Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22 results about "Twin screw extruder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superhigh melt index polypropene and preparing process thereof

Owner:DONGHUA UNIV

High-strength and high-modulus polyvinyl alcohol fiber and melt spinning method of high-strength and high-modulus polyvinyl alcohol fiber

InactiveCN102776597AHigh strengthMeet toughnessFilament forming substance formingArtificial filament washing/dryingAlcoholPolymer science

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

High bath-strength polypropylene and method for preparing same

Owner:SHANGHAI JIAO TONG UNIV

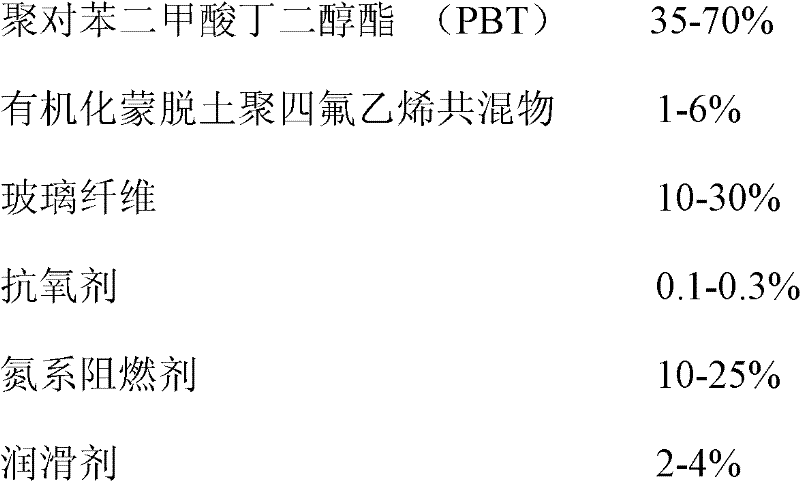

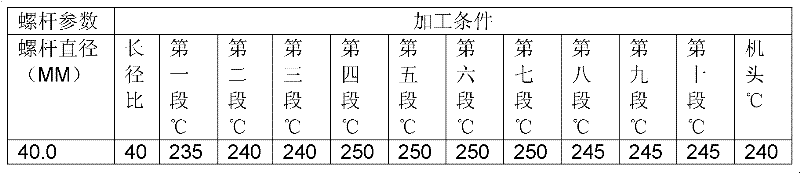

Halogen-free flame-retardant polybutylene terephthalate PBT (polybutylece terephthalate) composite material and preparation method thereof

ActiveCN102391624APhenomenon that limits floating fibersExcellent surface finishPolytetramethylene terephthalateAlkali free

Owner:LONGJAR SHANGHAI IND

Polylactic acid/starch whole biological-base composite material and preparation method of composite material

The invention discloses polylactic acid / starch whole biological-base composite material and a preparation method of the composite material. Based on 100 parts by weight of total raw materials, the composite material is prepared from the raw materials: 40-85 parts by weight of polylactic acid, 5-25 parts by weight of dextral polylactic acid-polyurethane and 7-50 parts of starch. The composite material is safe, non-toxic, and biodegradable, and has excellent mechanical properties. The preparation method comprises the following steps: uniformly mixing the raw material components, then adding themixed materials into a double-screw extruder for melting and blending, then performing pulling and pelletizing to obtain granular mixed resin, and performing drying to obtain the polylactic acid / starch whole biological-base composite material. The preparation method is simple and is easy to control; the operability is high; the implementation is easy; the production cost is low; the preparation method is easy for industrial large-scale production; and the prepared composite material can be applied to the fields of foaming materials, thin films, fibers, other special-shaped materials and the like.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

Method for preparing wear-resistant plastic particles by using waste polystyrene

InactiveCN110760138AImprove wear resistanceSolve the defect of poor wear resistanceCyclohexanoneSilicic acid

The invention discloses a method for preparing wear-resistant plastic particles by using waste polystyrene. The method specifically includes the following steps that (1) the waste polystyrene and liquid paraffin are put into a reactor for heat treatment under the nitrogen environment, then cobalt powder is added for natural cooling, and pretreated polystyrene is obtained; (2) tetraethyl orthosilicate is added into a chitosan solution, hydrochloric acid is added and then placed in a water bath, glutaraldehyde is added, and chitosan / silica particles are obtained by reaction; (3) the pretreated polystyrene is added into cyclohexanone after being cut into granules and dried, and polyvinyl pyrrolidone is added, stirred and dissolved, and then dried particles are added to obtain a coating solution; and (4) after the coating solution is treated, a film is scraped on a substrate, removed after phase transfer, and melted and extruded with a plasticizer and a lubricant through a twin-screw extruder. According to the method, by increasing the bond strength between the polystyrene and silicon dioxide, significant improvement of the wear resistance of the polystyrene is realized, and the methodis suitable for large-scale and industrial production.

Owner:ANHUI GUANHONG PLASTIC IND

Method for synthesizing heat resisting type vinyl aromatic monomer polymer

Owner:ZHEJIANG UNIV

Environment-friendly plastic material and preparation method thereof

The invention discloses an environment-friendly plastic material and a preparation method thereof. The preparation method comprises the following steps that 1, ball milling is performed on calcium sulfate and magnesium oxide through a ball mill, the ball milling time is 3-5 h, and the ratio of grinding media to the materials is 20:1-30:1; 2, 12-20 parts of polyamide-1010, 5-10 parts of polycarbonate, 4-9 parts of alkyd resin, 4-8 parts of polyvinyl alcohol, 3-8 parts of calcium sulfate, 4-10 parts of magnesium oxide, 2-6 parts of polytrimethylene terephthalate, 3-8 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 2-6 parts of polybutyl methacrylate and 4-10 parts of polyparahydroxybenzoic acid are weighed by weight, all the components are extruded inside a double-screw extruder, and the extruded components are the environment-friendly plastic material. The obtained plastic material effectively overcomes the defects that the tensile strength and the elongation at break of the conventional plastic material are low, and the mechanical performance of the plastic material is improved.

Owner:SUZHOU SHURUI ENVIRONMENTAL PROTECTION TECH CO LTD

Moisture-proof lead-free soldering nylon 46 composite material and preparation method thereof

InactiveCN102942785AImprove high temperature resistanceHigh tensile strengthGlass fiberMixed materials

The invention relates to a moisture-proof lead-free soldering nylon 46 composite material and a preparation method thereof. The nylon 46 composite material comprises the following components by weight: 40.4-89.2% of PA46 resin, 5-15% of PPO resin, 0-5% of a compatibilizer, 0-45% of glass fiber and 1-2% of other assistants. The preparation method of the composite material is as follows: weighing each component according to the above weight, and drying the components; adding the dried PA46 resin, PPO resin, compatibilizer and assistants into a high-speed mixer for mixing; and adding the mixed materials into a double-screw extruder, adding glass fiber for reinforcement, and extruding for granulation. The composite material provided by the invention has excellent wet proof lead-free soldering performance and good mechanical properties, and can be applied to the preparation of connector of electronic and electrical products requiring lead-free soldering and preparation of high-temperature resistant automotive plastic parts, etc.

Owner:HUIZHOU HUAJU PLASTIC TECH CO LTD +1

Polyester molded composition and production method and application thereof

InactiveCN109867923AMeet air tightness requirementsImprove bindingSemiconductor devicesArylPolymer science

The invention discloses a polyester molded composition. The polyester molded composition comprises the following components: 50-80 parts of PCT resin, 10-30 parts of white pigment, 10-30 parts of enhancing material and / or filler and 0.1-2 parts of phosphorous compound; and the phosphorous compound is of a structure as shown in the description, wherein R1 is aryl or OR2, R2 is aryl or alkyl containing 1-30 carbon atoms, R3 is alkyl containing 1-10 carbon atoms, and R4 and R5 are phenyl or alkyl containing 0-10 carbon atoms. A production method comprises the steps of mixing the polyester resin,the white pigment and the phosphorous compound in a high-speed mixer according to proportions, adding a mixture, the enhancing material and / or the filler into a twin-screw extruder, and conducting melt blending, extruding and granulating on a mixture to obtain the polyester molded composition. The polyester molded composition has high adhesion to a metal material strap and good air impermeability,reflectivity and light-resistant and heat-aging-resistant performance.

Owner:KINGFA SCI & TECH CO LTD +1

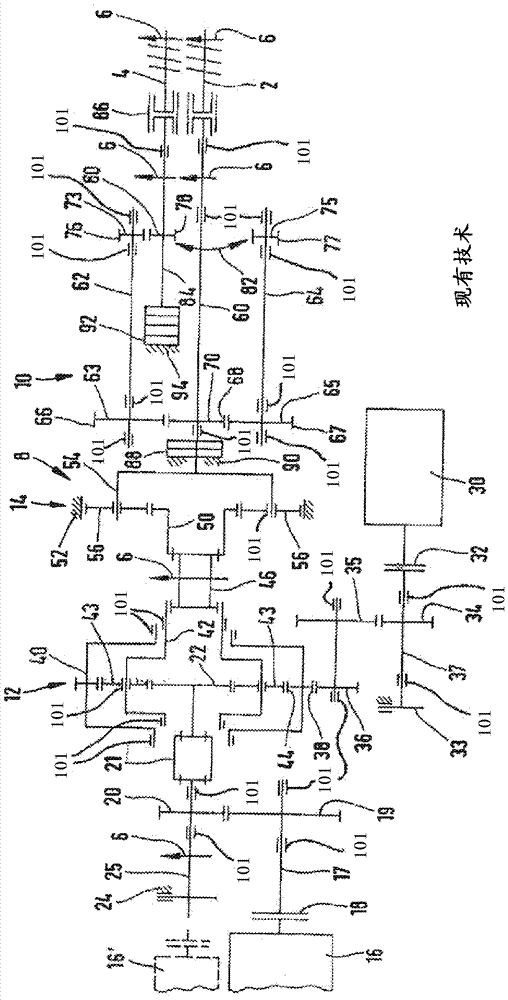

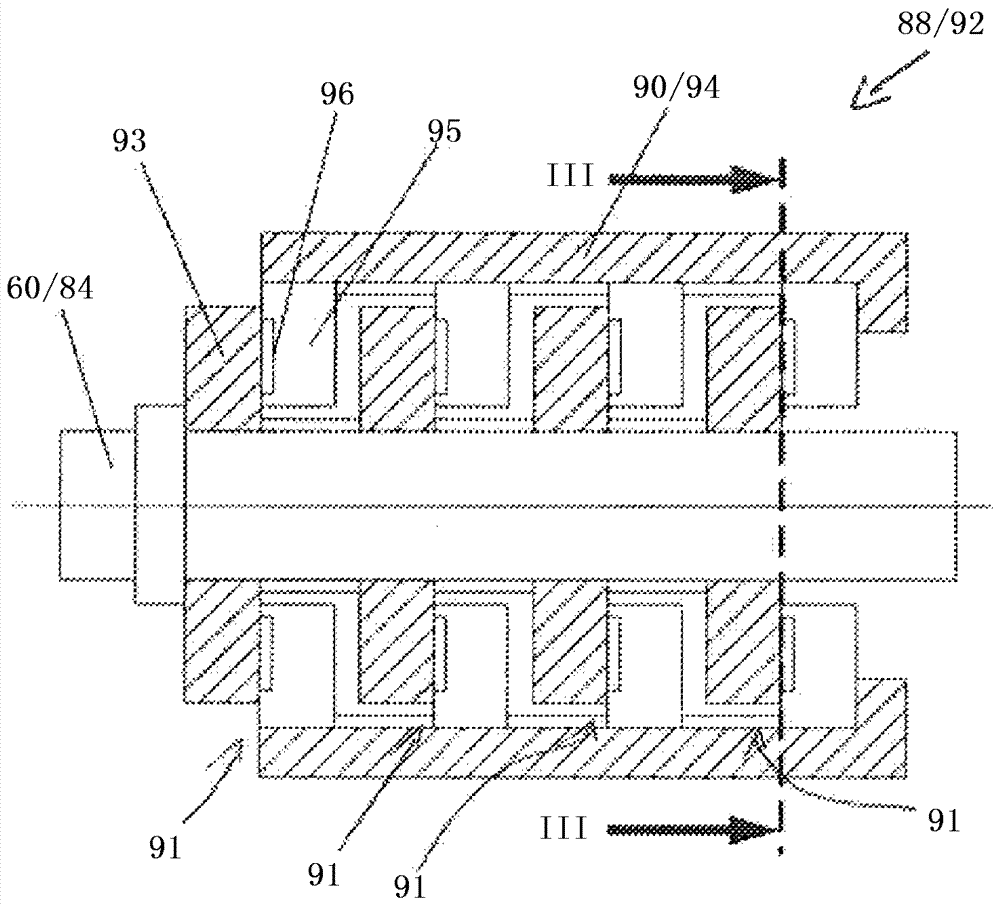

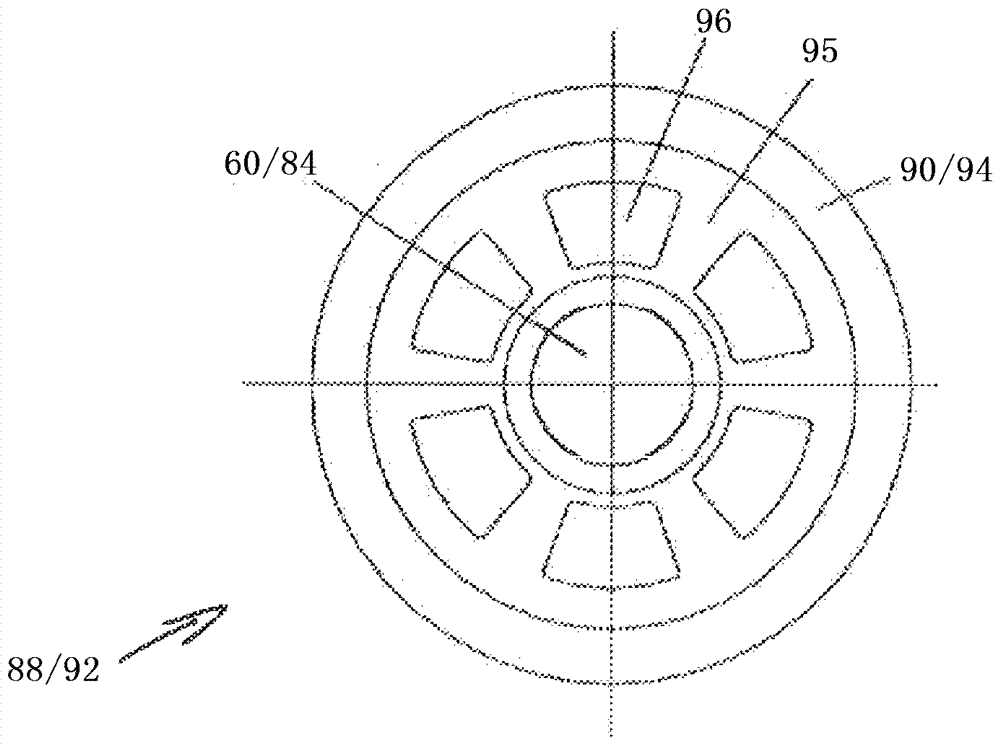

Drive device for twin-screw extruder

Owner:レンクゲーエムベーハー

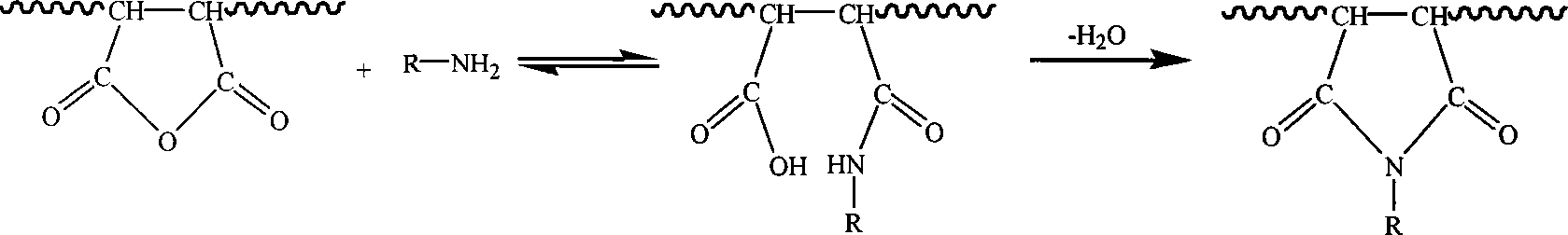

High-impact-resistance high-flowability ABS resin and preparation method thereof

InactiveCN108329646ASolve the problem of low impact strengthLiquidPolymer scienceBulk polymerization

The invention specifically relates to a preparation method for a high-impact-resistance high-flowability ABS resin, belonging to the technical field of high-molecular materials. The preparation methodcomprises the following steps: preparing ABS resin with high impact strength by using a DOW continuous bulk polymerization process, adding bulk ABS resin, SAN resin, a plasticizer, a lubricant and acompatibilizer in a certain mass ratio into a mixer for thorough mixing so as to obtain a mixed material; and then feeding the obtained mixed material into a twin-screw extruder for mixing, extruding,drawing, cooling and pelletizing so as to obtain the high-impact-resistance high-flowability ABS resin. The ABS resin prepared in the invention has superior impact performance; at the same time, thecompatibilizer is added during blending, so the compatibility between the ABS resin and the SAN resin is improved, the adhesion between the two polymers is increased, and a more stable structure is formed.

Owner:NORTH HUAJIN CHEM IND CO LTD

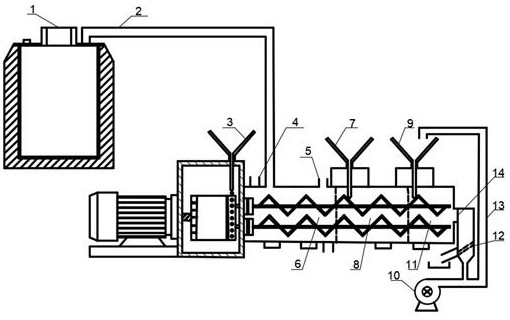

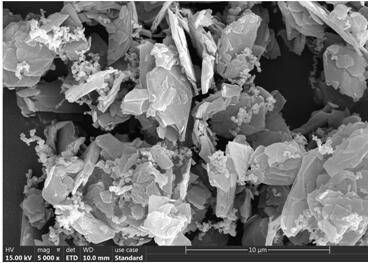

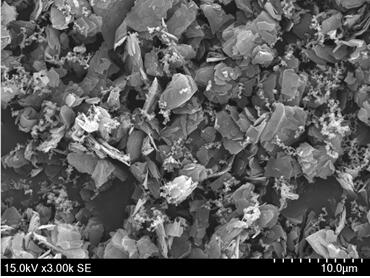

Method for preparing lithium battery negative electrode by compounding silicon, carbon and silicon dioxide in extruder

ActiveCN112151767AImprove composite effectAchieve physical wrappingNegative electrodesSecondary cellsNano siliconSilicon monoxide

Owner:梧州市同创新能源材料有限公司

Method for processing healthy and efficient bait

Owner:天门市兴发渔具厂

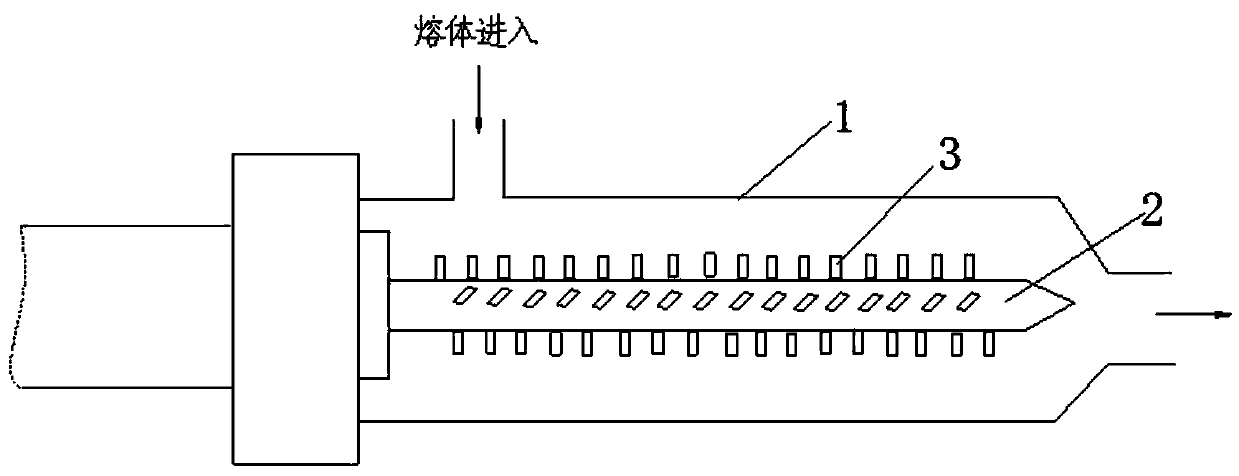

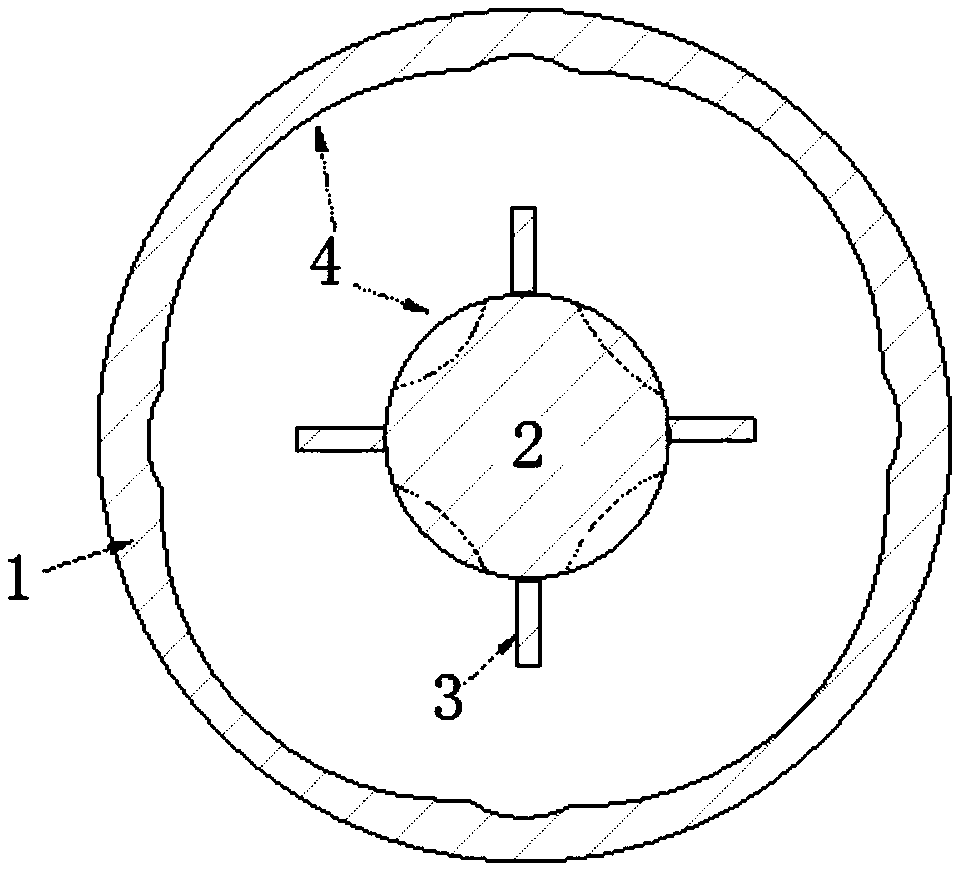

Cooling system for drive motor in twin-screw extruder

InactiveCN102832743AEffective coolingGuaranteed service lifeCooling/ventillation arrangementSupports/enclosures/casingsElectric machineEngineering

Owner:JIANGYIN LONGSHAN SYNTHETIC MATERIAL

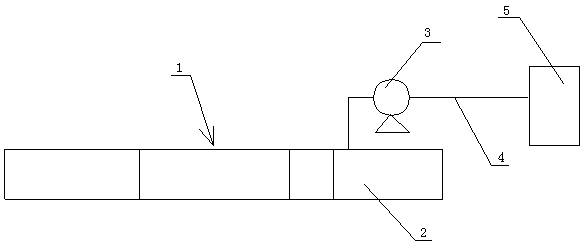

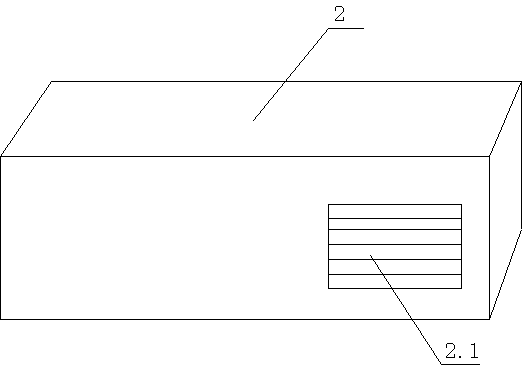

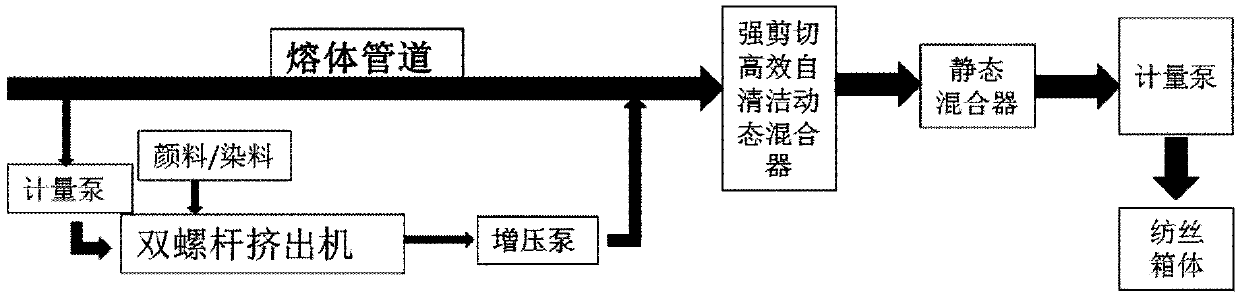

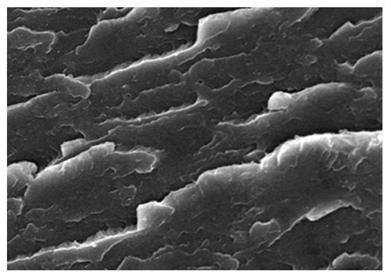

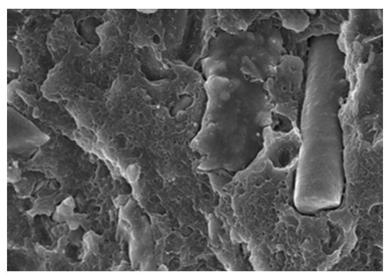

Direct-spun polyester colored staple fiber production equipment and direct-spun polyester colored staple fiber production method

InactiveCN111041564AEvenly dispersedRealize online direct spinningPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermally conductive insulating material for high-power LED substrate and preparation method thereof

ActiveCN103764743BImprove thermal conductivityNo reduction in physical and mechanical propertiesPolyolefinSolvent

Owner:CHANGZHOU TONGBAO PHOTOELECTRIC MFG CO LTD

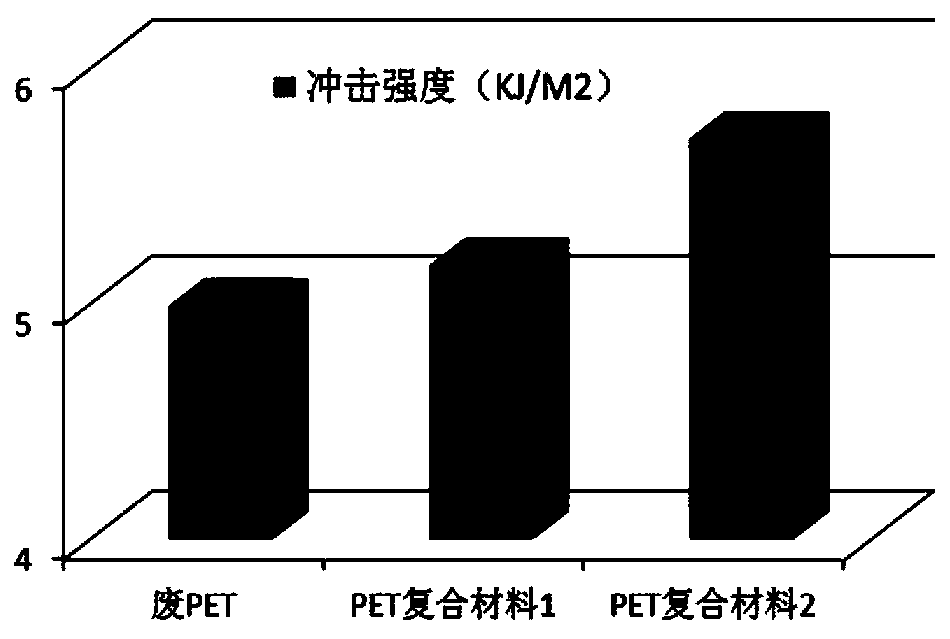

Waste PET composite material

ActiveCN109651776AOvercoming the problem of insufficient impact strengthImprove rigidityElastomerPolyolefin

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Heat-conducting POM (polyformaldehyde) material and preparation method thereof

Owner:NANTONG RED STONE TECH DEV

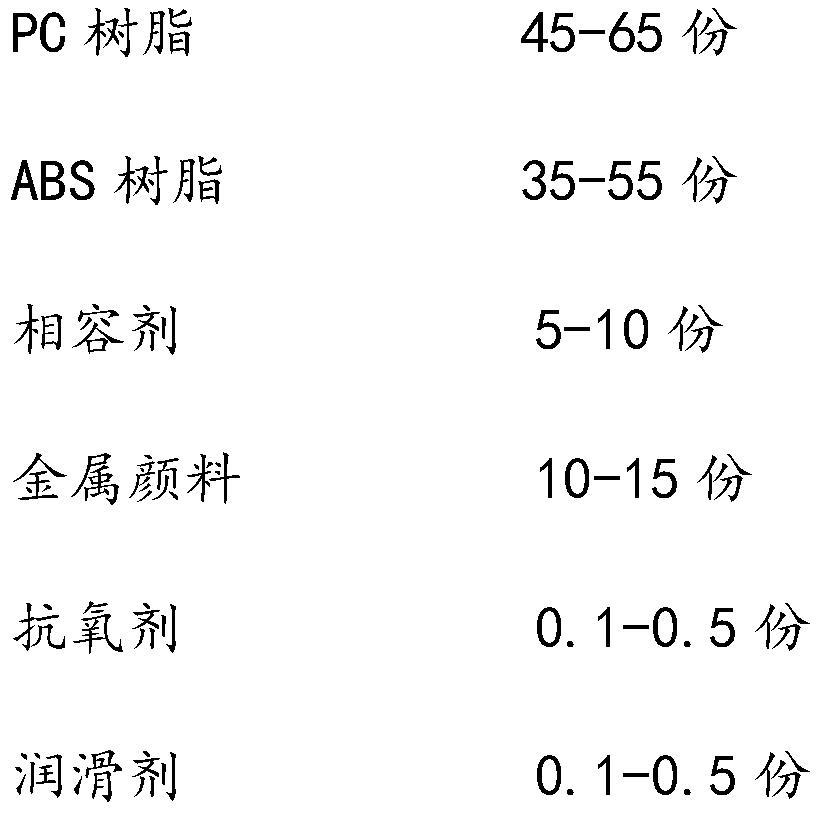

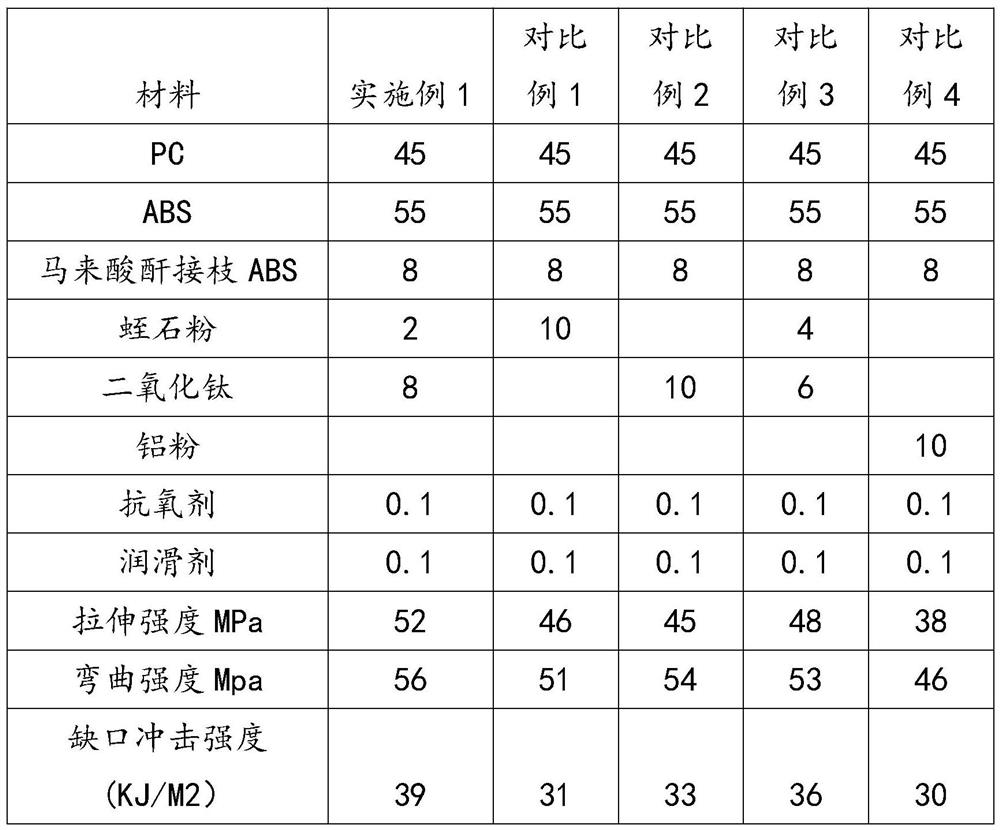

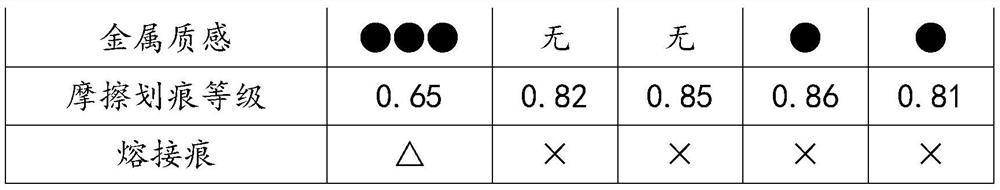

A kind of metallic texture, scratch-resistant PC/ABS composite material and preparation method thereof

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

Method for controlling discoloration of nylon

Owner:NANJING HONGRUI PLASTIC PROD

Manufacturing method of biodegradable cast film paper

PendingCN113956520ASolve non-degradable problemsImprove water vapor permeabilityFiberPolyethylene glycol

Owner:XIONGXIAN HENGTONG IND & TRADE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap