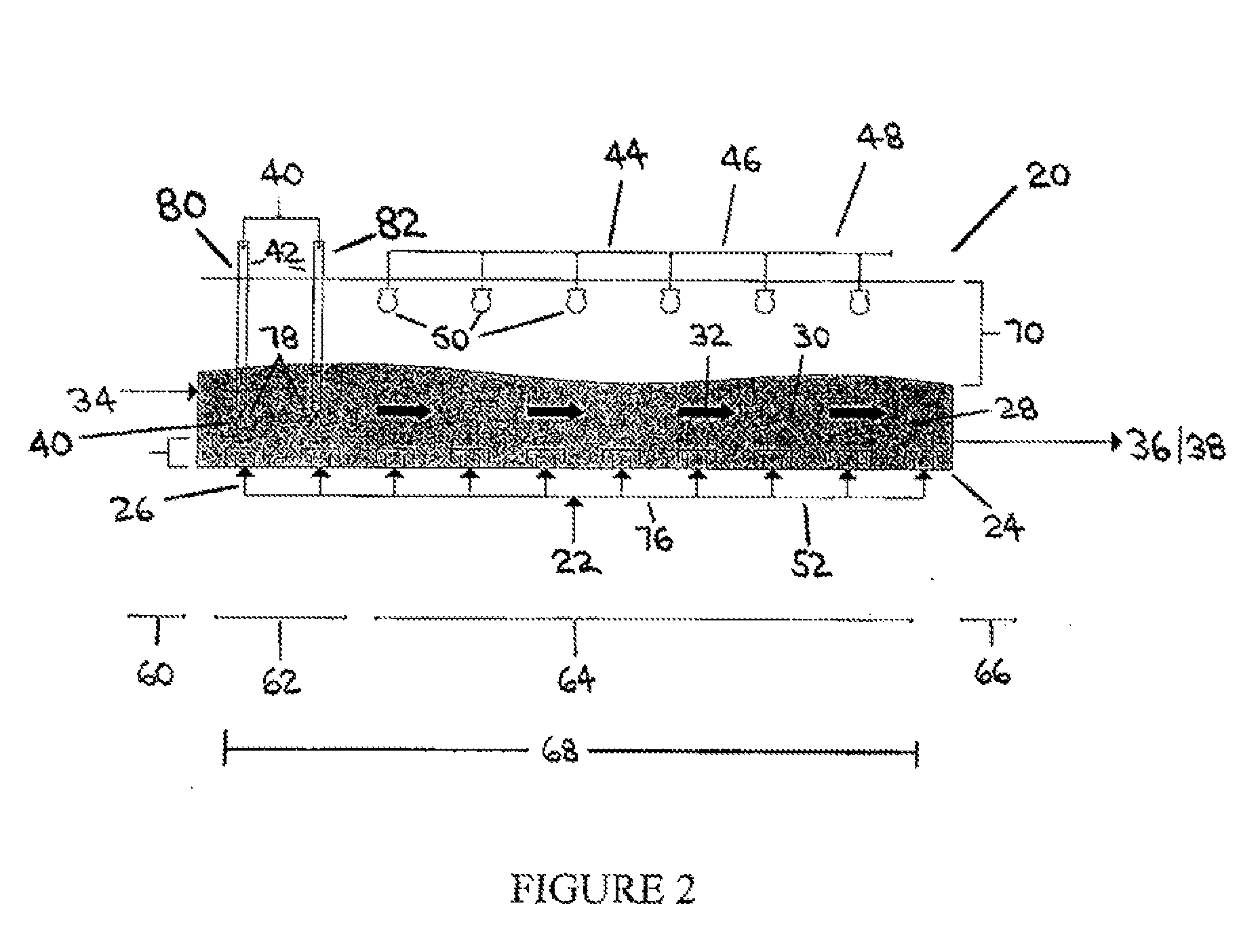

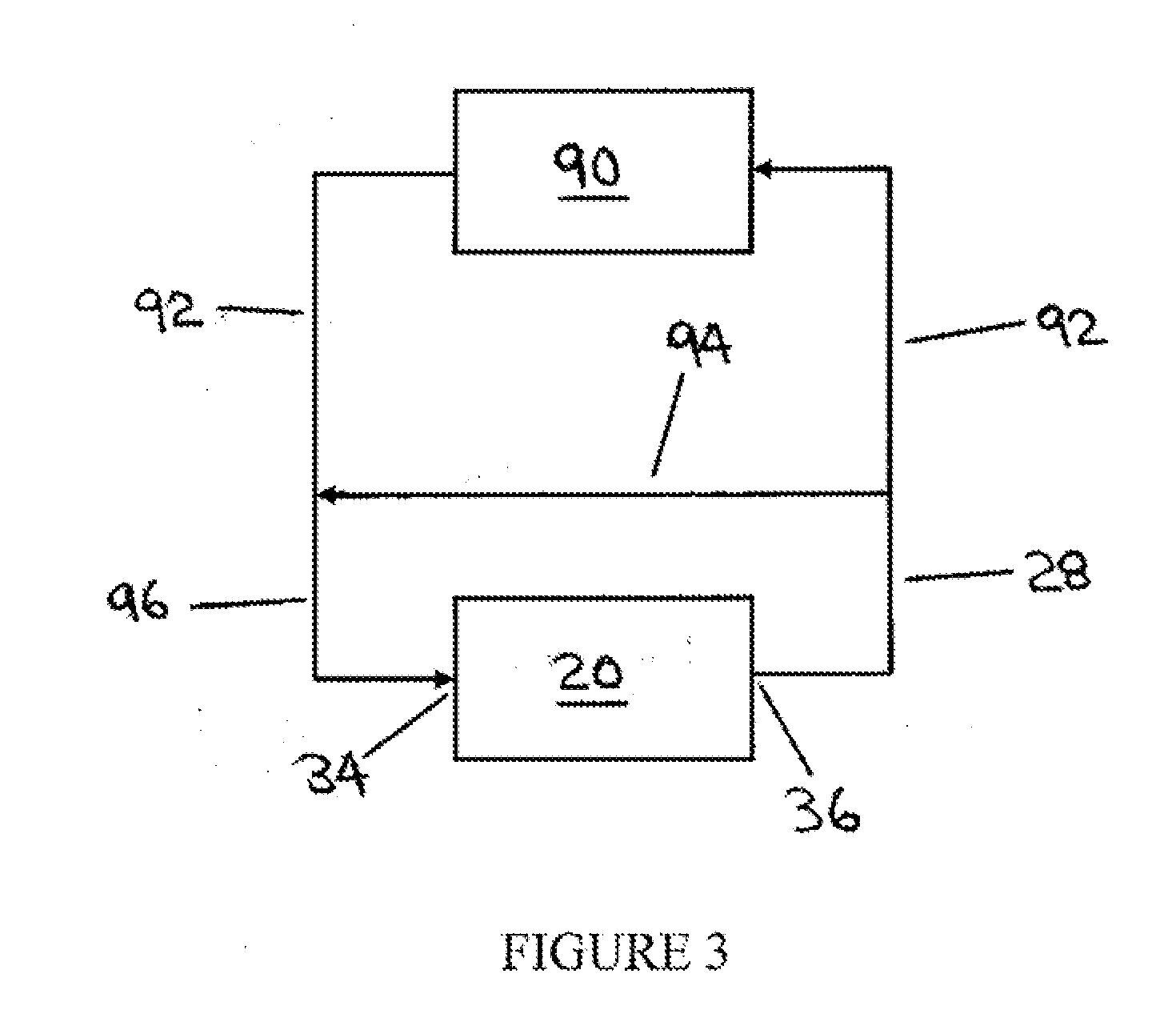

Process for converting a liquid feed material into a vapor phase product

InactiveUS20120211402A1High solids-to-oil ratioLower ratioThermal non-catalytic crackingRefining by heating/coolingFluidized bedGas phase

Owner:ETX SYST

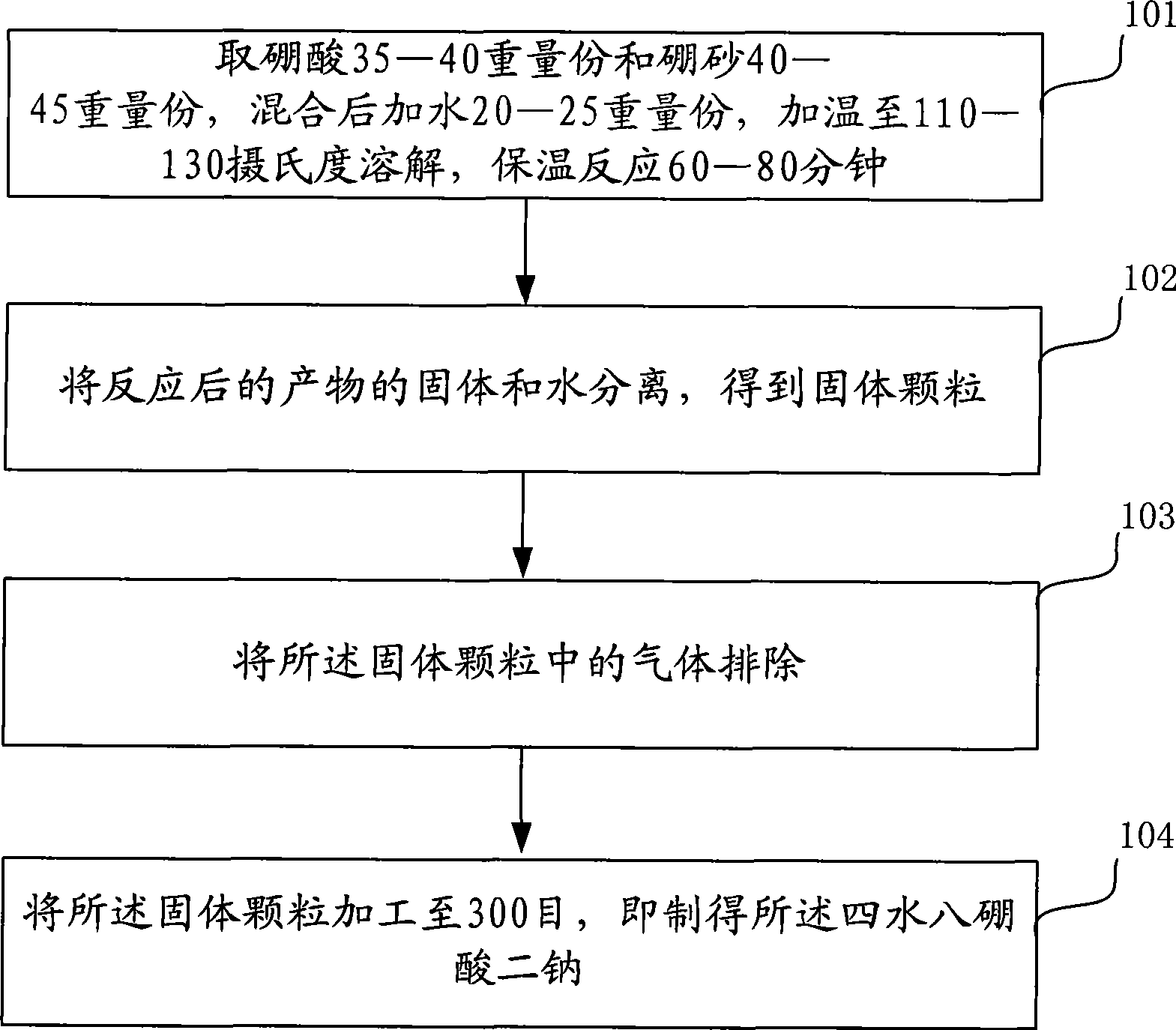

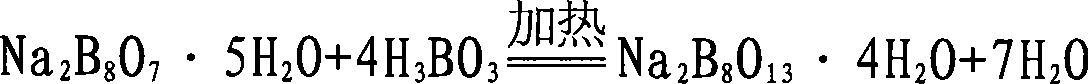

Method for preparing disodium octaborate tetrahydrate

InactiveCN101503200ABoratesSolid particleHydrate

Owner:杨保印

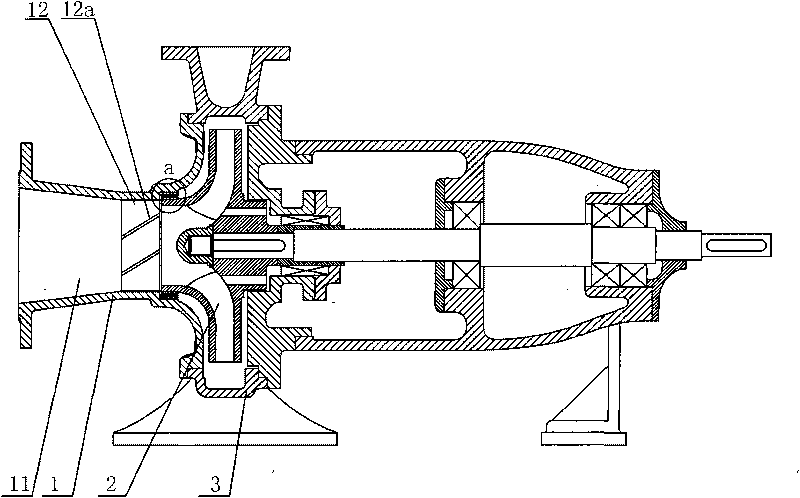

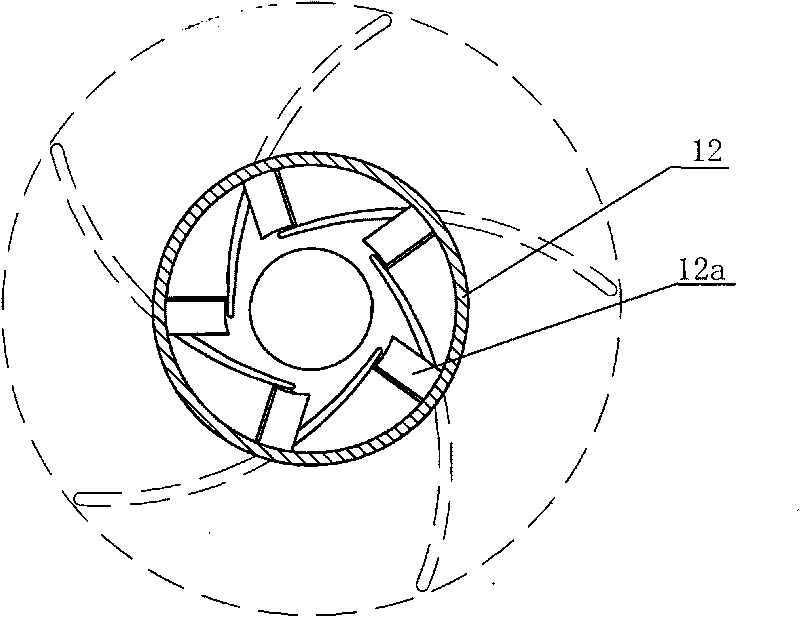

Novel high-efficient energy-saving pump

InactiveCN101709720AImprove efficiencySmooth speed changePump componentsRadial flow pumpsImpellerStraight tube

Owner:ZHEJIANG UNIV OF TECH

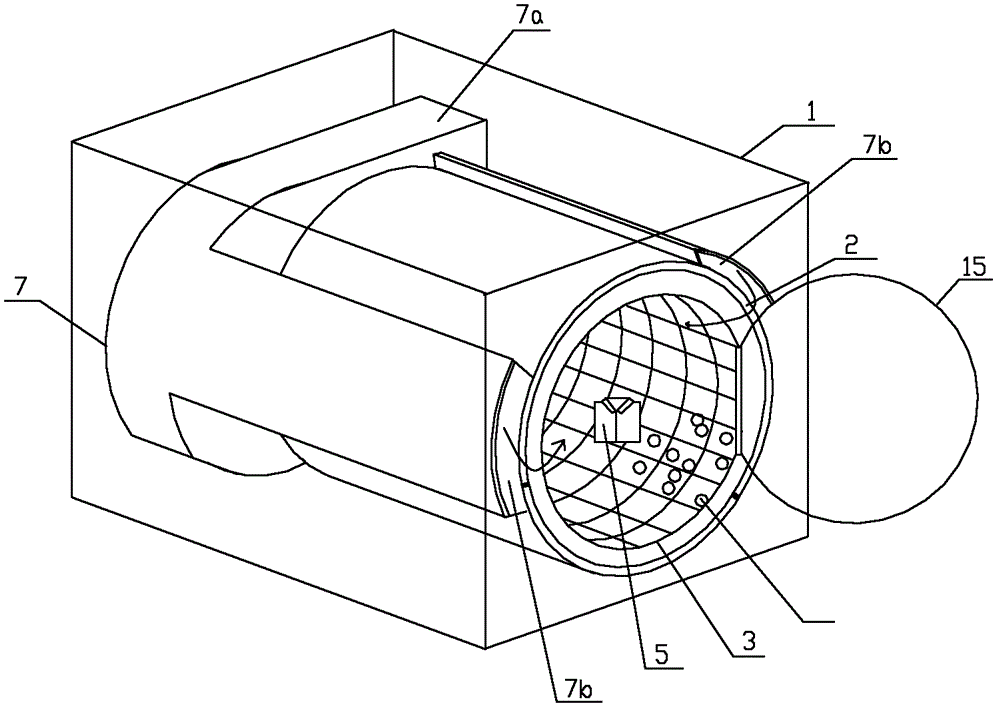

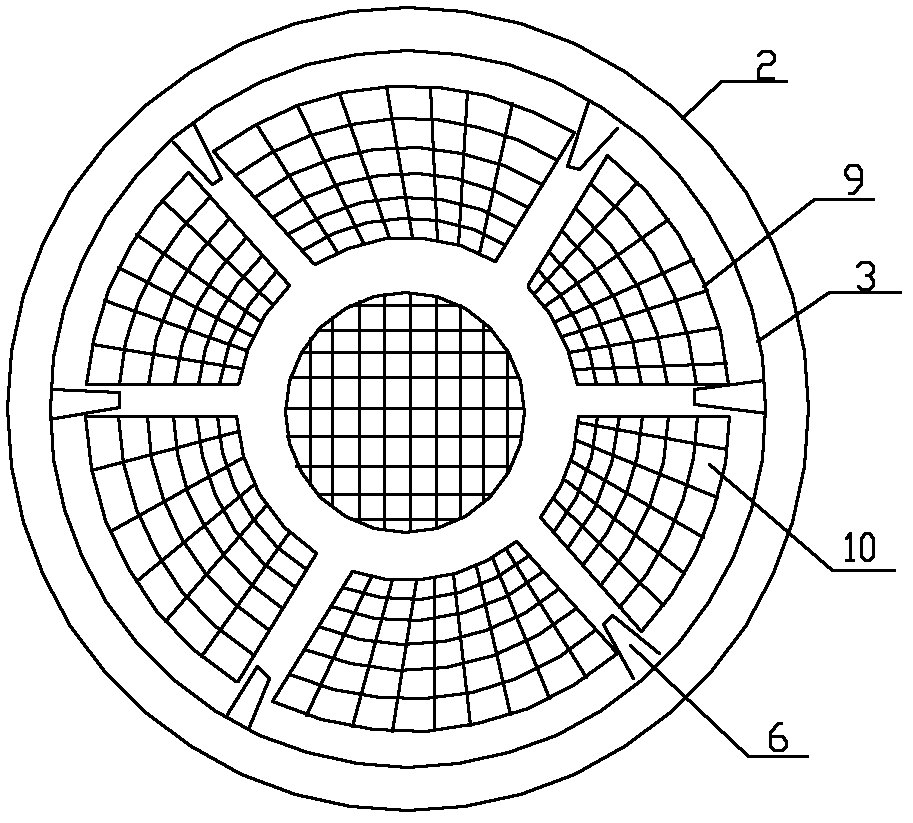

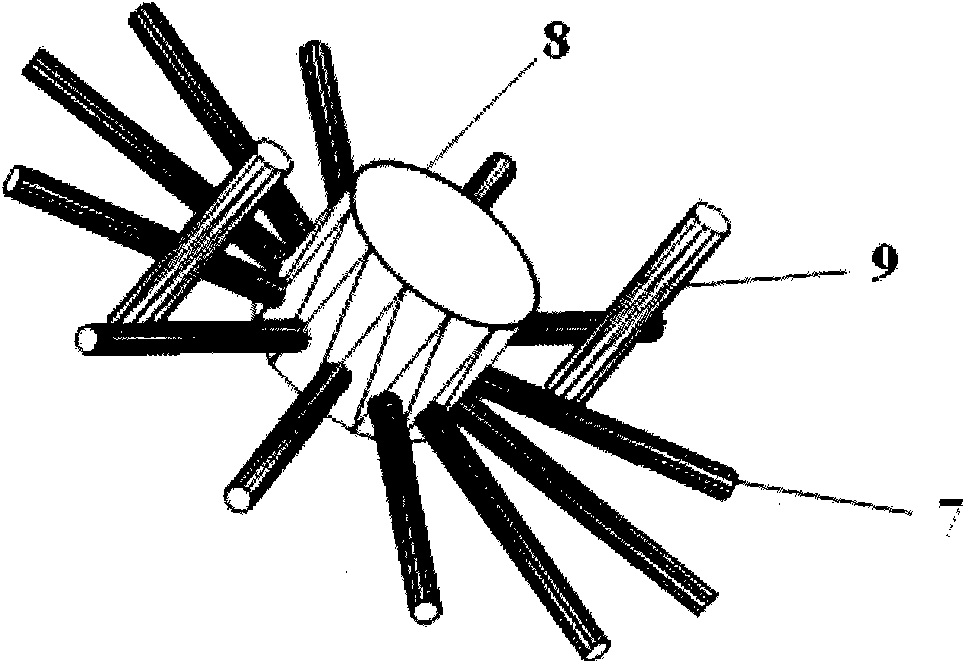

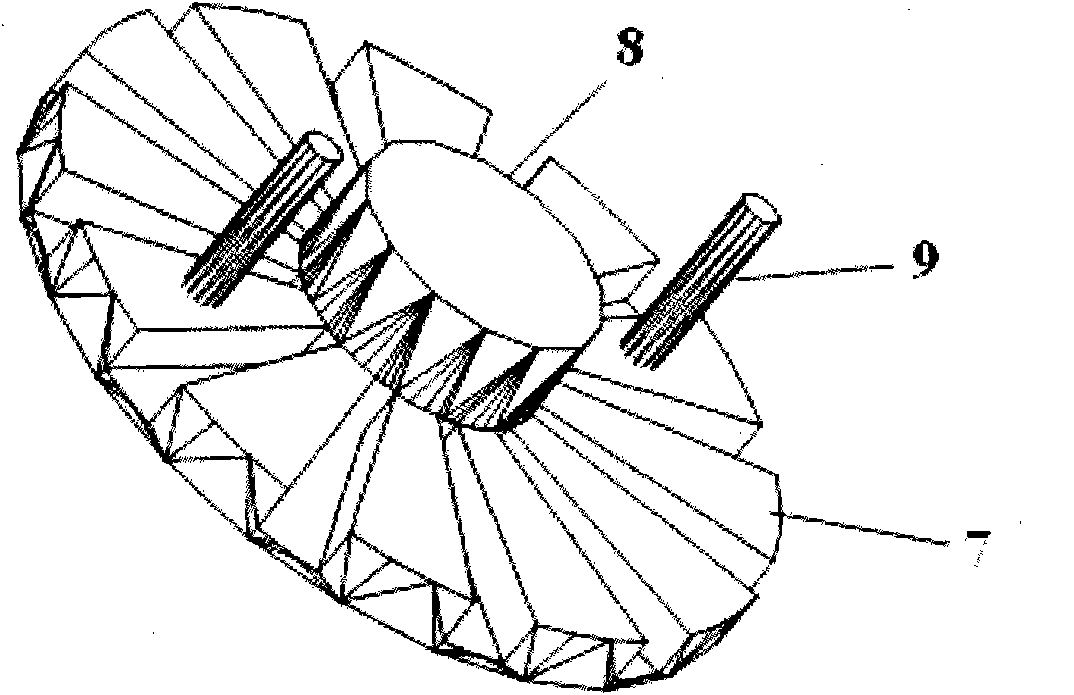

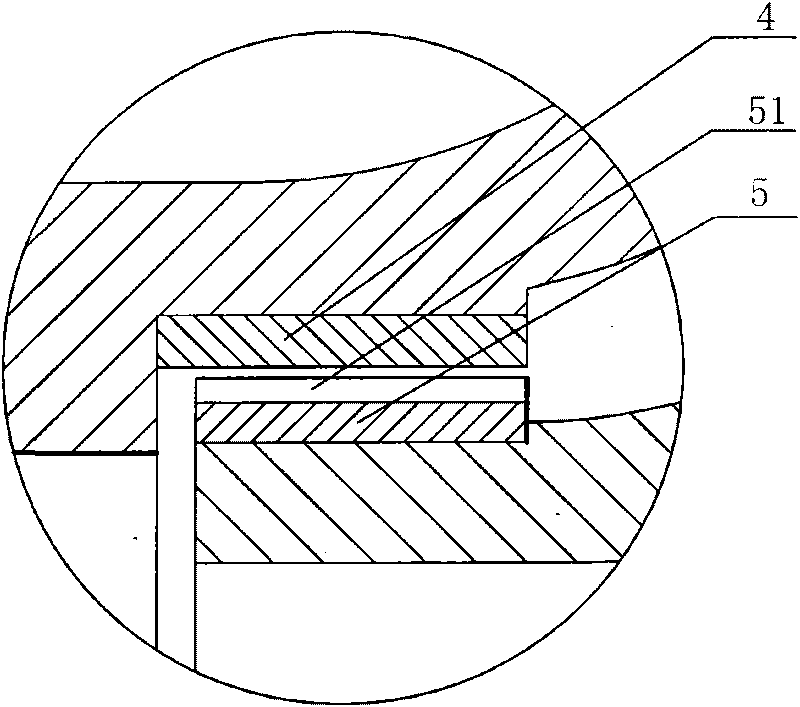

Lossless super-cavitation centrifugal pump impeller

ActiveCN106337835APrecise design methodReduce friction lossPump componentsPumpsCavitationSolid particle

The invention relates to a lossless super-cavitation centrifugal pump impeller. The impeller is mainly composed of blades (1), an impeller front cover plate (2) and an impeller rear cover plate (3) and mainly characterized in that geometric structures of the super-cavitation blade pump blades (1) are modified, and according to the requirements of different design conditions, single short super-cavitation blades or combined blades combining the super-cavitation blades and non-overloading blades are adopted; and geometric shapes of blade inlets are modified to simultaneously meet the super-cavitation requirement and the requirement of allowing larger solid particles to pass through the impeller without a plunger, the blades in the impeller are prevented from being abraded by the large solid particles in the operating process, the frictional resistance to the blades in the operating process can be effectively reduced, the working efficiency of a super-cavitation pump is improved, and the service life of the super-cavitation pump is prolonged.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH

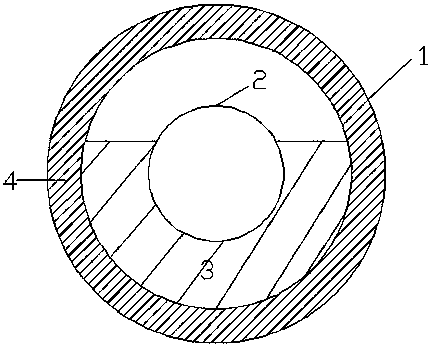

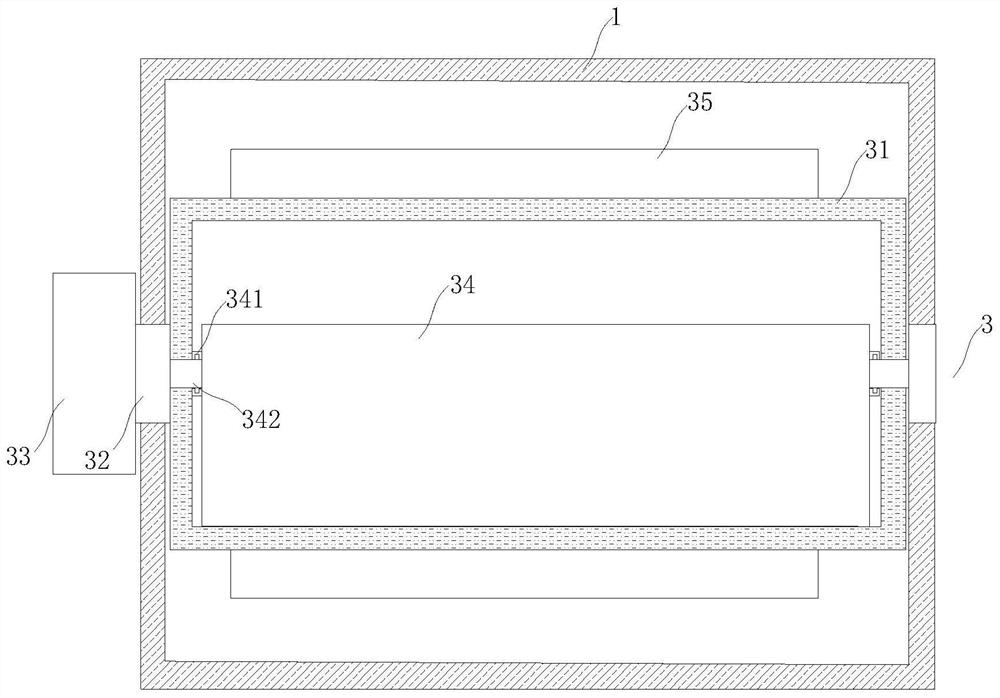

Nested and filled type particle damper

InactiveCN108547498ANear steady stateReduce quality problemsProtective buildings/sheltersShock proofingSolid massSolid particle

Owner:TONGJI UNIV

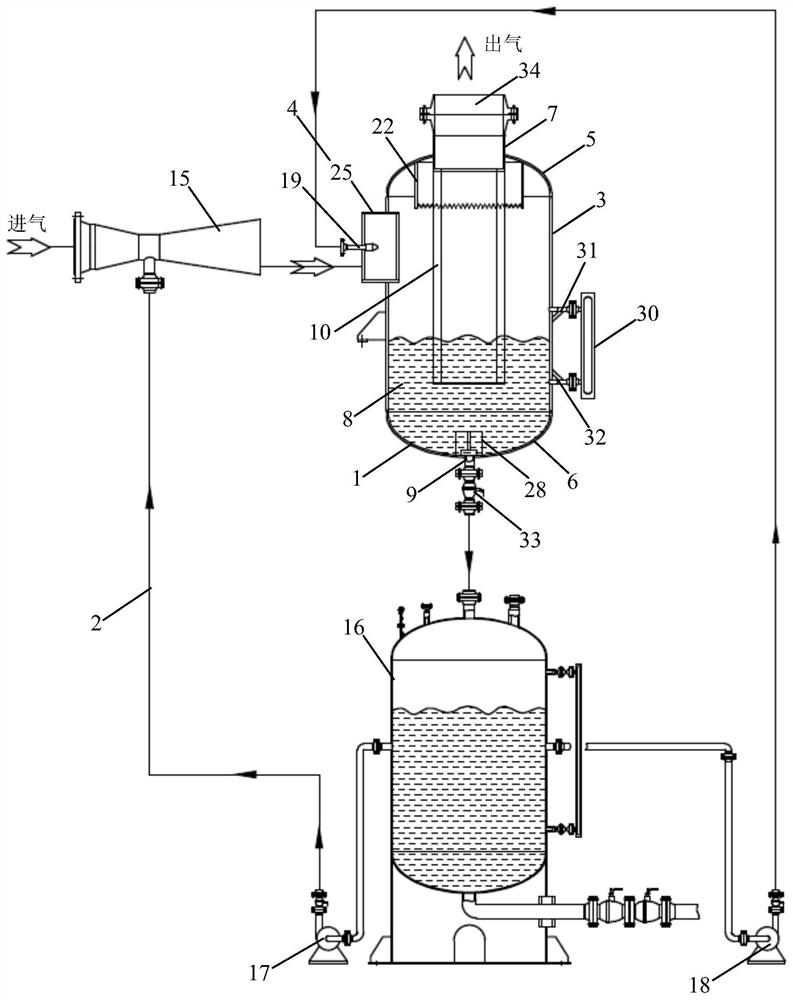

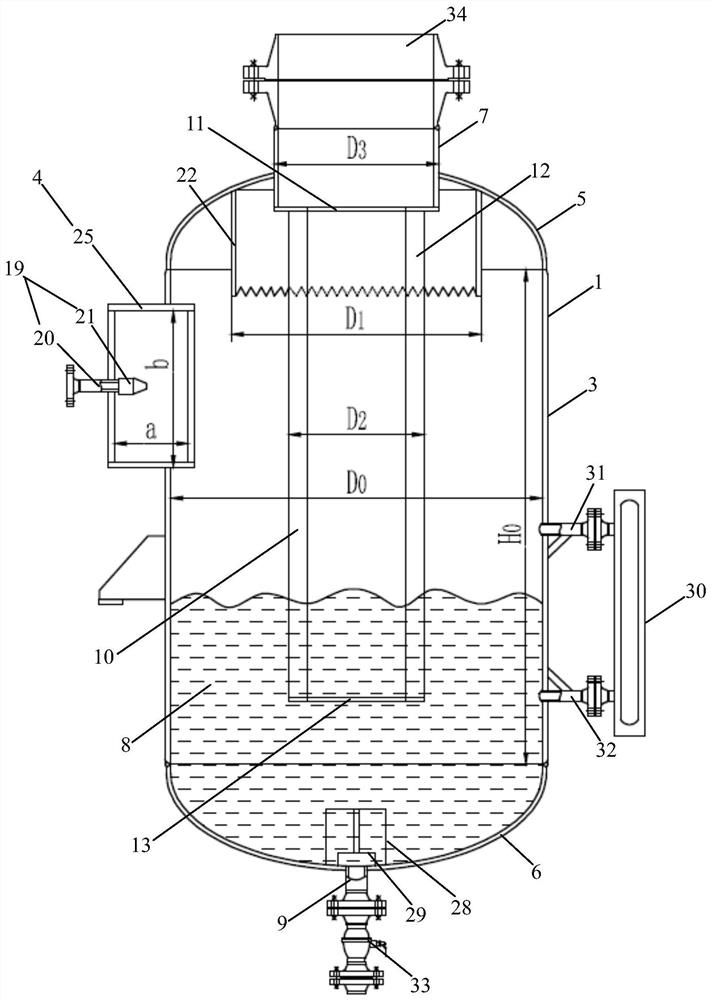

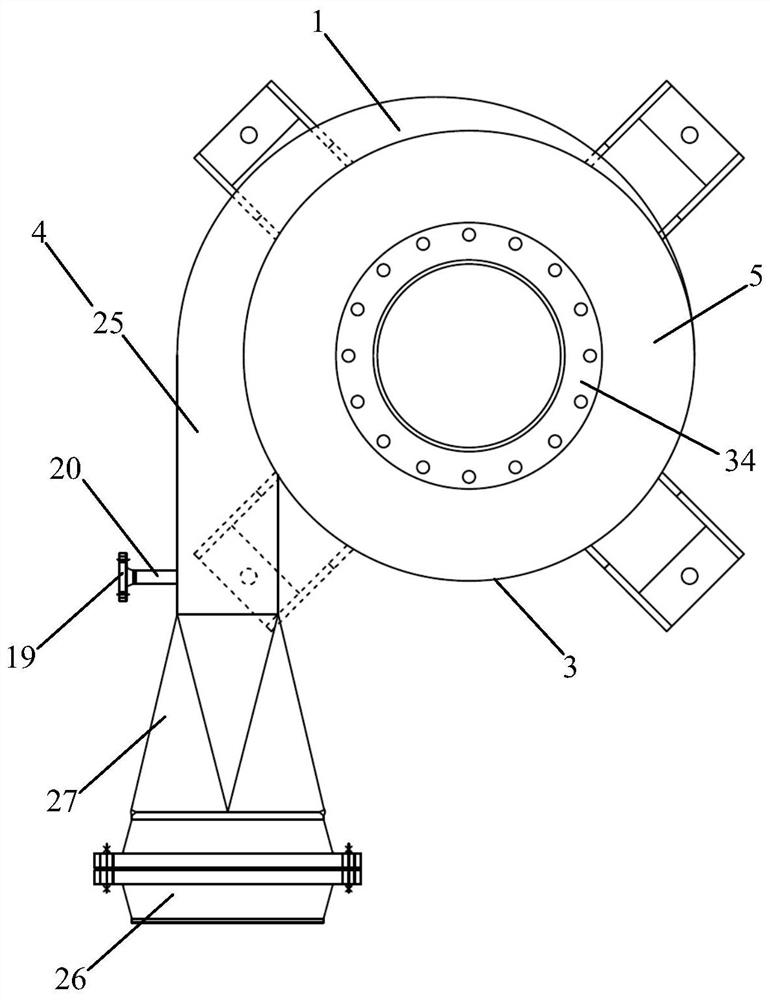

Efficient cyclone separator adopting liquid washing

PendingCN113041718AImprove separation efficiencyHigh Cyclone Collection EfficiencyDispersed particle separationEngineeringSolid particle

Owner:上海卓旋化工科技有限公司

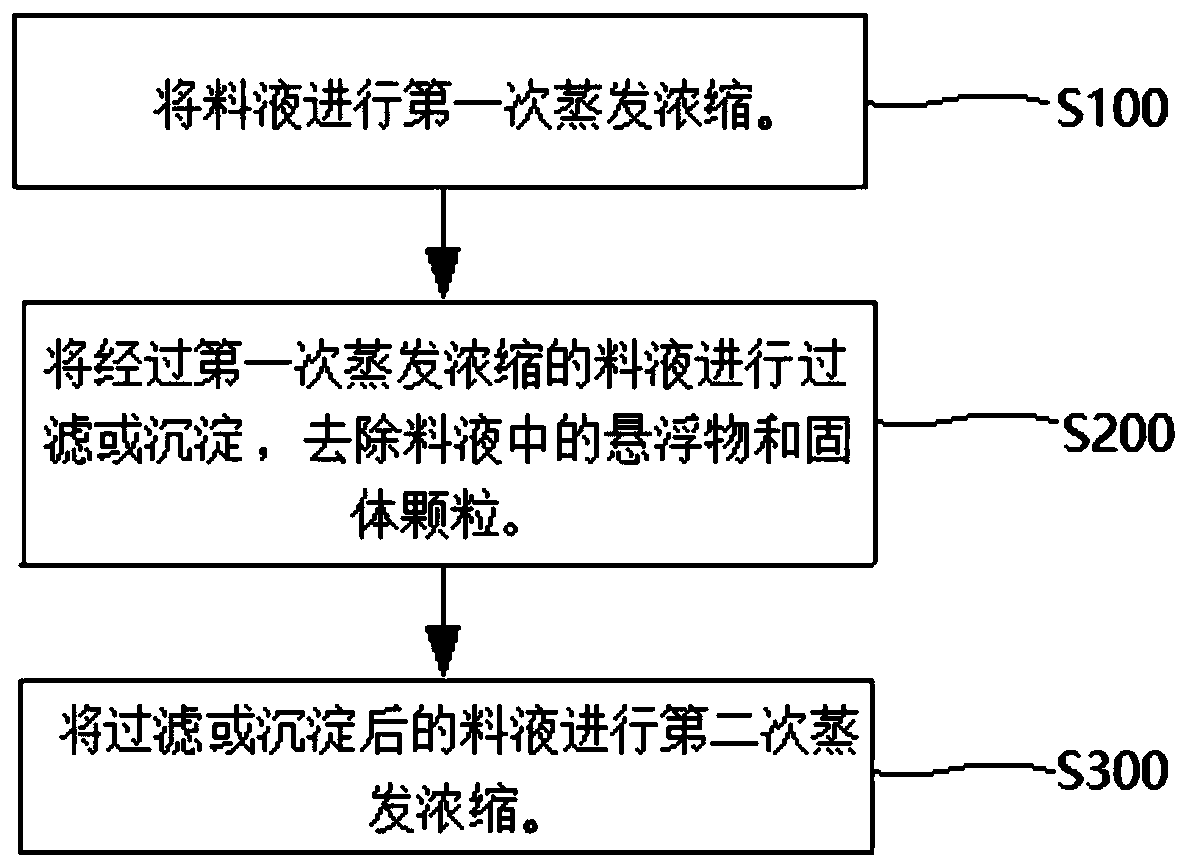

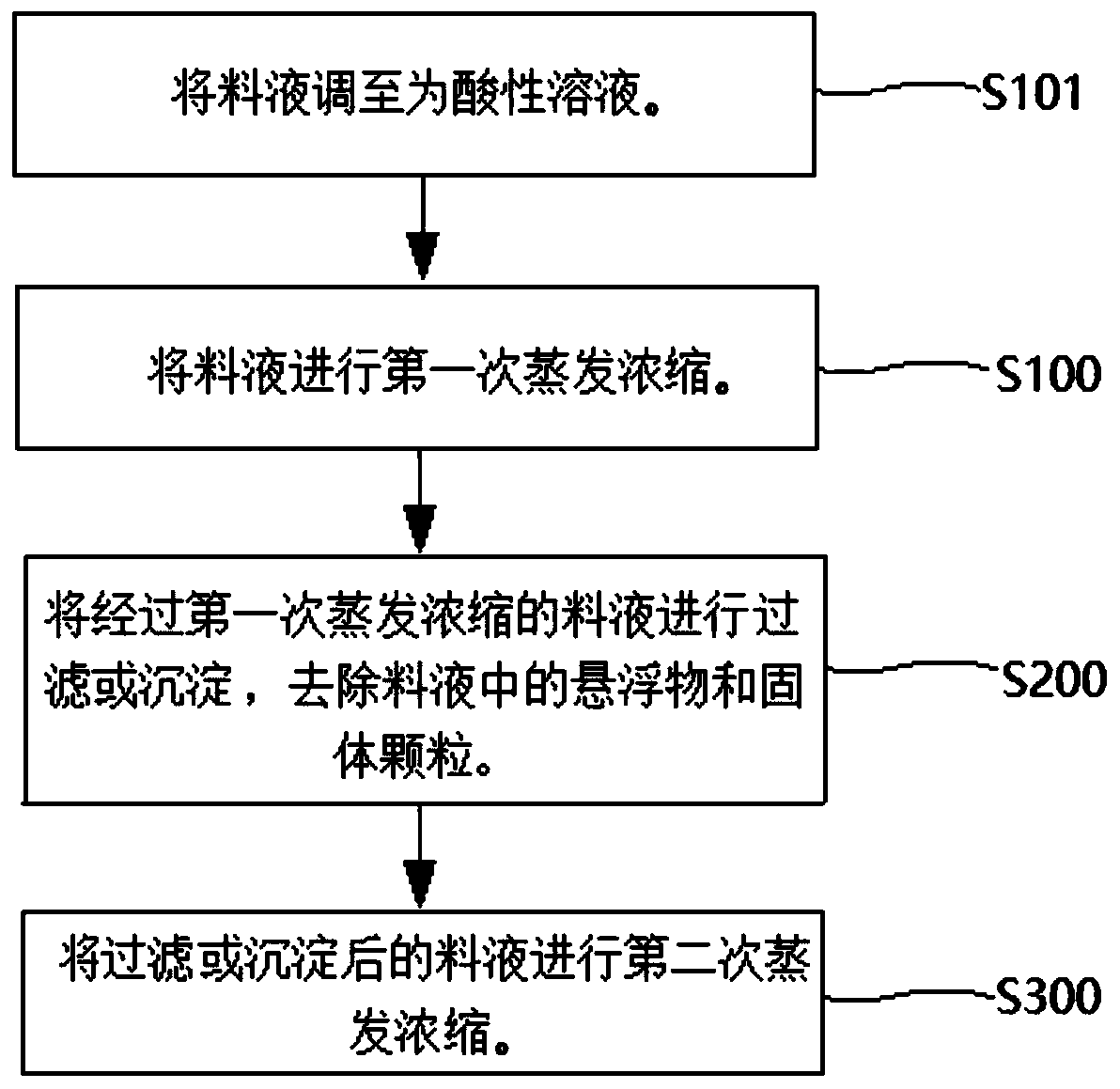

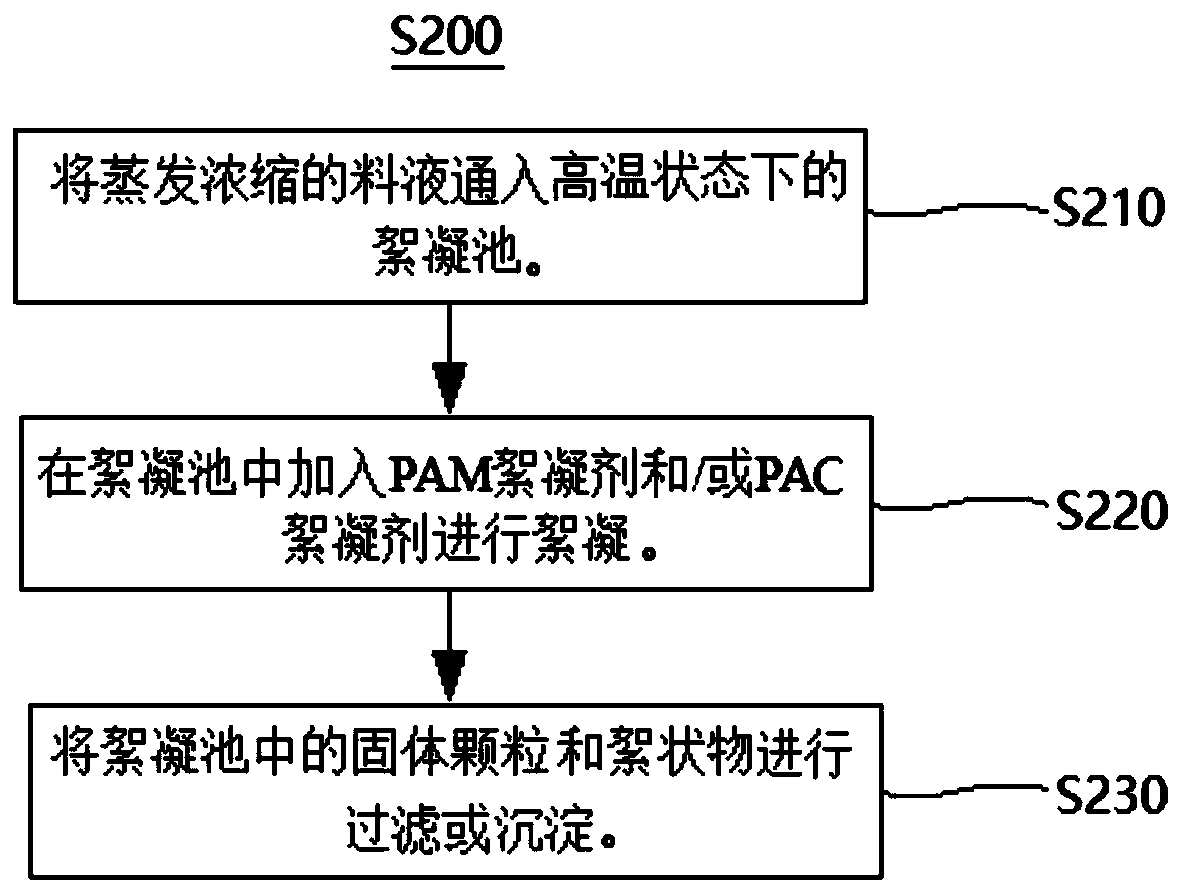

Percolate concentrated solution evaporation and concentration method and system

PendingCN111423047ANo lossAvoid inefficient heat transferTreatment involving filtrationMultistage water/sewage treatmentHeat transfer efficiencySolid particle

The embodiment of the invention provides a percolate concentrated solution evaporation and concentration method and system. The percolate concentrated solution evaporation and concentration method comprises the steps: carrying out primary evaporation and concentration on feed liquid; filtering or precipitating the feed liquid subjected to primary evaporation and concentration to remove suspended matters and solid particles in the feed liquid; and carrying out secondary evaporation and concentration on the filtered or precipitated feed liquid. According to the percolate concentrated solution evaporation and concentration method provided by the invention, the evaporation process of the leachate concentrated solution is divided into two parts; the operation pressure of the equipment is reduced; filtration or precipitation is carried out after the first evaporation and concentration; the reduction of the heat transfer efficiency of equipment caused by inorganic scaling and blockage of organic slime attached to a heat exchanger in the evaporation process of the leachate concentrated solution and unability to function properly are effectively avoided; and the filtering or precipitating process is carried out at high temperature, so that heat loss is avoided, the cleaning period of the equipment is shortened, and meanwhile, the evaporation and concentration continuous efficiency is improved.

Owner:BEIJING TDR ENVIRON TECH CO LTD

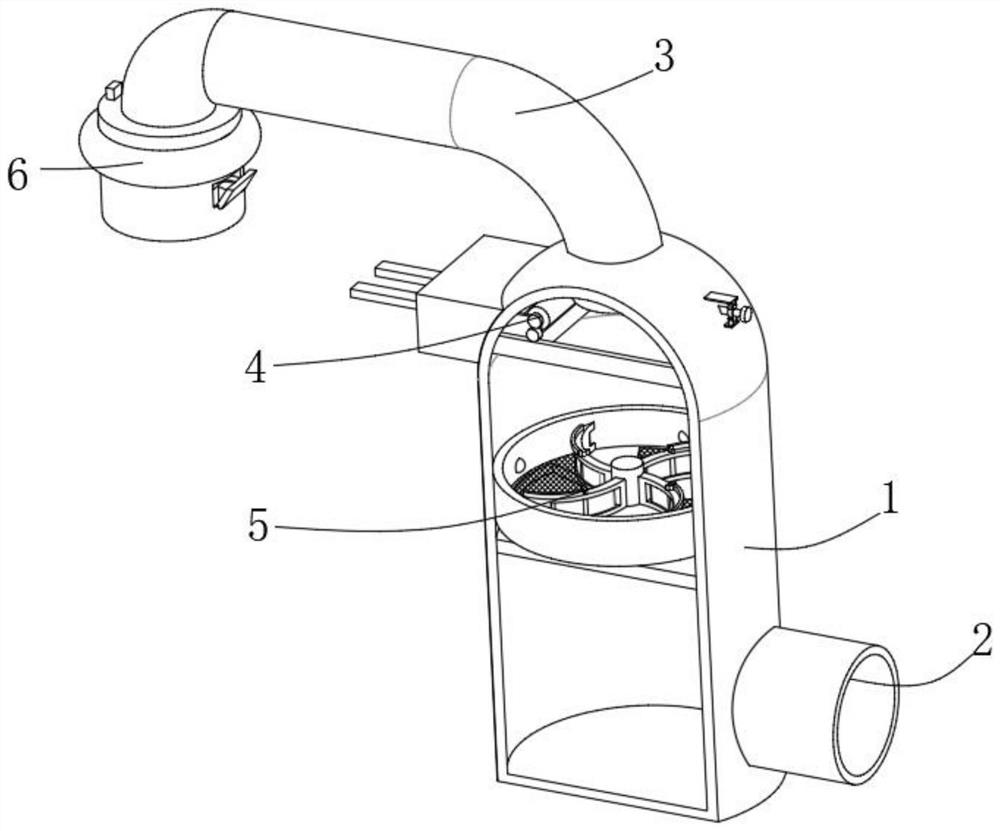

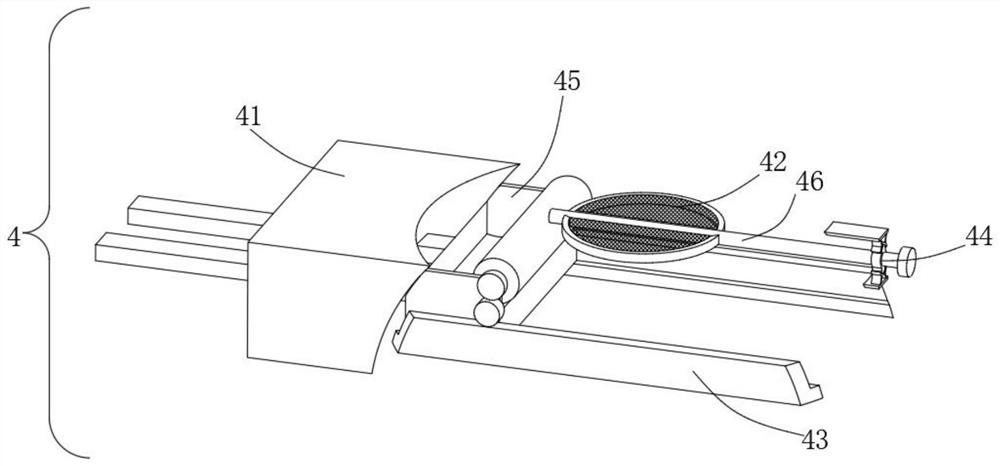

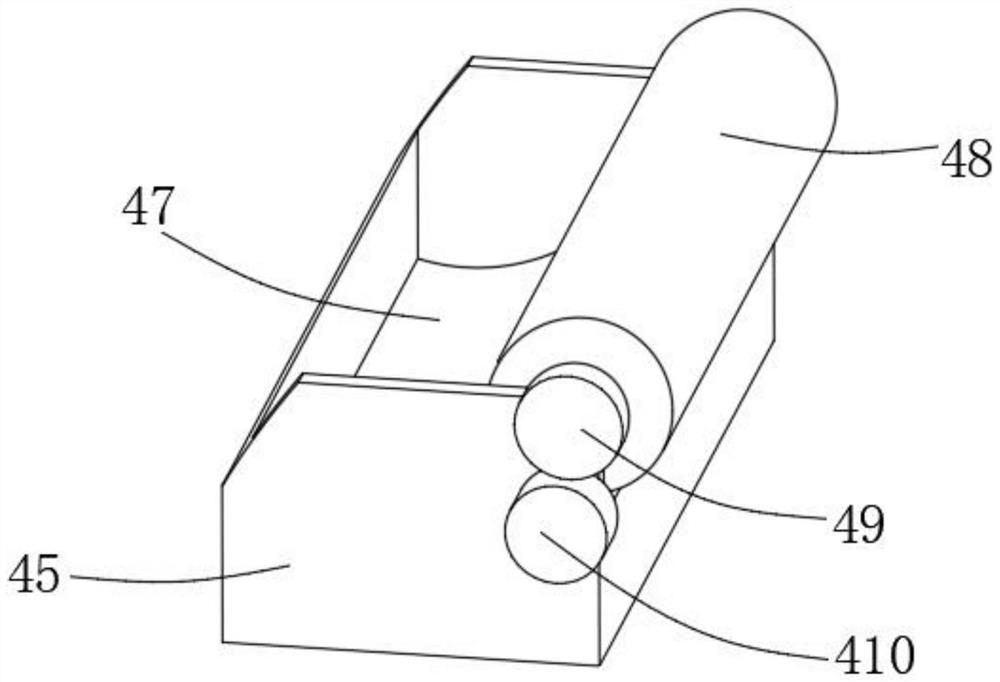

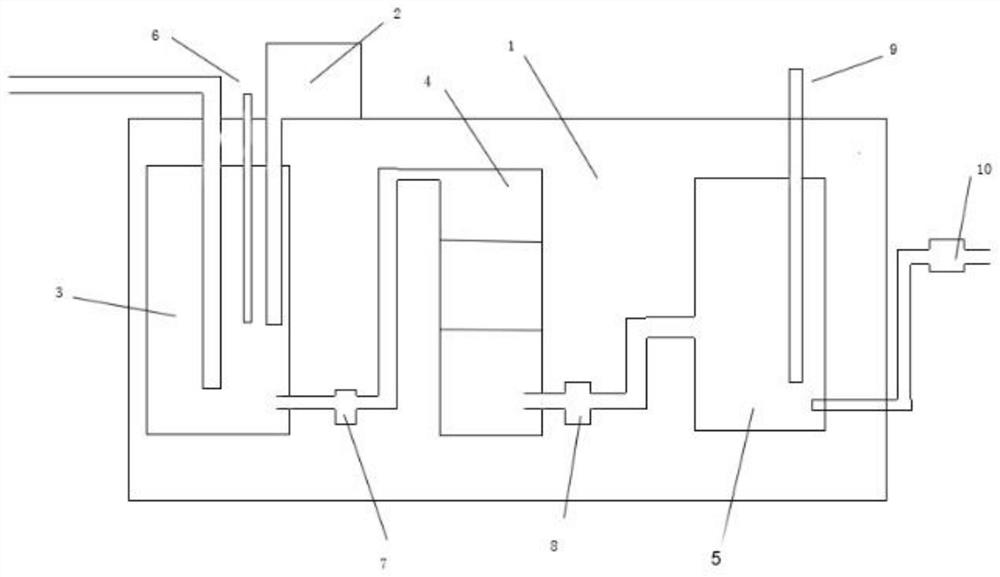

Flue gas semi-dry desulfurization device and method

ActiveCN111545042ASolve the increase in production costsReduce manufacturing costGas treatmentDispersed particle separationFlue gasAir pump

The invention discloses a flue gas semi-dry desulfurization device and method. The device comprises a shell assembly, a desulfurization assembly, a dedusting assembly, a fan and a precipitation tank;the shell assembly comprises a shell, an air inlet pipe and an air outlet pipe; the air inlet pipe is fixedly connected with the shell and extends into the shell; the air outlet pipe is fixedly connected with the shell and away from the air inlet pipe. The desulfurization assembly comprises a desulfurizing agent box and a first spray head; the first spray head is fixedly connected with the desulfurizing agent box; the first spray head extends into the air inlet pipe, a fan and the shell are fixedly connected, and the first spray head penetrates through the air inlet pipe; the dedusting assembly comprises an induced draft pipe and an air pump; the induced draft pipe is fixedly connected with the shell, an air pump is fixedly connected with the induced draft pipe, a desulfurizing agent in the air inlet pipe is mixed with flue gas, then the mixture is blown out through the fan, generated solid particles move outwards due to centrifugal force and are downwards introduced into the precipitation tank through airflow of the air pump for precipitation, pure air is exhausted through the air outlet pipe, reheating is not needed, and thus the production cost is reduced.

Owner:JIANGSU FENGFENG HONGYUN ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Double-mode dust suppression device for building construction sites

InactiveCN110975494AAvoid enteringImprove working environmentCombination devicesVehicle frameSprayer

The invention discloses a double-mode dust suppression device for building construction sites. The double-mode dust suppression device comprises a vehicle frame, a transfer cylinder and a sprayer; thetransfer cylinder is located at top of the vehicle frame, the sprayer is fixed at the top of the transfer cylinder; a treatment cylinder is also arranged on the vehicle frame; the treatment cylinderand the transfer cylinder are arranged in parallel; a lifting pump is arranged between the treatment cylinder and the transfer cylinder, an input end of the lifting pump is connected with the treatment cylinder through a transfer pipe, the output end of the lifting pump is connected with the transfer cylinder through a transfer pipe, a supplementing opening is formed in the top of the treatment cylinder, a fan box communicated with the interior of the treatment cylinder is arranged on the upper portion of the side face of the treatment cylinder, and an induced draft fan is arranged in the fanbox. According to the device, dust-containing air is subjected to double-mode dust suppression treatment through the sprayer at the top of the transfer cylinder and the treatment cylinder; the workingenvironment of a building construction site can be effectively improved, the operation safety is guaranteed, solid particles are intercepted through an interception box and prevented from entering the transfer cylinder, and the operation safety of equipment is guaranteed while double-mode treatment is guaranteed.

Owner:李付民

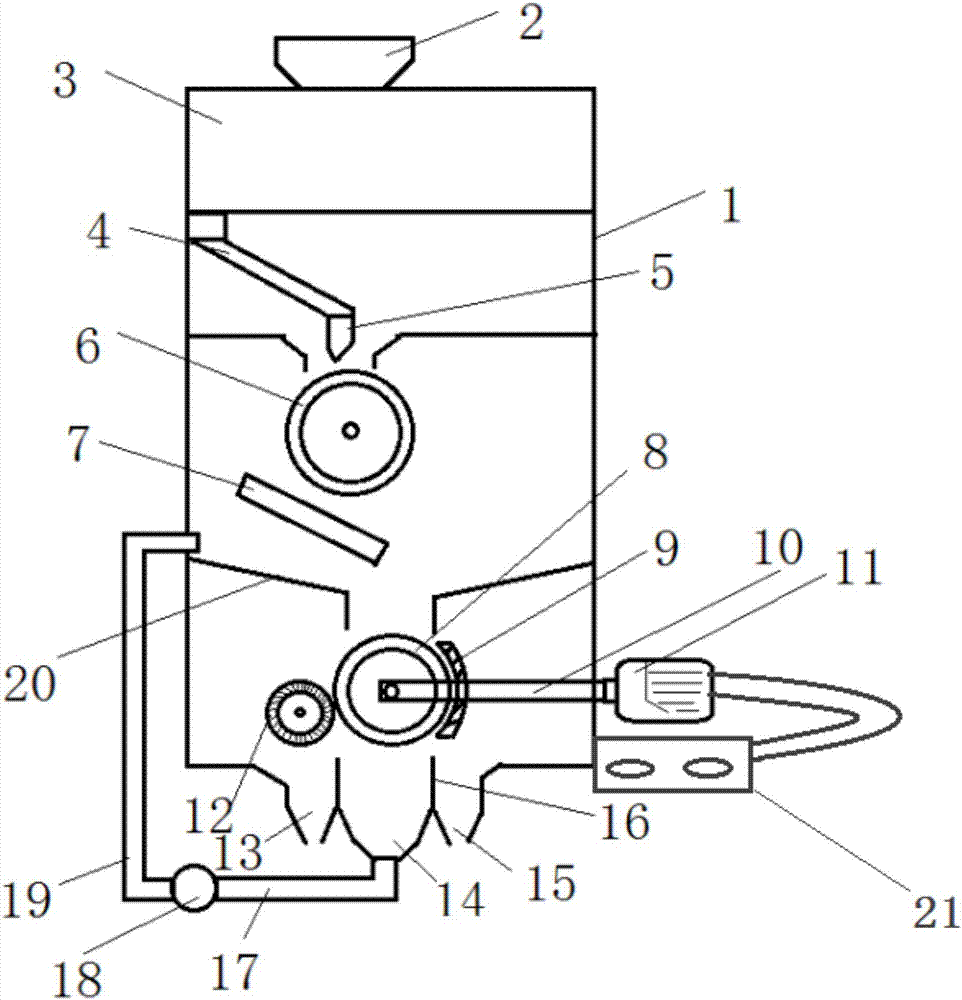

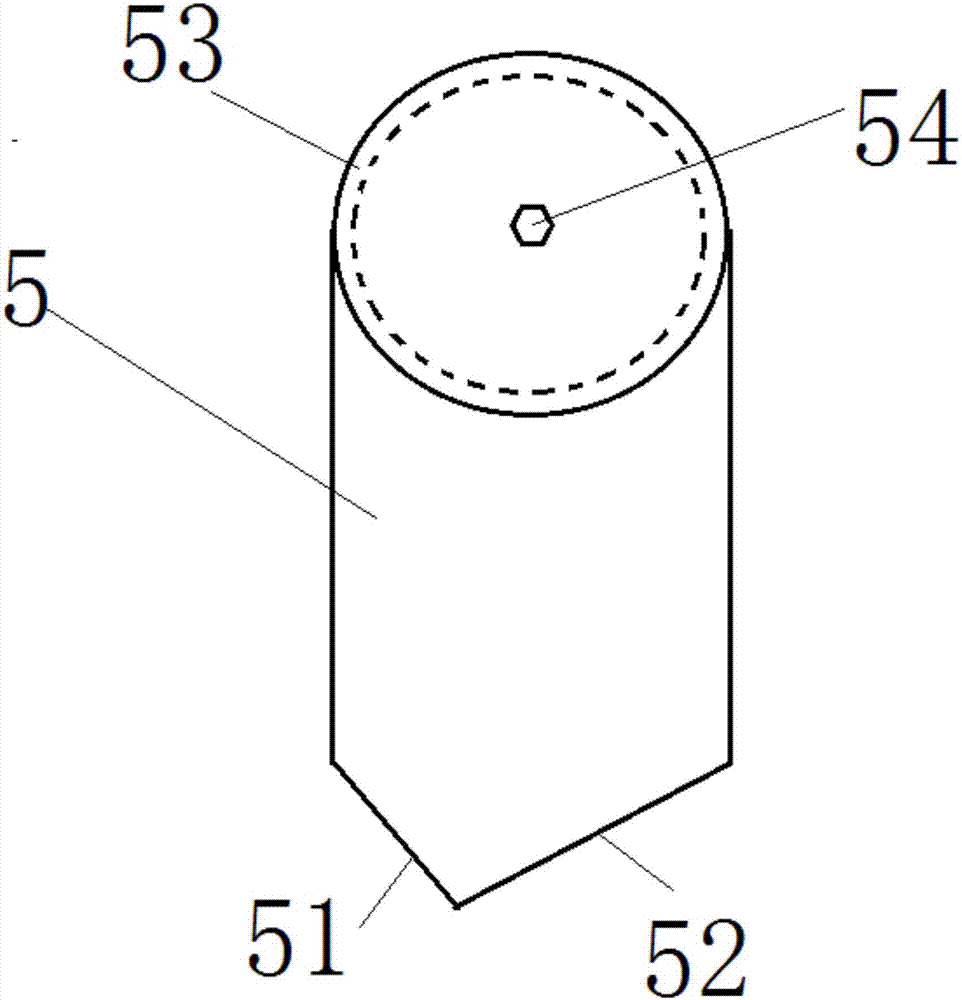

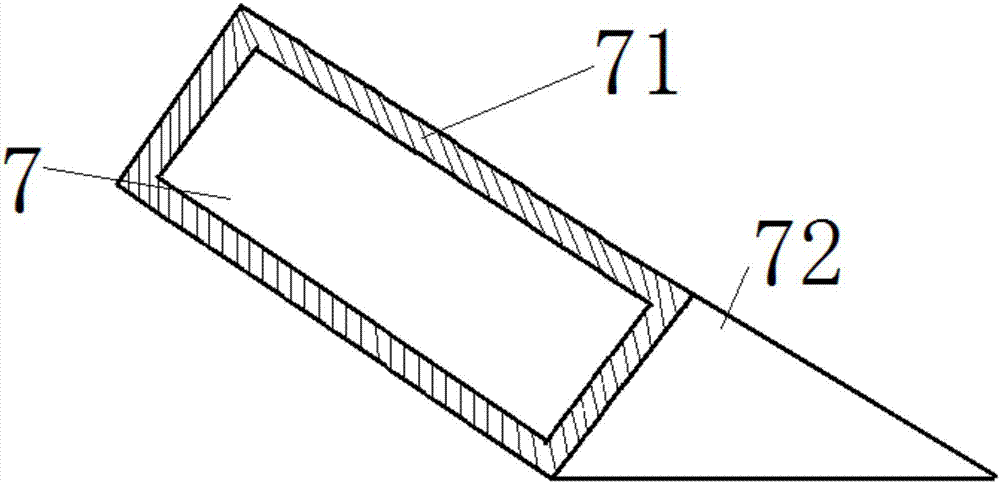

Domestic deepening processor for wet garbage under water tank and control method thereof

PendingCN112726753AEasy to separateImprove decomposition efficiencyDomestic plumbingStationary filtering element filtersProcess engineeringEnvironmental engineering

The invention discloses a domestic deepening processor for wet garbage under a water tank and a control method thereof. The domestic deepening processor comprises a shell, and a shredding device, a solid-liquid separation device, a stirring device and a waste gas treatment device which are arranged in the shell and connected in sequence, the shredding device shreds wet garbage into particles and discharges the particles to the solid-liquid separation device, the solid-liquid separation device is used for separating wet garbage and discharging separated solid particles to the stirring device and liquid at the same time; and the stirring device stirs the solid particles and then performs fermentation, and the waste gas treatment device purifies waste gas generated in the stirring and fermentation process. The shredding device shreds wet garbage into particles, solid-liquid separation is facilitated, and the separation efficiency is improved; the inlet of the shredding device is directly connected with the outfall of the water tank, so that the space is saved, and the odor generation probability is reduced; and the solid outlet of the solid-liquid separation device is connected to the stirring device, and the liquid outlet is connected to a drainage pipeline, so that the space deployment is more reasonable, and the whole machine is more attractive and easy to store.

Owner:INTRADIN HUZHOU HARDWARE CO LTD

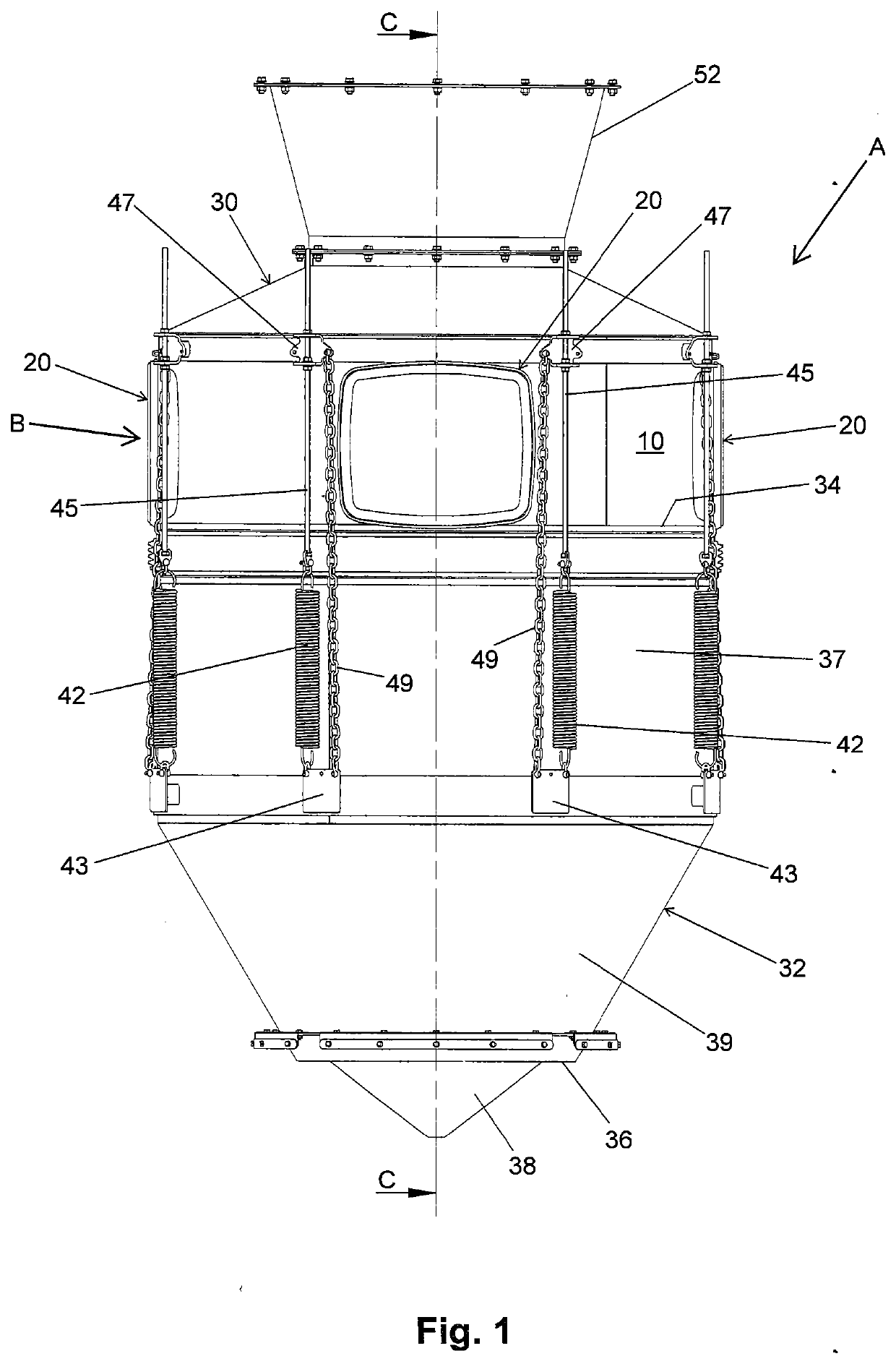

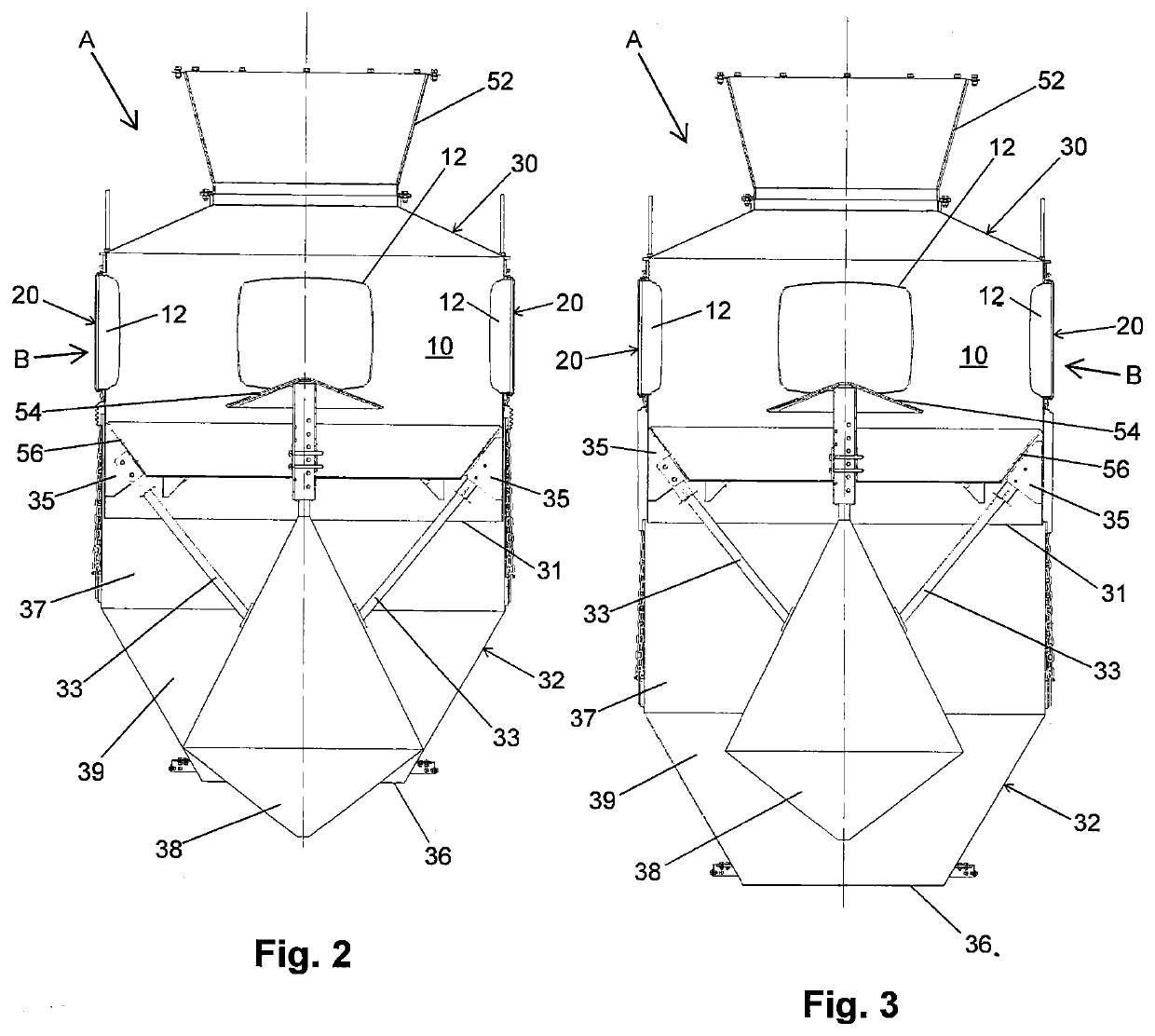

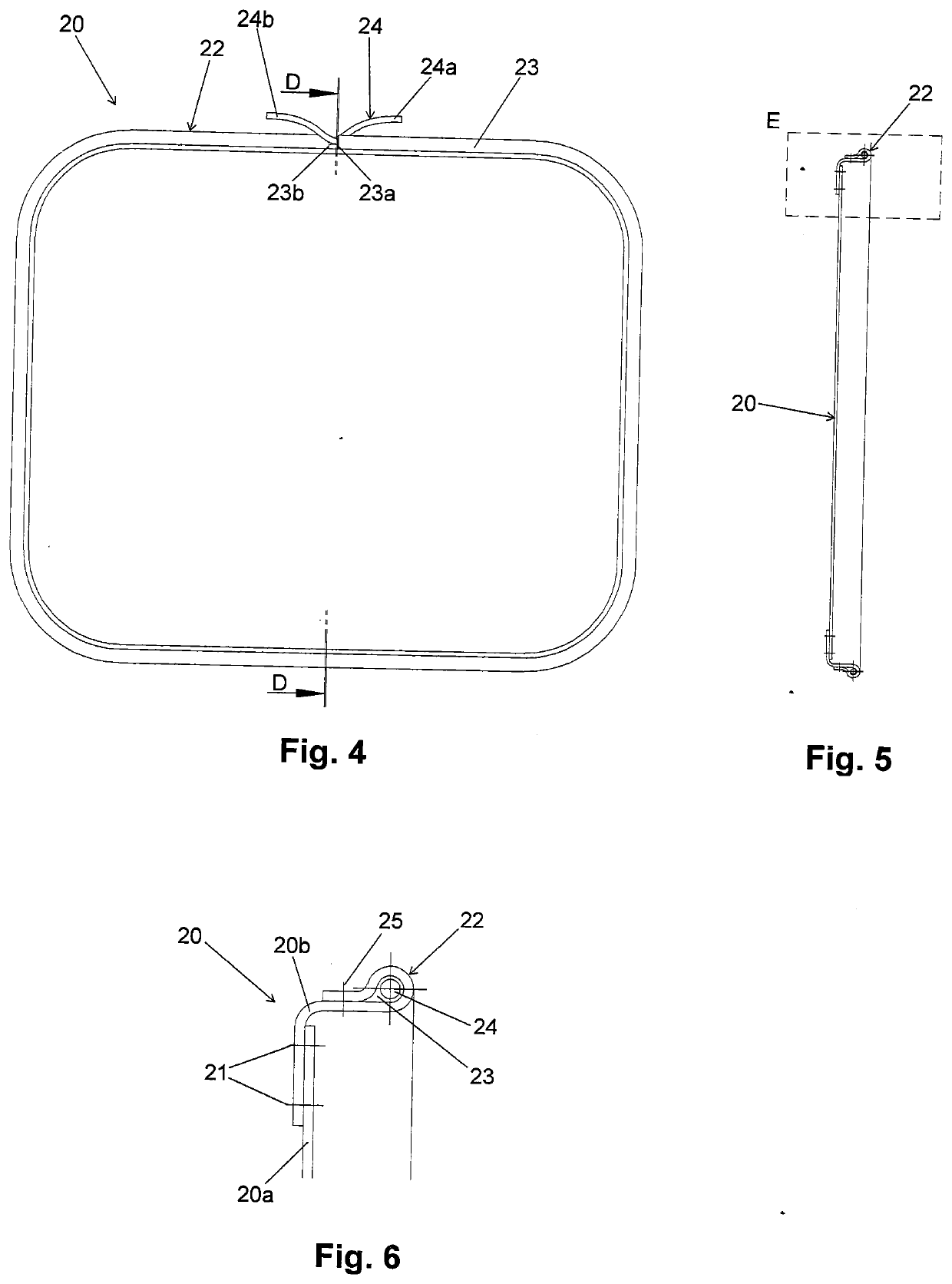

Relief module and device for unloading bulk material

ActiveUS20220017296A1Reduce the risk of explosionReduce inconvenienceLarge containersLoading/unloadingClassical mechanicsEngineering

Owner:TMSA TECH EM MOVIMENTO SA

Rare earth particle separation system

PendingCN114177685AReduce the probability of cloggingEasy to separateProcess efficiency improvementStationary filtering element filtersWastewaterSolid particle

Owner:张清

Automatic ore screening machine

InactiveCN107138283APrevent jumpingAvoid wastingElectrostatic separationElectrical conductorStandby power

Owner:郑州永泰澳新商贸有限公司

Waste gas treatment equipment for incinerator

PendingCN114768410AIncrease contact areaImprove the effect of reaction filteringDispersed particle filtrationTransportation and packagingElectric machineProcess engineering

Owner:谭瑞平

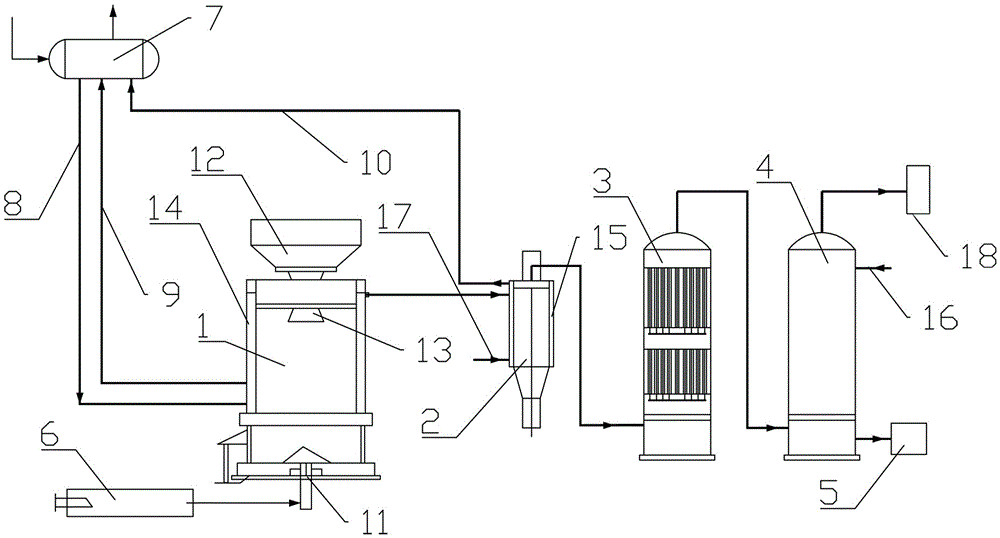

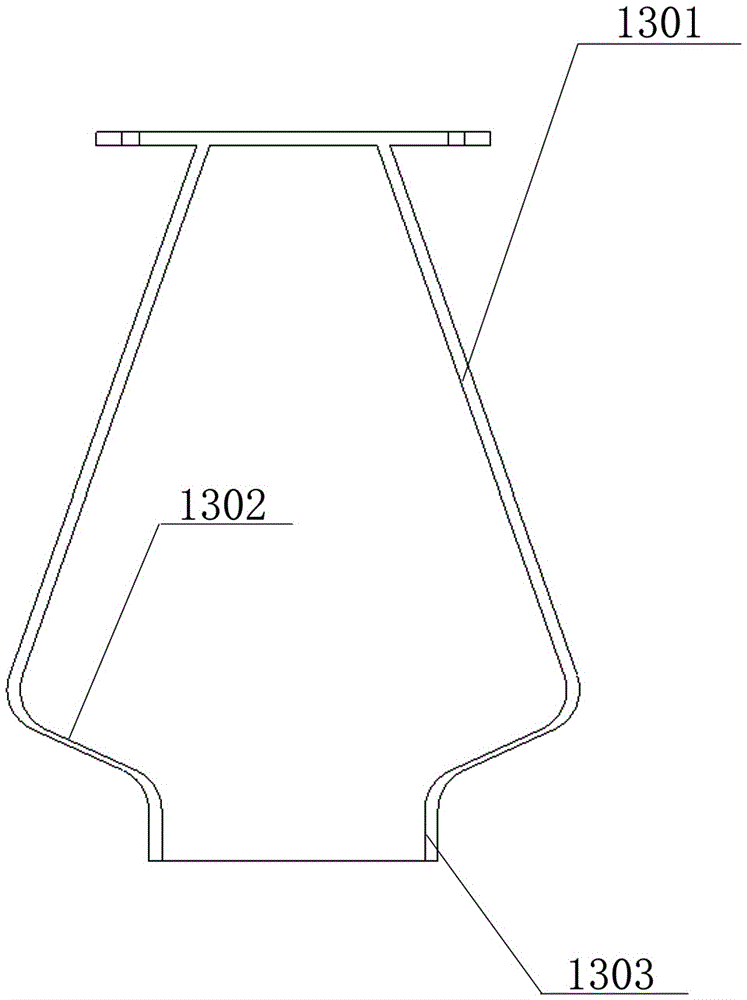

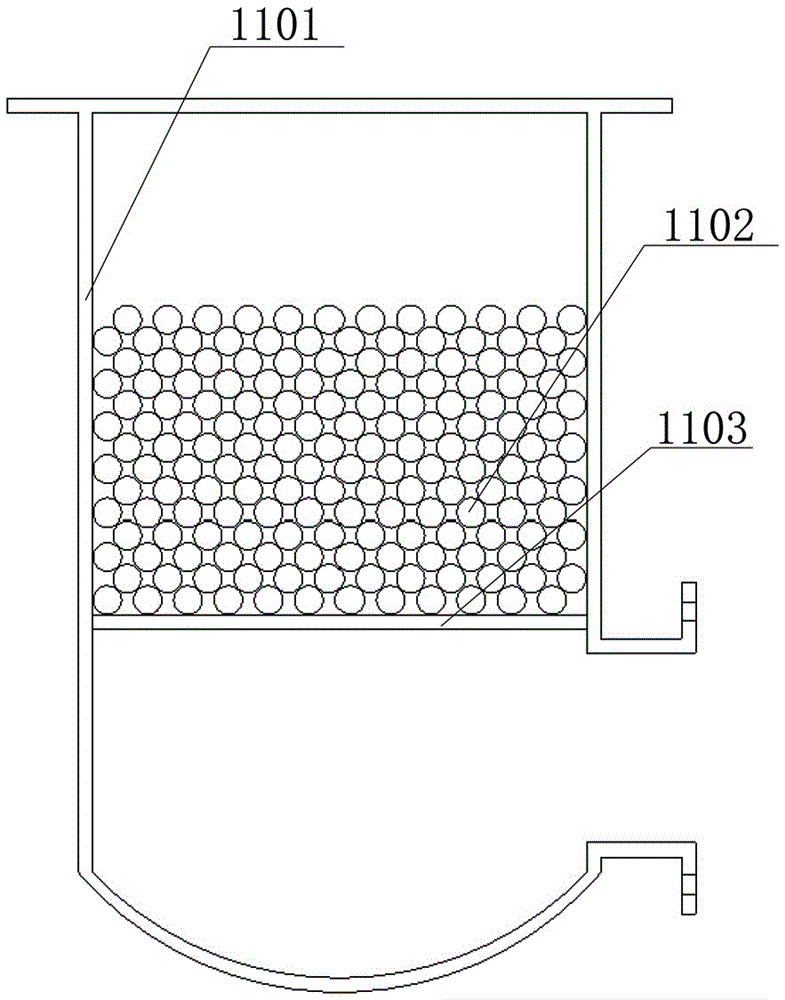

Cutting fluid regeneration device

PendingCN112174426AQuick removalReduce dosageFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processLiquid storage tankSolid particle

Owner:常永青

Fixed-bed pure-oxygen continuous gasification device and process adaptable to diversified coals

ActiveCN105542860AImprove decomposition rateHigh effective gas contentChemical industryGasification processes detailsAdditive ingredientFixed bed

Owner:河南顺达新能源科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap