Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19 results about "Polyester resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester resins are unsaturated synthetic resins formed by the reaction of dibasic organic acids and polyhydric alcohols. Maleic Anhydride is a commonly used raw material with diacid functionality. Polyester resins are used in sheet moulding compound, bulk moulding compound and the toner of laser printers. Wall panels fabricated from polyester resins reinforced with fiberglass—so-called fiberglass reinforced plastic (FRP)—are typically used in restaurants, kitchens, restrooms and other areas that require washable low-maintenance walls. They are also used extensively in cured-in-place pipe applications. Departments of Transportation in the USA also specify them for use as overlays on roads and bridges. In this application they are known as PCO Polyester Concrete Overlays. These are usually based on isophthalic acid and cut with styrene at high levels—usually up to 50%. Polyesters are also used in anchor bolt adhesives though epoxy based materials are also used. Many companies have and continue to introduce styrene free systems mainly due to odor issues. Most polyester resins are viscous, pale coloured liquids consisting of a solution of a polyester in a monomer which is usually styrene..

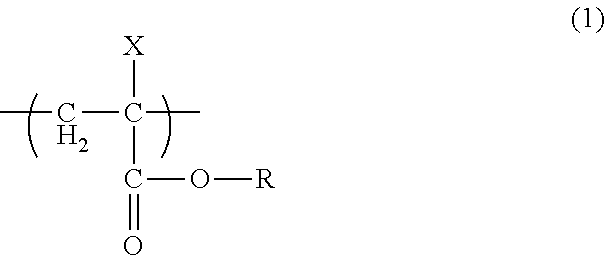

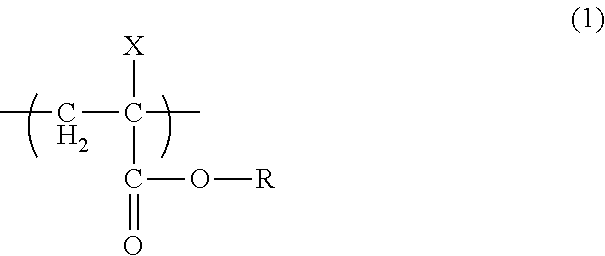

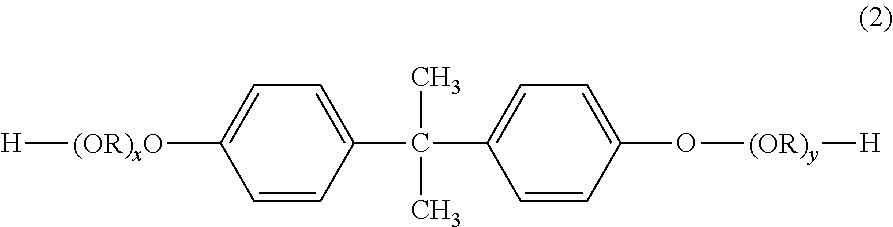

Weather-resistant type coating material of acrylic acid-polyester powder modified by inorganic nano composite material, and its prepn. method

InactiveCN1462784AImprove anti-aging propertiesIncreased weather resistance indexPowdery paintsPolyester coatingsAcrylic resinAdhesive

Owner:SICHUAN UNIV +1

Preparation technology of perfluoropolyether for resin

Owner:XUZHOU ZENITH COATING

Waterborne polyester resin and preparation method thereof

InactiveCN106893087AImprove hydrolysis resistanceGood dispersionPolyester coatingsWater dispersibleAdipic acid

The invention discloses waterborne polyester resin, comprising polyols and polyacids; the polyols include 8-12% of trimethylol propane, 12-24% of neopentyl glycol, 6-12% of ethylene glycol, and 8-12% of propylene glycol; the polyacids include 5-15% of purified terephthalic acid, 12-24% of isophthalic acid, 6-12% of phthalic acid, 10-18% of trimellitic anhydride, 6-12% of hexahydro-phthalic acid, 10-20% of maleic anhydride, and 5-10% of adipic acid; the waterborne polyester resin also comprises 0.1-0.3% of p-methoxyphenol, 6-24% of ethylene glycol butyl ether, 8-16% of dimethylethanolamine, and 60-100% of deionized water. The waterborne polyester resin can gain improved hydrolysis resistance, water dispersibility and storage stability, has improved stability of polyester main chain hydrolysis and is widely applicable to waterborne insulating devices, the defects of the prior art can be overcome, and the requirement on actual use can be met.

Owner:CHUZHOU QUAN FENG MATERIALS CO LTD

Thermoplastic Elastomer Composition And Shaped Article

Owner:ZEON CORP

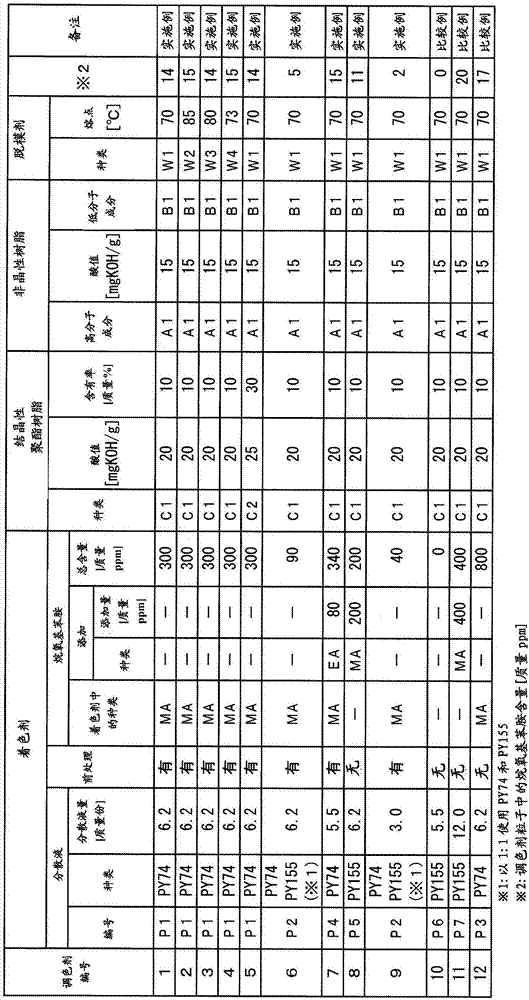

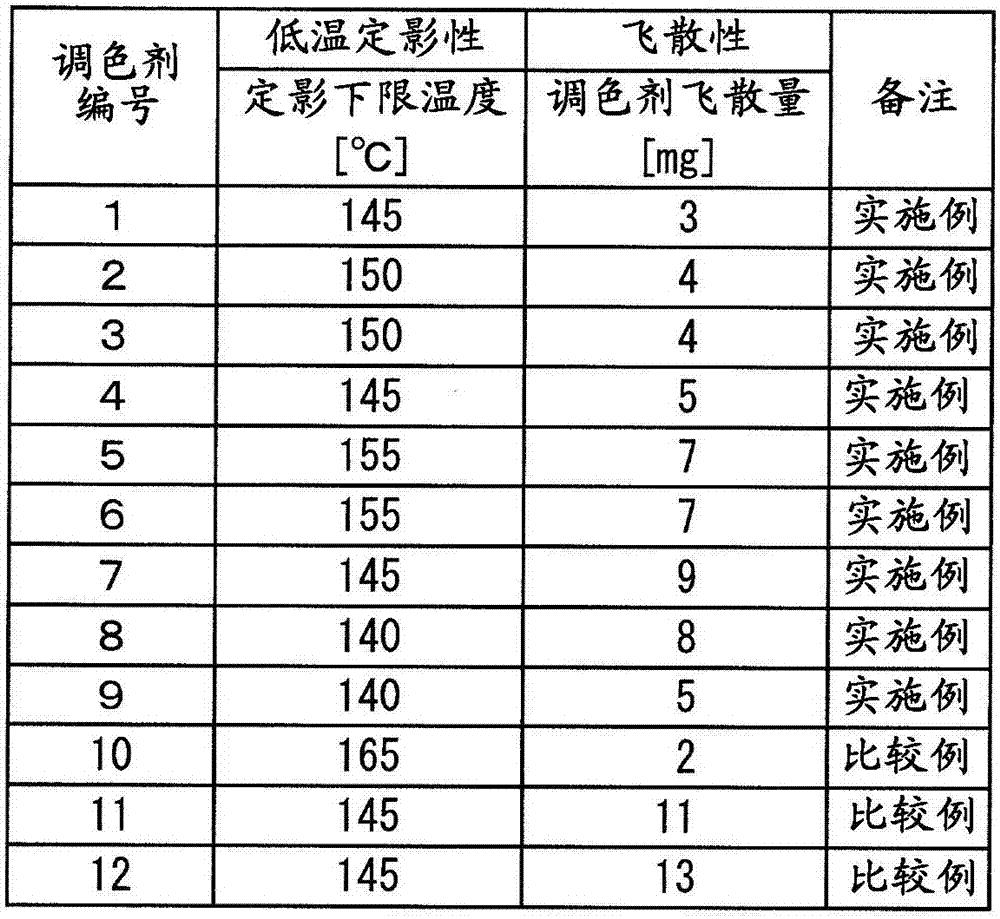

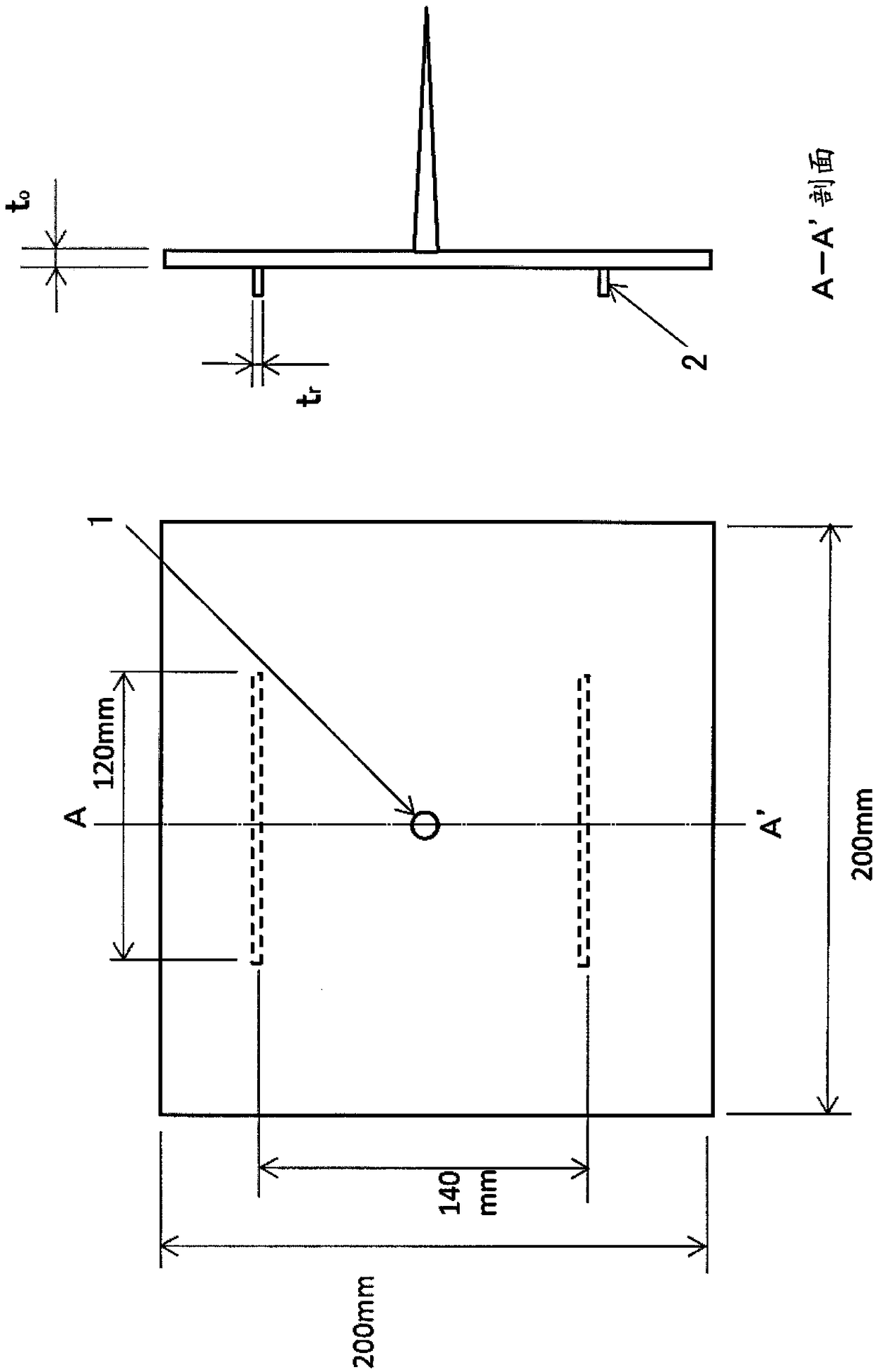

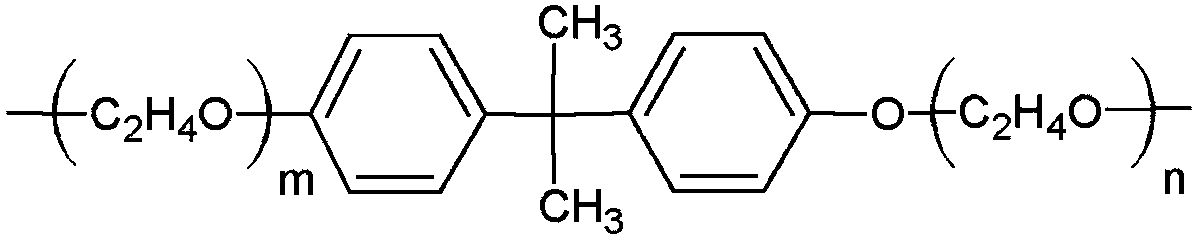

Toner and two-component developer

ActiveUS20150177635A1Easy to fixHigh hot offset resistanceDevelopersPolyester resinPolymer chemistry

Owner:CANON KK

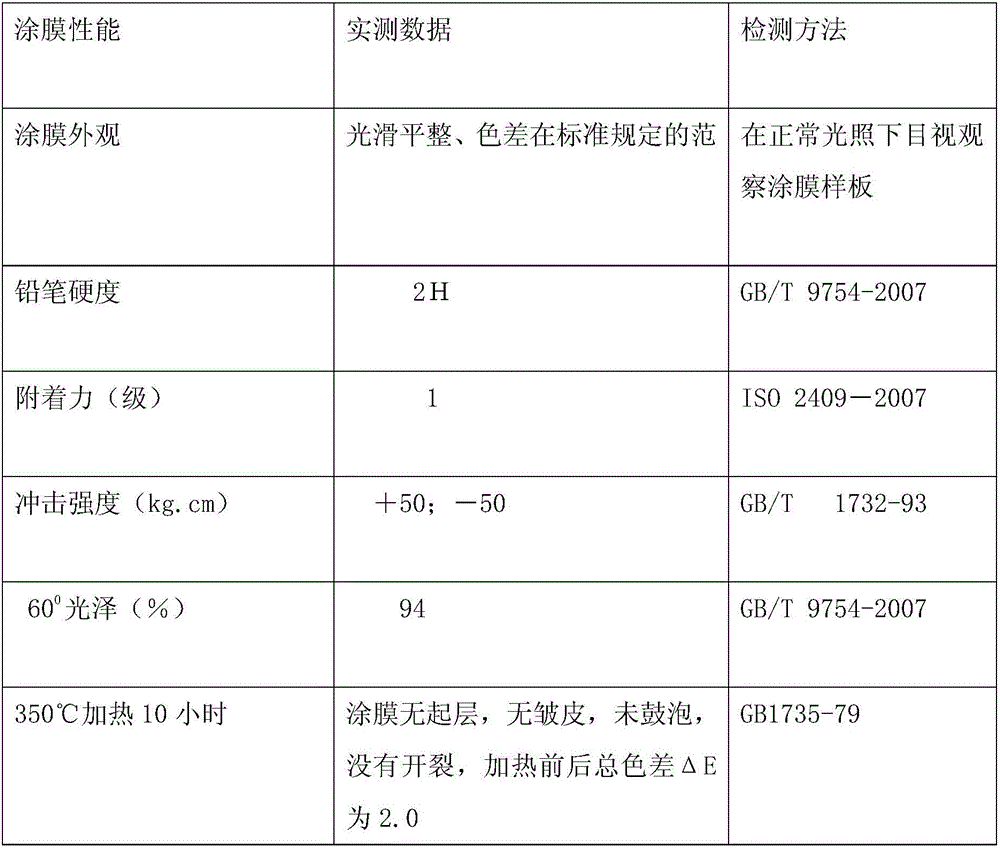

High-temperature-resistant powder paint and preparation method thereof

InactiveCN105860765ALow curing temperatureShort curing timeFireproof paintsPowdery paintsPolyester resinTemperature resistance

Owner:合肥燕美新材料科技有限公司

Thin-film capacitor housing heat dissipation coating and preparation method thereof

A thin-film capacitor housing heat dissipation coating is prepared from, by mass, 35 parts of resol, 3 parts of gelatin, 5 parts of glycidyl methacrylate, 3 parts of sodium dodecyl benzene sulfonate, 3 parts of gloss oil, 5 parts of dimethyl dicarbonate, 3 parts of olive oil, 3 parts of colored glaze carbylic acid, 3 parts of olive oil, 3 parts of graphene, 5 parts of pigment, 50 parts of distilled water, 3 parts of benzoyl paeoniflorin, 3 parts of sodium hypochlorite, 5 parts of a modifying agent, 3 parts of calcium carbonate, 3 parts of glacial acetic acid, 3 parts of magic acid, 5 parts of polyester resin, 3 parts of potassium dihydrogen phosphate, 1 part of sodium phosphate, 3 parts of aluminum silicate, 3 parts of imidazole, 3 parts of cohesive soil, 3 parts of polyvinyl alcohol and 3 parts of sodium borohydride. The modifying agent is added in a traditional formula to perform modification processing, the coating coated on a capacitor housing can effectively guide capacitor inside temperature rising due to work to the housing and convert heat into infrared radiation waves, and the working voltage of a capacitor can be also in a stable state in addition to prolonging of the service life of the capacitor.

Owner:HUAIAN SHENGYU ELECTRONICS

Antibacterial and anti-static paint and preparation method thereof

InactiveCN106519927AGood dispersionImprove adhesionFireproof paintsAntifouling/underwater paintsEpoxyAntistatic agent

Owner:WUXI BENNIU BIOTECH CO LTD

Polyester molded composition and production method and application thereof

InactiveCN109867923AMeet air tightness requirementsImprove bindingSemiconductor devicesArylPolymer science

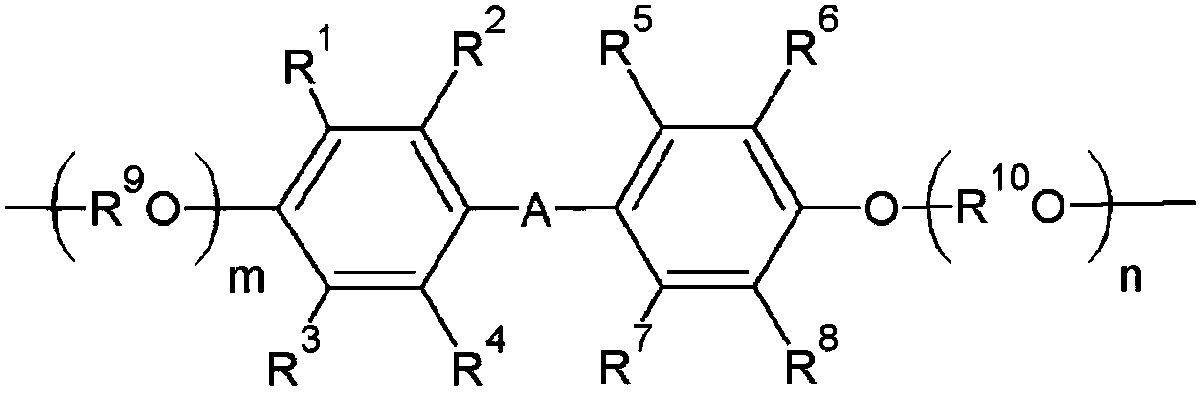

The invention discloses a polyester molded composition. The polyester molded composition comprises the following components: 50-80 parts of PCT resin, 10-30 parts of white pigment, 10-30 parts of enhancing material and / or filler and 0.1-2 parts of phosphorous compound; and the phosphorous compound is of a structure as shown in the description, wherein R1 is aryl or OR2, R2 is aryl or alkyl containing 1-30 carbon atoms, R3 is alkyl containing 1-10 carbon atoms, and R4 and R5 are phenyl or alkyl containing 0-10 carbon atoms. A production method comprises the steps of mixing the polyester resin,the white pigment and the phosphorous compound in a high-speed mixer according to proportions, adding a mixture, the enhancing material and / or the filler into a twin-screw extruder, and conducting melt blending, extruding and granulating on a mixture to obtain the polyester molded composition. The polyester molded composition has high adhesion to a metal material strap and good air impermeability,reflectivity and light-resistant and heat-aging-resistant performance.

Owner:KINGFA SCI & TECH CO LTD +1

3c1b coating, method of applying the same and substrate coated therewith

Provided is a multi-layer coating system, comprising a first coating composition, a second coating composition, and a third coating composition, wherein the first coating composition comprises a polyester resin and an amino resin, the second coating composition comprises a nitro-modified acrylic resin and electro-plated aluminum powders, and the third coating composition comprises an acrylic resin and an anti-sagging resin. Also provided are a method of coating a substrate with the multi-layer coating system and the substrate coated therewith.

Owner:PPG COATINGS TIANJIN

Electrostatic image developing toner

InactiveCN107450291AExcellent low temperature fixabilityReduce flyingDevelopersEngineeringPolyester resin

Owner:KONICA MINOLTA INC

Injection-molded foam of resin composition with satisfactory surface property and capable of weight reduction and rib design

Owner:KANEKA CORP

Powder coating

InactiveCN107418394AHigh hardnessWipe resistantPowdery paintsPolyester coatingsCelluloseCalcium hydroxide

Owner:RUGAO CITY LEHENG CHEM COMPANY

Nano titania modified unsaturated polyester resin and its prepn.

The invention refers to a kind of nano titanium dioxide-modified, unsaturated polyester resin and its preparation method. The technical project is as follows: the products is gained by the polymeric reaction of the dibasic acid, the dibasic alcohol and nano titanium dioxide powder, and the ratio of the dibasic acid with the dibasic alcohol is 0.95-1.05:0.95-1.05 (mol ratio), and the content of the nano titanium dioxide powder is 1-20% of the total bulk of the nano titanium dioxide-modified, unsaturated polyester resin; the provided preparation method is that: after mixing the dibasic acid, the dibasic alcohol and the nano iron dioxide powder, raise the temperature to 160-240 centigrade to have the return reaction, then get rid of the little molecules, and then cool the mixture to 80-100 centigrade to eject the material.

Owner:李明利 +1

Anti-skid and anti-fouling tableware paint and preparation method thereof

InactiveCN111100533AEasy to prepareLow costAntifouling/underwater paintsPaints with biocidesPolymer sciencePolyester resin

Owner:DONGLAI COATING TECH SHANGHAI

Method for preparing marine zinc chromate antirust paint

InactiveCN106085152ALow priceReduce dosageAntifouling/underwater paintsPaints with biocidesPlasticizerPhosphoric acid

Owner:TIANCHANG YINHU PAINT

Processing material for stirring paddle of chemical reaction kettle and preparation method of processing material

InactiveCN106633653AImprove corrosion resistanceImprove wear resistanceChemical/physical/physico-chemical processesFiberChemical reaction

Owner:DONGZHI TIANFU CHEM

Water-based fluorine-modified polyester can-making coating and preparation method thereof

InactiveCN114716877AImprove performanceImprove acid resistancePolyester coatingsPolymer scienceWeather resistance

The invention discloses a water-based fluorine-modified polyester can-making coating and a preparation method thereof, relates to the technical field of industrial water-based coatings, and particularly relates to a water-based fluorine-modified polyester can-making coating and a preparation method thereof. Comprising the following raw materials in parts by weight: 20-50 parts of modified fluorocarbon emulsion, 10-30 parts of waterborne polyester resin, 10-20 parts of deionized water, 0.2-1 part of a dispersing agent, 0.2-0.5 part of a defoaming agent, 20-40 parts of pigment filler, 0.5-2 parts of a thickening agent, 0.5-2 parts of a coalescing agent, 0.2-0.8 part of a wetting agent and 30-80 parts of a curing agent. According to the water-based paint prepared by the preparation method disclosed by the invention, the ultraviolet crosslinking elastic emulsion is introduced into the single fluorocarbon emulsion so as to modify the fluorocarbon emulsion, and then the fluorocarbon emulsion is mixed with the water-based polyester resin, so that the water-based fluorine-modified polyester can-making paint is prepared; the phenomenon that a single water-based fluorocarbon coating is poor in weather resistance, gloss retention and hardness compared with a solvent-type fluorocarbon coating in the using process can be effectively reduced, the service life of the coating is prolonged, and the using effect of the coating is improved.

Owner:SHENZHEN SHENSAIER CO LTD

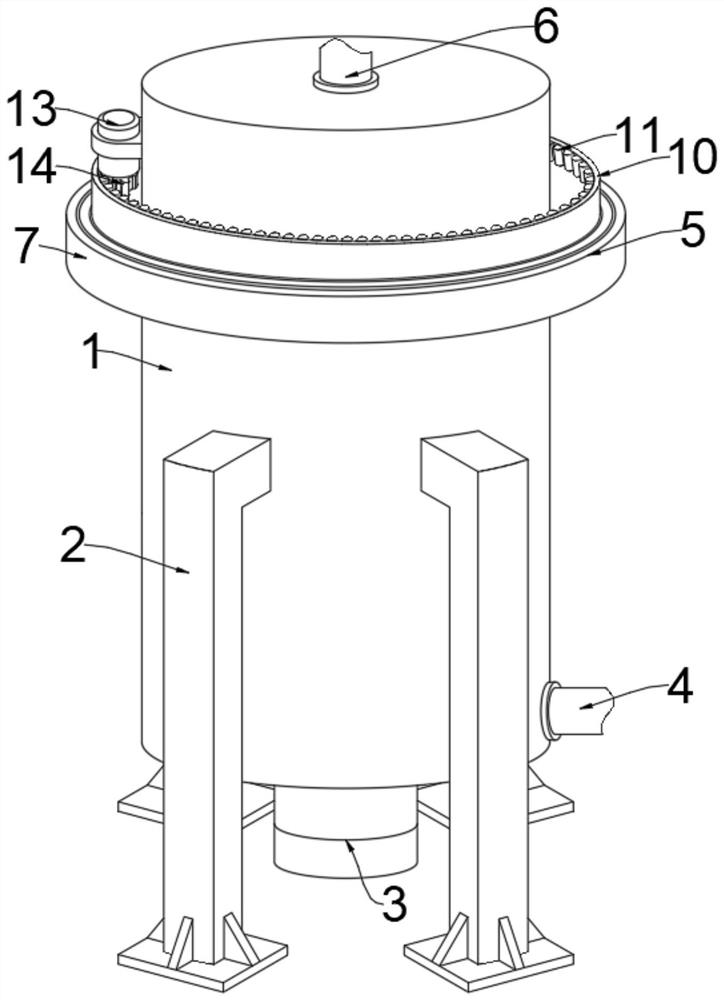

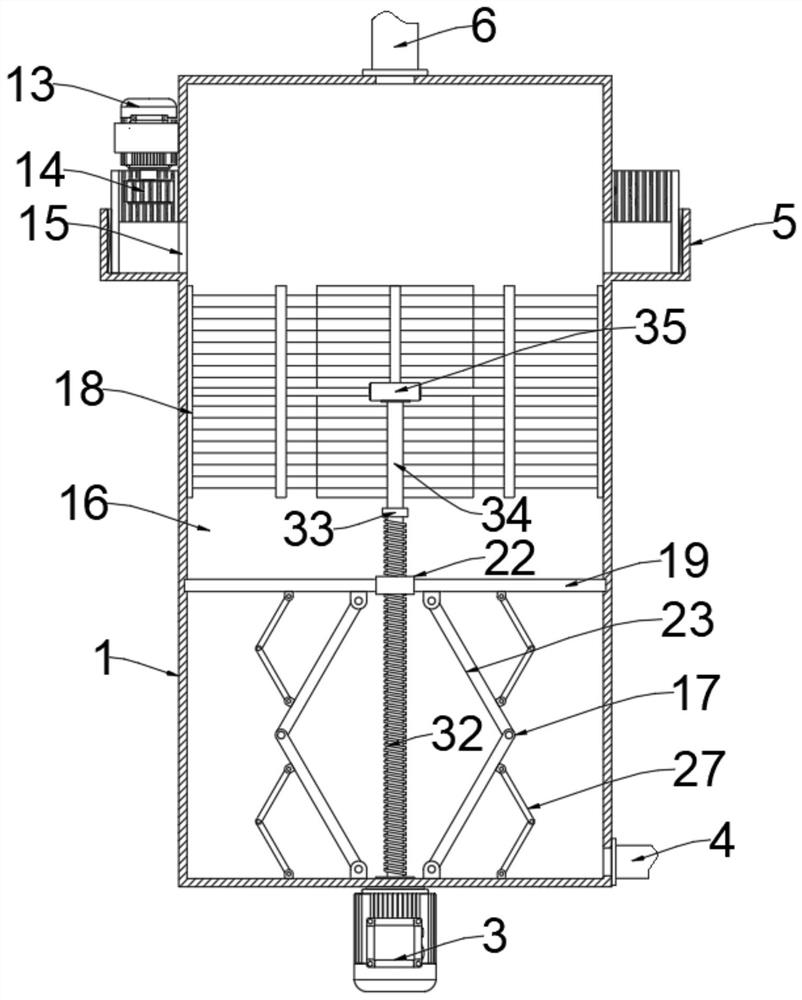

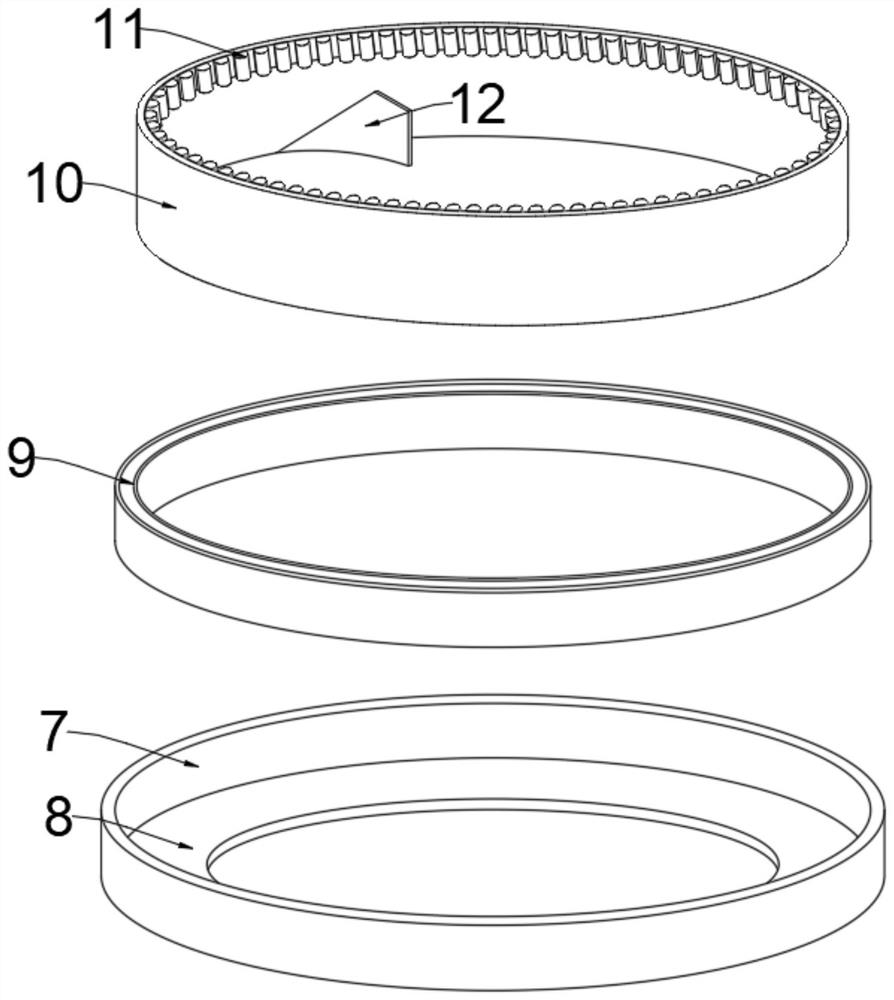

Toughening equipment for polyester resin

InactiveCN114347289ASolve the problem of toughening effectGood dispersionPolymer sciencePolyester resin

Owner:安徽永昌新材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap