Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29 results about "Silicon oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon oxide may refer to either of the following: Silicon dioxide, SiO₂, very well characterized Silicon monoxide, SiO, not very well characterized

Chemical Mechanical Polishing Slurry Composition for Polishing Phase-Change Memory Device and Method for Polishing Phase-Change Memory Device Using the Same

InactiveUS20090001339A1Increase chanceMinimize occurrenceOther chemical processesSolid-state devicesHigh ratePhase-change memory

Owner:CHEIL IND INC

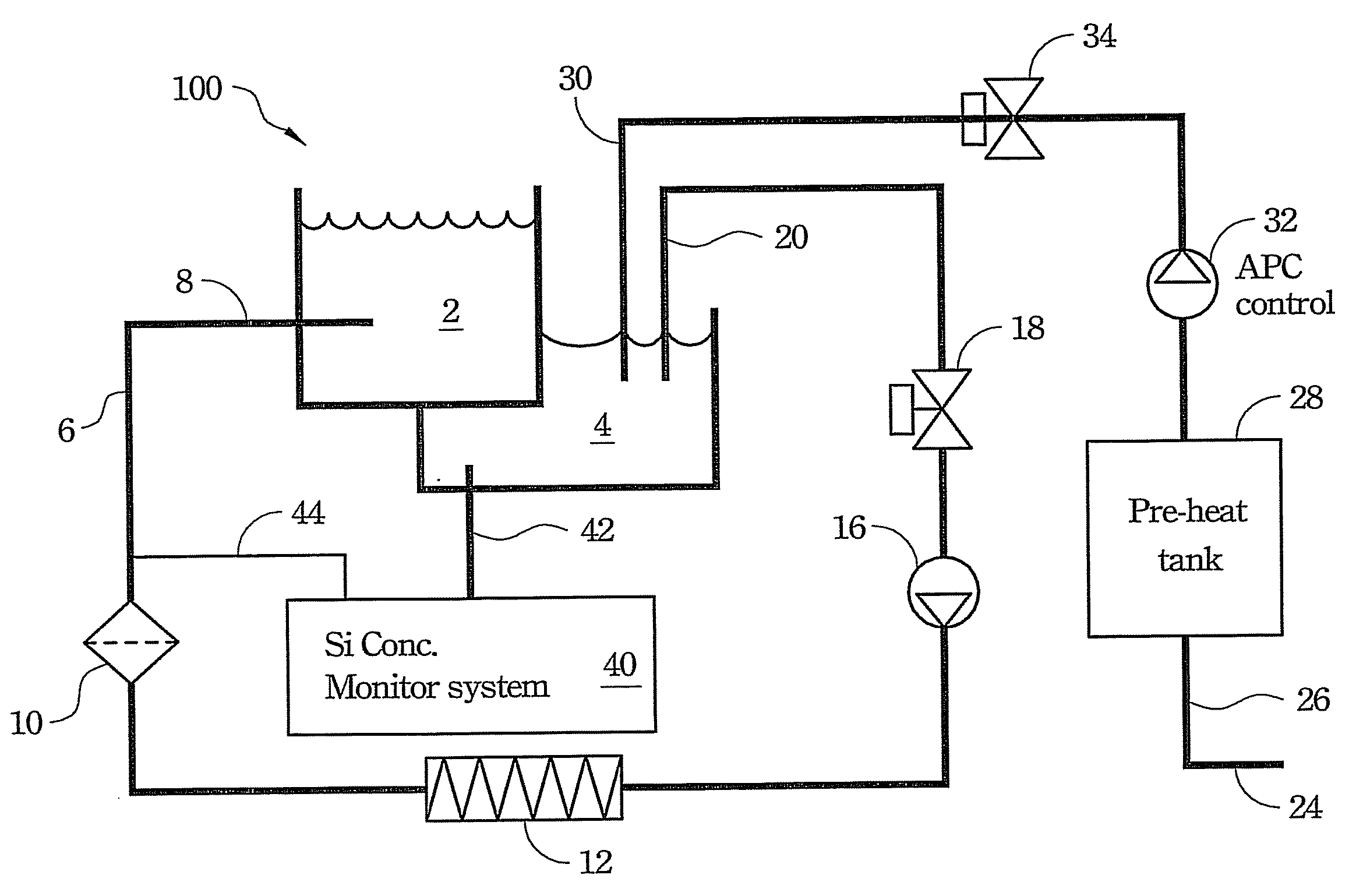

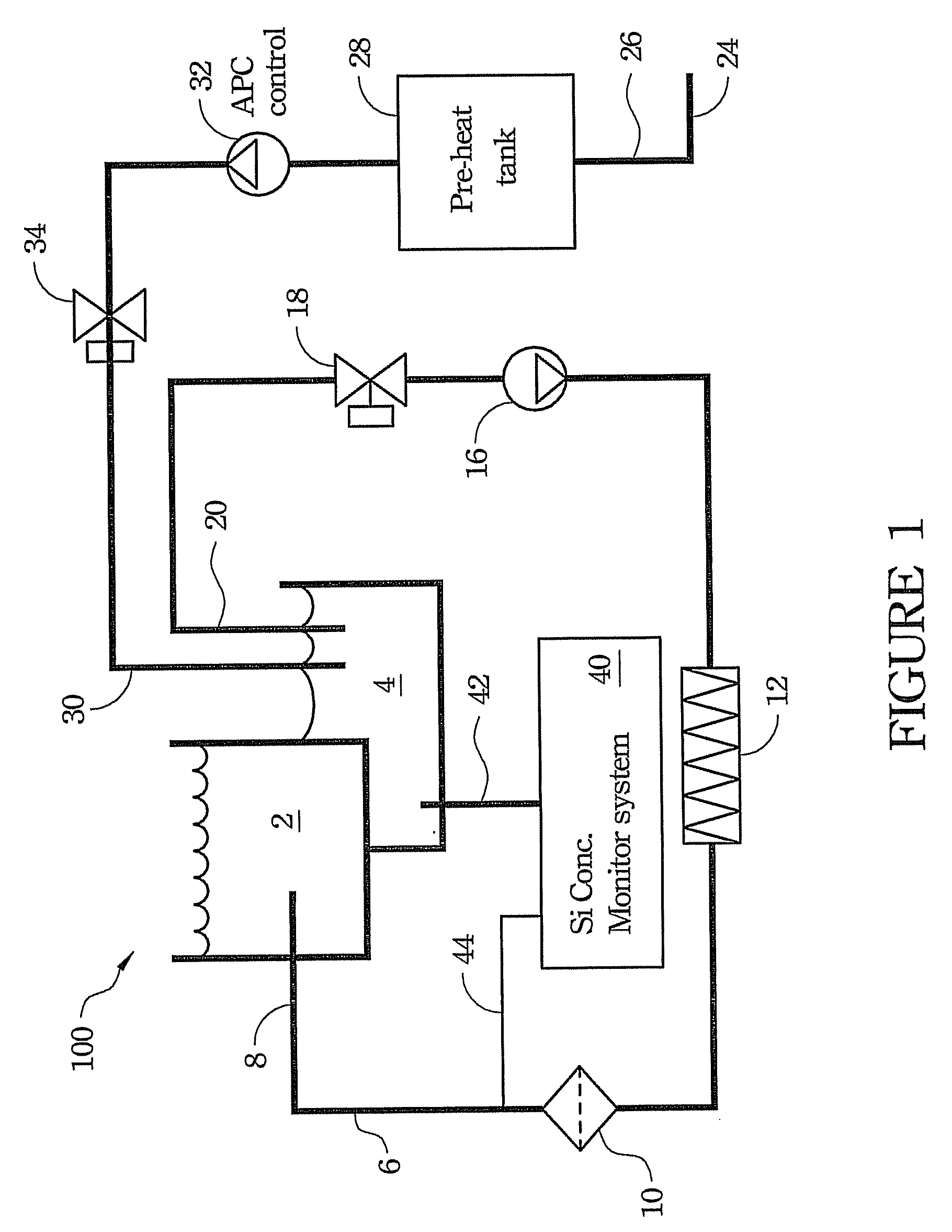

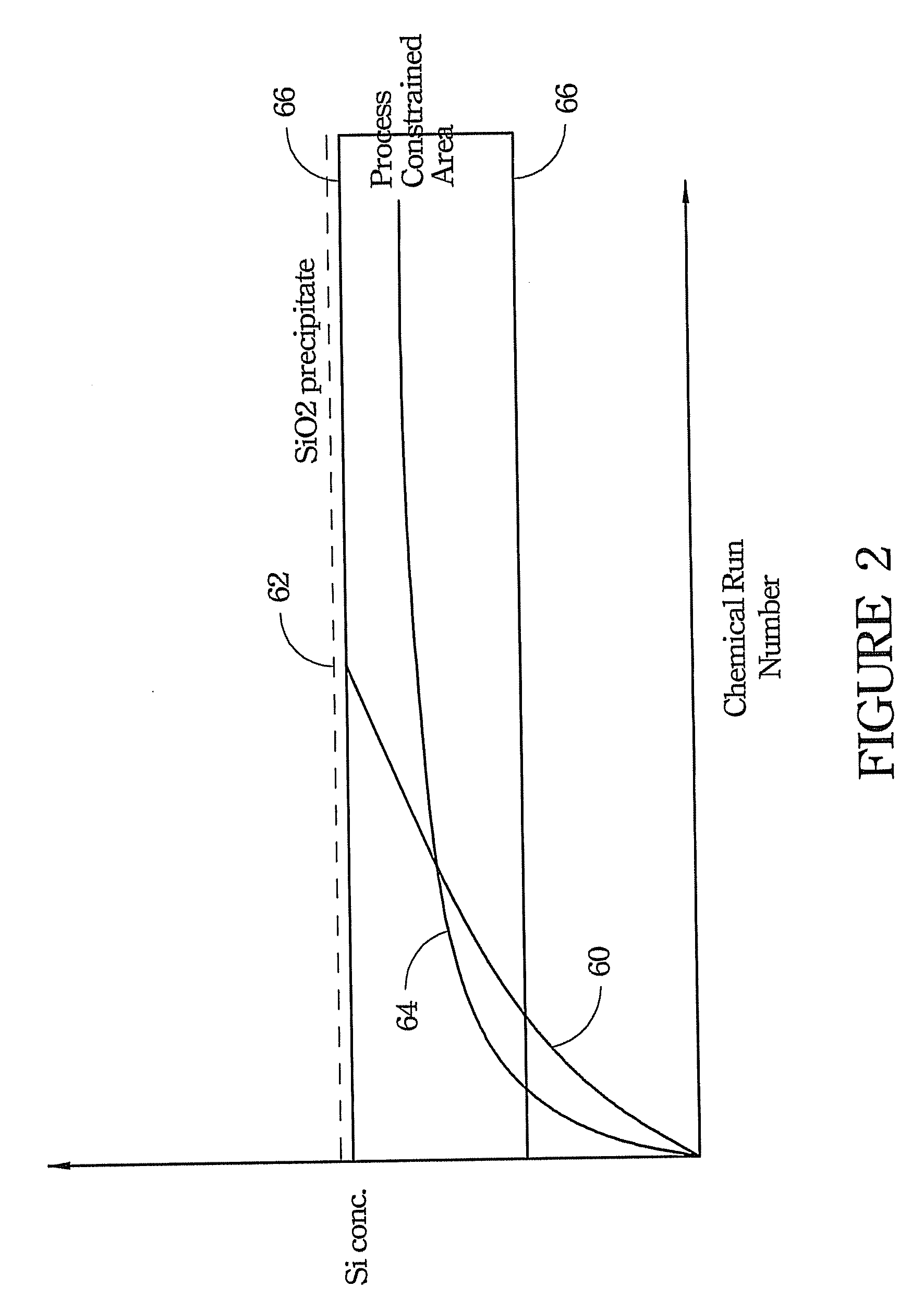

Apparatus and method for controlling silicon nitride etching tank

ActiveUS20080179293A1Semiconductor/solid-state device testing/measurementDecorative surface effectsO-Phosphoric AcidSteady state temperature

Owner:TAIWAN SEMICON MFG CO LTD

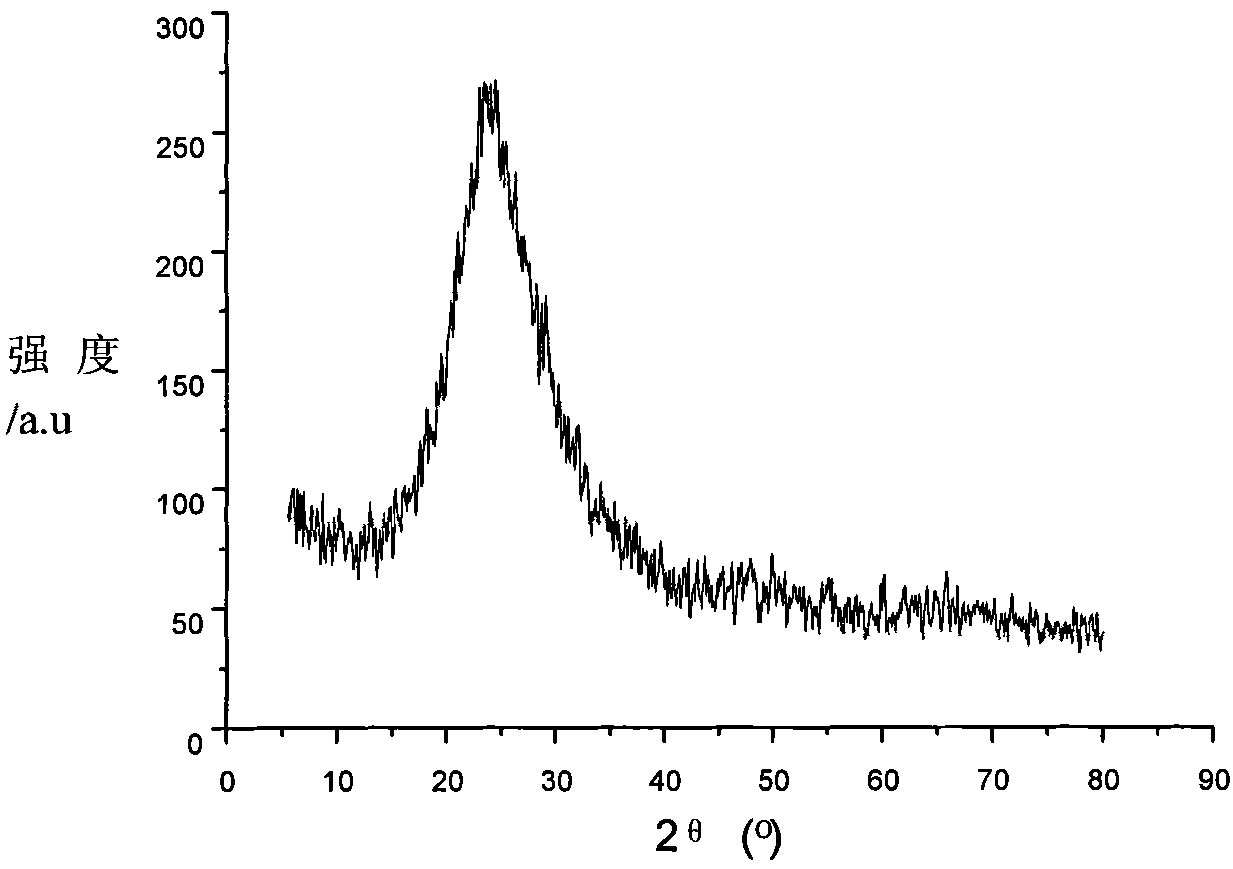

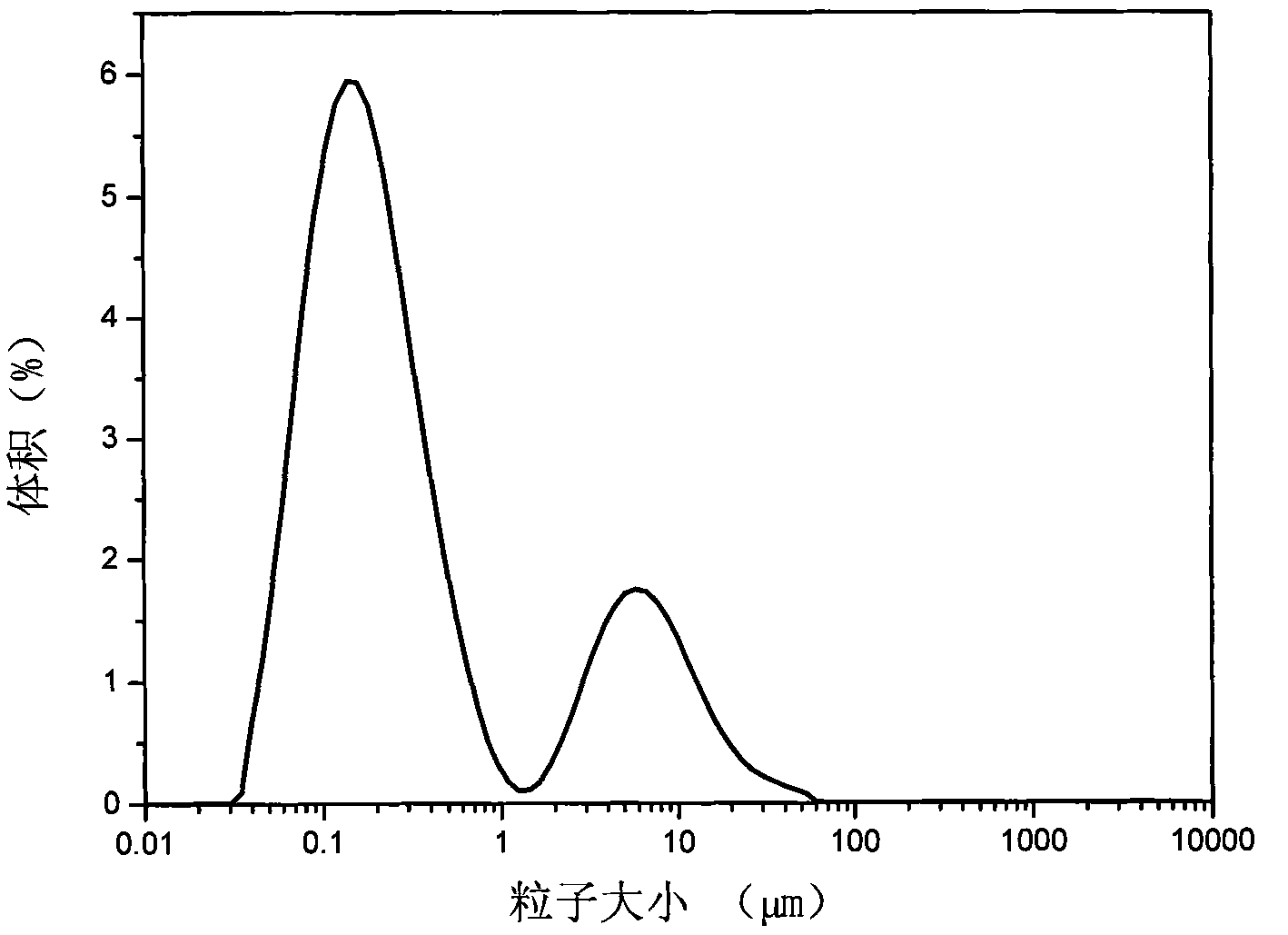

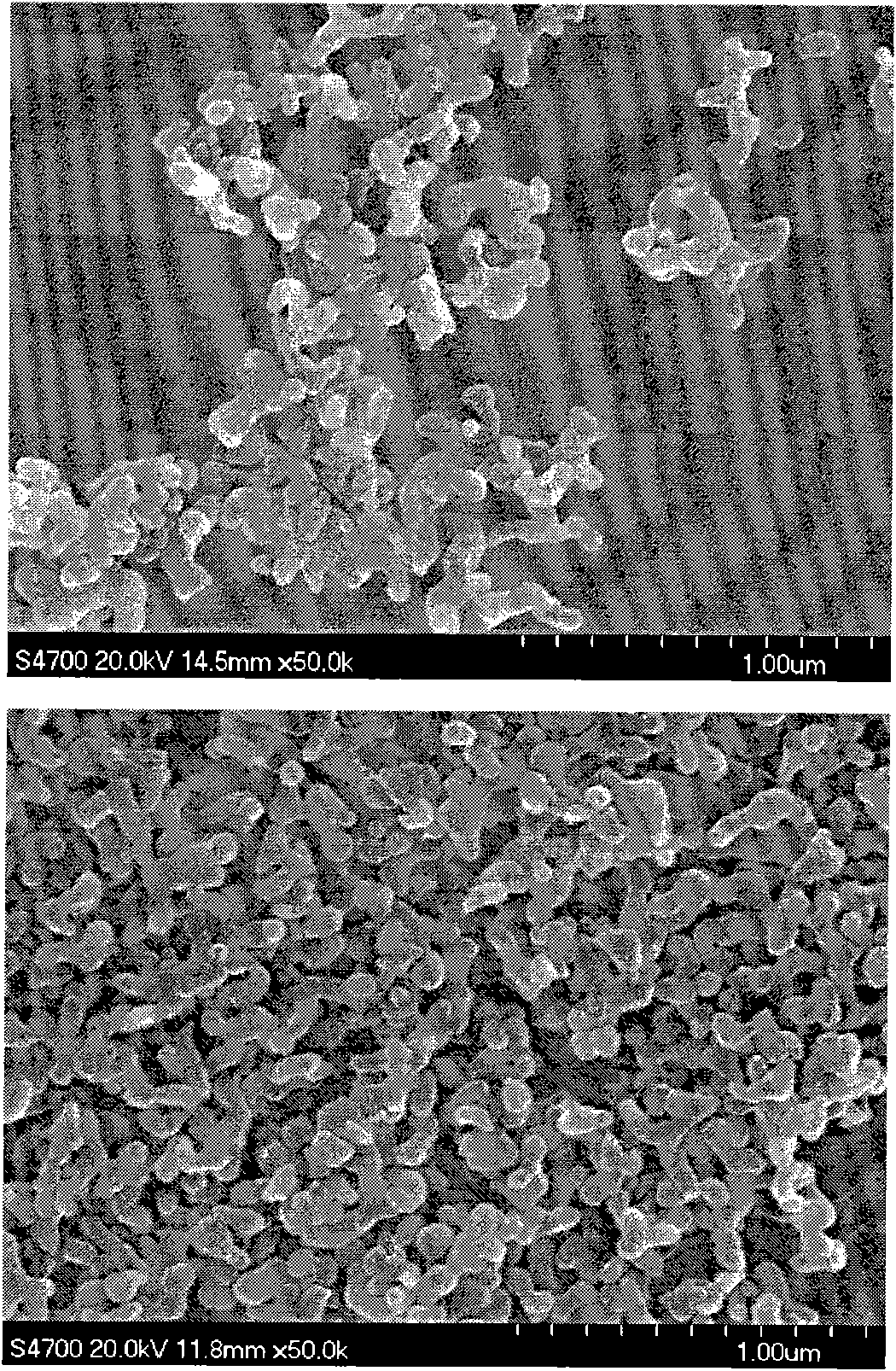

Preparation method of zirconium oxide-silicon oxide composite aerogel

ActiveCN103214034ALow densityLow thermal conductivitySilicon compoundsZirconium oxidesAlcoholSilicon oxide

The invention relates to a preparation method of zirconium oxide-silicon oxide composite aerogel. The method comprises the following steps of: dissolving siloxane in alcohol and uniformly stirring the solution to obtain alcohol solution of the siloxane; titrating concentrated nitric acid with 65-68% of mass concentration, titrating deionized water after stirring uniformly and continuously stirring; titrating the concentrated nitric acid to the pre-hydrolyzed siloxane solution, titrating zirconium alkoxide after mixing uniformly, adding the deionized water after stirring uniformly and stirring continuously to obtain clear and transparent gel; transferring the gel to a mould, and still standing and aging the gel to obtain the zirconium oxide-silicon oxide composite wet gel; soaking the wet gel by using aging solution; and finally soaking the gel by using absolute ethyl alcohol or isopropanol solvent. The blocky zirconium oxide-silicon oxide composite aerogel featured with low density and low thermal conductivity prepared by the invention basically keeps the former microcosmic undefined structure after thermal treatment at 1000 DEG C, and has specific area up to 353m<2> / g and good high-temperature stability.

Owner:LINXIAO (TIANJIN CHINA) TECH CO LTD

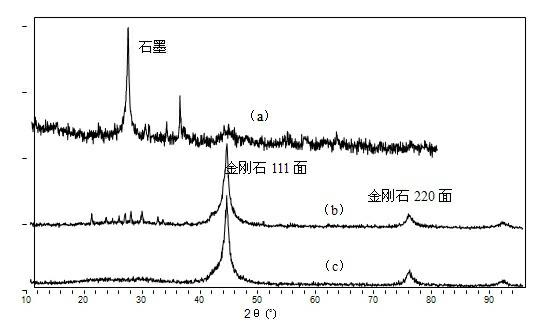

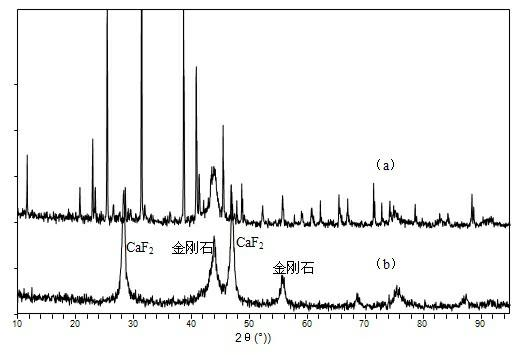

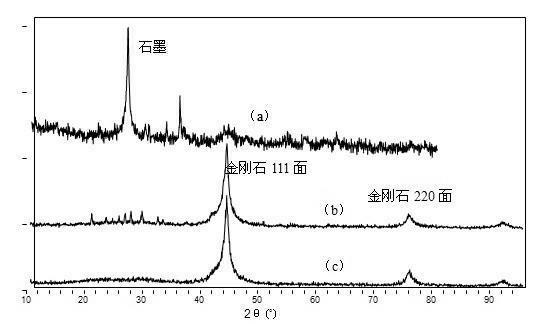

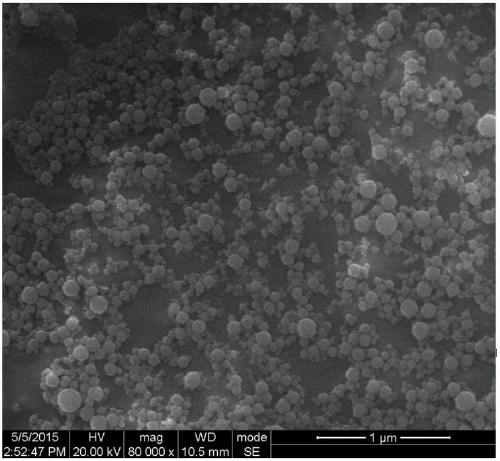

Purification method of nano diamond ash material

Owner:江苏金海丰硬质材料科技有限公司

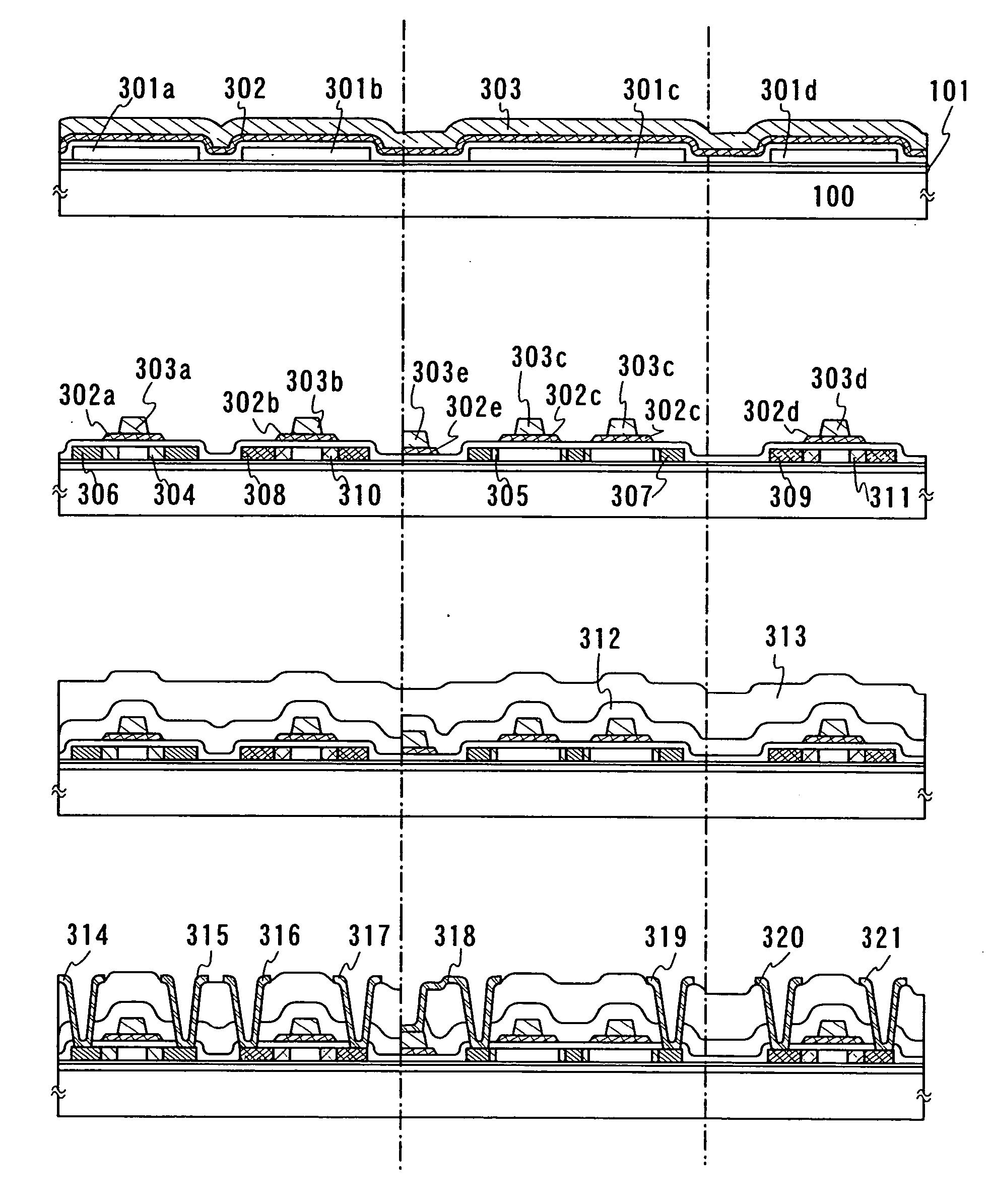

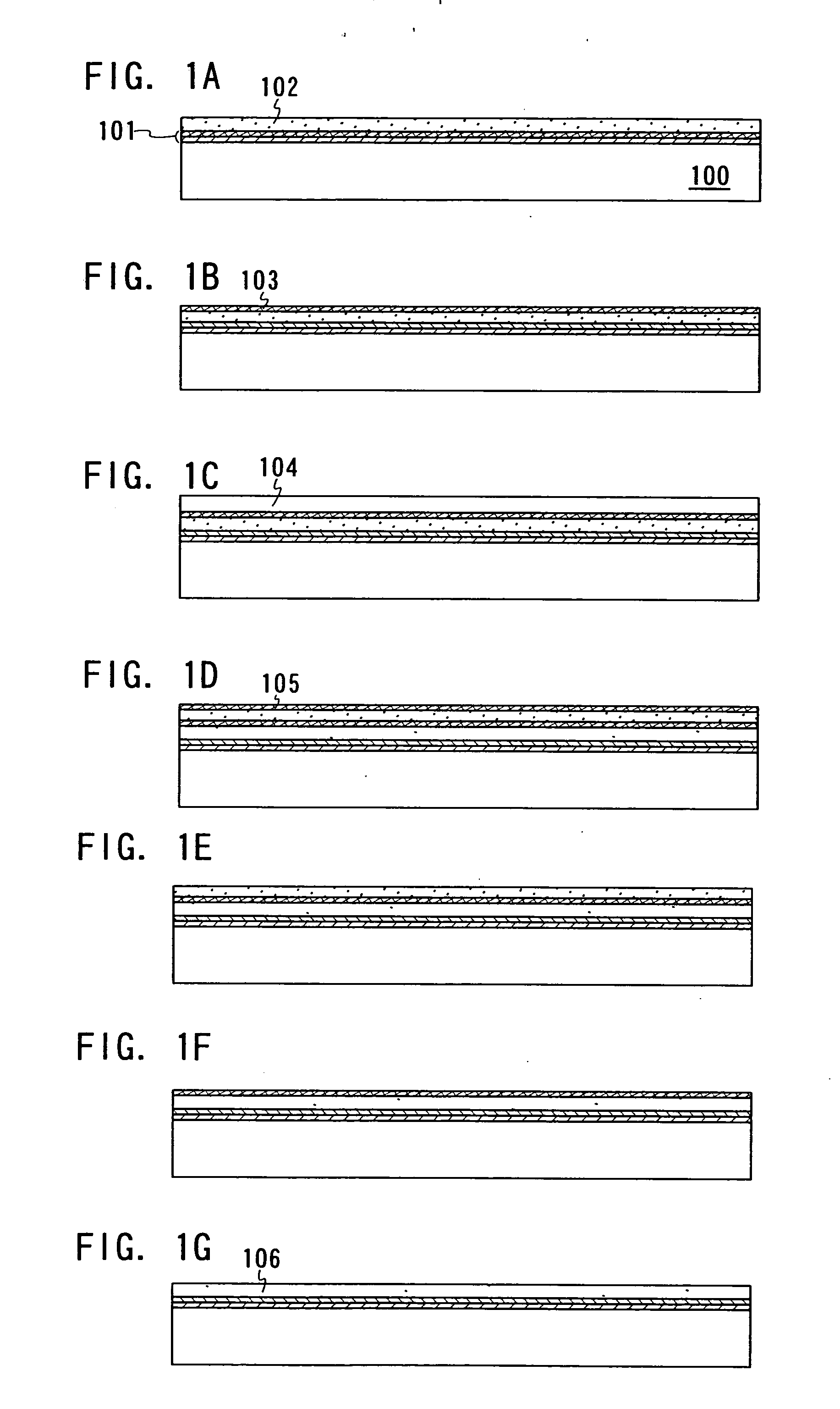

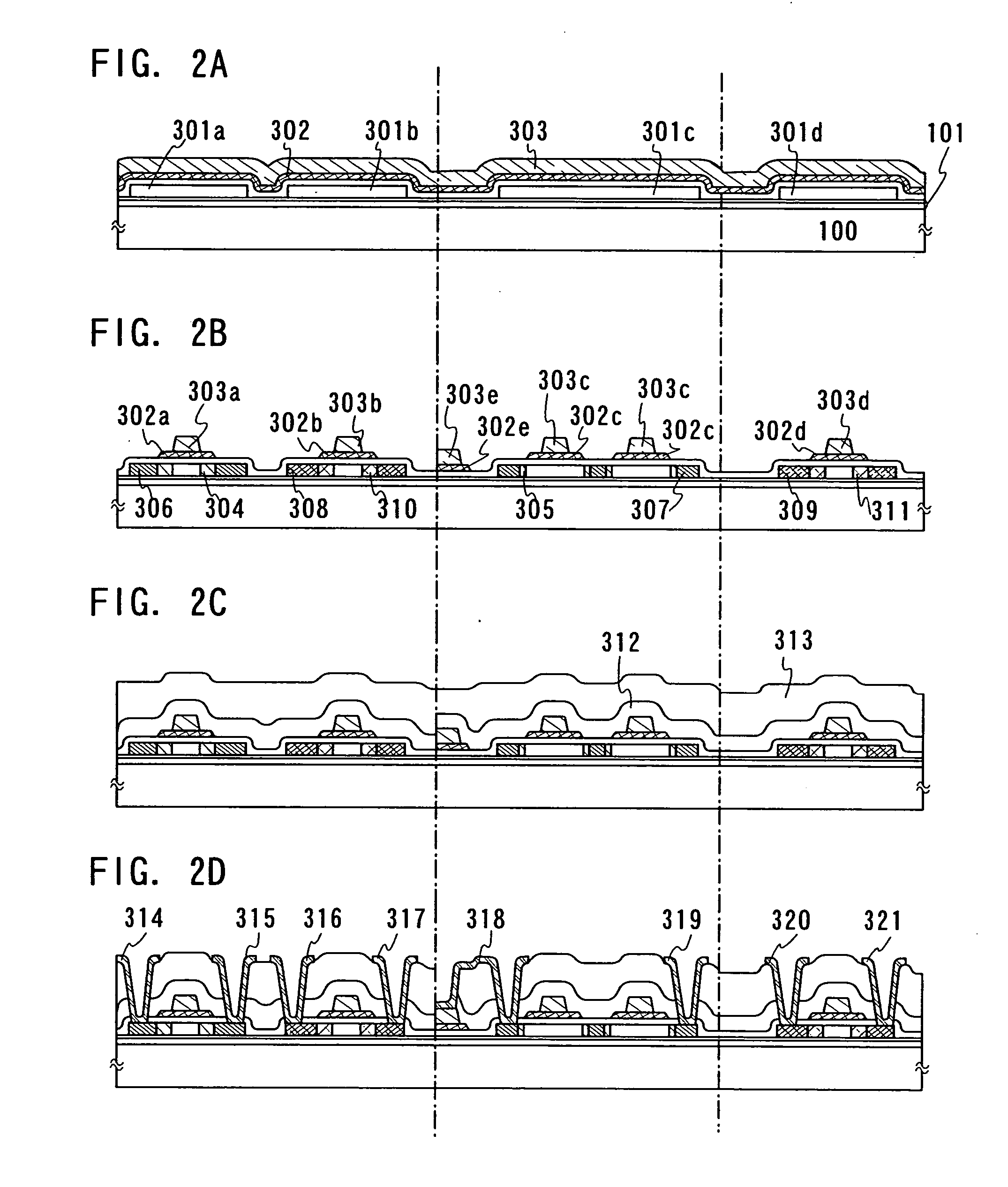

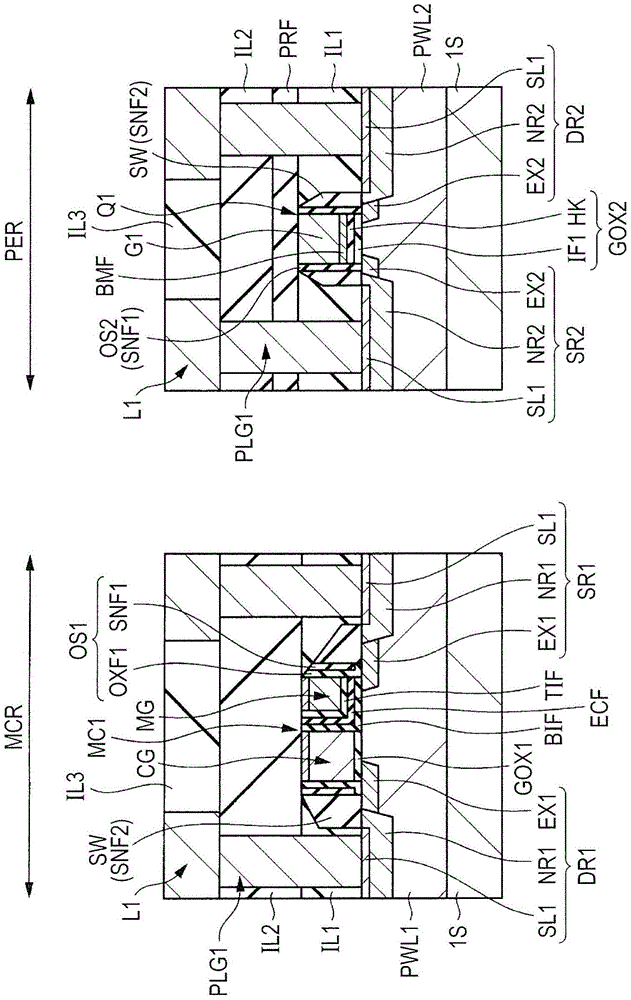

Method for manufacturing semiconductor device

InactiveUS20060134891A1Improve reliabilityHigh yieldSolid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideCrystalline semiconductor

Owner:SEMICON ENERGY LAB CO LTD

Catalyst for oxidative dehydrogenation of raw materials containing CO (carbon monoxide) gas

InactiveCN102649055ACarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsLoss rateAdditive ingredient

The invention relates to a catalyst for oxidative dehydrogenation of raw materials containing CO (carbon monoxide) gas, which mainly solves the technical problems in the prior art that the hydrogen removal rate is low, and the loss rate of CO is high. The catalyst comprises a carrier, an active component and an accessory ingredient in percentage by weight: (a) the active component which is selected from at least one of platinum metals, and has the dosage being 0.003-2 percent of the weight of the catalyst in a metering manner of a simple substance; (b) the accessory ingredient which is selected from at least one of Pr, Nd, Cs and Ba, and has the dosage being 0.005-15 percent of the weight of the catalyst in a metering manner of a simple substance; and (c) 84-99.5 percent of carrier, wherein the carrier is selected from a compound type carrier of aluminum oxide and silicon oxide, and the weight ratio of the aluminum oxide to the silicon oxide is 0.01-100:1. According to the technical scheme, the problems are better solved, and the catalyst can be applied in industrial production of oxidative dehydrogenation of raw materials containing the CO gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing amorphous ultrafine silicon oxide by hydrothermal method

Owner:BEIJING UNIV OF CHEM TECH

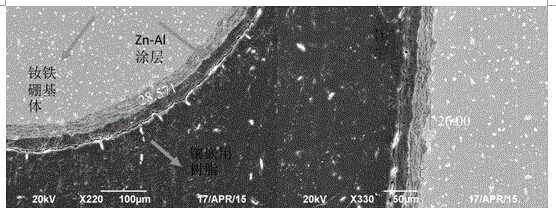

Zinc-aluminum coating enhanced with particles in micro-nano sizes and production method of zinc-aluminum coating

InactiveCN104984889AImprove mechanical propertiesImprove scratch resistancePretreated surfacesSpecial surfacesMicro nanoSilicon oxide

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Decomposable environmentally-friendly heat-insulation packaging bag

Owner:桐城市人和包装有限公司

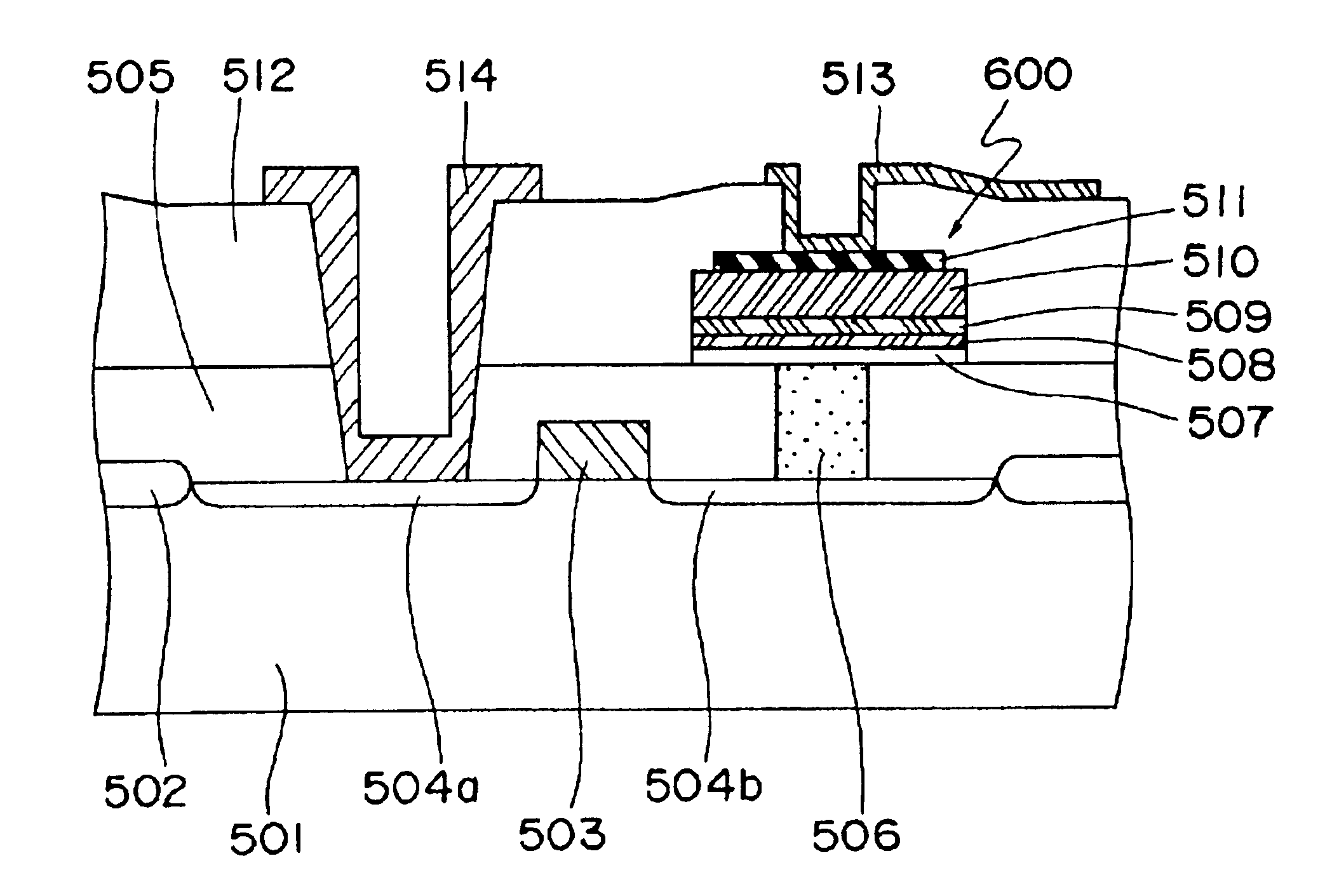

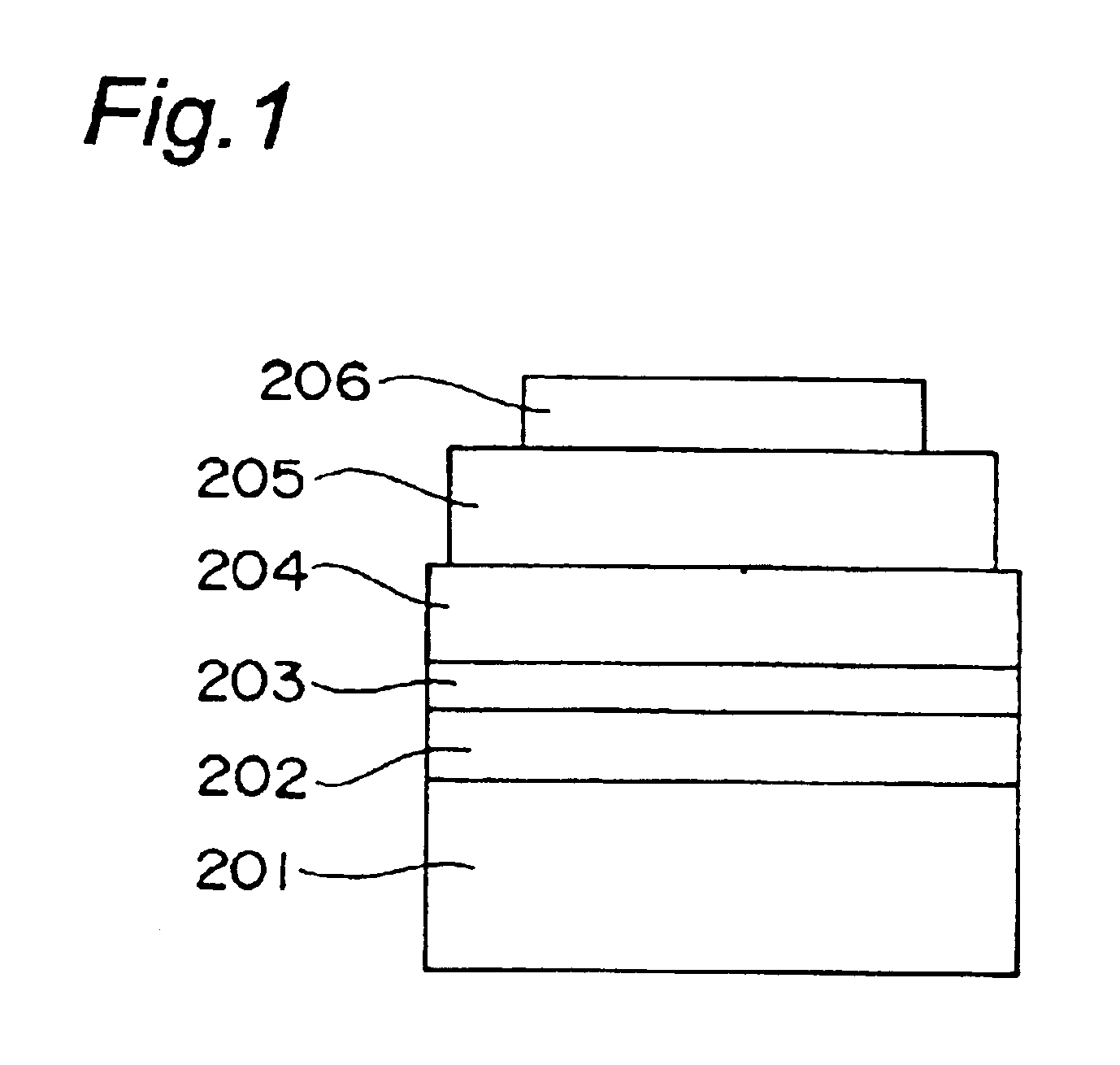

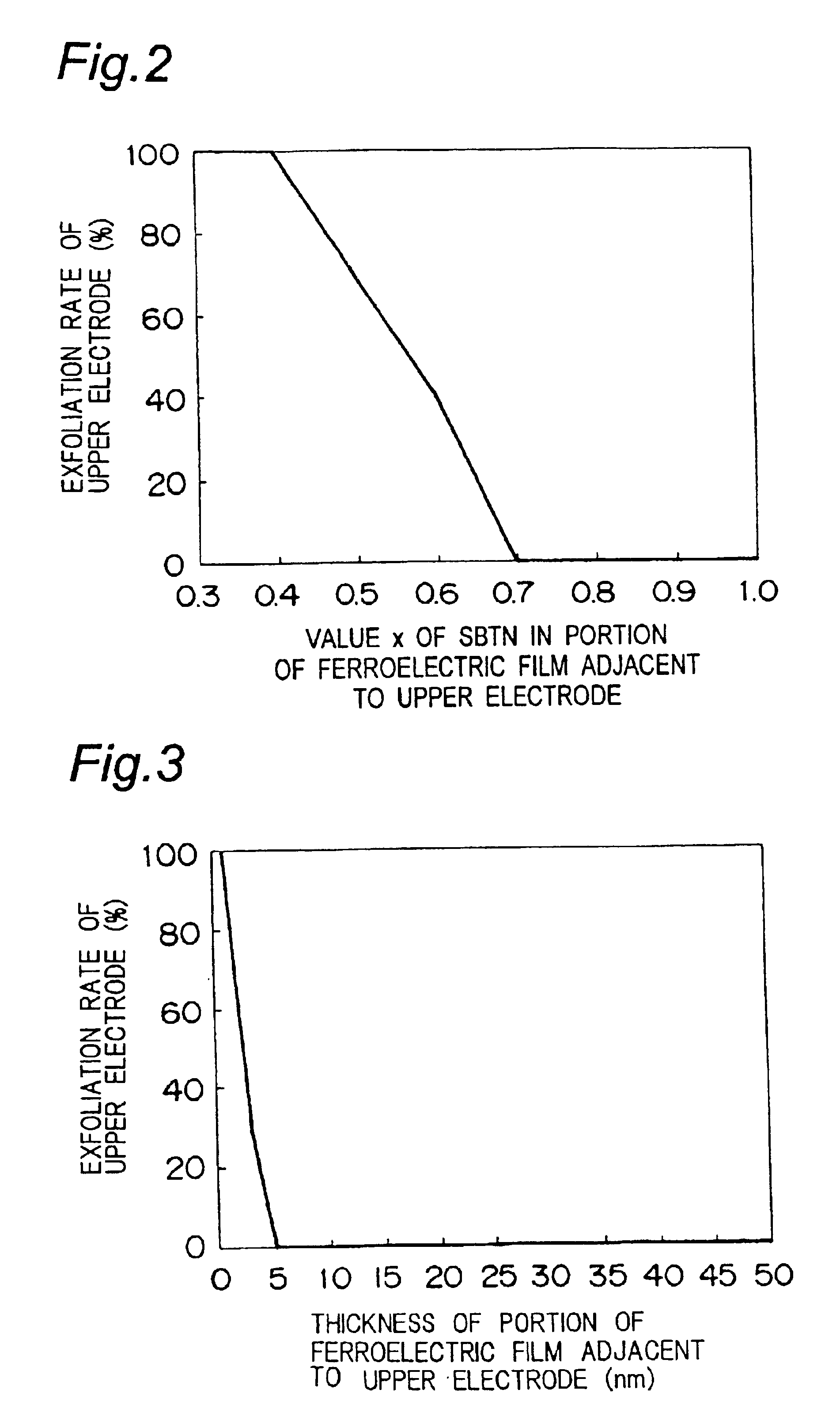

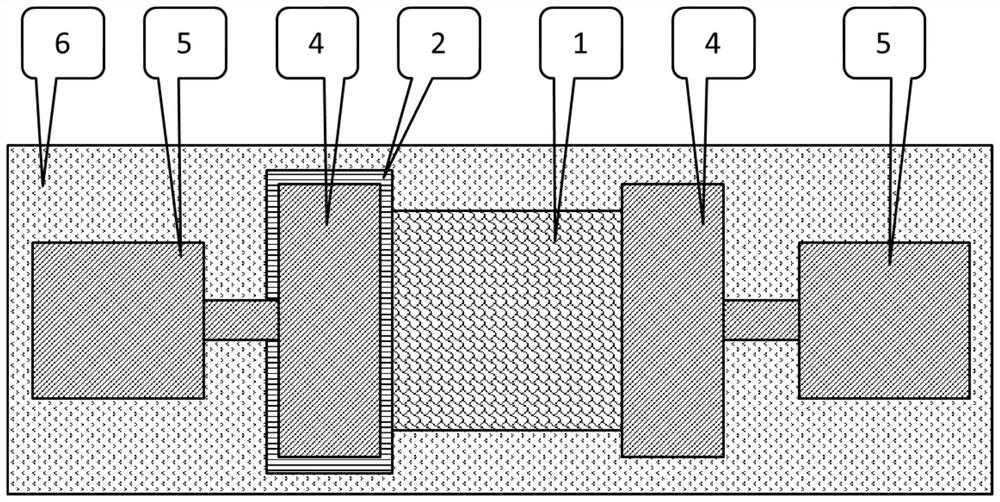

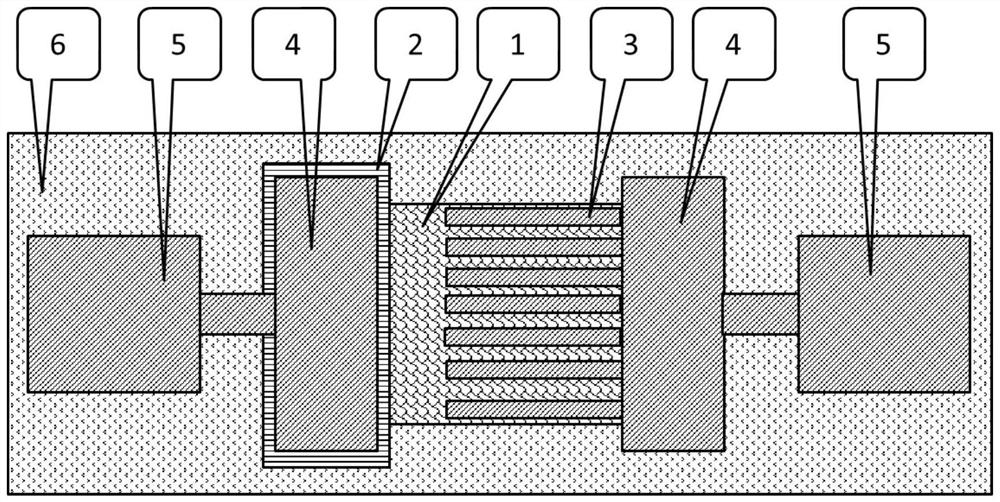

Semiconductor memory device including a capacitor an upper electrode of which being resistant of exfoliation

InactiveUS6855973B2Swiftly and easily formedTransistorSolid-state devicesFerroelectric thin filmsSilicon oxide

Owner:SHARP KK

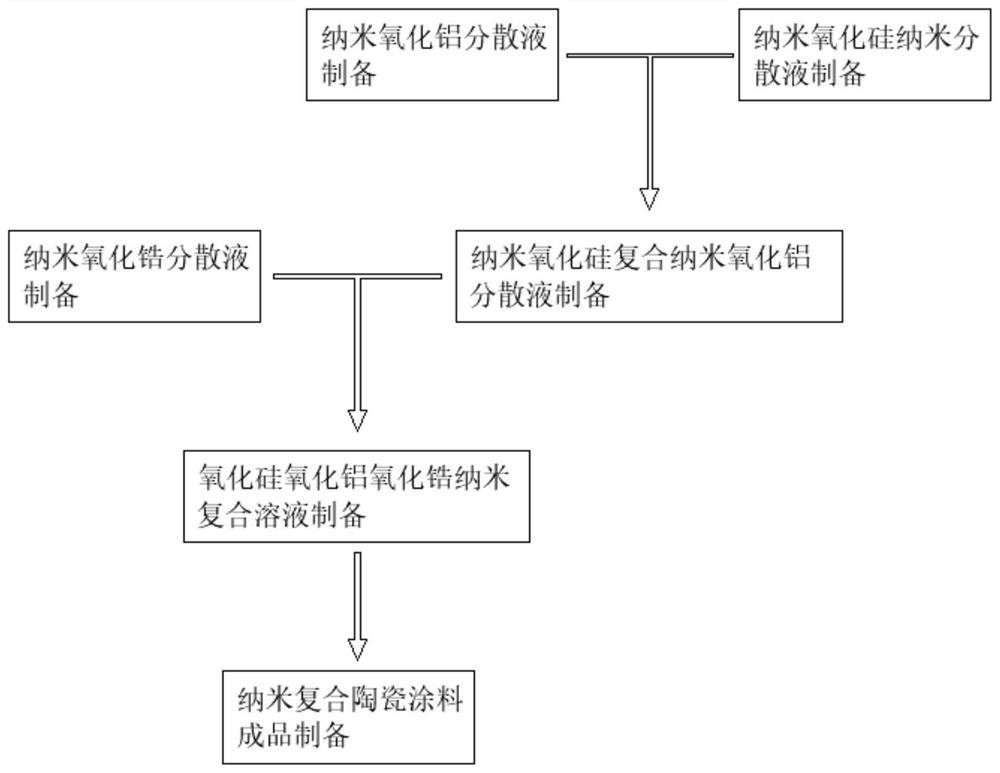

Transparent high-temperature-resistant anti-corrosion nano composite ceramic coating suitable for welding part

InactiveCN112898806AEasy to useGood value for moneyFireproof paintsAnti-corrosive paintsNano siliconComposite ceramic

Owner:薛国旺

A kind of etching method of diffusion layer of crystalline silicon solar cell

InactiveCN102290491ASimple processLow equipment requirementsAfter-treatment detailsFinal product manufactureEtchingPhosphoric acid

Owner:WUXI SAIJING SOLAR

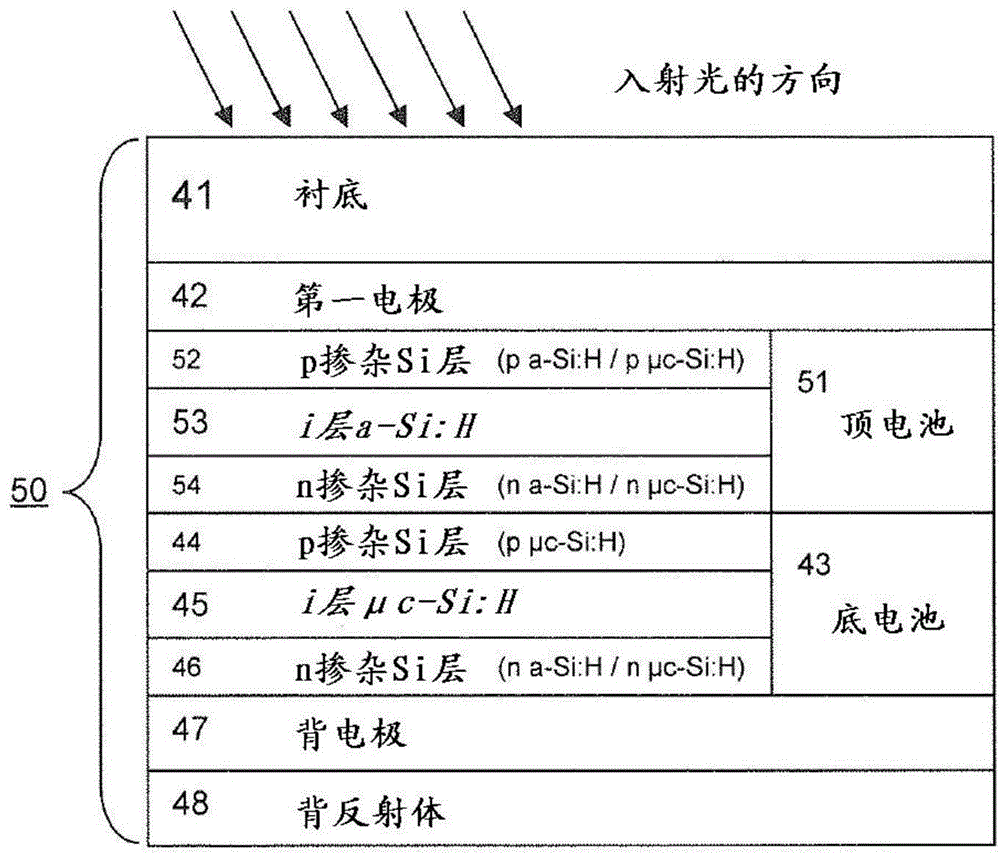

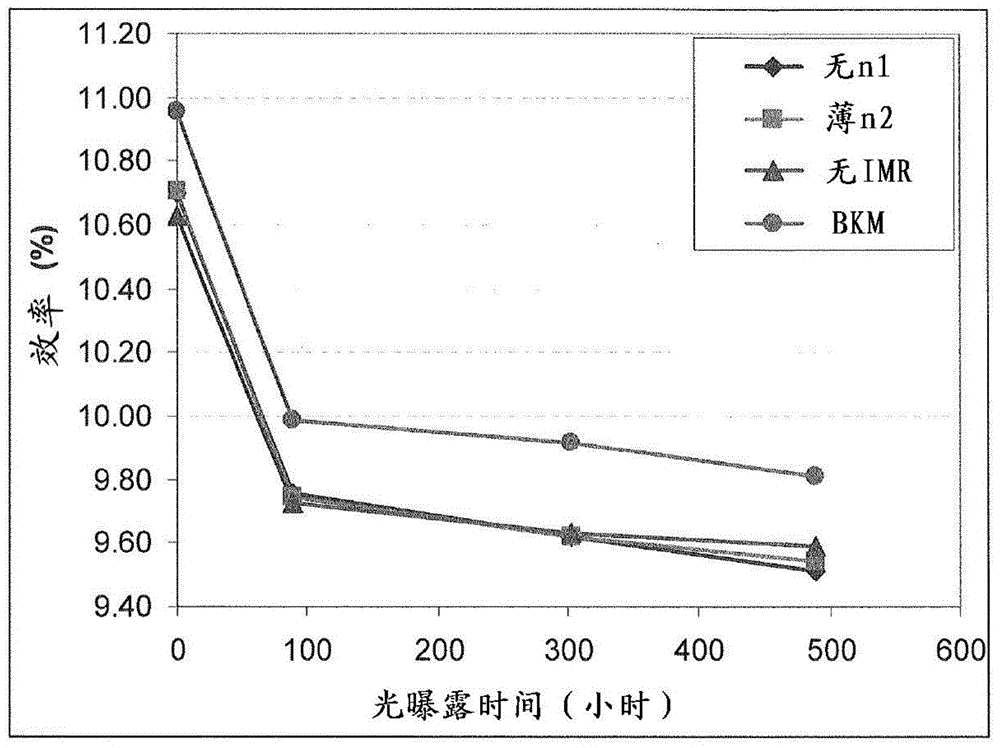

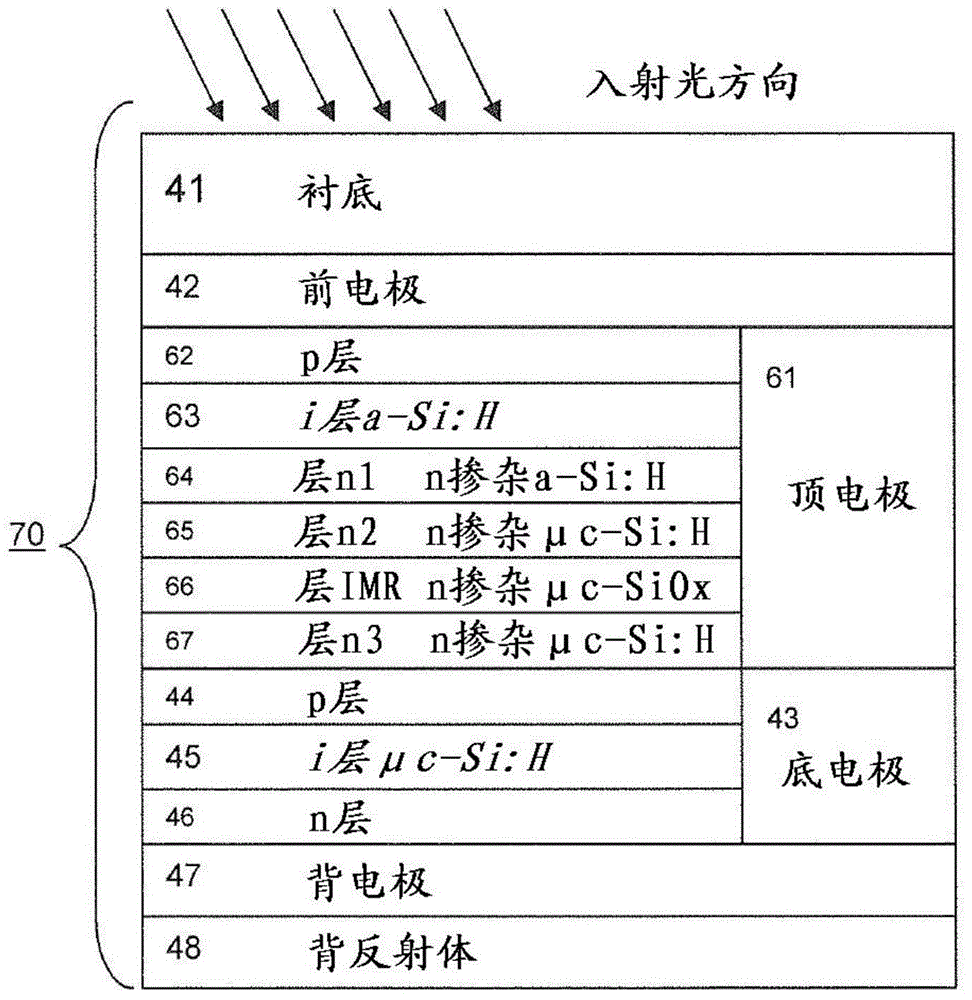

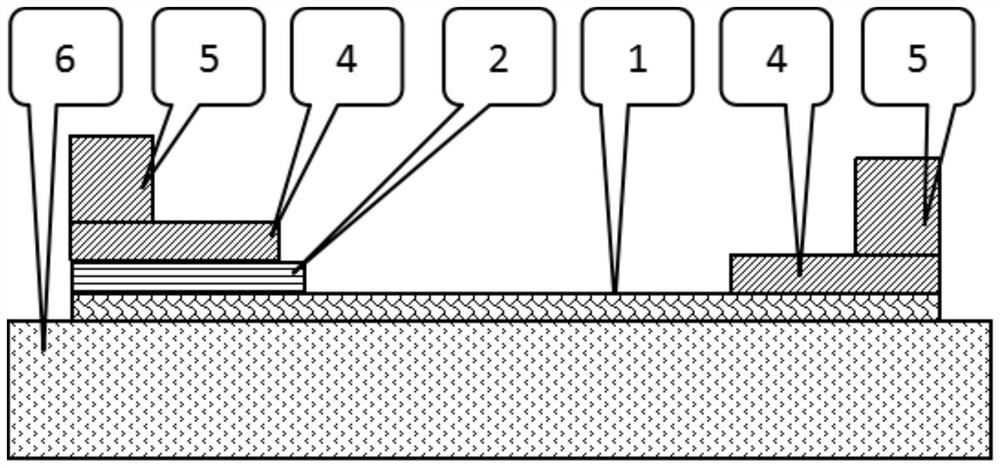

Intermediate reflection structure in thin film solar cells

InactiveCN104025307AGood electrical contactEasy to produceFinal product manufacturePhotovoltaic energy generationSilicon oxideReflective layer

Owner:TEL太阳能公司

Asymmetric induced room-temperature high-sensitivity photoelectric detection device and preparation method thereof

PendingCN114784125AEnhanced photoresponsive currentPhotoresponsive current suppressionSemiconductor devicesMetallic electrodeSilicon oxide

Owner:HANGZHOU INST FOR ADVANCED STUDY UCAS

Production and preparation method of pesticide residue removal agent

InactiveCN109304225AControl overgrowthPrevent collisions from growingOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsPesticide residueNanoparticle

Owner:孙梓译 +1

Stainless steel grinding fluid containing silicon oxide and diamond and preparation method of stainless steel grinding fluid

Owner:深圳市佳欣纳米科技有限公司

Composite electrolyte material and preparation method thereof

PendingCN112615052AImprove space efficiencyImprove adsorption efficiencySecondary cellsComposite electrolytesFiberComposite electrolyte

Owner:JIANGSU NADN SCI TECH CO LTD +1

Photoresponse silicon dioxide material as well as preparation method and application thereof

PendingCN114306636AGood biocompatibilityImprove stabilityEnergy modified materialsEther/acetal active ingredientsCarboxylic acidSilicon oxide

Owner:SOUTH CHINA UNIV OF TECH

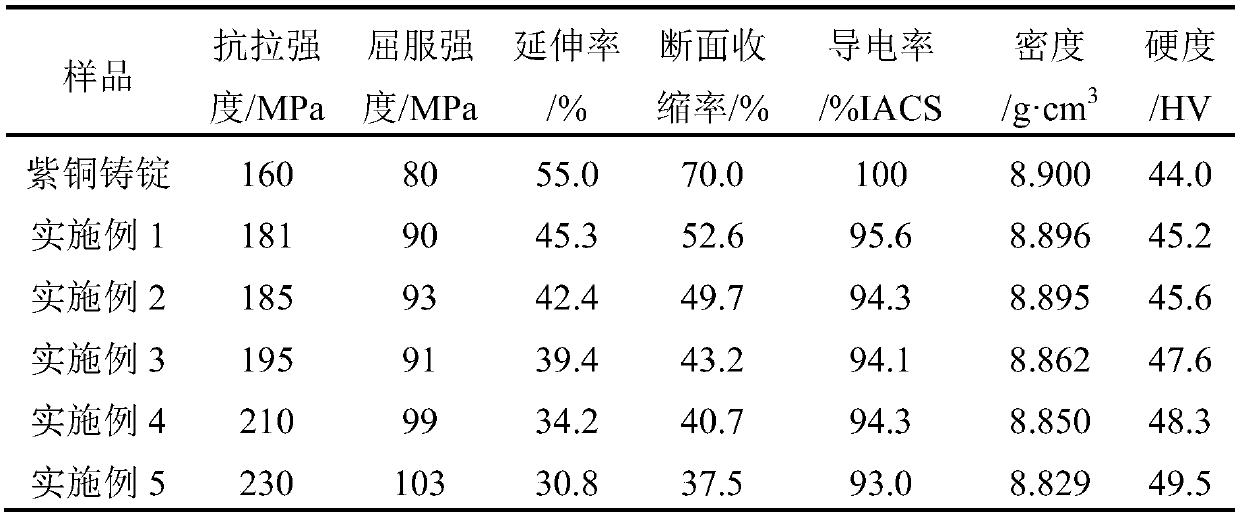

Silicon dioxide aerogel reinforced copper-based composite material and preparation method thereof

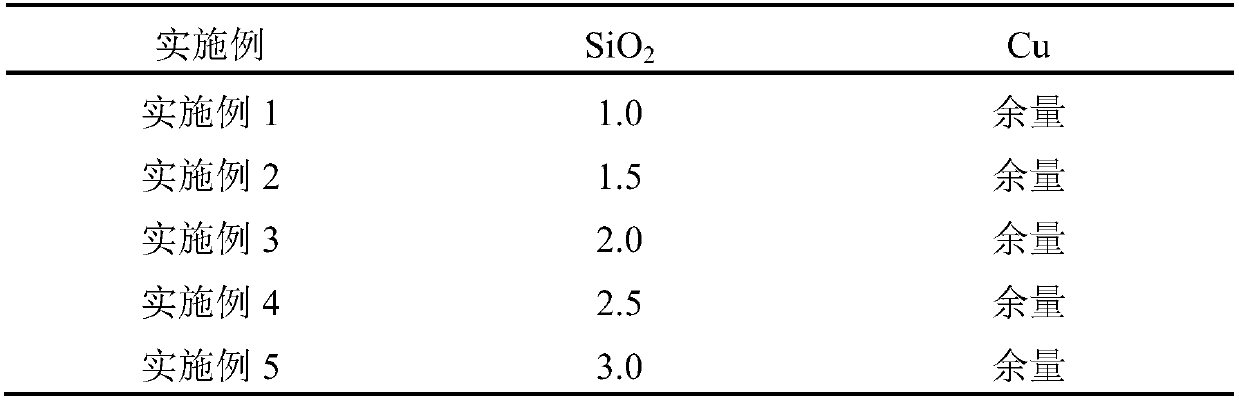

ActiveCN111378863ASilicon oxideIngot casting

Owner:GRIMAT ENG INST CO LTD

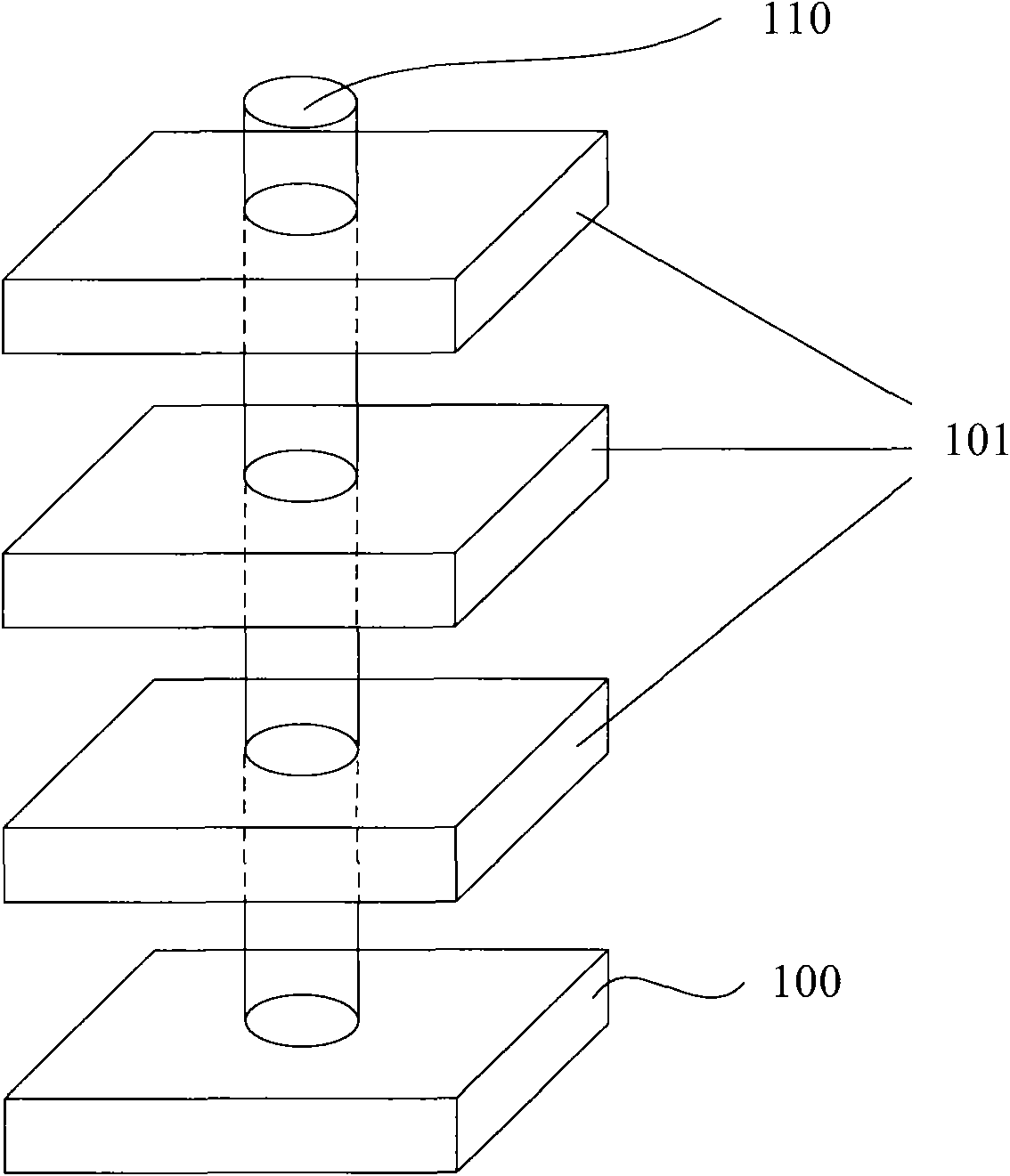

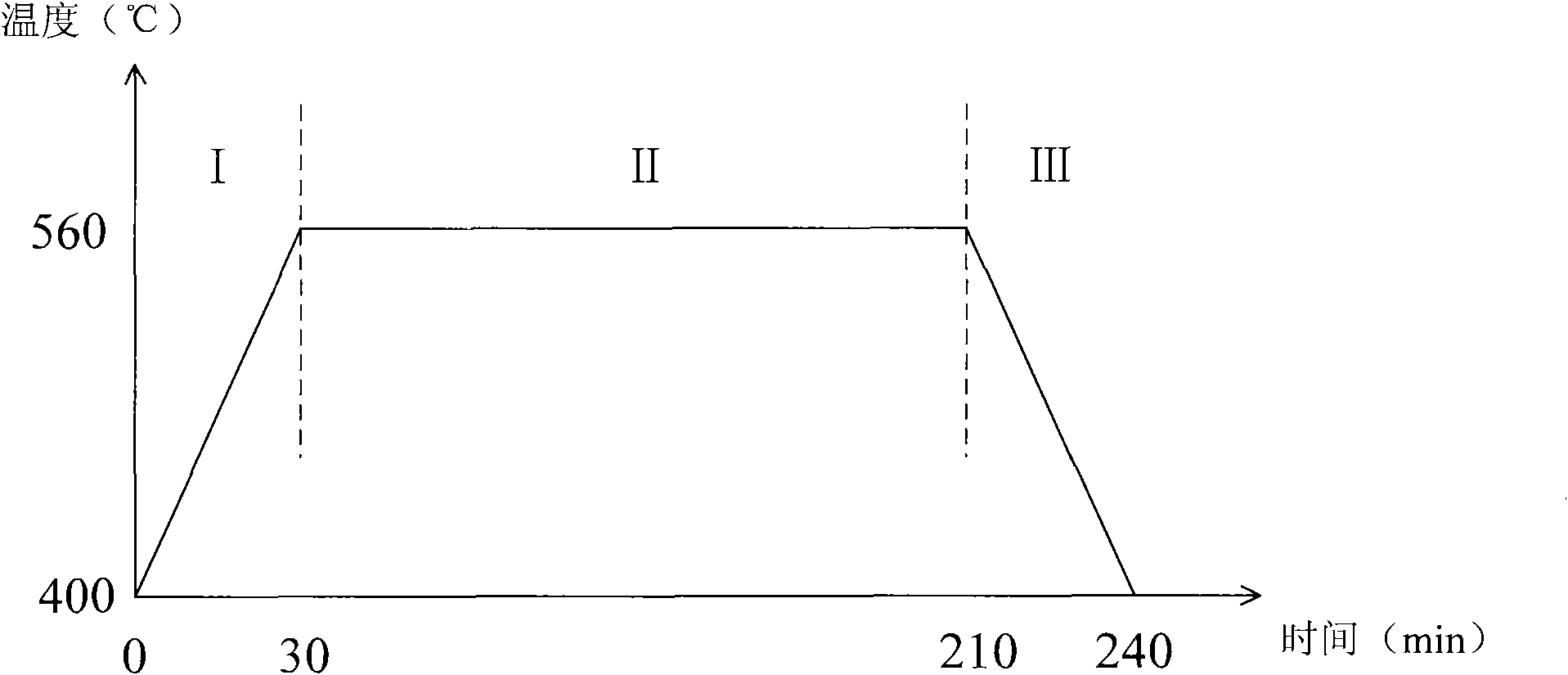

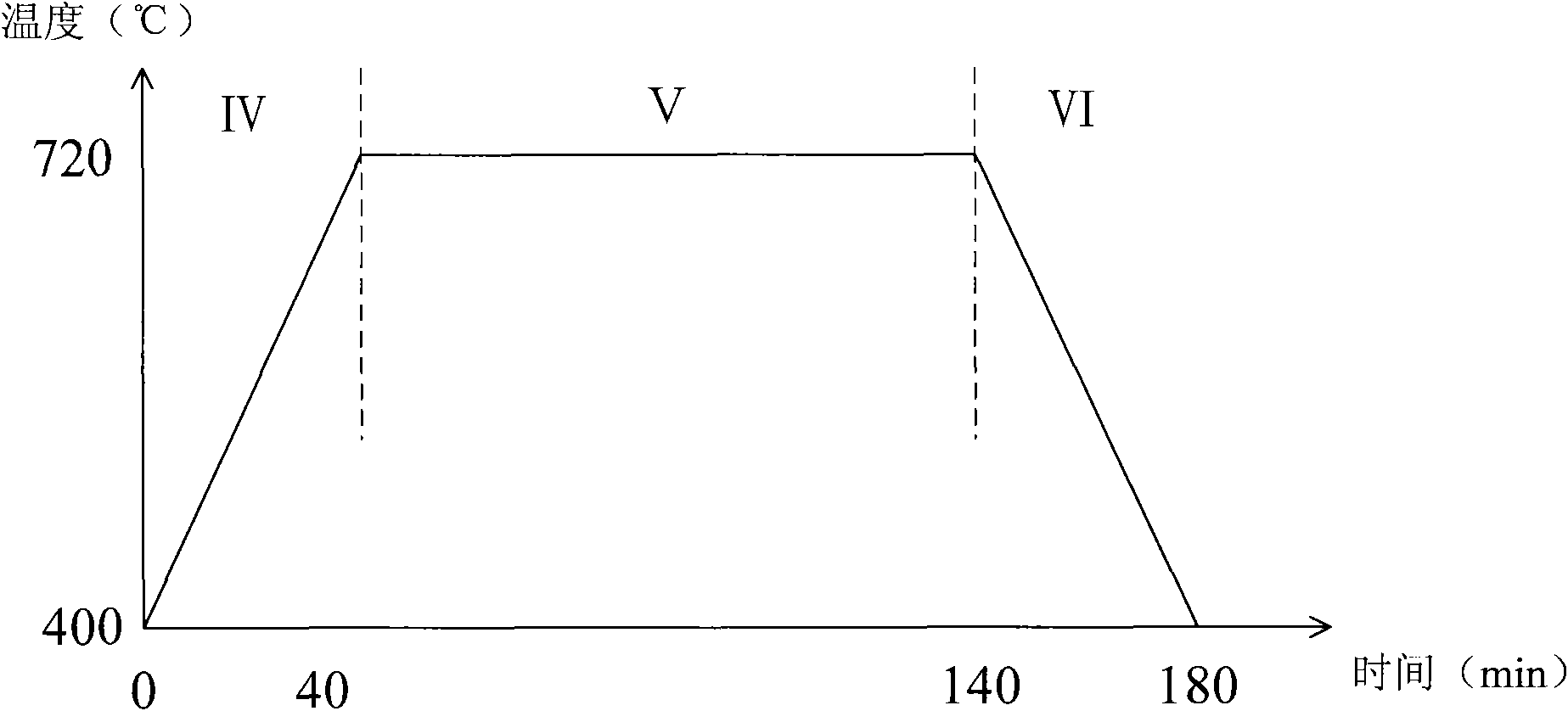

Heat treatment method of quartz glass

PendingCN110655305ALow stress birefringenceShort holding timeGlass shaping apparatusGlass productionVitrificationThermal insulation

The invention provides a heat treatment method of quartz glass. The heat treatment method adopts a vitrification molding and heat treatment integrated process, and comprises: (1) vitrifying a silicondioxide raw material to obtain a transparent quartz glass; (2) directly cooling the vitrified high-temperature transparent quartz glass to a heat treatment temperature, and carrying out thermal insulation; and (3) cooling the obtained quartz glass to a room temperature at a certain annealing rate to obtain the transparent quartz glass with low stress birefringence. According to the method of the invention, vitrification forming and heat treatment are carried out in the same sintering furnace, the temperature after vitrification forming is directly reduced to the heat treatment temperature, andthermal insulation is carried out, so that the heat treatment thermal insulation time is effectively shortened, the pollution risk is reduced, the production efficiency is improved, and the stress birefringence of the prepared quartz glass is smaller than 1.8 nm / cm.

Owner:ZHONGTIAN TECH

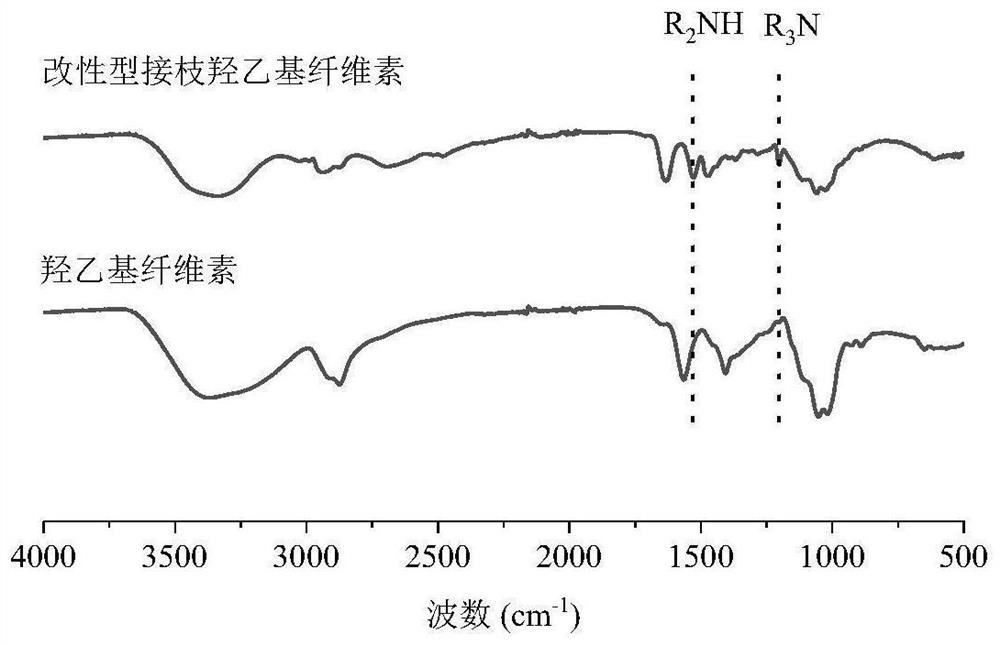

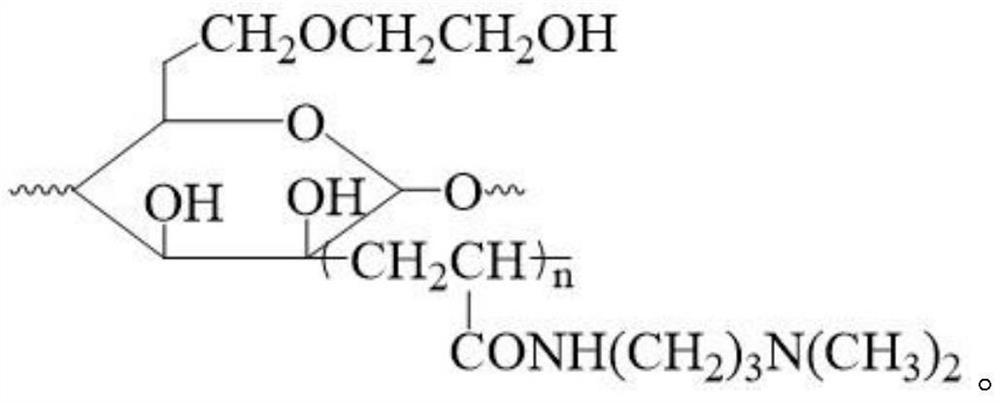

Hydroxyethyl cellulose modified scale inhibitor capable of effectively inhibiting silicon dioxide scale bodies in green and efficient manner

ActiveCN113955865ASmall sizeImprove solubilityMembranesGeneral water supply conservationGraft reactionReverse osmosis

Owner:NANJING UNIV +1

Composite nano photocatalytic material as well as preparation method and application thereof

ActiveCN114392771AHigh removal rateInhibitory complexMaterial nanotechnologyWater treatment parameter controlPotassium persulfatePolypyrrole

Owner:NORTHWEST UNIV

Preparation method of 12 [mu]m battery aluminum foil

PendingCN113444921AGuaranteed mechanical propertiesElectrode carriers/collectorsMetal rolling arrangementsAl powderFerrosilicon

Owner:山东德利铝业科技有限公司

Dry cleaning apparatus using plasma and steam

ActiveCN113811400AReduce processing timeExtended cleaning cycleElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringSilicon oxide

A dry cleaning apparatus using plasma and steam, according to the present invention, comprises: a chamber having an upper supply port formed on an upper surface part thereof, having a discharge port formed on a lower surface part thereof, having a side supply port formed on a side surface part thereof, and providing a cleaning space; a chuck which is coupled to the lower surface part of the chamber, and on which a monocrystalline silicon substrate including amorphous silicon, polycrystalline silicon, silicon oxide, or silicon nitride is arranged; an RF electrode which is coupled to the upper surface part of the chamber, and to which RF power is applied; an upper shower head which is coupled to the RF electrode so as to communicate with the upper supply port formed on the upper surface part of the chamber, and which has a plurality of upper spray holes formed thereon; a lower shower head, which is coupled to the side surface part of the chamber, has a plurality of first lower spray holes, has a plurality of second lower spray holes that allow communicating with the side supply port, formed thereon and are electrically grounded; a reaction gas supply unit for supplying reaction gas through the upper supply port formed on the upper surface part of the chamber; and a stem supply unit for supplying hot steam through the side supply port formed on the side surface part of the chamber.

Owner:ASEI CO LTD

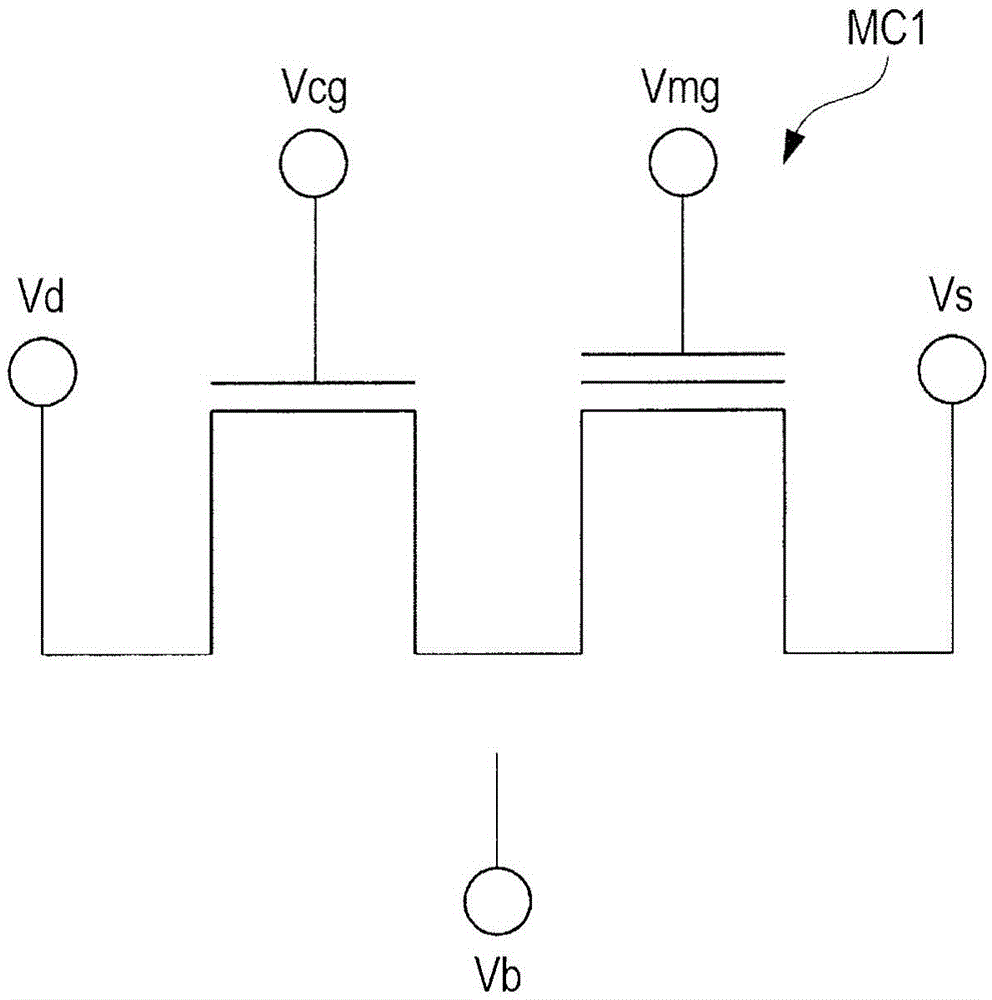

Semiconductor device and manufacturing method thereof

Owner:RENESAS ELECTRONICS CORP

Method for forming amorphous silicon oxide laminated structure

InactiveCN102074470AReduce time consumptionIncrease production capacitySemiconductor/solid-state device manufacturingReaction temperatureAmorphous silicon

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for improving stability of organic silicon emulsion

The invention relates to a method for improving the stability of an organic silicon emulsion, raw materials for preparing the emulsion comprise polysiloxane, polyether modified polysiloxane, a cross-linking agent, a basic catalyst, silicon dioxide, an emulsifier, a thickener, water and a preservative, and the emulsion is obtained by polymerization, cross-linking, grinding and dispersion. Compared with an emulsion prepared by a common method, the organic silicon emulsion has more excellent high-temperature resistance, low-temperature resistance, dilution resistance and shear resistance, and can be used in the fields of buildings, electronics and electrics, textiles, automobiles, machinery, leather, papermaking, metal processing, printing ink, coatings and the like.

Owner:NANJING RUISI CHEM TECH CO LTD

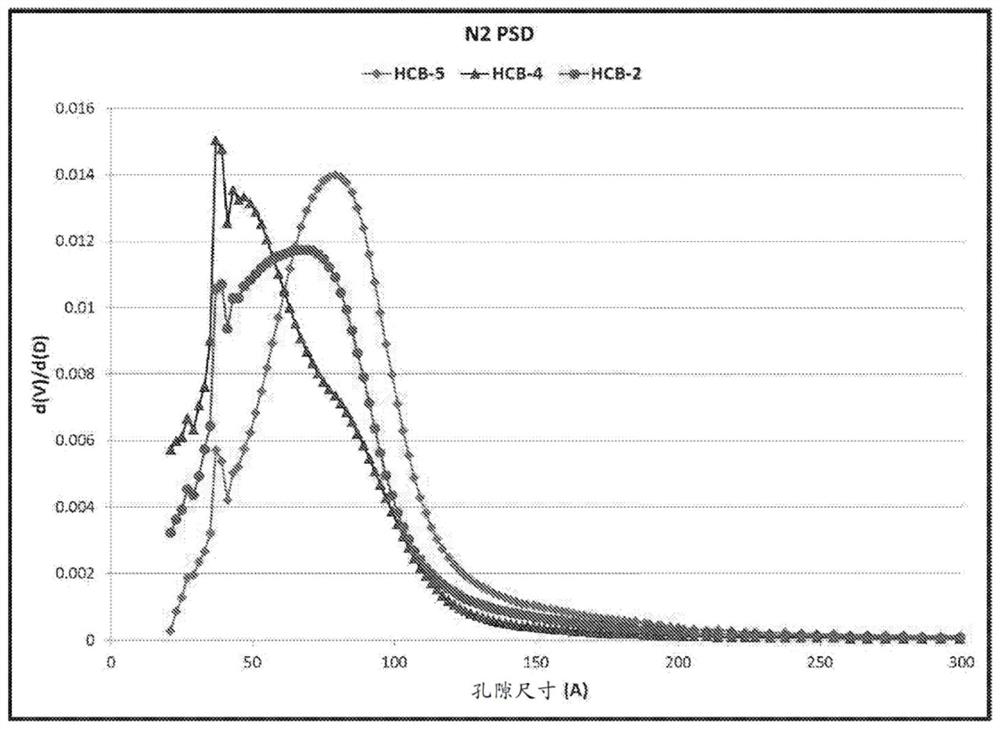

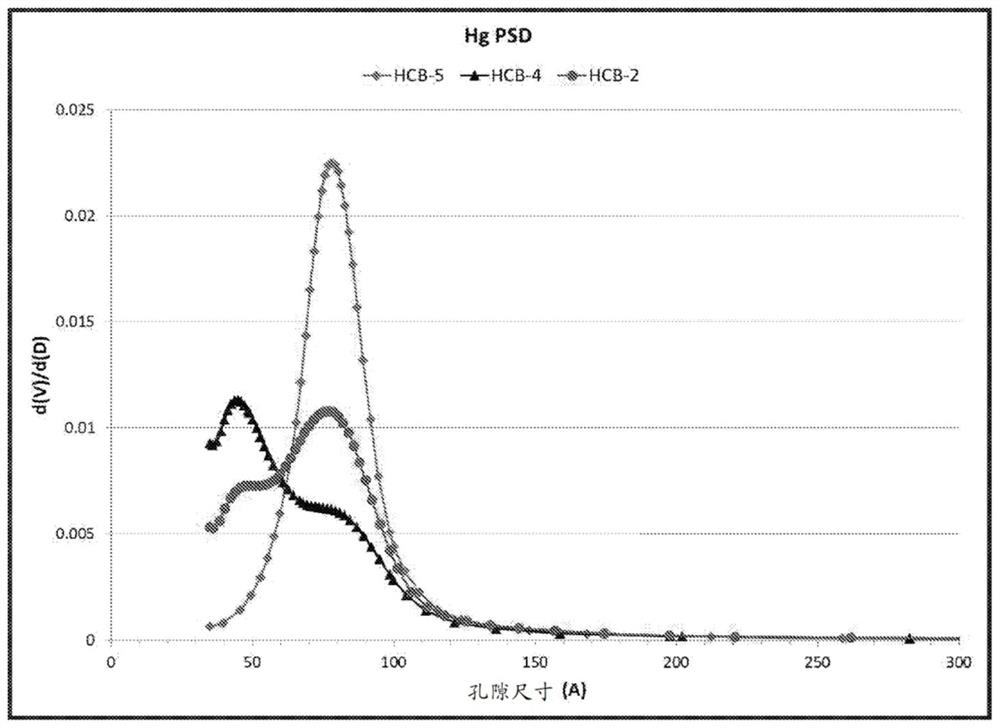

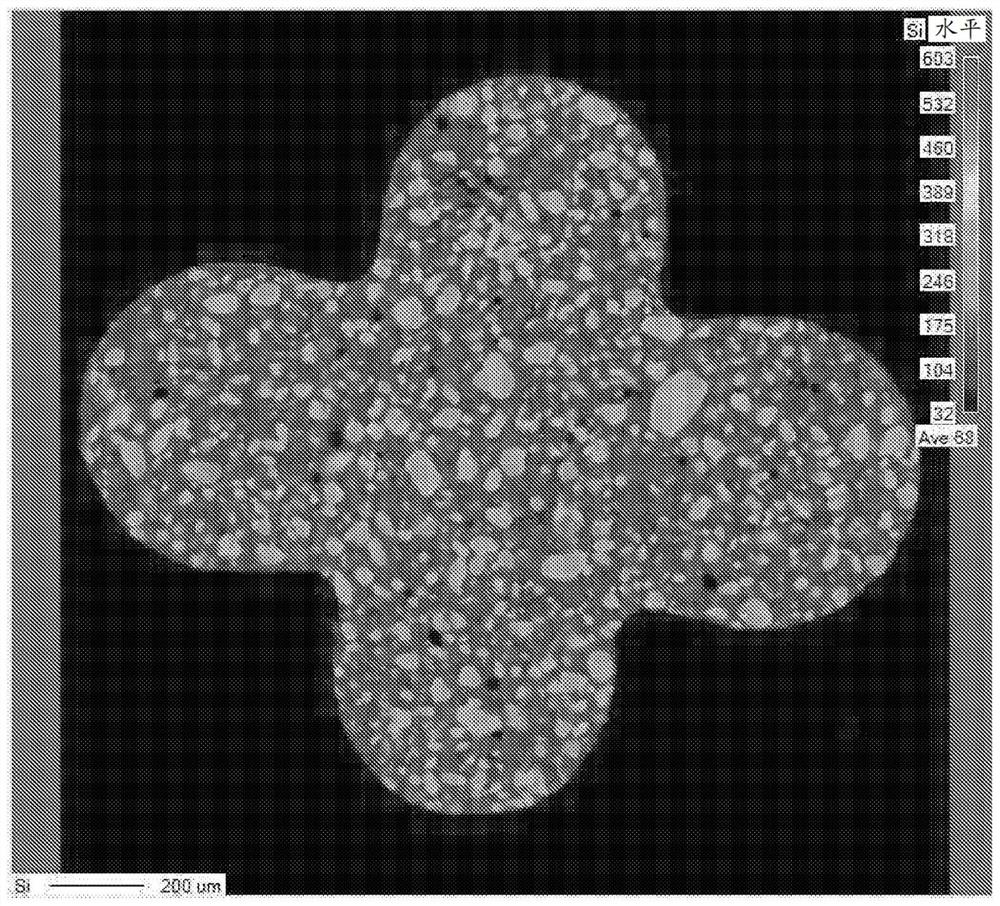

Silica-alumina composites for hydrotreating applications

PendingCN114728270AMolecular sieve catalystsCatalyst activation/preparationAlumina compositeSilicon oxide

Silica-alumina based composites for the preparation of hydrotreating catalysts are disclosed. The silica-alumina composite generally includes at least two silica-alumina, the first being a modified first silica-alumina and the second being an unmodified or modified second silica-alumina. The first silica-alumina is modified to include silica and alumina domains and a silica-alumina interfacial phase. The second silica-alumina may also be modified simultaneously or separately to include silica and alumina domains and a silica-alumina interfacial phase. The first silica-alumina and the second silica-alumina differ in one or more physical and / or chemical properties, such as silica to alumina ratio, surface area, pore size, pore volume, silica domain size, or alumina domain size. The invention can be used to prepare catalyst substrate materials and catalysts that can be used to upgrade hydrocarbon feedstocks to produce fuels, lubricants, chemicals, and other hydrocarbonaceous compositions.

Owner:CHEVROU USA INC

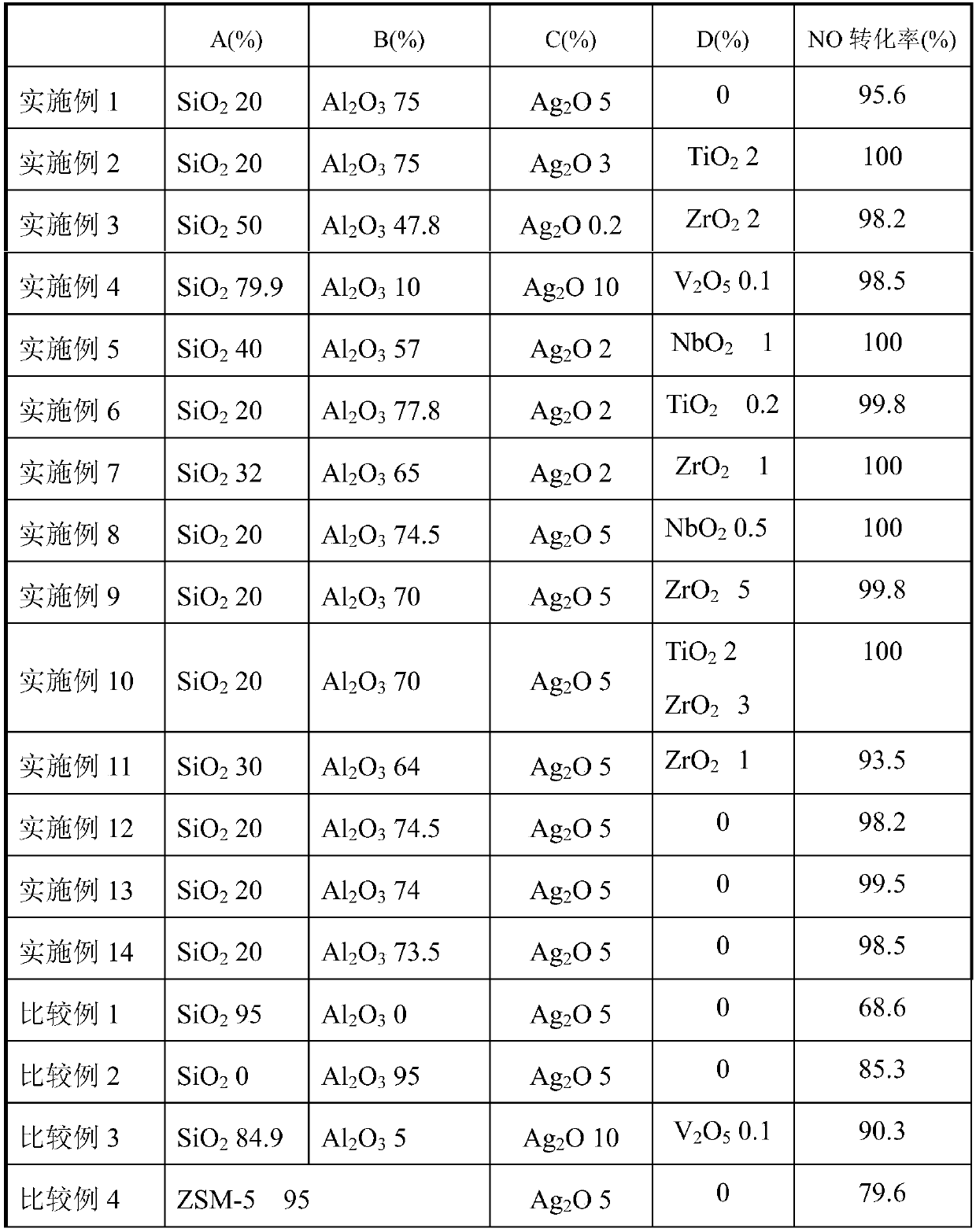

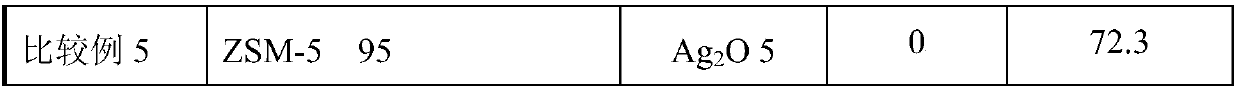

Catalyst for removing nitric oxide and preparation method thereof

InactiveCN109701525AOvercome stabilityOvercoming conversion rateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideNitric oxide

Owner:CHINA PETROLEUM & CHEM CORP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap