Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Compatibilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compatibilization in polymer chemistry is the addition of a substance to an immiscible blend of polymers that will increase their stability. Polymer blends are typically described by coarse, unstable phase morphologies. This results in poor mechanical properties. Compatibilizing the system will make a more stable and better blended phase morphology by creating interactions between the two previously immiscible polymers. Not only does this enhance the mechanical properties of the blend, but it often yields properties that are generally not attainable in either single pure component.

Wax-based binder for compacting process in powder metallurgy as well as preparation method and application thereof

ActiveCN103642253AGood compatibility of ingredientsEfficient mixingPolyethylene vinyl acetateParaffin wax

Owner:HUNAN UNIV

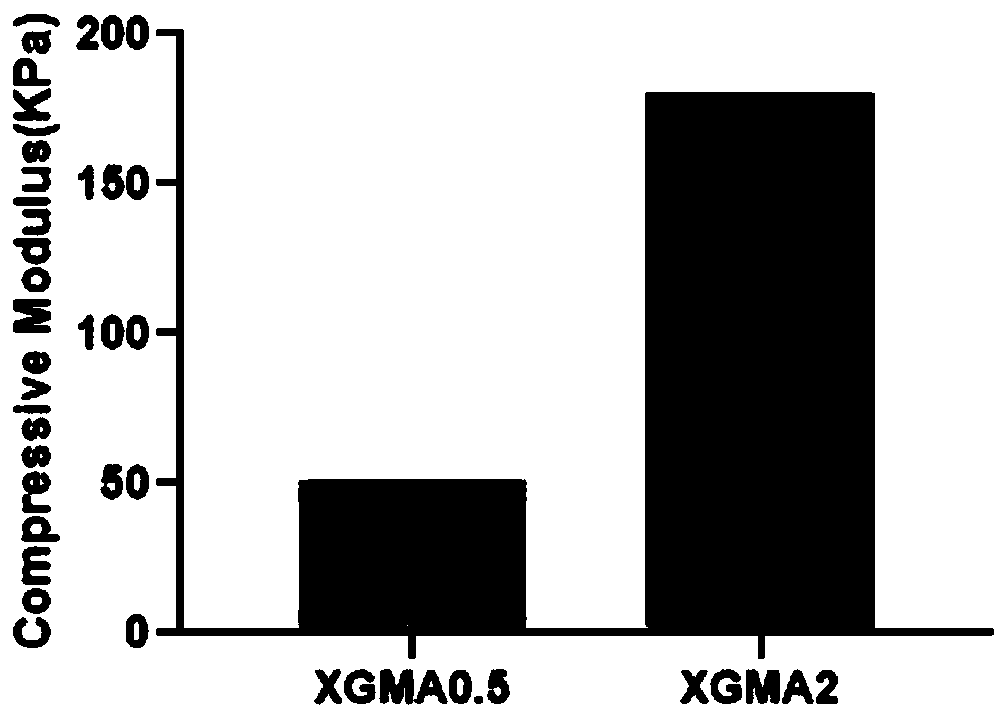

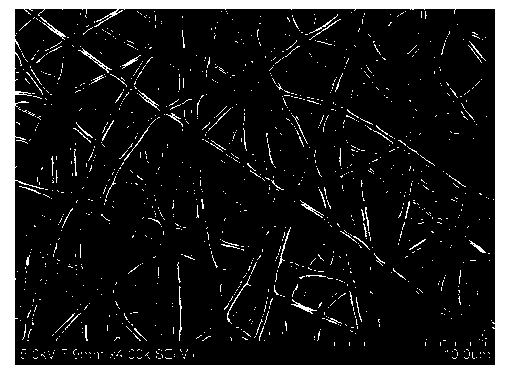

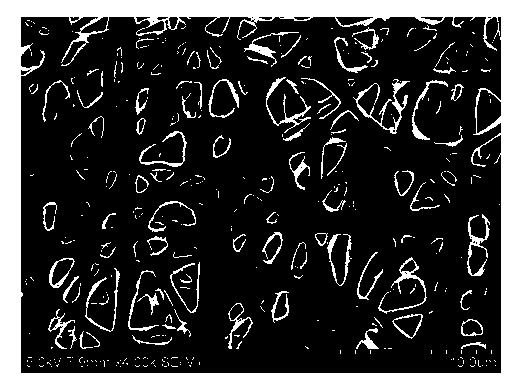

3D-printed xanthan glue gel scaffold and preparation method thereof

InactiveCN110680954AShape controllableHigh precisionTissue regenerationProsthesisCartilage cellsComputer printing

Owner:GUANGXI MEDICAL UNIVERSITY

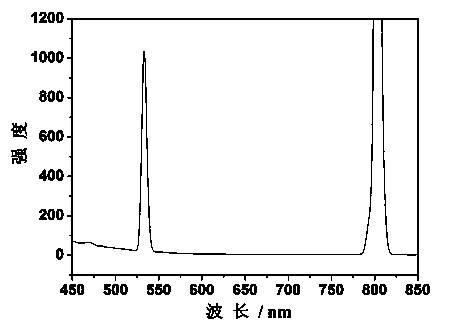

Glowing nanometer fibre with biocompatibility and preparation method of glowing nanometer fibre

InactiveCN103806115AGood biocompatibilityBoth luminousNew-spun product collectionArtificial filament physical treatmentPolymer scienceSpinning

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

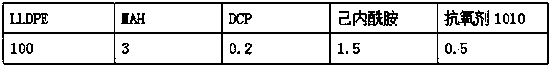

Grafted LLDPE (Linear Low-Density Polyethylene) based metal bonding film

ActiveCN103436193AImprove adhesionGood compatibilityFilm/foil adhesivesGraft polymer adhesivesLinear low-density polyethyleneLow-density polyethylene

Owner:成都雨田新材料有限责任公司

Graphene reinforced waterborne polyurethane high-barrier material and condom

ActiveCN111995860AImprove mechanical propertiesImprove barrier propertiesMale contraceptivesCompatibilizationFree-radical reaction

The invention provides a graphene reinforced waterborne polyurethane high-barrier material and a condom. According to the high-barrier material, the compatibility with a polyurethane material is improved by adopting modified graphene oxide, the interaction between graphene and a polyurethane molecular chain is increased, and the purpose of improving the mechanical property and barrier property ofpolyurethane is achieved; meanwhile, carbon-carbon double bonds are introduced into the tail end of a polyurethane molecular chain, so that the carbon-carbon double bonds are bonded with the carbon-carbon double bonds on the natural latex molecular chain through a free radical reaction, and the interface fusion between the natural latex layer and the graphene / waterborne polyurethane interlayer isrealized. The material can be used for manufacturing a condom with a graphene / polyurethane / natural latex composite structure and having good barrier property and low cost.

Owner:CHONGQING MENDUO NEW MATERIAL TECH CO LTD

Anti-corrosion power protection pipe

Owner:安徽盛华管业有限公司

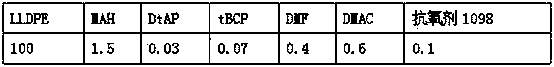

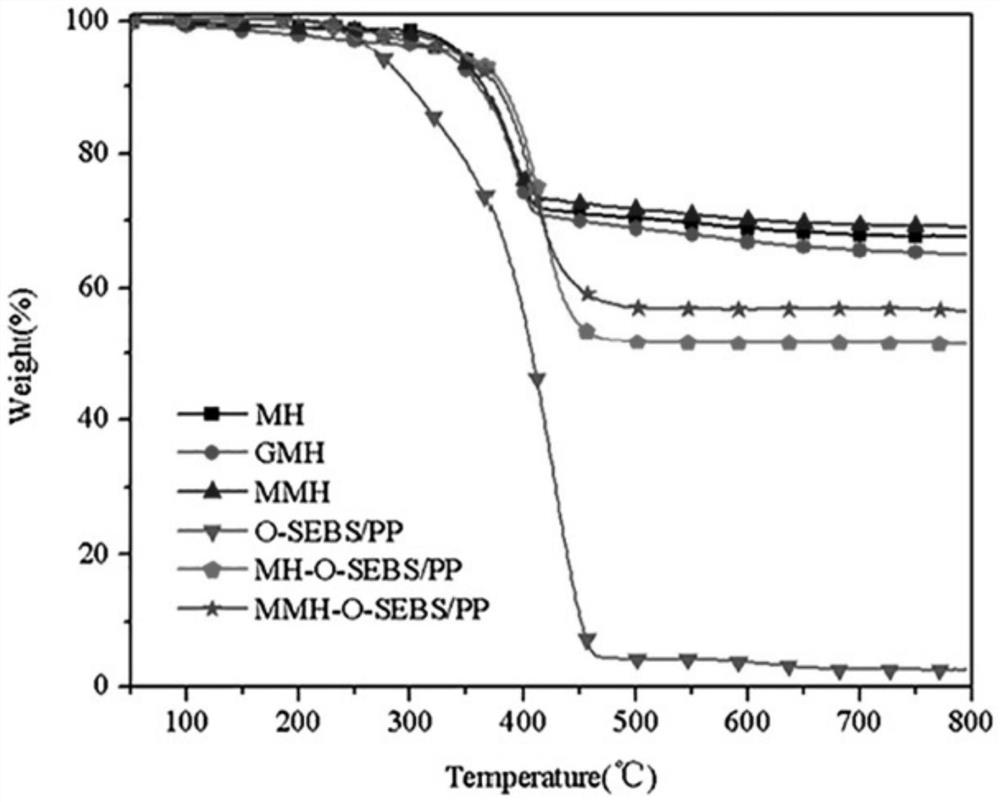

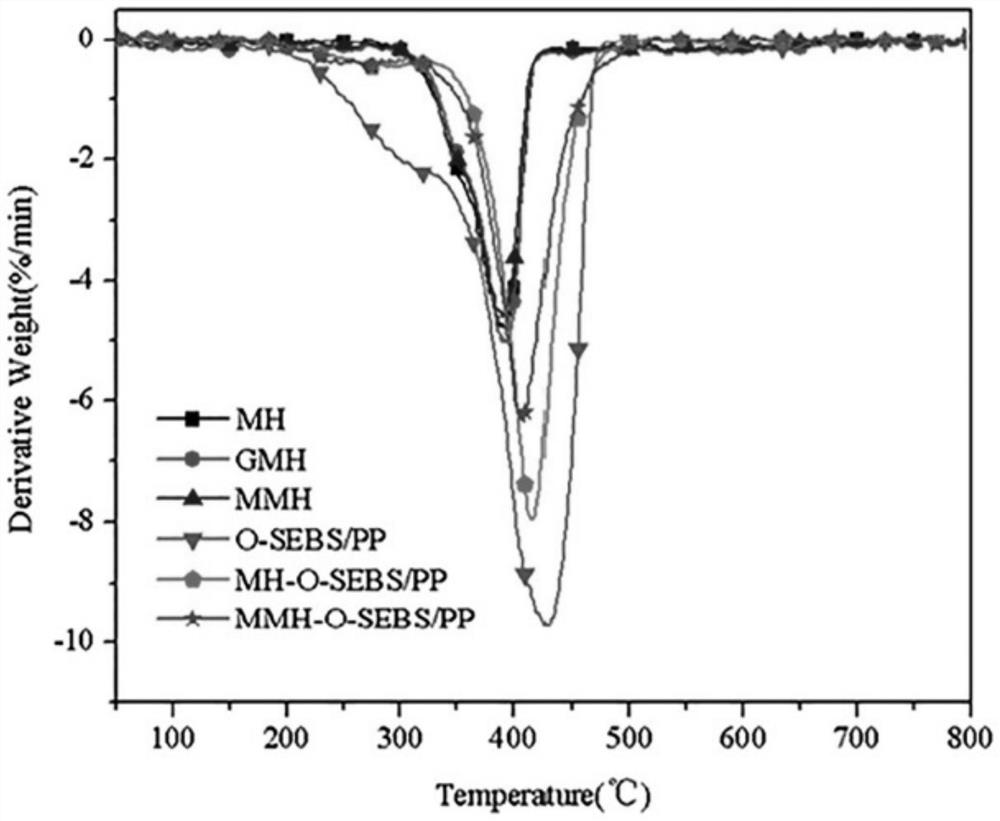

Olefin halogen-free flame retardant and preparation method thereof

InactiveCN103360655AGood compatibilityHigh content of active ingredientsPolymer scienceOlefin polymerization

Owner:CHENGDU SOLVER TECH

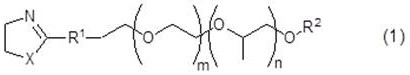

PEG coupled heterocyclic compound and application thereof in acidic bright copper plating

Owner:WENZHOU INST UNIV OF CHINESE ACAD OF SCI

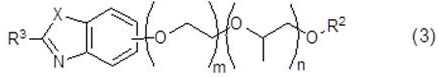

Aqueous emulsion of ultraviolet-absorbing resin and emulsion resin composition

InactiveUS20060155015A1Improve compatibilityAvoid bleedingOrganic chemistryOrganic dyesEmulsionBoiling point

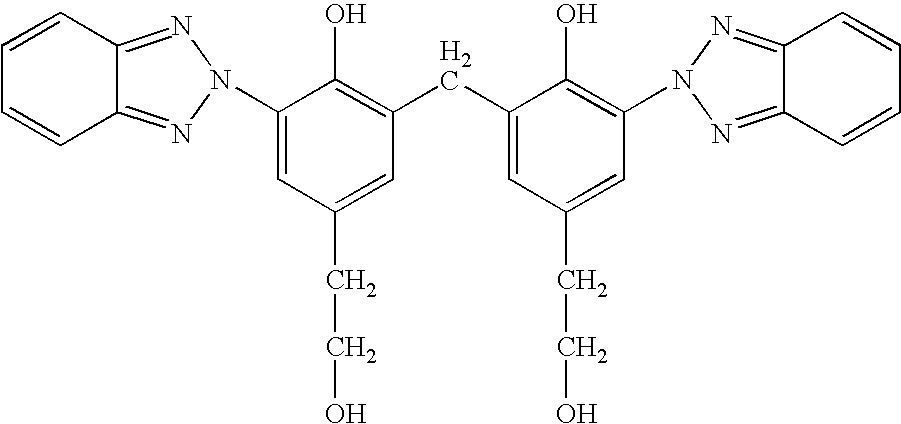

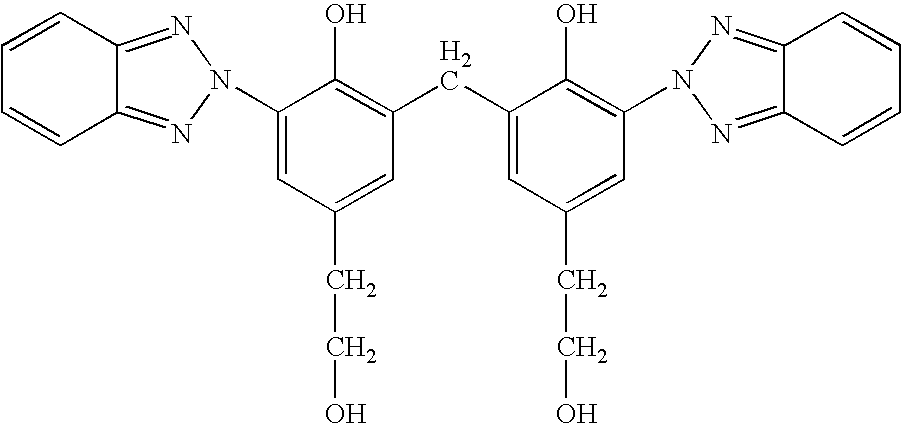

An aqueous ultraviolet-absorbing resin emulsion, and an aqueous resin emulsion composition containing the emulsion is provided, wherein the emulsion is excellent in compatibility with a synthetic resin and light resistance. Also, the emulsion improves stability in blending with an aqueous emulsion of the synthetic resin, and prevents bleed out of the ultraviolet-absorbing resin on the surface of a coating film. Further, the aqueous ultraviolet-absorbing resin emulsion imparts excellent alkali or solvent resistance to a synthetic resin poor in alkali or solvent resistance. More specifically, an aqueous resin emulsion composition comprising (I) an aqueous ultraviolet-absorbing resin emulsion and (II) an other aqueous resin emulsion is provided, wherein the emulsion (I) is obtained by urethanizing (A) a polyol component having an ultraviolet-absorbing group {e.g., 1,1-bis[3-(2H-benzotriazol-2-yl)-4-hydroxy-benzeneethanol]methane}, (B) a polyol if necessary, (C) an alkyl or aryl dialkanolamine compound, and (D) an organic polyisocyanate in (E) an organic solvent, diluting the reaction mixture with (F) an organic solvent having a boiling point lower than 100° C. to give a resin solution, neutralizing the resin solution with (G) a neutralizing agent, and dispersing the resultant in water.

Owner:DAICEL CHEM IND LTD

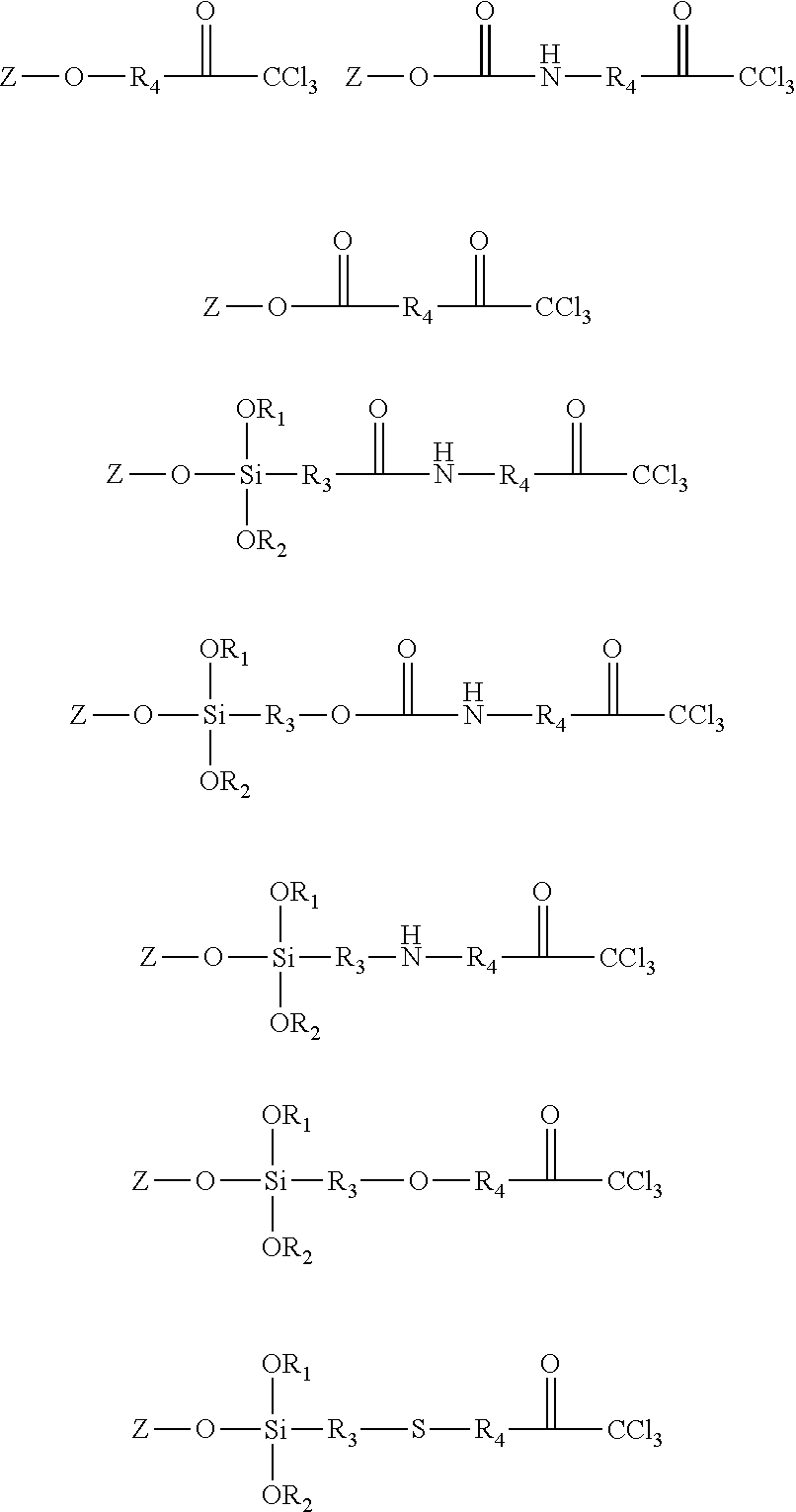

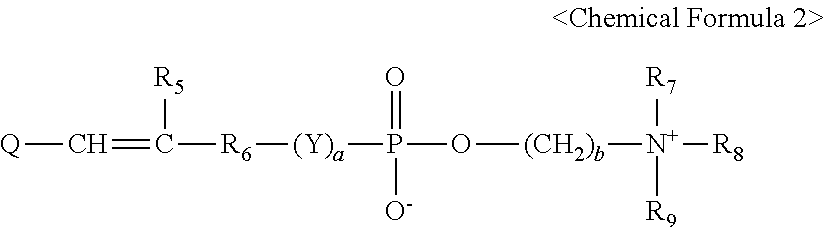

Surface-modified ultraviolet blocking powder and ultraviolet blocking composition including same

InactiveUS20140288259A1Good biocompatibilityImprove stabilityCosmetic preparationsToilet preparationsPhospholipinPtru catalyst

Owner:KCI

FG-coated MOF composite material, coating containing composite material, and preparation methods and application of coating

InactiveCN112442187ARegulatory loadModulation of crosslink densityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceWater methanol

The invention belongs to the technical field of anticorrosive materials in a marine environment, and particularly relates to an FG-coated MOF composite material, a coating containing the composite material, and preparation methods and application of the composite material and coating. The preparation method of the coating comprises the following steps: dispersing FG in absolute methanol, carryingout ultrasonic oscillation, adding a metal salt and an imidazole ligand into an FG methanol dispersion liquid, conducting stirring to obtain a turbid liquid, carrying out centrifugal separation to obtain a solid, alternately conducting washing with methanol and deionized water, and carrying out vacuum drying to obtain an FG-coated MOF composite material; and mixing epoxy resin, the FG-coated MOF composite material and a diluent, carrying out ball-milling stirring, adding a curing agent, and conducting uniform mixing to obtain a composite coating. A composite coating layer is obtained by coating the surface of a pretreated metal matrix with the composite coating, and conducting drying and curing. The epoxy resin is modified by the FG-coated MOF composite material, so that an imidazole ringin the composite material is chemically bonded with the epoxy resin, the problem of interfacial compatibility between the FG and the epoxy resin is solved, and the corrosion resistance and the mechanical property of an epoxy resin coating are improved.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

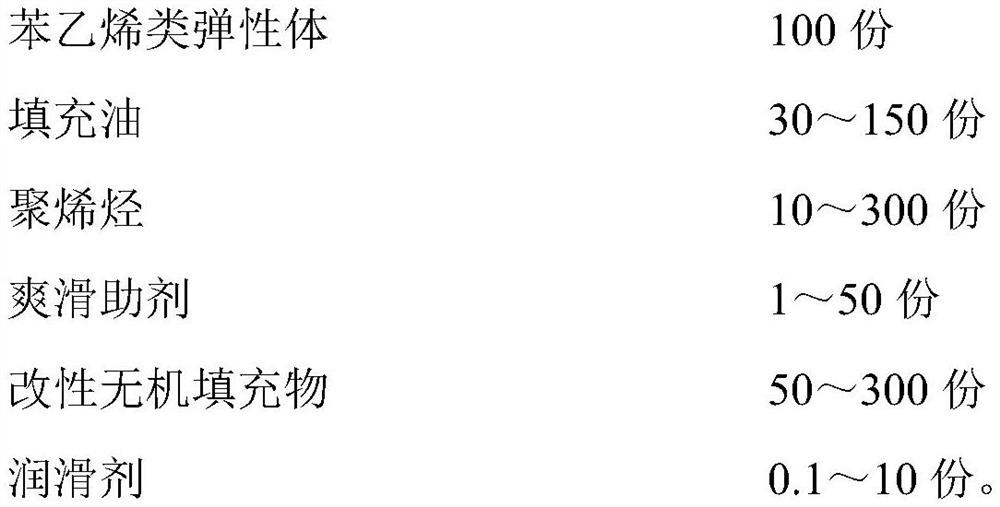

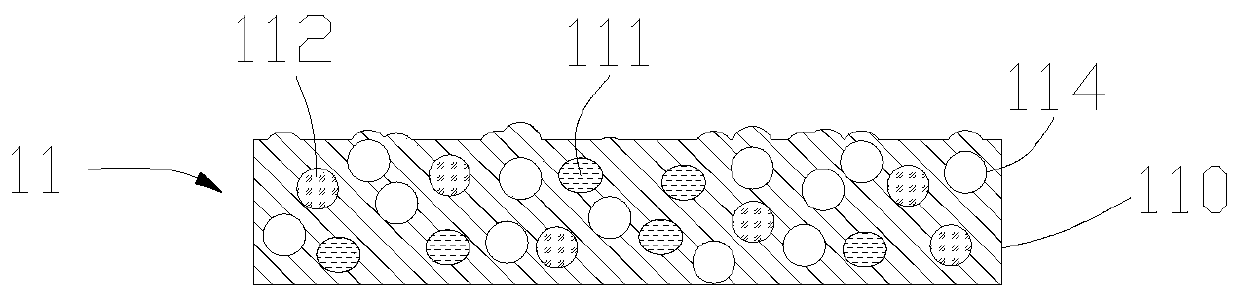

High-filling scratch-resistant extrusion-grade thermoplastic elastomer material and preparation method thereof

Owner:NANTONG POLYMAX ELASTOMER TECH

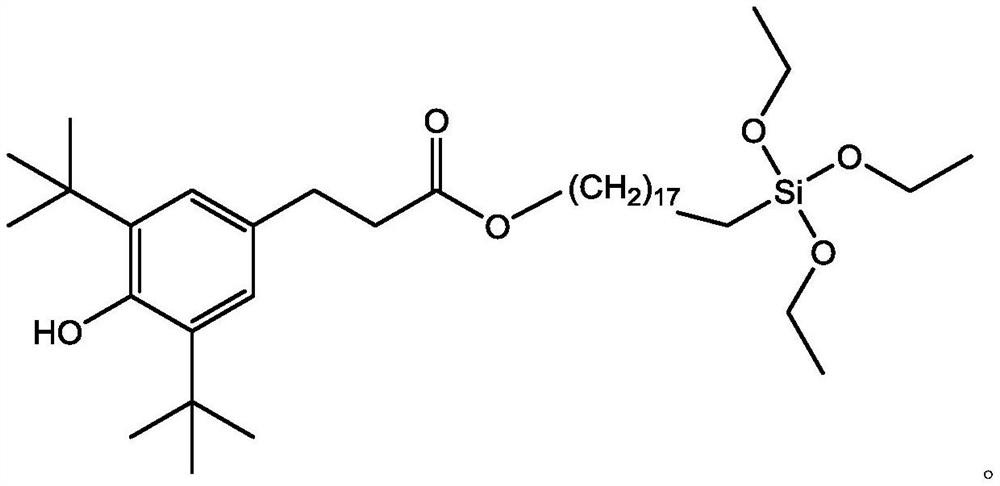

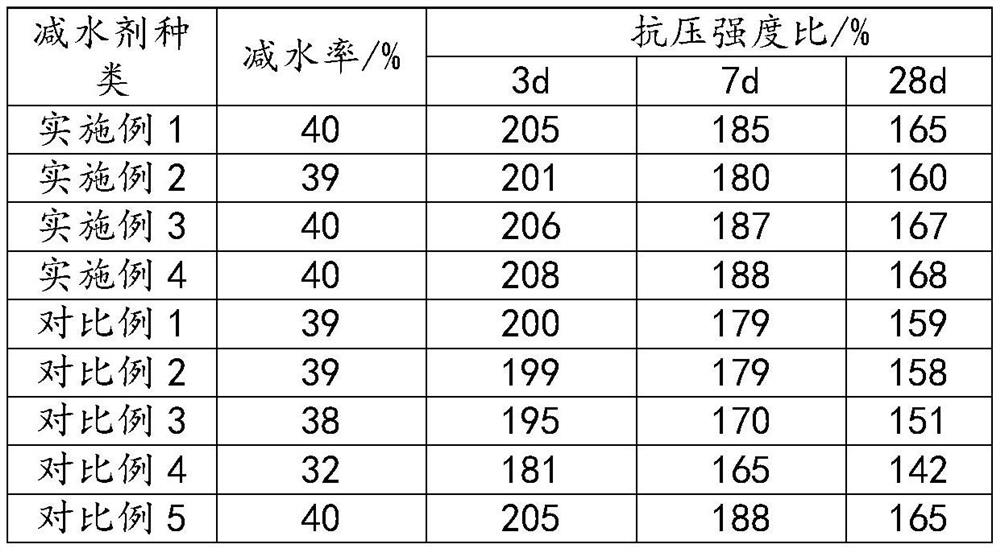

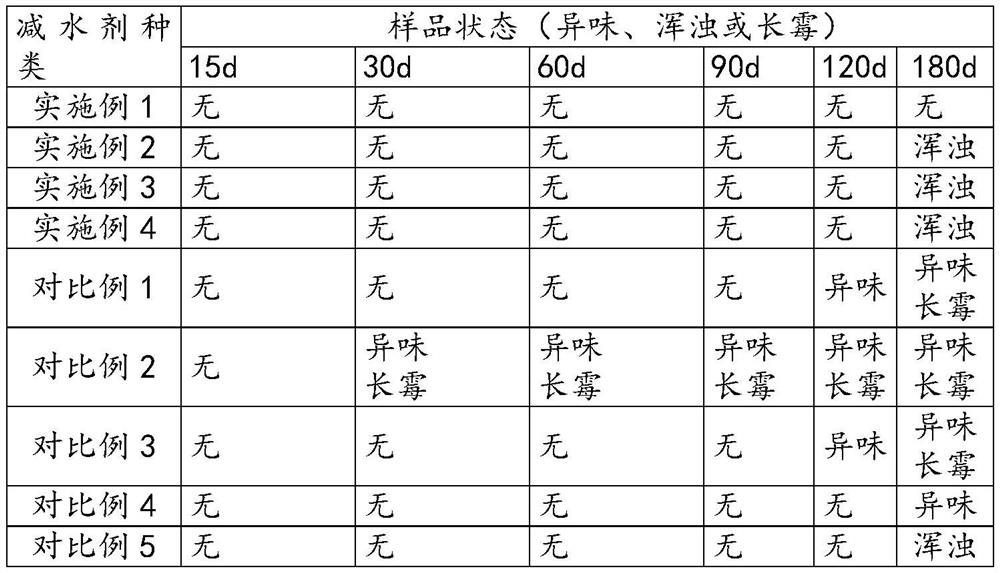

Esterification product for preparing water reducing agent, preparation method of esterification product, high-workability polycarboxylic acid water reducing agent and preparation method of high-workability polycarboxylic acid water reducing agent

PendingCN114181086AThere is no problem of uneven distributionExcellent high temperature corrosion resistanceOrganic compound preparationCarboxylic acid esters preparationSuperplasticizerBackbone chain

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Preparation method of electrochemiluminescence biosensor for detecting organochlorine pesticides

ActiveCN106198500AEasy to makeEasy to operateChemiluminescene/bioluminescenceAntigenElectrochemical response

Owner:河南安必诺检测技术有限公司

Anti-wear electrical ternary fluororubber nonmetal compensator and preparation method thereof

InactiveCN106566140AHigh bonding strengthImprove heat resistancePipeline expansion-compensationYarnPolymer science

The invention discloses a wear-resistant electrical ternary fluororubber nonmetal compensator, which is prepared from the following raw materials in parts by weight: a proper amount of ternary fluorubber, 100-110 of alkali-free bulked yarn fiberglass fabric, 50-55 of vinylidene fluoride-hexafluoropropylene copolymer, 200-220 of acetone, 2-2.5 of TEBA, 80-85 of 5-5.5 wt% potassium hydroxide aqueous solution, 110-120 of 30-31 wt% hydrogen peroxide aqueous solution, a proper amount of 36-38 wt% hydrochloric acid aqueous solution, 3-3.5 of zinc oxide crystal whiskers, 0.5-0.7 of zirconium oxychloride, 2.5-3 of PPS micron powder, and 0.3-0.5 of trifluoroethyl acrylate. According to the technical scheme of the invention, the compatibility and the heat resistance of PPS micron powder and rubber are improved. Meanwhile, the PPS micron powder can improve the toughness and the wear resistance of the rubber. Therefore, the toughness and the wear resistance of the compensator are improved.

Owner:DANGTU JINLONGFENG TECH CO LTD

Preparation method of heat-conducting flame retardant and application of heat-conducting flame retardant to battery shell

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

Functional slurry and application thereof

PendingCN111060234AHigh dielectric constantLow dielectric lossFluid pressure measurement using piezo-electric devicesMaterial nanotechnologyOrganic groupThin membrane

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG +1

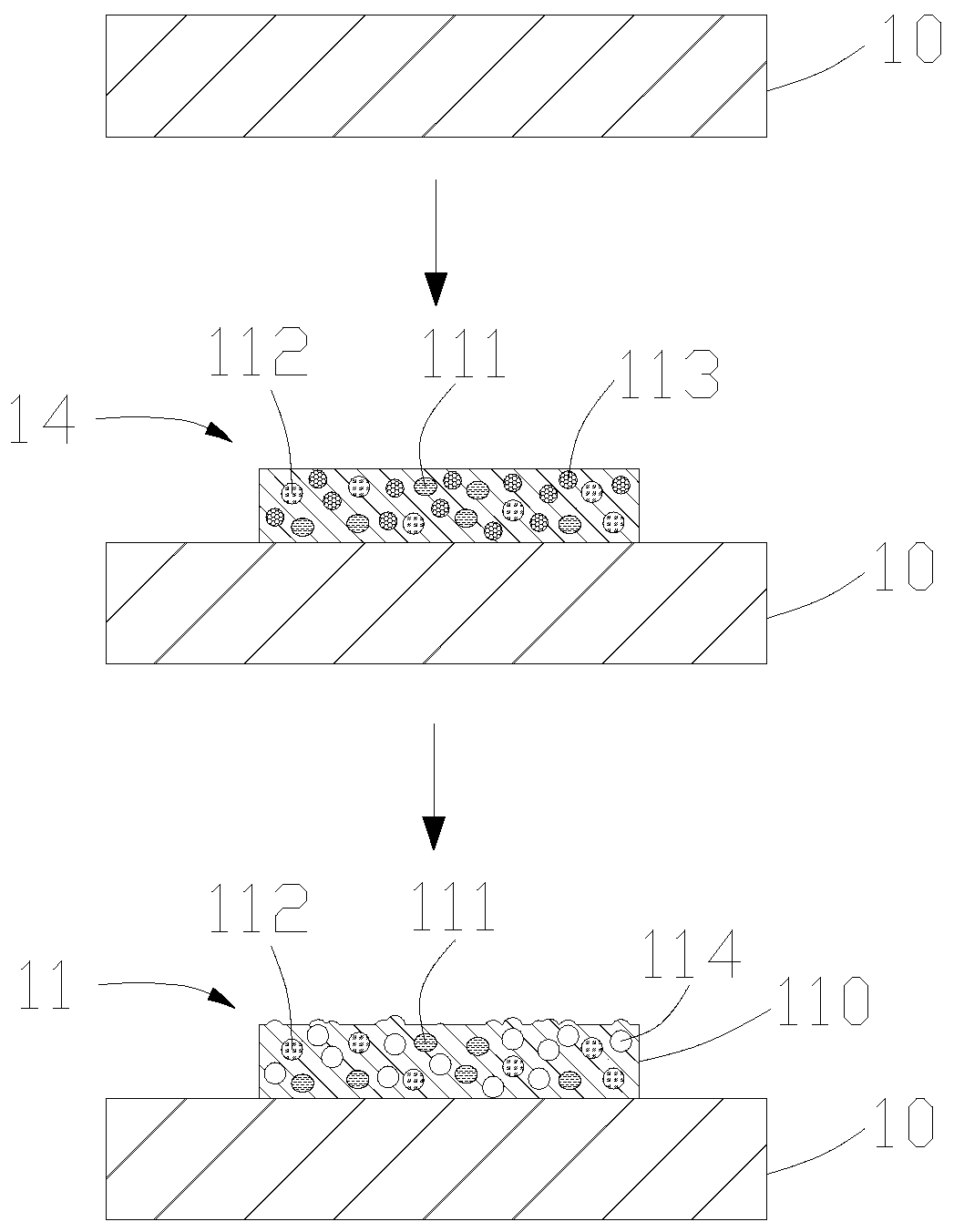

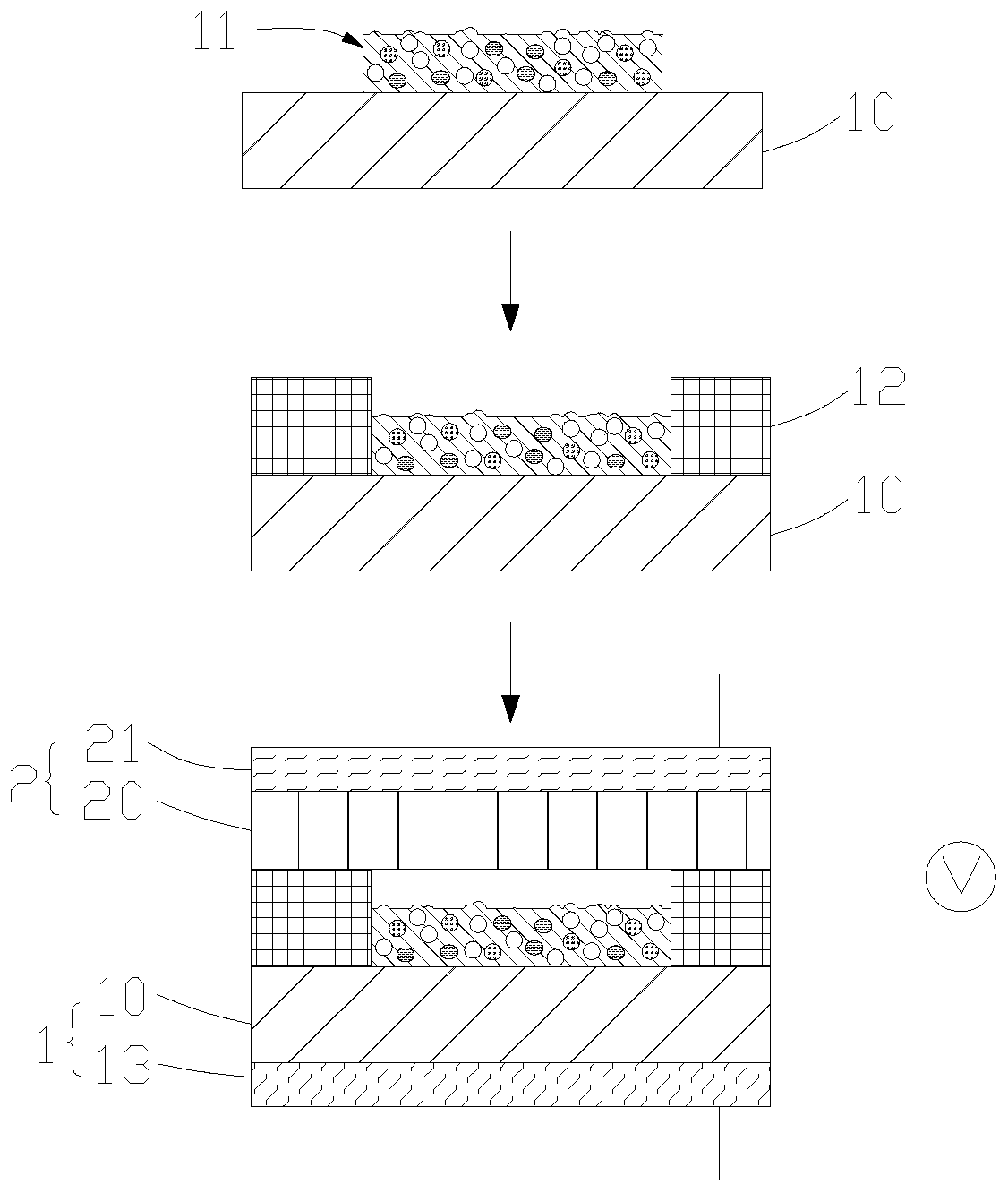

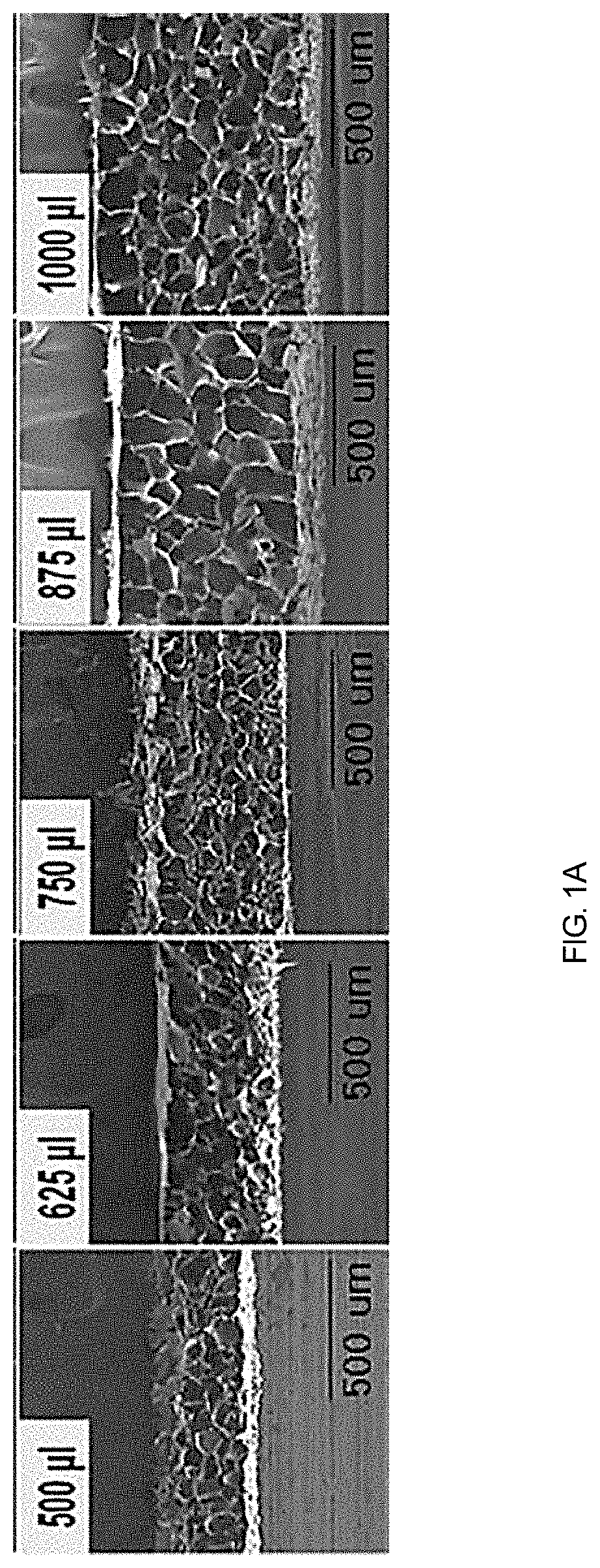

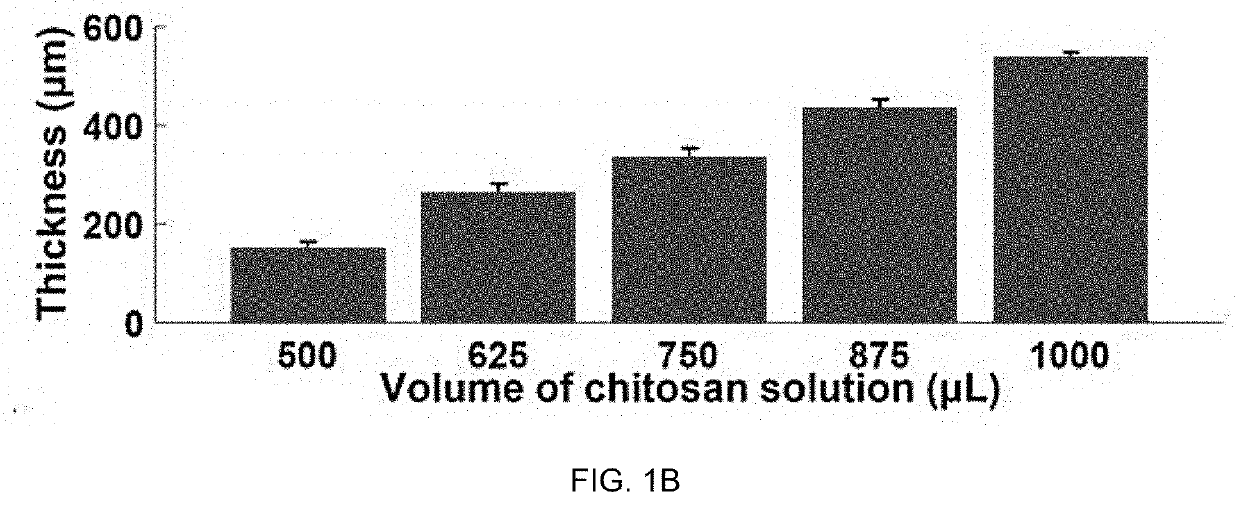

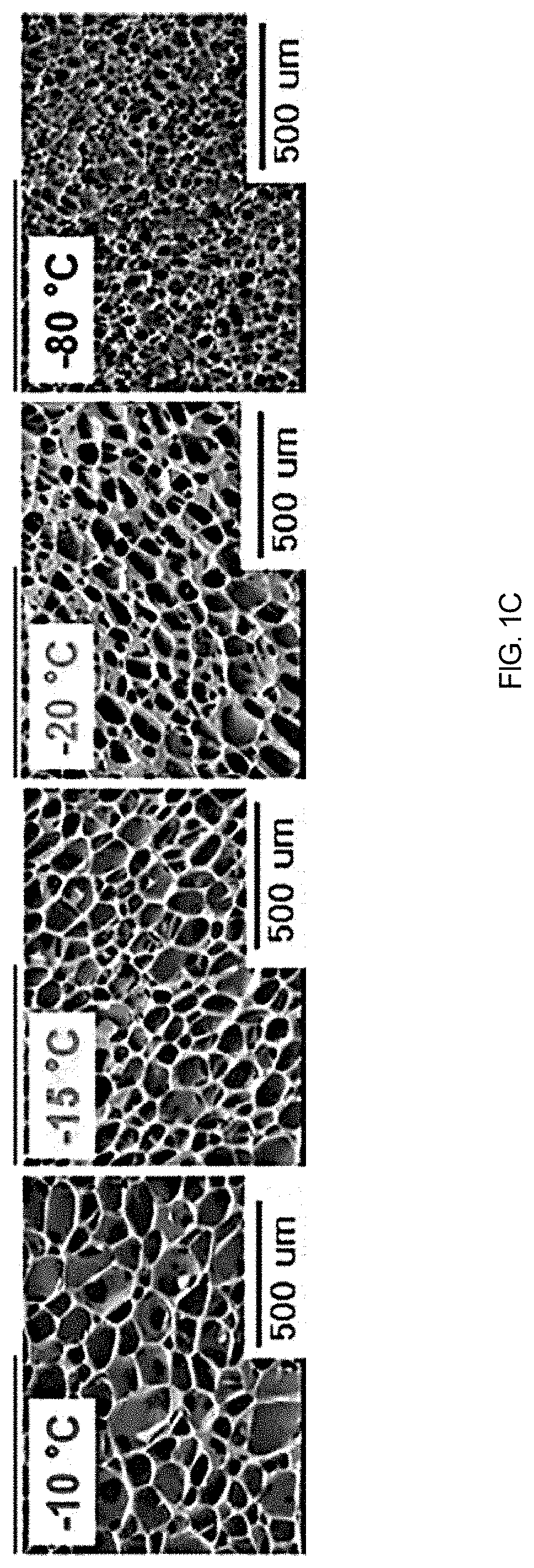

Chitosan porous structure-based magnetically actuated microrobot

PendingUS20220305243A1Precision therapyPowder deliveryEnergy modified materialsMagnetite NanoparticlesBiology

Owner:BIOT KOREA INC +1

High-elasticity-modulus and high-strength glass fiber laminated board and preparation method thereof

ActiveCN114030250AHigh elastic modulusHigh strengthSynthetic resin layered productsLaminationEpoxyGlass fiber

Owner:SHANDONG FIBERGLASS GRP

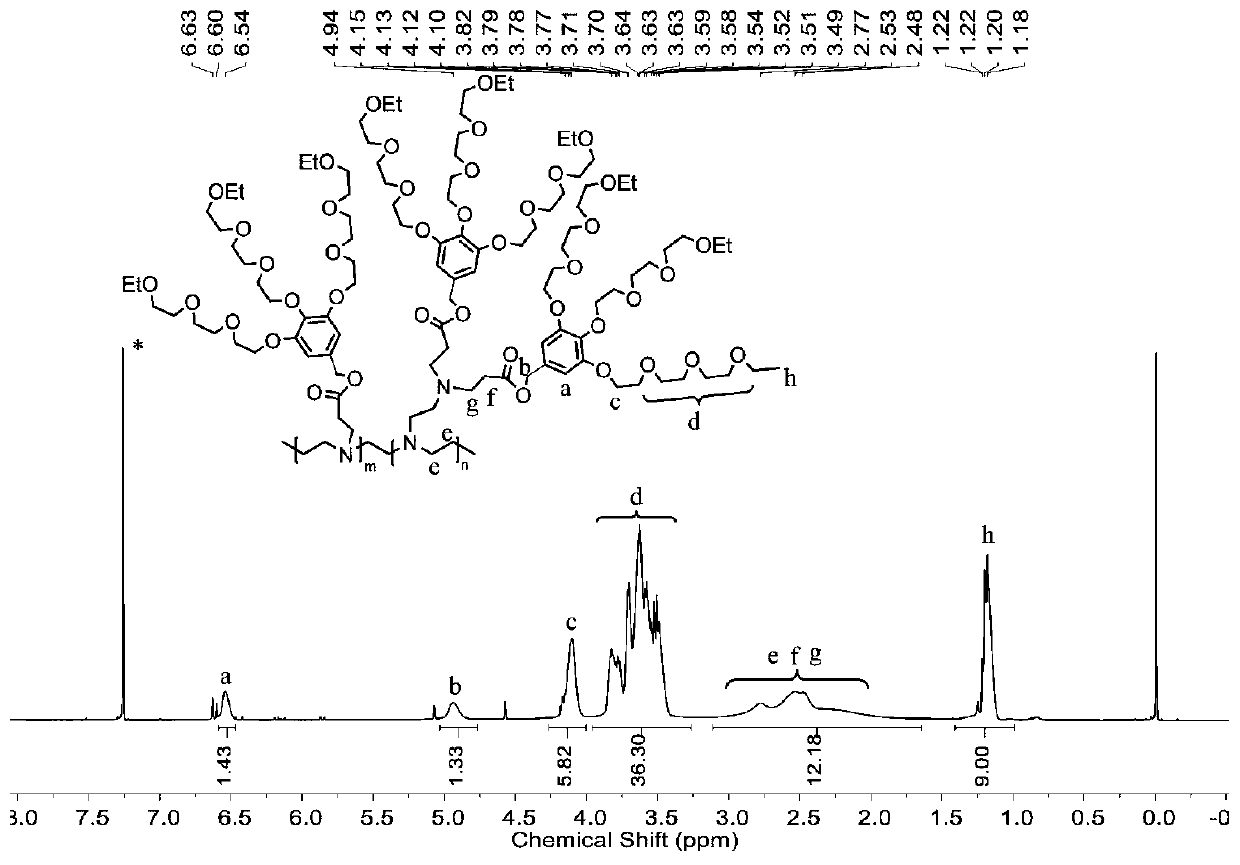

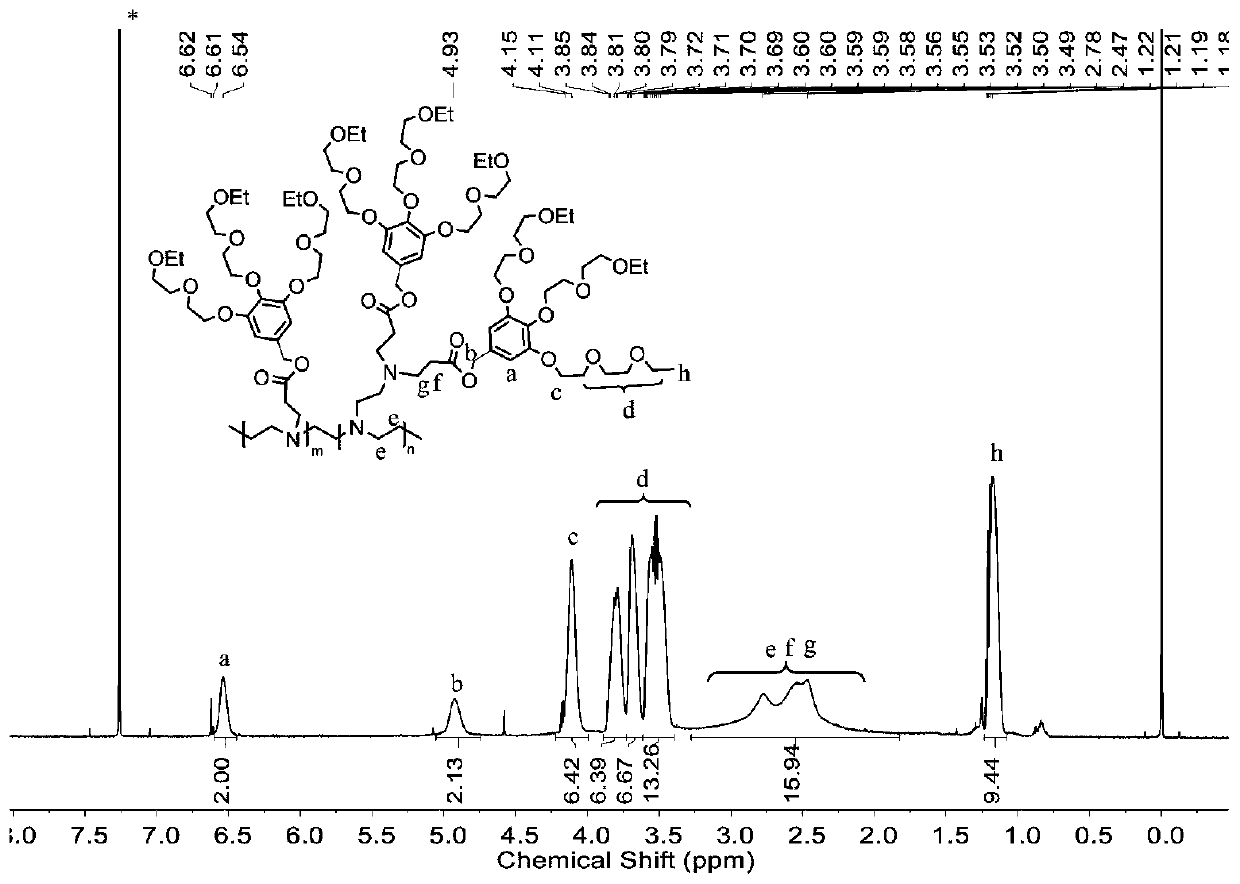

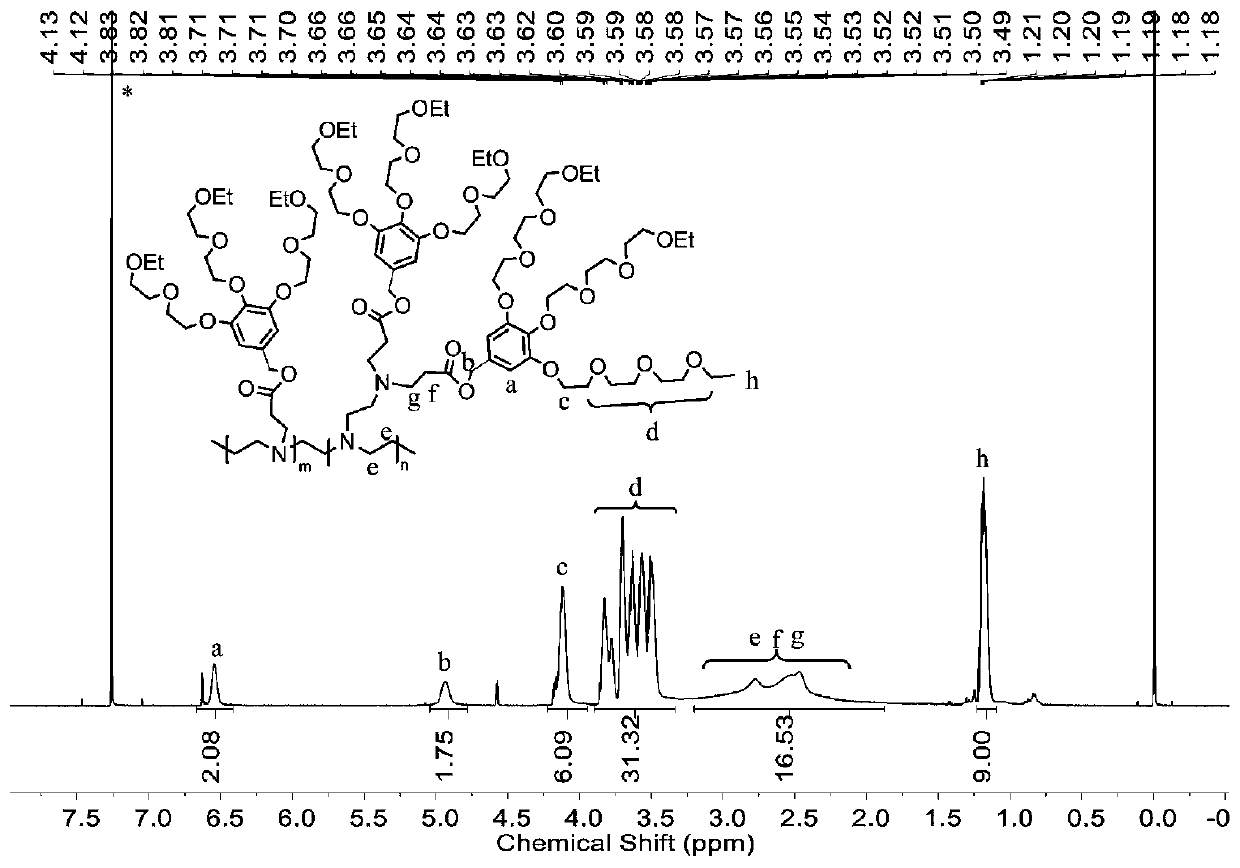

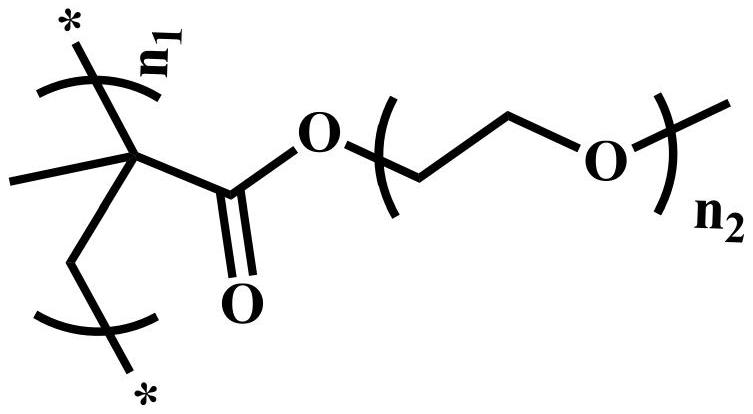

Alkoxy ether dendritic hyperbranched polymer, and preparation method and application thereof

ActiveCN111592656AFlexible control of intelligent response behaviorGood water solubilityPharmaceutical non-active ingredientsControlled releasePolymer science

Owner:SHANGHAI UNIV

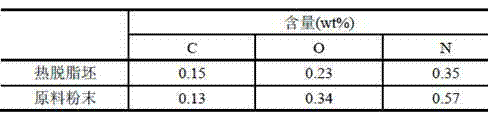

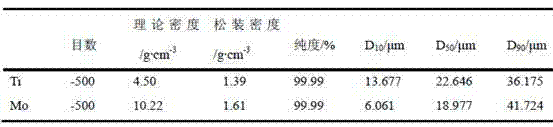

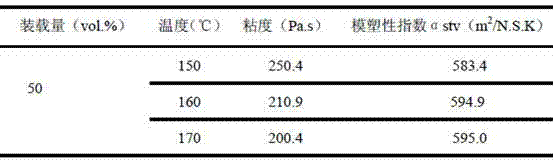

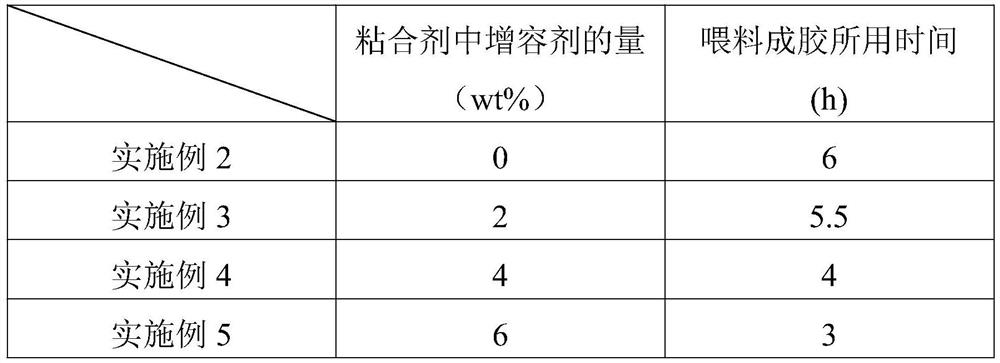

Compatibilizer for powder injection molding process, adhesive, feed and preparation method

Owner:HEFEI HUIZHI NEW MATERIAL TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap